Content Menu

● Introduction to FlashForge Extruders

>> FlashForge Creator 3 Extruder System

● The Role of the Aluminum Strip

>> Thermal Management

>> Structural Support

● Maintenance and Troubleshooting

● Upgrades and Modifications

>> Installing an All-Metal Hotend

>> Custom Modifications

● Advanced Printing Techniques

>> Mirror Printing

>> Dual-Material Printing

● Conclusion

● FAQ

>> 1. What is the purpose of the aluminum strip in FlashForge extruders?

>> 2. How do I clean the extruder gear on a FlashForge printer?

>> 3. What materials are compatible with the FlashForge Creator 3 extruders?

>> 4. How do I troubleshoot a clogged nozzle on a FlashForge printer?

>> 5. Can I upgrade the extruder assembly on my FlashForge printer?

● Citations:

The FlashForge extruder aluminum strip is a critical component in the extruder assembly of FlashForge 3D printers, such as the Creator Pro and Creator 3 models. This strip, often part of a larger extruder assembly, plays a crucial role in maintaining the structural integrity and thermal management of the extruder system. In this article, we will delve into the details of the FlashForge extruder aluminum strip, its functions, and how it contributes to the overall performance of the printer.

Introduction to FlashForge Extruders

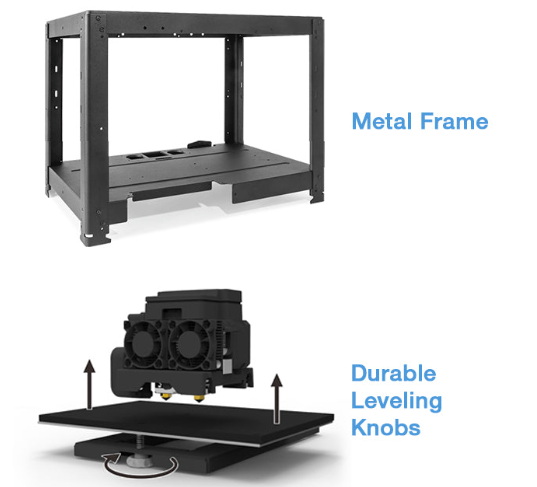

FlashForge is a well-known brand in the 3D printing industry, offering a range of printers that cater to both hobbyists and professionals. Their printers, like the Creator 3, feature advanced extruder systems designed to handle complex printing tasks with precision and efficiency. The extruder system is responsible for melting and depositing filament onto the build plate, layer by layer, to create the final printed object.

FlashForge Creator 3 Extruder System

The FlashForge Creator 3, for instance, boasts an independent dual-extruder system. This setup allows for printing with two different colors or materials simultaneously, enhancing productivity and versatility. The extruders are equipped with stainless steel nozzles, compatible with a variety of filaments including PLA, ABS, ASA, PETG, PC, PA, and various composite materials like carbon fiber and metal-filled filaments.

The Role of the Aluminum Strip

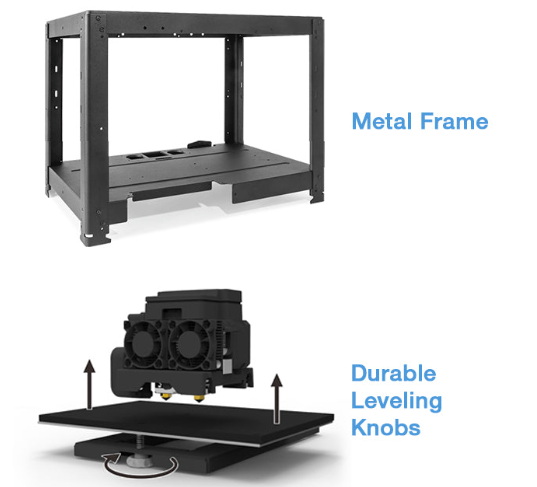

In the context of FlashForge extruders, the aluminum strip is typically part of the extruder assembly's structural framework. It helps in maintaining the alignment and stability of the extruder components, such as the heat block, nozzle, and cooling fans. Aluminum is chosen for its excellent thermal conductivity, which aids in dissipating heat generated during the printing process.

Thermal Management

Effective thermal management is crucial for consistent and high-quality prints. The aluminum strip assists in regulating the temperature around the extruder, ensuring that the heat block and nozzle operate within optimal temperature ranges. This is particularly important when printing with materials that require precise temperature control, such as ABS or polycarbonate.

Structural Support

Beyond thermal management, the aluminum strip provides structural support to the extruder assembly. It helps maintain the alignment of the extruder components, ensuring smooth movement and precise filament deposition. This structural integrity is vital for achieving consistent print quality, especially in complex prints that require precise layer alignment.

Maintenance and Troubleshooting

Regular maintenance of the extruder assembly, including the aluminum strip, is essential for preventing issues such as clogged nozzles or under-extrusion. Here are some steps to maintain and troubleshoot common problems:

1. Cleaning the Extruder Gear: Use a small brass wire brush to clean the hobbed bolt, which can become clogged with filament residue. Ensure the gear is firmly attached to the motor shaft and tighten any stop screws if necessary[5].

2. Nozzle Clogging: Use an unclogging tool or replace the nozzle if necessary. Heating the extruder to its operating temperature can make nozzle removal easier[8].

