Content Menu

● Introduction

● Understanding Aluminum Extrusion Pivot Joints

>> Key Features

● How Aluminum Extrusion Pivot Joints Work

>> Components

>> Operation

● Installation Process

● Applications of Aluminum Extrusion Pivot Joints

● Advantages of Using Aluminum Extrusion Pivot Joints

● Considerations When Using Pivot Joints

● Types of Aluminum Extrusion Pivot Joints

● Selecting the Right Pivot Joint

● Maintenance and Care

● Innovations in Pivot Joint Design

● Case Studies

>> Case Study 1: Industrial Automation

>> Case Study 2: Architectural Design

● Conclusion

● FAQ

>> 1. What is the load capacity of a typical aluminum extrusion pivot joint?

>> 2. Can aluminum extrusion pivot joints be used outdoors?

>> 3. How do I determine the correct size of pivot joint for my aluminum extrusion?

>> 4. Can I use aluminum extrusion pivot joints in applications that require frequent adjustment?

>> 5. Are there any alternatives to aluminum extrusion pivot joints for creating adjustable connections?

● Citations:

Introduction

Aluminum extrusion pivot joints are essential components in the world of modular construction and industrial design. These versatile connectors allow two aluminum extrusion bars to be positioned at various angles, providing flexibility and strength to structures. In this comprehensive guide, we'll explore the intricacies of aluminum extrusion pivot joints, their functionality, applications, and installation process.

Understanding Aluminum Extrusion Pivot Joints

Aluminum extrusion pivot joints are specialized connectors designed to join two pieces of aluminum extrusion at adjustable angles. These joints are crucial in creating flexible, modular structures that can be easily modified or reconfigured[1].

Key Features

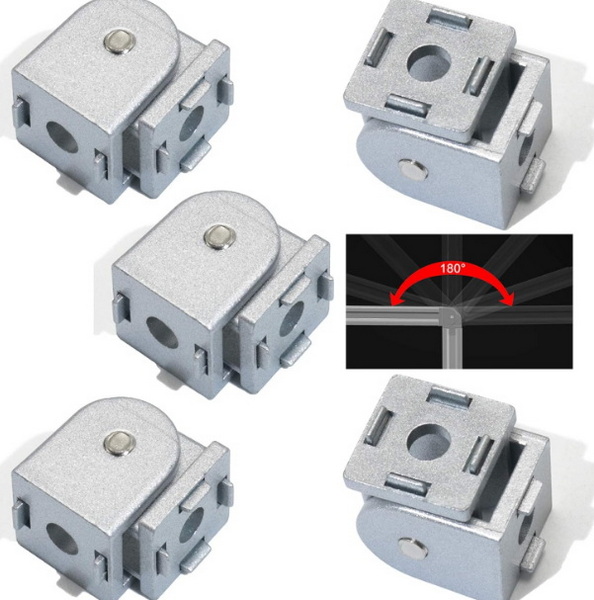

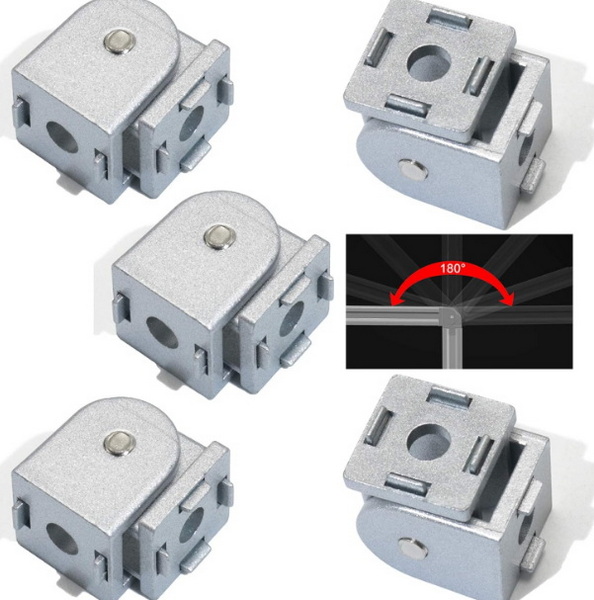

1. Adjustable Angles: Pivot joints allow for a wide range of motion, typically up to 180 degrees.

2. Compatibility: Available for various profile series, including fractional and metric sizes.

3. Strength: When properly installed, pivot joints provide a secure and durable connection.

4. Easy Installation: Designed for straightforward assembly with minimal tools required.

How Aluminum Extrusion Pivot Joints Work

The functionality of aluminum extrusion pivot joints is based on a simple yet effective mechanical principle. Let's break down the components and operation of these joints:

