Content Menu

● Introduction to Aluminum Extrusion Bending

>> Applications of Aluminum Extrusion Bending Equipment

● Types of Aluminum Extrusion Bending Equipment

● Benefits of Aluminum Extrusion Bending Equipment

● Design Considerations for Aluminum Extrusion Bending

● Technological Advancements in Aluminum Extrusion Bending

>> Impact of Industry 4.0 on Bending Machines

● Market Trends and Future Outlook

>> Sustainability Initiatives in Aluminum Extrusion

● Case Studies: Successful Applications of Aluminum Extrusion Bending

● Conclusion

● FAQs

>> 1. What are the primary applications of aluminum extrusion bending equipment?

>> 2. What types of bending methods are commonly used for aluminum extrusions?

>> 3. How does aluminum extrusion bending contribute to environmental sustainability?

>> 4. What are the key design considerations for aluminum extrusions intended for bending?

>> 5. What are the benefits of using CNC-controlled bending machines for aluminum extrusions?

● Citations:

Aluminum extrusion bending equipment is a crucial tool in various industries, including construction, automotive, aerospace, and more. This equipment is designed to shape aluminum profiles into complex forms, offering precision, efficiency, and versatility. In this article, we will delve into the applications, types, and benefits of aluminum extrusion bending equipment, along with examples and explanations to enhance understanding.

Introduction to Aluminum Extrusion Bending

Aluminum extrusion bending involves the process of shaping aluminum profiles into desired forms using specialized machinery. This process is essential for creating components that require both strength and lightness, such as structural elements in buildings or vehicle parts. The versatility of aluminum extrusion bending equipment allows it to be used across multiple sectors, from architectural features to automotive components.

Applications of Aluminum Extrusion Bending Equipment

1. Construction and Architecture: Aluminum extrusions are widely used in building frameworks, exterior cladding, and decorative elements due to their durability and aesthetic appeal. Bending equipment helps create curved architectural features, such as arched windows or domed ceilings.

2. Automotive Industry: In the automotive sector, aluminum extrusion bending is used to produce lightweight yet strong components, such as door frames and structural members. This helps improve fuel efficiency and reduce emissions.

3. Aerospace: The aerospace industry relies on aluminum extrusions for structural components like fuselage frames and wing spars due to their high strength-to-weight ratio and resistance to corrosion.

4. Furniture and Decor: Aluminum extrusions are used in furniture frames and decorative elements, offering a lightweight yet durable option for interior design.

