Content Menu

● Introduction to Squeegee Holder Extrusion

>> Automatic Squeegee Holder Extrusion Machines

● Industries Utilizing Automatic Squeegee Holder Extrusion Machines

>> 1. Screen Printing Industry

>> 2. Textile Industry

>> 3. Electronics Industry

>> 4. Glass Printing Industry

>> 5. Industrial Printing

● Benefits of Automatic Squeegee Holder Extrusion Machines

● Challenges and Future Developments

● Materials Used in Squeegee Holder Extrusion

● Squeegee Storage and Handling

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary materials used in automatic squeegee holder extrusion?

>> 2. How does the hardness of a squeegee affect print quality?

>> 3. What are the benefits of using automatic squeegee holder extrusion machines?

>> 4. Can automatic squeegee holder extrusion machines be used for small-scale printing operations?

>> 5. How do environmental regulations impact the choice of materials in squeegee holder extrusion?

● Citations:

Automatic squeegee holder extrusion machines are crucial in various industries where precision and efficiency in screen printing are essential. These machines play a vital role in manufacturing squeegee holders, which are used to apply ink or other materials onto surfaces through a screen. The process involves extruding a continuous profile of material, such as aluminum or polyurethane, to create the squeegee holder. This article will explore the industries that utilize automatic squeegee holder extrusion machines and highlight their applications.