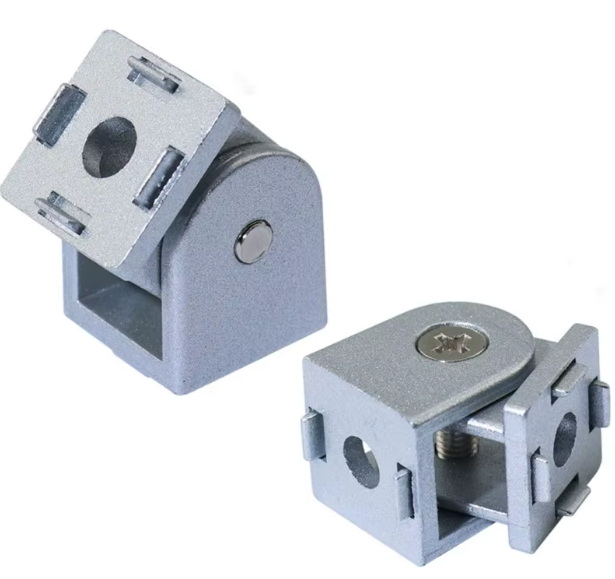

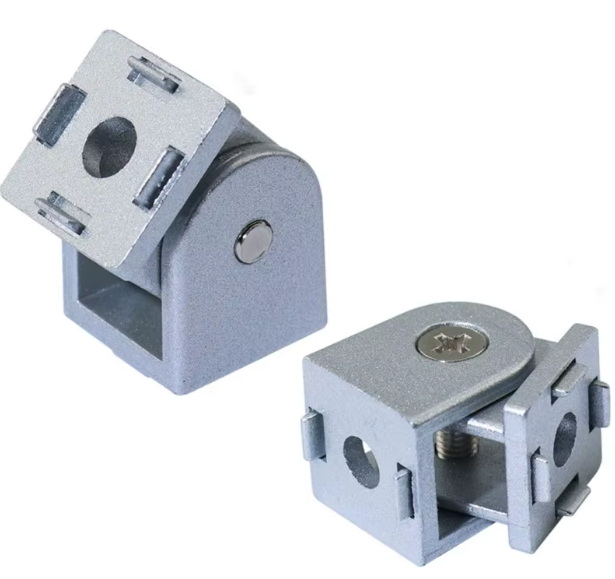

Components

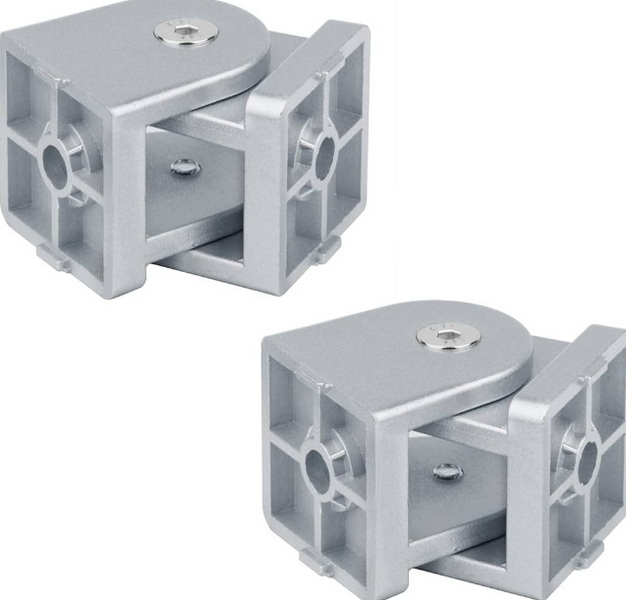

1. Joint Body: Usually made of zinc alloy or aluminum, this is the main structure of the pivot joint.

2. Pivot Point: The central axis around which the joint rotates.

3. Fastening Bolts: Used to secure the joint to the aluminum extrusions.

4. Locking Mechanism: Allows the joint to be fixed at a specific angle.

Operation

1. The pivot joint is attached to the end of two aluminum extrusion bars.

2. The joint's design allows the bars to rotate around the pivot point.

3. Once the desired angle is achieved, the locking mechanism is engaged to hold the position.

Installation Process

Installing an aluminum extrusion pivot joint requires attention to detail and the right tools. Here's a step-by-step guide:

