Content Menu

● Introduction to Wade Extruder

>> Wade Extruder Design

● Aluminum Extrusion Basics

>> Aluminum Extrusion Process

>> Applications of Aluminum Extrusions

● Connection Between Wade Extruder and Aluminum

>> Use of Aluminum in 3D Printing

>> Advantages of Using Aluminum in 3D Printing

● Comparison of Wade Extruder with Other Extruders

● Future Developments in Extrusion Technology

>> Potential Applications of Advanced Extrusion

● Conclusion

● FAQ

>> 1. What is a Wade Extruder?

>> 2. How Does Aluminum Extrusion Work?

>> 3. Can Aluminum Be Used in 3D Printing?

>> 4. What Are the Applications of Aluminum Extrusions?

>> 5. How Does the Wade Extruder Compare to Other Extruders?

In the realm of 3D printing and aluminum extrusion, understanding the mechanisms and applications of various tools is crucial. This article delves into the concept of a Wade extruder, its connection to aluminum, and how it functions. While the term "Wade extruder aluminum" might not directly refer to a specific type of aluminum extrusion, it can be related to the use of aluminum in 3D printing extruders or the broader context of extrusion technology.

Introduction to Wade Extruder

The Wade extruder is a type of 3D printing extruder designed for improved performance and efficiency. It is not directly related to aluminum extrusion but is an important component in additive manufacturing.

Wade Extruder Design

The Wade extruder is known for its innovative design, which often includes a geared system to enhance the extrusion process. This design allows for better control over the filament flow, ensuring consistent and precise printing. The geared mechanism helps in providing a higher torque, which is beneficial for handling thicker filaments or materials with higher viscosity.

Aluminum Extrusion Basics

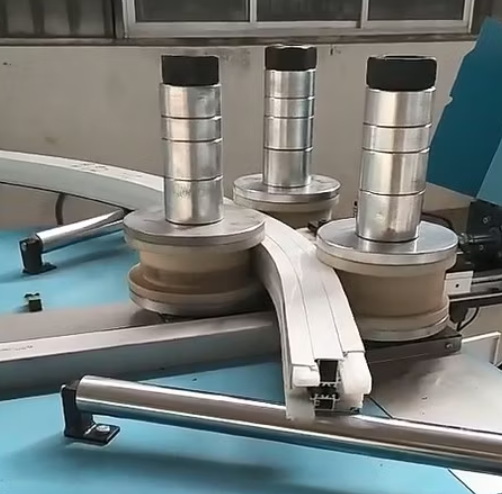

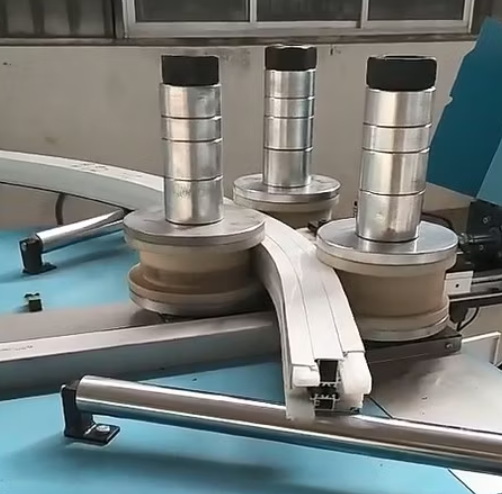

Aluminum extrusion is a process used to create complex shapes from aluminum alloys. It involves forcing heated aluminum billets through a die to form the desired profile. This process is widely used in various industries due to the versatility and strength of aluminum.

Aluminum Extrusion Process

1. Billet Preparation: Aluminum billets are prepared by melting and alloying aluminum with other elements to achieve desired properties. The billets are then cut to the appropriate size for extrusion.

2. Extrusion: The billet is heated and forced through a die using high pressure. The die determines the shape of the extruded profile.

3. Cooling and Straightening: The extruded profile is cooled and straightened to remove any deformities.

4. Aging: The profile is heat-treated to achieve the desired strength and durability.

Applications of Aluminum Extrusions

Aluminum extrusions are widely used in construction, automotive, and consumer goods industries due to their strength, corrosion resistance, and ability to form complex shapes. They are also used in electrical components and machinery parts.

Connection Between Wade Extruder and Aluminum

While the Wade extruder is primarily used in 3D printing, the concept of extrusion is similar to that in aluminum extrusion. Both involve forcing material through a confined space to achieve a specific shape. However, the Wade extruder typically uses plastic filaments, not aluminum.

Use of Aluminum in 3D Printing

Aluminum is sometimes used in 3D printing for parts like printer frames or components due to its strength and durability. However, it is not commonly extruded in 3D printing like plastic filaments. Instead, aluminum is often used as a structural material to enhance the stability and longevity of the printer.

Advantages of Using Aluminum in 3D Printing

- Durability: Aluminum provides a robust framework that can withstand the rigors of continuous printing.

- Heat Dissipation: Aluminum is a good conductor of heat, which can help in managing the thermal conditions around the printer.

- Aesthetics: Aluminum components can add a sleek and professional look to the printer.

Comparison of Wade Extruder with Other Extruders

The Wade extruder offers improved control and efficiency compared to other extruders due to its geared design, making it suitable for precise 3D printing applications. Here are some key differences:

- Precision: The Wade extruder provides better control over filament flow, ensuring precise layering and reduced errors.

- Material Handling: It can handle a variety of filaments, including those with higher viscosity, thanks to its geared mechanism.

- Reliability: The design is robust and less prone to jamming, making it reliable for long printing sessions.

Future Developments in Extrusion Technology

As technology advances, both 3D printing extruders and aluminum extrusion processes are expected to see improvements. Innovations in materials science and mechanical engineering will likely lead to more efficient and versatile extrusion methods.

Potential Applications of Advanced Extrusion

- Sustainable Materials: The use of recycled or sustainable materials in both 3D printing and aluminum extrusion could become more prevalent.

- Complex Geometries: Advances in extrusion technology might enable the creation of even more complex shapes and structures.

- Integration with Other Technologies: Extrusion could be integrated with other manufacturing techniques to create hybrid processes that combine the benefits of different technologies.

Conclusion

In conclusion, while the term "Wade extruder aluminum" does not directly refer to a specific type of aluminum extrusion, it highlights the broader context of extrusion technology. The Wade extruder is a tool used in 3D printing, and aluminum extrusion is a separate process used to create complex aluminum profiles. Understanding both technologies can provide insights into how materials are shaped and used across different industries.

FAQ

1. What is a Wade Extruder?

A Wade extruder is a type of 3D printing extruder designed for efficient filament extrusion. It is known for its geared system, which enhances control over the printing process.

2. How Does Aluminum Extrusion Work?

Aluminum extrusion involves heating aluminum billets and forcing them through a die to create specific profiles. The process includes cooling, straightening, and aging the extruded profiles.

3. Can Aluminum Be Used in 3D Printing?

Yes, aluminum can be used in 3D printing, often for structural components due to its strength and durability. However, it is not commonly extruded like plastic filaments.

4. What Are the Applications of Aluminum Extrusions?

Aluminum extrusions are widely used in construction, automotive, and consumer goods industries due to their strength, corrosion resistance, and ability to form complex shapes.

5. How Does the Wade Extruder Compare to Other Extruders?

The Wade extruder offers improved control and efficiency compared to other extruders due to its geared design, making it suitable for precise 3D printing applications.