Introduction to Squeegee Holder Extrusion

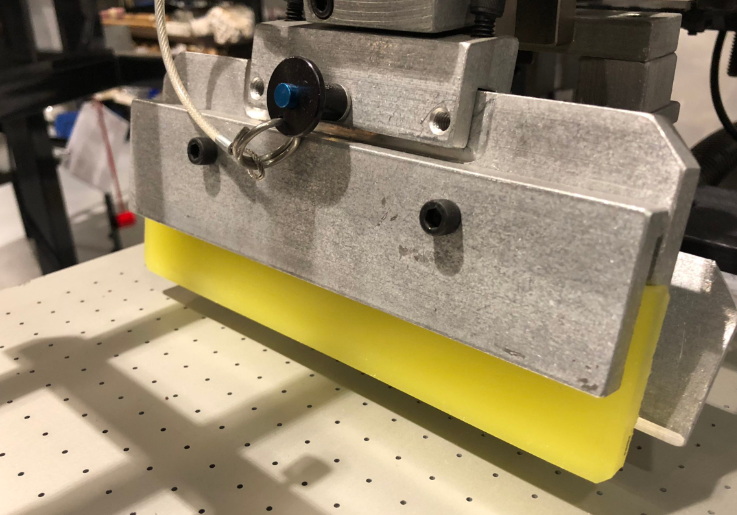

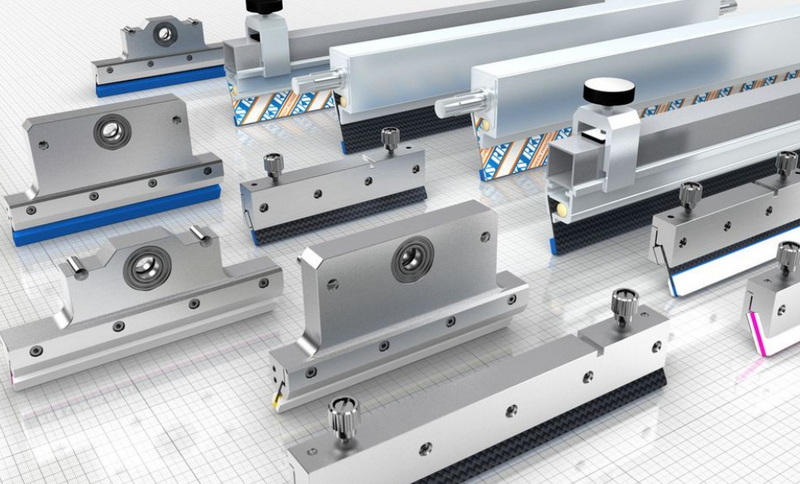

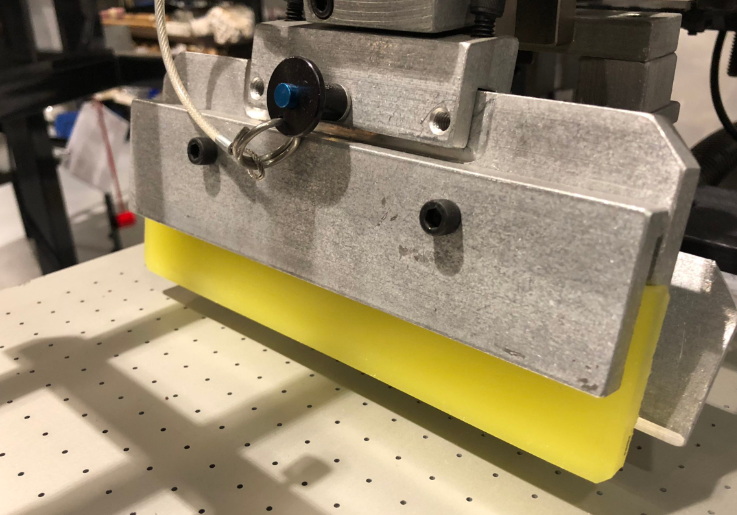

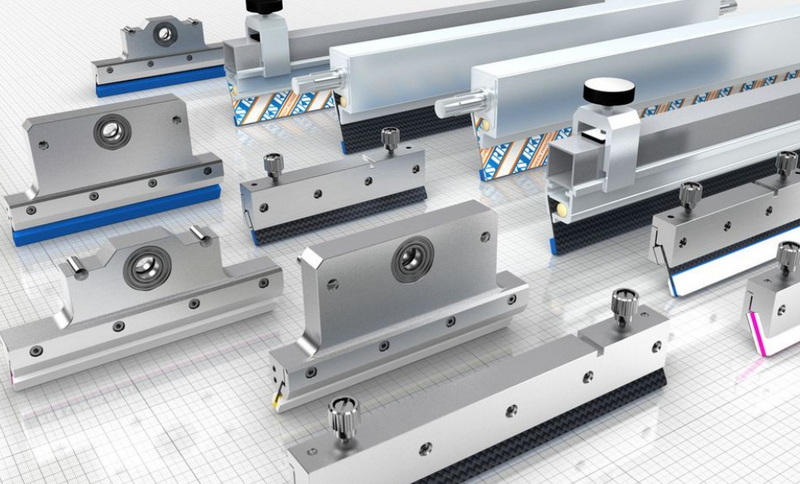

Squeegee holder extrusion involves creating a continuous profile of material that serves as the base for squeegee blades. These blades are critical in screen printing, as they ensure uniform ink distribution and quality print results. The extrusion process allows for customization in terms of material, shape, and size, catering to different printing needs.

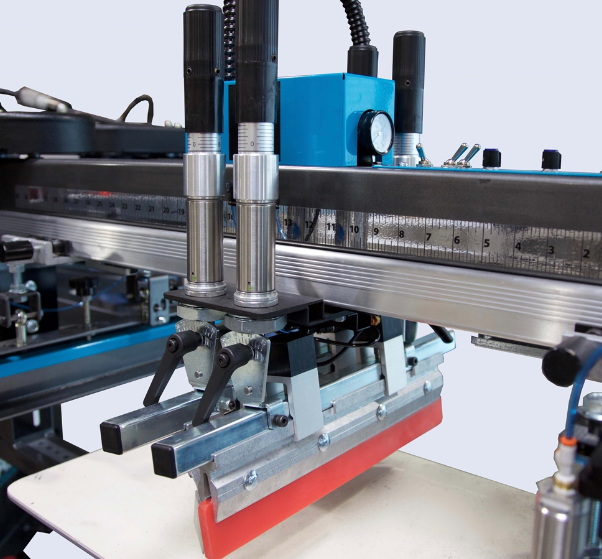

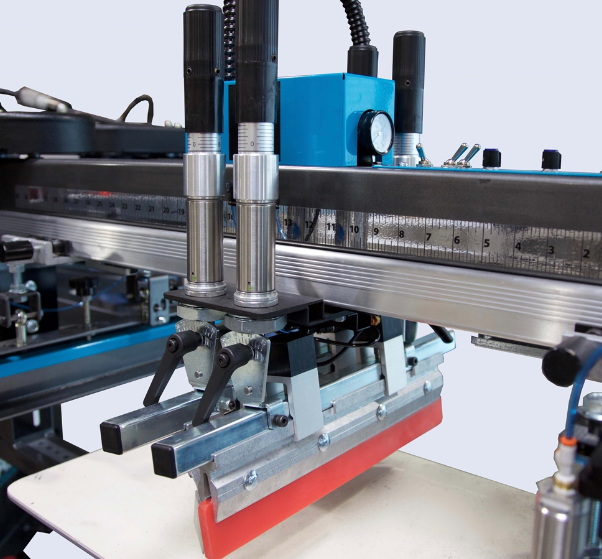

Automatic Squeegee Holder Extrusion Machines

These machines automate the extrusion process, enhancing precision and reducing production time. They are equipped with advanced technology that ensures consistent quality and can handle various materials, including aluminum and polyurethane. The use of automation and AI in extrusion technology further improves the precision and efficiency of these machines, allowing for more complex geometries and better material utilization[3].

Industries Utilizing Automatic Squeegee Holder Extrusion Machines

1. Screen Printing Industry

The screen printing industry is the primary user of automatic squeegee holder extrusion machines. These machines are essential for producing high-quality squeegee holders that are used in both manual and automatic screen printing presses. The precision and consistency provided by these machines ensure optimal print quality. In screen printing, adjusting the squeegee angle is crucial for achieving the desired ink volume and print quality[7].

2. Textile Industry

In the textile industry, automatic squeegee holder extrusion machines are used to produce squeegees for printing fabrics. The ability to customize squeegee hardness and shape allows for various fabric types and designs. For instance, squeegees with softer blades are used for delicate fabrics, while harder blades are used for thicker materials.

3. Electronics Industry

For electronics manufacturing, precise squeegee holders are necessary for applying solder paste or other materials onto circuit boards. Automatic squeegee holder extrusion machines help ensure the quality and consistency required in this field. The use of high-performance polymers in extrusion can enhance the durability and chemical resistance of squeegee holders, making them suitable for demanding applications like PCB manufacturing[3].

4. Glass Printing Industry

In glass printing, squeegee holders must withstand the rigors of printing on glass surfaces. Automatic extrusion machines enable the production of durable squeegee holders suitable for this application. The materials used in these holders are often resistant to corrosion and abrasion, ensuring long-term performance.

5. Industrial Printing

Industrial printing encompasses a wide range of applications, from labels to large-format prints. Automatic squeegee holder extrusion machines support these diverse needs by providing customizable squeegee holders. The versatility of these machines allows them to be used in various settings, from small-scale operations to large industrial facilities.

Benefits of Automatic Squeegee Holder Extrusion Machines

- Precision and Consistency: These machines ensure that every squeegee holder produced meets precise specifications, leading to consistent print quality.

- Efficiency: Automatic extrusion reduces production time and labor costs compared to manual methods.

- Customization: Machines can be set to produce squeegee holders of various sizes and materials, catering to different industry needs.

Challenges and Future Developments

While automatic squeegee holder extrusion machines offer numerous benefits, there are challenges related to material durability and environmental sustainability. Future developments will likely focus on using eco-friendly materials, such as bioplastics, and enhancing machine efficiency through automation and AI[3]. The integration of 3D printing with extrusion technology could also enable the creation of complex geometries that were previously difficult to achieve.