1. Prepare the Extrusions: Ensure the ends of your aluminum extrusions are machined with end taps[1].

2. Position the Joint: Place the pivot joint over the end tap of one extrusion bar.

3. Secure the First Side: Insert the bolt into the end tap and tighten it using a wrench[1].

4. Attach the Second Bar: Repeat the process with the second extrusion bar.

5. Set the Angle: Adjust the bars to your desired angle.

6. Lock the Joint: Tighten the bolts on the pivot joint itself to secure the angle[1].

Applications of Aluminum Extrusion Pivot Joints

Aluminum extrusion pivot joints find applications in various industries and settings:

1. Industrial Machinery: Used in adjustable components of manufacturing equipment.

2. Modular Furniture: Enables creation of customizable furniture pieces.

3. Exhibition Displays: Allows for flexible and reconfigurable display stands.

4. Architectural Elements: Used in adjustable shading systems or movable partitions.

5. Robotics: Provides articulation points in robotic arms and structures.

Advantages of Using Aluminum Extrusion Pivot Joints

1. Flexibility: Easily adjust angles to suit different needs.

2. Strength: Provides a sturdy connection when properly installed.

3. Modularity: Allows for easy reconfiguration of structures.

4. Cost-Effective: Eliminates the need for welding or specialized fabrication.

5. Time-Saving: Quick to install and modify compared to fixed joints.

Considerations When Using Pivot Joints

While aluminum extrusion pivot joints offer numerous benefits, there are some factors to consider:

1. Load Capacity: Ensure the joint can handle the expected load in your application.

2. Maintenance: Periodic checking and tightening may be necessary.

3. Environmental Factors: Consider the effects of temperature and humidity on the joint's performance.

4. Precision: For applications requiring exact angles, additional measuring tools may be needed.

Types of Aluminum Extrusion Pivot Joints

There are several types of pivot joints available, each suited for different applications:

1. Standard Pivot Joint: The most common type, allowing for a wide range of motion.

2. Locking Pivot Joint: Includes a mechanism to lock the joint at specific angles.

3. Heavy-Duty Pivot Joint: Designed for applications with higher load requirements.

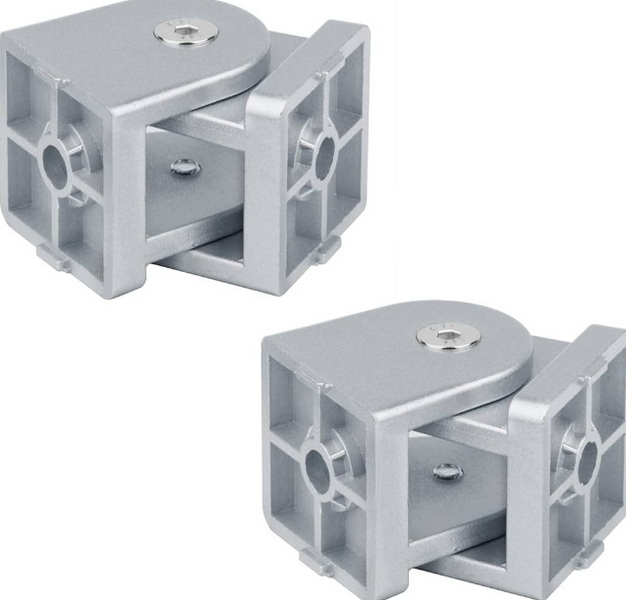

4. Multi-Axis Pivot Joint: Allows for movement in multiple directions.

Selecting the Right Pivot Joint

Choosing the appropriate aluminum extrusion pivot joint depends on several factors:

1. Extrusion Size: Ensure compatibility with your aluminum profile dimensions.

2. Load Requirements: Consider the weight and forces the joint will need to support.

3. Angle Range: Determine the range of motion needed for your application.

4. Environmental Conditions: Select materials suitable for your operating environment.

5. Aesthetic Considerations: Choose finishes that match your overall design.

Maintenance and Care

To ensure the longevity and proper function of aluminum extrusion pivot joints:

