Content Menu

● What is a Creality Aluminum Extruder?

>> Key Features

● Advantages of Using a Creality Aluminum Extruder

● Applications of Creality Aluminum Extruders

● How to Install a Creality Aluminum Extruder

● Maintenance Tips for Your Creality Aluminum Extruder

● Conclusion

● FAQ

>> 1. What types of filaments can I use with a Creality aluminum extruder?

>> 2. How do I know if my current extruder needs an upgrade?

>> 3. Can I install a Creality aluminum extruder on any 3D printer?

>> 4. Is it difficult to install a Creality aluminum extruder?

>> 5. How often should I maintain my aluminum extruder?

● Citations:

In the world of 3D printing, the extruder plays a pivotal role in determining the quality and precision of printed objects. Among various options available, the "Creality aluminum extruder" has gained significant attention due to its robust design and superior performance. This article delves into what a Creality aluminum extruder is, its advantages, applications, and why it should be your choice for 3D printing.

What is a Creality Aluminum Extruder?

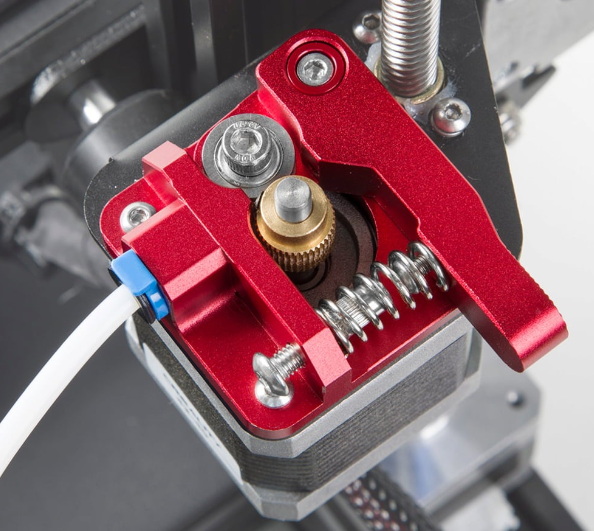