3. Temperature Calibration: Ensure the extruder temperature matches the filament's recommended settings. Incorrect temperatures can lead to poor print quality or extruder damage.

Upgrades and Modifications

For enthusiasts looking to enhance their printer's performance, upgrading or modifying the extruder assembly can be beneficial. This might involve installing an all-metal hotend for improved thermal stability or replacing the aluminum strip with a custom design for better heat dissipation.

Installing an All-Metal Hotend

Installing an all-metal hotend, like the Micro Swiss All Metal Hotend, can significantly improve thermal performance. This upgrade allows for more consistent temperature control, which is crucial for printing with materials that require high temperatures, such as polycarbonate or ABS.

Custom Modifications

Custom modifications can also enhance the printer's capabilities. For example, using a thicker aluminum strip or adding additional cooling components can improve thermal management and structural stability. However, such modifications should be approached with caution and ideally done by experienced users.

Advanced Printing Techniques

Beyond basic printing, advanced techniques can further leverage the capabilities of FlashForge printers. Techniques like mirror printing or dual-material printing require precise extruder calibration and temperature control.

Mirror Printing

Mirror printing involves printing two identical models simultaneously using both extruders. This technique requires precise calibration to ensure that both extruders are aligned correctly and operate at the same height. The FlashForge Creator 3's software automatically compensates for any height differences between the extruders, ensuring consistent print quality[7].

Dual-Material Printing

Dual-material printing allows for the use of different materials or colors in a single print. This technique is particularly useful for creating complex models with varied properties, such as combining PLA for the main structure with PVA for support material.

Conclusion

The FlashForge extruder aluminum strip is a vital component in the extruder assembly of FlashForge 3D printers, contributing to both structural integrity and thermal management. Understanding its role and how to maintain it can significantly improve print quality and extend the lifespan of the printer. Whether you're a beginner or an experienced user, recognizing the importance of this component can help you troubleshoot common issues and optimize your printing experience.

FAQ

1. What is the purpose of the aluminum strip in FlashForge extruders?

The aluminum strip in FlashForge extruders serves as a structural component that maintains the alignment and stability of the extruder assembly. It also aids in thermal management by helping to dissipate heat generated during the printing process.

2. How do I clean the extruder gear on a FlashForge printer?

To clean the extruder gear, use a small brass wire brush to remove any filament residue that may have accumulated. This is a common maintenance task to prevent under-extrusion issues.

3. What materials are compatible with the FlashForge Creator 3 extruders?

The FlashForge Creator 3 supports a wide range of filaments including PLA, ABS, ASA, PETG, PC, PA, and various composite materials like carbon fiber and metal-filled filaments.

4. How do I troubleshoot a clogged nozzle on a FlashForge printer?

To troubleshoot a clogged nozzle, first ensure the filament is not tangled. Then, check the nozzle temperature and try to push the filament manually. If the issue persists, use an unclogging tool or replace the nozzle.

5. Can I upgrade the extruder assembly on my FlashForge printer?

Yes, upgrading the extruder assembly is possible. Common upgrades include installing an all-metal hotend for improved thermal stability. However, such modifications should be approached with caution and ideally done by experienced users.

Citations:

[1] https://en.fss.flashforge.com/10000/software/5fed199886c6a9b740f002862063ea60.pdf

[2] https://www.youtube.com/watch?v=FepYpYRethg

[3] https://www.youtube.com/watch?v=bSZcnSrRnS4

[4] https://www.flashforge.com.hk/uploads/5/8/1/9/58196085/flashforge_creator_pro_user_manual_en_version04.29.2015.3.2._latest.pdf

[5] https://flashforgeeu.freshdesk.com/support/solutions/articles/24000012787-basic-maintenance-of-3d-printers-and-preventive-actions

[6] https://www.instructables.com/Upgrading-the-Flashforge-Finder/

[7] https://en.fss.flashforge.com/10000/software/61817cc4fa72e8e2d4654a6192d895f1.pdf

[8] https://www.hubs.com/talk/t/how-to-disassemble-flashforge-creator-extuder/2272/

[9] https://flashforge.com/a/docs/adventurer-5m-series/faq-for-adventurer-5m-pro

[10] https://en.fss.flashforge.com/10000/software/692ef075fcb6db012b38a885dca0e057.pdf

[11] https://www.instructables.com/Flashforge-Dual-Head-Printer-Print-Head-Repair/

[12] https://www.printables.com/model/334818-flashforge-dreamer-upgrades-and-ideas

[13] https://gzhls.at/blob/ldb/8/3/a/c/6706a696e2cf599f4ec044463cbb918933d9.pdf

[14] https://www.youtube.com/watch?v=vmIY9_6s8Ss

[15] https://www.reddit.com/r/FlashForge/comments/1dl3yf7/flashforge_creator_pro_upgrades/

[16] https://www.elitemetaltools.com/sites/default/files/product-data/manuals/Creator_3_User_Guide_EN2.pdf

[17] https://wiki.flashforge.com/en/adventurer-series/maintenance/linear_guide_Maintenance_for_AD5M_Series

[18] https://flashforge-usa.com/collections/parts-accessories

[19] https://pentaprint3d.fr/wp-content/uploads/2023/12/Creator4-User-Manual_EN.pdf

[20] https://www.reddit.com/r/FlashForge/comments/z69v83/help_with_removing_prints_im_unable_to_remove_the/