Types of Aluminum Extrusion Bending Equipment

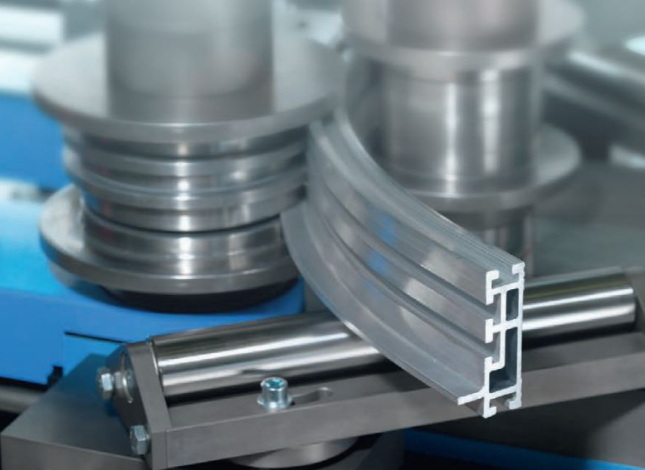

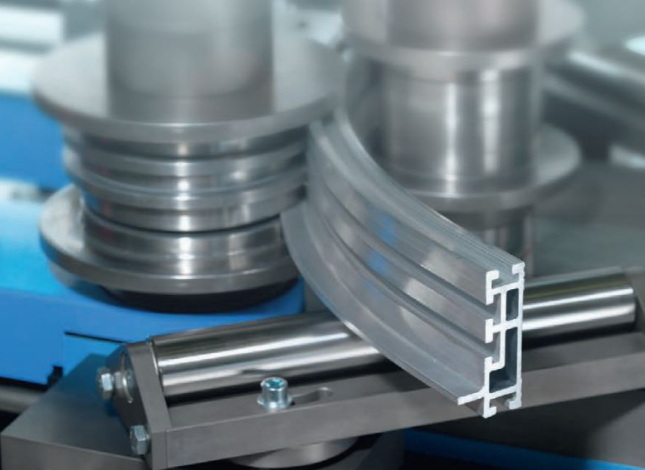

Several types of equipment are used for bending aluminum extrusions, each with its unique advantages and applications:

1. Roller Bending Machines: These machines are ideal for creating large radius bends with minimal tooling costs. They can bend the entire length of an extrusion at once, making them suitable for low-to-medium production runs.

2. Rotary Draw Bending: This method offers high precision and is capable of handling complex profiles. It involves clamping the extrusion and pulling it around a rotating die.

3. Stretch Forming: This technique is used for large radius bends and minimizes surface distortion. It is often used in architectural and aerospace applications.

4. Press Bending (Ram Bending): A simpler and less expensive method, press bending is suitable for bending one portion of an extrusion at a time.

5. CNC Bending Machines: These machines leverage computer algorithms to control the bending process with unparalleled accuracy and repeatability. They are equipped with sensors that monitor various parameters in real-time, ensuring high precision and enabling immediate adjustments to maintain quality standards[1][4].

Benefits of Aluminum Extrusion Bending Equipment

The use of aluminum extrusion bending equipment offers several benefits:

- Precision and Versatility: These machines can create complex shapes with high accuracy, making them ideal for custom designs.

- Efficiency: Bending equipment allows for rapid production of parts, reducing manufacturing time and costs.

- Material Conservation: By bending rather than welding, less material is wasted, and the structural integrity of the aluminum is maintained.

Design Considerations for Aluminum Extrusion Bending

When designing aluminum extrusions for bending, several factors must be considered:

- Profile Geometry: The design should minimize hollows and ensure symmetrical profiles for easier extrusion and bending.

- Material Properties: The choice of alloy affects formability, with 6XXX series alloys being commonly used due to their balance of strength and flexibility.

- Bending Techniques: The method of bending (e.g., rotary draw, stretch forming) should be selected based on the desired shape and precision required.

Technological Advancements in Aluminum Extrusion Bending

Recent advancements in technology have significantly enhanced the capabilities of aluminum extrusion bending equipment. CNC machines, for instance, offer reduced setup times, increased repeatability, and minimized human error, making them essential for industries demanding intricate aluminum profiles[4]. The integration of smart technologies like IoT and AI has further revolutionized bending machines by enabling real-time monitoring and dynamic adjustments during the bending process[4].

Impact of Industry 4.0 on Bending Machines

The adoption of Industry 4.0 technologies, including IoT and AI, has transformed the metal bending industry by introducing real-time tracking, predictive maintenance, and remote operation. This shift towards automation and digitalization has increased efficiency and reduced dependency on manual labor, aligning with global trends towards sustainability and efficiency[6].

Market Trends and Future Outlook

The aluminum extrusion market is experiencing rapid growth due to increasing demand for lightweight materials, technological innovations, and sustainability initiatives. The bending machine market, in particular, is expected to grow significantly, driven by the adoption of CNC and automated bending machines across industries like automotive and aerospace[6].

Sustainability Initiatives in Aluminum Extrusion

Sustainability is becoming a central focus in the aluminum extrusion market. Companies are adopting eco-friendly practices, such as using recycled aluminum and implementing energy-efficient processes, to reduce their carbon footprint and appeal to environmentally conscious consumers[3]. The recyclability of aluminum makes extrusion an eco-friendly option, aligning with global efforts to reduce energy use and carbon emissions[7].