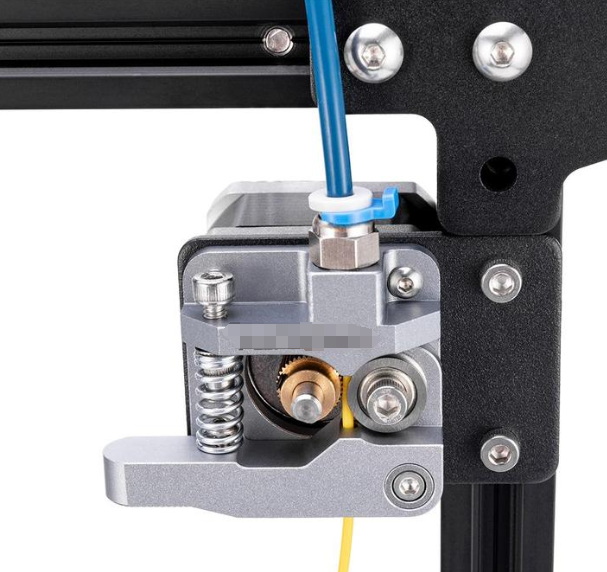

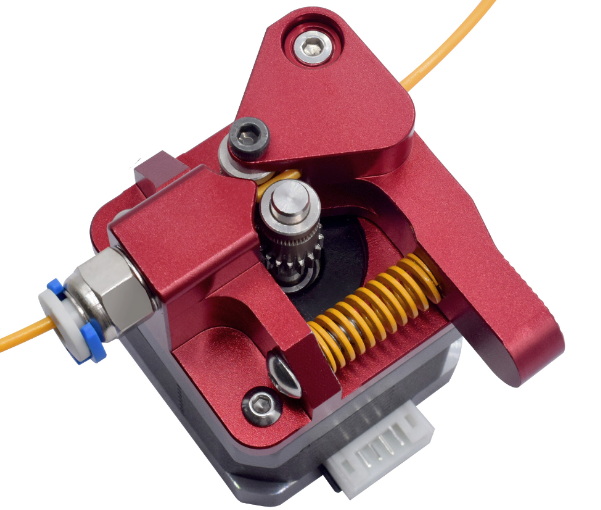

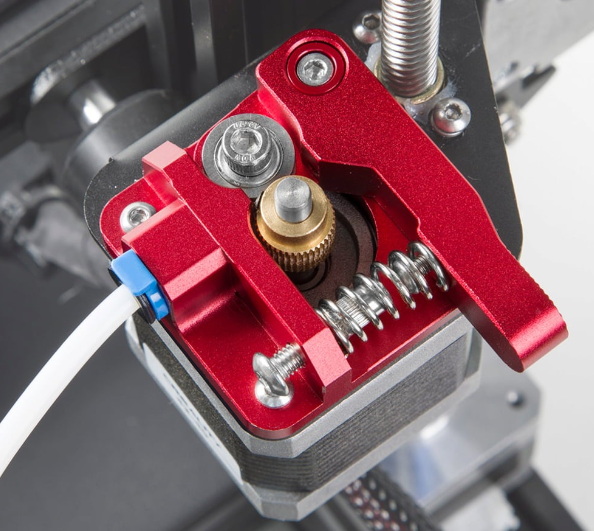

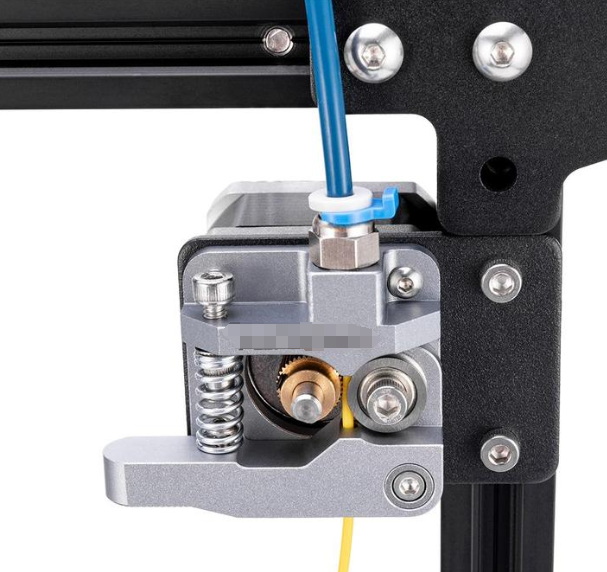

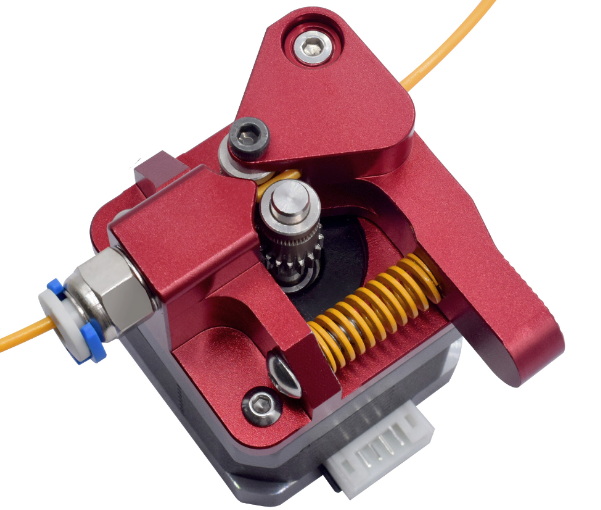

A Creality aluminum extruder is a component used in 3D printers, particularly those manufactured by Creality, such as the Ender and CR series. Made from high-quality aluminum alloy, this extruder is designed to provide a reliable and efficient feeding mechanism for filament during the printing process.

Key Features

- Material: Constructed from durable aluminum alloy, ensuring longevity and resistance to wear.

- Design: Often features a double gear extrusion mechanism that enhances grip on the filament, leading to smoother operation.

- Compatibility: Suitable for various Creality models including Ender 3, Ender 5, and CR-10 series.

Advantages of Using a Creality Aluminum Extruder

1. Improved Filament Feeding: The double gear system provides better grip and feeding stability compared to single gear designs. This minimizes slippage and ensures consistent extrusion of filament[1][4].

2. Durability: Aluminum is known for its strength and resistance to corrosion. This means that a Creality aluminum extruder can withstand the rigors of continuous use without significant degradation in performance[2][5].

3. Lightweight Design: Despite its strength, aluminum is lightweight, which helps in maintaining the overall weight of the 3D printer, contributing to better print quality by reducing vibrations during operation[5][6].

4. Cost-Effectiveness: The manufacturing process for aluminum extruders is efficient, making them a cost-effective choice for both manufacturers and hobbyists alike[2][4].

5. Versatility: The design of the aluminum extruder allows it to work with various types of filaments, including PLA, ABS, and PETG. This versatility makes it suitable for a wide range of printing applications[1][2].

Applications of Creality Aluminum Extruders

Creality aluminum extruders are utilized in various applications across different industries:

- Prototyping: Ideal for creating prototypes due to their precision and reliability.

- Hobbyist Projects: Popular among hobbyists for personal projects where quality is paramount.

- Educational Purposes: Used in educational settings to teach students about 3D printing technology.

- Small Scale Manufacturing: Suitable for small businesses looking to produce custom parts or products.

How to Install a Creality Aluminum Extruder

Installing a Creality aluminum extruder can enhance your 3D printer's performance significantly. Here's a step-by-step guide:

1. Gather Tools and Materials:

- Creality aluminum extruder kit

- Allen wrench

- Screwdriver

- Filament

2. Remove the Existing Extruder:

- Power off the printer.

- Disconnect the wiring harness connected to the existing extruder.

- Unscrew and remove the old extruder from its mount.

3. Install the New Extruder:

- Align the new Creality aluminum extruder with the mounting holes.

- Secure it using screws provided in the kit.

4. Reconnect Wiring:

- Carefully connect the wiring harness to the new extruder according to the manufacturer's instructions.

5. Calibrate Your Printer:

- Once installed, run calibration prints to ensure that everything is functioning correctly.

Maintenance Tips for Your Creality Aluminum Extruder

To keep your Creality aluminum extruder in optimal condition:

- Regular Cleaning: Clean any filament residue from the gears and feed path regularly.

- Check for Wear: Inspect gears and other moving parts for signs of wear or damage.

- Lubrication: Apply lubricant sparingly on moving parts if necessary to ensure smooth operation.

Conclusion

The Creality aluminum extruder stands out as an essential upgrade for anyone serious about 3D printing. Its combination of durability, precision, and versatility makes it an excellent choice for both novice and experienced users alike. By investing in this component, you can significantly enhance your printer's performance and achieve higher quality prints.

FAQ

1. What types of filaments can I use with a Creality aluminum extruder?

You can use various filaments including PLA, ABS, PETG, and TPU with a Creality aluminum extruder.

2. How do I know if my current extruder needs an upgrade?

Signs that your current extruder may need an upgrade include inconsistent extrusion, frequent jams, or visible wear on components.

3. Can I install a Creality aluminum extruder on any 3D printer?

While primarily designed for Creality printers like Ender 3 and CR-10 series, some modifications may allow installation on other brands.

4. Is it difficult to install a Creality aluminum extruder?

No, installation is straightforward with basic tools and can typically be completed within an hour by following manufacturer instructions.

5. How often should I maintain my aluminum extruder?

Regular maintenance every few weeks or after significant use will help ensure optimal performance.

Citations:

[1] https://www.reprapwarehouse.com/products/official-creality-all-metal-aluminum-extruder-ender-3-pro-ender-5-cr-10-series

[2] https://www.yjing-extrusion.com/what-are-the-benefits-of-using-aluminum-extrusion-in-3d-printing.html

[3] https://tricityextrusion.com/roxyfileman/uploads/AEC_2018_Aluminum_Extrusion_Manual.pdf

[4] https://www.crealityexperts.com/creality-extruder-guide

[5] https://aec.org/features-benefits

[6] https://www.extrusion.net/publications

[7] https://www.youtube.com/watch?v=GzbwLE92g9A

[8] https://www.aliexpress.com/i/1005001431887581.html