Materials Used in Squeegee Holder Extrusion

The choice of materials for squeegee holder extrusion is critical. Common materials include aluminum, polyurethane, and mixed materials like polyacetal, epoxy, and polyethylene. Aluminum is favored for its durability and light weight, while polyurethane is used for its flexibility and resistance to abrasion[1][5]. The use of mixed materials can enhance the strength and durability of squeegee holders, making them suitable for demanding applications.

Squeegee Storage and Handling

In addition to production, the storage and handling of squeegees are important for maintaining efficiency in printing operations. Devices like the Squeegee-Prop provide convenient storage solutions, allowing squeegees to be stored within the screen between prints[2]. This not only saves space but also helps maintain cleanliness by preventing ink from spreading.

Conclusion

Automatic squeegee holder extrusion machines are pivotal in various industries, including screen printing, textiles, electronics, glass printing, and industrial printing. Their ability to produce high-quality, customizable squeegee holders efficiently supports the diverse needs of these sectors. As technology advances, these machines will continue to play a crucial role in enhancing print quality and efficiency.

Frequently Asked Questions

1. What are the primary materials used in automatic squeegee holder extrusion?

- The primary materials used are aluminum and polyurethane. Aluminum is often used for the squeegee holder itself due to its durability and resistance to corrosion, while polyurethane is commonly used for the squeegee blades because of its flexibility and resistance to abrasion.

2. How does the hardness of a squeegee affect print quality?

- The hardness of a squeegee affects print quality by influencing the amount of ink deposited onto the surface. Softer squeegees deposit more ink but may result in less definition, while harder squeegees deposit less ink but provide higher definition.

3. What are the benefits of using automatic squeegee holder extrusion machines?

- The benefits include precision, consistency, efficiency, and customization. These machines ensure that every squeegee holder produced meets precise specifications, reduce production time, and can be set to produce holders of various sizes and materials.

4. Can automatic squeegee holder extrusion machines be used for small-scale printing operations?

- Yes, these machines can be used for small-scale operations. However, their cost-effectiveness may vary depending on the scale of production. For very small operations, manual methods might be more economical.

5. How do environmental regulations impact the choice of materials in squeegee holder extrusion?

- Environmental regulations, such as those promoting the use of bioplastics, influence the choice of materials by encouraging the adoption of eco-friendly and non-toxic substances. Manufacturers must ensure that their materials comply with these standards to minimize environmental impact.

Citations:

[1] https://patents.google.com/patent/KR100292630B1/en

[2] https://inkinnovationsusa.com/products/squeegee-prop-in-screen-storage-device

[3] https://kama-packaging.com/en/the-future-of-extrusion-technology-new-materials-and-technologies/

[4] https://actionengineering.com/squeegees-1/

[5] https://huajinscreenprinting.en.made-in-china.com/product/fwktJXTGvcaq/China-Squeegee-Holder-Aluminum-with-Squeegees-Rubber.html

[6] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[7] https://www.macrokun.com/News/screen-printing-squeegee-news/224.html

[8] https://store.creality.com/blog/3d-screen-printing-squeegee

[9] https://www.tesa.com/en/about-tesa/product-and-technology-development

[10] https://macrokun.en.made-in-china.com/product/WZcmQLDubHVs/China-Squeegee-with-Wooden-Handle-for-Screen-Printing.html

[11] https://www.youtube.com/watch?v=uXv1uXuRcyQ

[12] https://screenprintingmag.com/the-identity-of-a-squeegee/

[13] https://www.alibaba.com/product-detail/aluminium-squeegee-for-screen-printing-machine_1601250470699.html

[14] https://www.mrprint.com/store/category/1214-squeegee-holders

[15] https://www.tesa.com/en/about-tesa/career/current-vacancies/working-student-or-intern-m-f-d-technology-development-ac-extrusion-lab-11868821.html

[16] https://patents.google.com/patent/US20110041278A1/en_2

[17] https://gastropod.com/search/the+microbe+revolution/feed/rss2/

[18] https://www.fimor.com/en/screen-printing/