Case Studies: Successful Applications of Aluminum Extrusion Bending

Several businesses have successfully leveraged aluminum extrusion bending equipment to enhance their operations:

- Automotive Sector: A leading automotive manufacturer uses advanced metal bending machines to produce intricate exhaust systems, ensuring consistent bend radii and angles for optimal performance[2].

- Furniture Design: An award-winning furniture designer utilizes metal bending machines to craft intricate steel frames for bespoke furniture, showcasing the versatility of bending technology in custom design[2].

Conclusion

Aluminum extrusion bending equipment plays a vital role in shaping the modern world, from architectural marvels to high-performance vehicles. Its ability to produce complex shapes with precision and efficiency makes it indispensable across various industries. As technology advances, the capabilities of these machines continue to expand, offering even more versatility and accuracy in bending aluminum profiles.

FAQs

1. What are the primary applications of aluminum extrusion bending equipment?

Aluminum extrusion bending equipment is primarily used in industries such as construction, automotive, aerospace, and furniture manufacturing. It is essential for creating lightweight yet strong components that require complex shapes.

2. What types of bending methods are commonly used for aluminum extrusions?

Common methods include roller bending, rotary draw bending, stretch forming, press bending, and CNC bending. Each method has its advantages and is chosen based on the specific requirements of the application.

3. How does aluminum extrusion bending contribute to environmental sustainability?

Aluminum extrusion bending contributes to sustainability by reducing material waste and promoting the use of lightweight components, which can improve fuel efficiency in vehicles and reduce energy consumption in buildings.

4. What are the key design considerations for aluminum extrusions intended for bending?

Key considerations include profile geometry, material properties (such as alloy choice), and the selection of appropriate bending techniques to ensure successful bending without compromising structural integrity.

5. What are the benefits of using CNC-controlled bending machines for aluminum extrusions?

CNC-controlled machines offer high precision and repeatability, allowing for consistent production of complex shapes. They also enable quick setup and adjustment for different designs, enhancing productivity and reducing downtime.

Citations:

[1] https://elkamehr.com/en/how-to-bend-aluminum-rods/

[2] https://www.metmac.com/article/detail/case-studies-successful-businesses-using-metal-bending-machines.html

[3] https://www.beskamold.com/aluminum-extrusion-industry/

[4] https://www.alubend.com/2023/08/16/future-of-aluminium-profile-bending/

[5] https://www.gabrian.com/aluminum-extrusion-bending/

[6] https://www.gminsights.com/industry-analysis/bending-machine-market

[7] https://www.3erp.com/blog/history-future-aluminum-extrusion/

[8] https://www.thebusinessresearchcompany.com/report/aluminum-extrusion-global-market-report

[9] https://shop.machinemfg.com/mastering-aluminum-extrusion-bending-techniques-design-and-applications/

[10] https://www.rollerdie.com/company/case-studies/roll-forming-shapes-vs-aluminum-extrusion/

[11] https://www.snsinsider.com/reports/bending-machines-market-4314

[12] https://www.inductaflex.com/induction-pipe-bending-machine-aluminium-bending-machine-news/the-art-and-precision-of-3d-bending-in-aluminium-profiles/

[13] https://www.barnshaws.com/services/aluminium-bending

[14] https://www.linkedin.com/pulse/whats-next-automatic-bending-machine-market-look-13-cagr-slk7e

[15] https://www.mdpi.com/1996-1944/14/7/1603

[16] https://www.barnshaws.com/services-dev/aluminium-bending/detail

[17] https://www.marketresearchfuture.com/reports/bending-machines-market-21590

[18] https://www.alubend.com/aluminium-bending-news/

[19] https://www.chinametalworking.com/case-studies/aluminum-sheet-metal-bending-tools-box/

[20] https://www.academia.edu/67204627/A_Case_Study_on_Aluminium_Extrusion_Press_Problems_Identified_and_Probable_Alternative_Solution_for_its_Problem_Related_to_Guideways