1. Regularly inspect for signs of wear or loosening.

2. Keep the joint clean and free from debris.

3. Lubricate moving parts as recommended by the manufacturer.

4. Retighten bolts periodically, especially in high-vibration environments.

Innovations in Pivot Joint Design

The field of aluminum extrusion pivot joints continues to evolve, with new innovations enhancing their functionality:

1. Smart Pivot Joints: Incorporating sensors for angle measurement and position feedback.

2. Lightweight Materials: Development of stronger, lighter alloys for improved performance.

3. Modular Designs: Pivot joints that can be easily customized for specific applications.

4. Integrated Locking Mechanisms: More sophisticated and user-friendly locking systems.

Case Studies

Case Study 1: Industrial Automation

A manufacturing company used aluminum extrusion pivot joints to create an adjustable conveyor system. The pivot joints allowed for easy reconfiguration of the production line, significantly reducing downtime during product changeovers.

Case Study 2: Architectural Design

An architectural firm incorporated pivot joints in a large-scale sunshade system for a commercial building. The joints allowed the shades to be adjusted throughout the day, optimizing energy efficiency and occupant comfort.

Conclusion

Aluminum extrusion pivot joints are versatile and essential components in modern construction and design. Their ability to provide flexible, strong connections between aluminum extrusions makes them invaluable in a wide range of applications. From industrial machinery to architectural elements, these joints offer a combination of strength, adjustability, and ease of use that is hard to match with other joining methods.

As technology advances, we can expect to see even more innovative uses for aluminum extrusion pivot joints, further expanding their role in creating adaptable and efficient structures. Whether you're a designer, engineer, or DIY enthusiast, understanding the capabilities and proper use of pivot joints can open up new possibilities in your projects.

FAQ

1. What is the load capacity of a typical aluminum extrusion pivot joint?

The load capacity of an aluminum extrusion pivot joint varies depending on the specific model and size. Generally, standard pivot joints can support loads ranging from 50 to 500 pounds, while heavy-duty versions can handle even greater weights. It's crucial to consult the manufacturer's specifications for the exact load capacity of a particular joint.

2. Can aluminum extrusion pivot joints be used outdoors?

Yes, aluminum extrusion pivot joints can be used outdoors, but it's important to choose models specifically designed for exterior use. These outdoor-rated joints are typically made from corrosion-resistant materials and may have additional sealing to protect against moisture and environmental factors.

3. How do I determine the correct size of pivot joint for my aluminum extrusion?

To determine the correct size of pivot joint, you need to know the profile series of your aluminum extrusion. Most pivot joints are designed to work with specific extrusion sizes, such as 20 series, 30 series, or 40 series. Measure the width of the T-slot on your extrusion and match it to the corresponding pivot joint size.

4. Can I use aluminum extrusion pivot joints in applications that require frequent adjustment?

Yes, aluminum extrusion pivot joints are suitable for applications requiring frequent adjustments. However, for such uses, it's recommended to choose pivot joints with easy-to-use locking mechanisms and durable construction. Regular maintenance and inspection are also important to ensure smooth operation over time.

5. Are there any alternatives to aluminum extrusion pivot joints for creating adjustable connections?

While aluminum extrusion pivot joints are popular, there are alternatives for creating adjustable connections:

- Hinges: Offer a fixed axis of rotation, suitable for door-like applications.

- Ball joints: Provide multi-directional movement but may have lower load capacities.

- Flexible connectors: Made of materials like rubber, offering limited adjustability and vibration dampening.

- Custom machined joints: Can be tailored to specific requirements but are often more expensive.

The choice depends on the specific needs of your application, including load requirements, range of motion, and environmental conditions.

Citations:

[1] https://www.youtube.com/watch?v=4j5jfy99DZg

[2] https://www.industrialprofile.com/aluminum-extrusion-joints-design-and-assembly-considerations/

[3] https://www.aliexpress.com/item/1005004514859893.html

[4] https://www.youtube.com/watch?v=xcbTVGI69u4

[5] https://www.framingtech.com/products/connectors/pivot-joints

[6] https://www.tuli-shop.com/alu-profile-systems

[7] https://uge-one.com/product/pivot-joint-for-2020-aluminum-profile-extrusion/

[8] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions