Content Menu

● Introduction

● The Aluminum Extrusion Process

>> Overview

>> Types of Extrusion Dies

>> Press Tooling

>> Customization Options

● Industries Utilizing Aluminum Extruders in Michigan

>> Automotive Industry

>> Construction and Architecture

>> Marine Industry

>> Medical Industry

>> Retail Industry

>> Other Industries

● Key Companies in Michigan's Aluminum Extrusion Industry

>> Michigan Extruded Aluminum

>> Hydro Aluminum Cassopolis

>> Extruded Aluminum Corporation

>> Offshore Direct Metals

>> Huppert Engineering

>> Bonnell Aluminum

>> Kaiser Aluminum

● Advantages of Using Aluminum Extrusions

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. What are the main advantages of using aluminum extrusions?

>> 3. Which industries benefit the most from aluminum extrusions in Michigan?

>> 4. Can aluminum extrusions be customized?

>> 5. How does aluminum extrusion contribute to sustainability?

● Citations:

Introduction

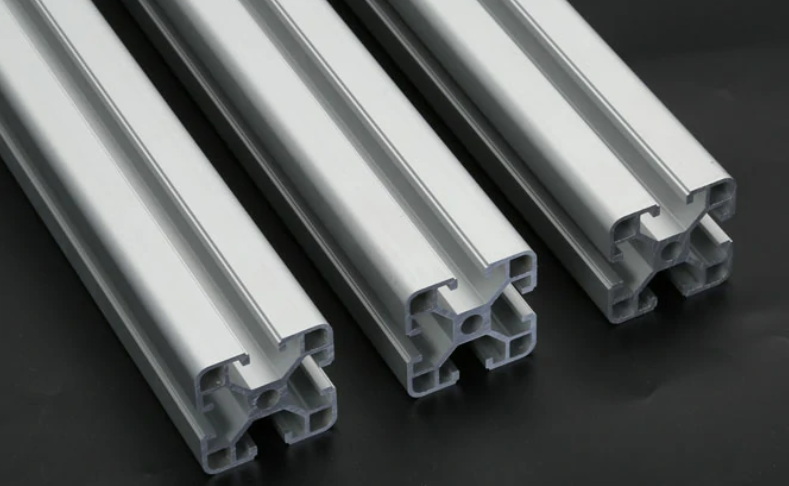

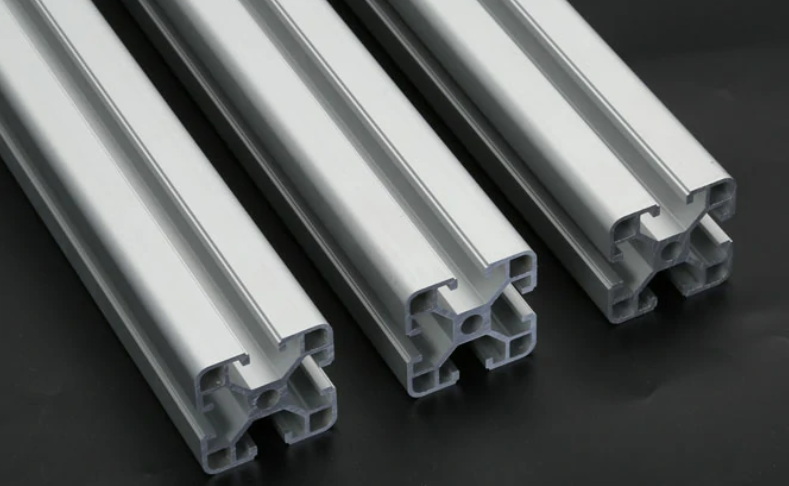

Aluminum extrusion is a versatile manufacturing process that involves forcing heated aluminum billets through a die to create specific shapes and profiles. This process is widely used in various industries due to aluminum's unique properties, such as its lightweight nature, corrosion resistance, high strength-to-weight ratio, and recyclability[2]. Michigan, with its rich industrial history and strong manufacturing base, is home to numerous companies that specialize in aluminum extrusion. These companies serve a diverse range of industries, providing custom and standard aluminum extrusions tailored to meet specific needs[1][2][5]. This article explores the key industries that utilize aluminum extruders in Michigan, highlighting the applications and benefits of this essential manufacturing process.

The Aluminum Extrusion Process

Overview

The aluminum extrusion process begins with preheating aluminum billets, which are solid cylindrical logs, to temperatures between 700-930°F (370-500°C) to achieve the necessary plasticity[4]. The preheated billet is then loaded into a heat container within the extrusion press. A hydraulic ram applies immense pressure, ranging from 1,000 to 15,000 tons, to force the softened aluminum through the die opening[4]. As the aluminum is pushed through the die, it takes on the shape of the die opening, forming the desired profile. The extruded profile is then cooled using air or water and transferred for further processing, such as stretching, machining, and surface treatments[4].

Types of Extrusion Dies

The most crucial component in the aluminum extrusion process is the extrusion die. It shapes the aluminum as it is forced through the die opening under immense pressure, requiring incredible precision and reliability[4].

Press Tooling

The aluminum extrusion process relies on a comprehensive set of press tooling to control the temperature of the billet and push the aluminum through the die[4]. Key press tooling components include the stem, dummy block, container, container liner, die slide, and horse shoe[4].

Customization Options

Custom aluminum extrusions offer a wide range of design options, including complex cross-sections and tight tolerances[2]. This makes them ideal for applications where standard profiles are unsuitable or where specific performance characteristics are required[2]. Customization options include:

- Custom Dies[2]

- Custom Finishes[2]

- Shapes & Size[2]

- Wall Thickness[2]

- Material/Alloy Selection[2]

- Machining & Fabrication[2]

Industries Utilizing Aluminum Extruders in Michigan

Automotive Industry

The automotive industry is one of the largest consumers of aluminum extrusions in Michigan[2][6][7]. Aluminum extrusions are used in a variety of automotive applications due to their lightweight properties, which contribute to improved fuel efficiency and reduced emissions[6]. Aluminum components can be found in:

- Body Structures: Aluminum extrusions are used in the construction of lightweight vehicle frames and body panels[6].

- Chassis Components: These include suspension parts, control arms, and subframes[6].

- Heat Exchangers: Aluminum's excellent thermal conductivity makes it ideal for radiators and air conditioning systems.

- Interior Trim: Aluminum extrusions are used for decorative and functional interior components.

- Electric Vehicles: With the rise of electric vehicles (EVs), aluminum extrusions are increasingly used in battery housings and other structural components to reduce weight and extend driving range[7].

Construction and Architecture

Aluminum extrusions are widely used in the construction and architecture industries for their strength, durability, and corrosion resistance[1][2][6]. Common applications include:

- Window and Door Frames: Aluminum provides excellent thermal insulation and structural support[3].

- Curtain Walls: These non-structural outer walls of buildings benefit from aluminum's lightweight and aesthetic appeal.

- Solar Panels: Aluminum frames and mounting structures are essential for solar energy systems[10].

- Structural Components: Beams, supports, and roofing systems utilize aluminum extrusions for their strength and ease of installation[6].

- Building Trim: Aluminum is used for decorative elements such as railings, trims, and facades.

Marine Industry

Aluminum extrusions are highly valued in the marine industry due to their corrosion resistance and lightweight properties[2]. Key applications include:

- Boat Hulls: Aluminum extrusions are used to construct lightweight and durable boat hulls[2].

- Decking and Railings: Aluminum provides a safe and low-maintenance solution for marine decking and railing systems.

- Structural Supports: Aluminum extrusions are used for internal supports and framing in boats and ships.

- Docks and Piers: Aluminum components offer long-lasting resistance to saltwater corrosion.

Medical Industry

The medical industry relies on aluminum extrusions for various applications that require precision, hygiene, and durability[2][3]. These include:

- Medical Equipment Frames: Aluminum is used in the construction of lightweight and sturdy frames for medical devices[3].

- Surgical Instruments: Aluminum components are used in surgical instruments for their precision and corrosion resistance.

- Diagnostic Equipment Housings: Aluminum provides a protective and lightweight housing for diagnostic machines.

- Assistive Devices: Wheelchairs, walkers, and other assistive devices benefit from aluminum's lightweight and strength[3].

Retail Industry

Aluminum extrusions are used extensively in the retail sector for their aesthetic appeal and functional benefits[2]. Common applications include:

- Display Cases: Aluminum frames provide a sleek and modern look for display cases[2].

- Shelving Systems: Aluminum extrusions offer strong and adjustable shelving solutions.

- Signage: Aluminum is used for both indoor and outdoor signage due to its durability and weather resistance.

- Store Fixtures: Racks, stands, and other store fixtures benefit from aluminum's lightweight and robust properties.

Other Industries

In addition to the major sectors listed above, aluminum extruders in Michigan also serve a variety of other industries[1][2][3]:

- Aerospace: Aluminum extrusions are used in aircraft components due to their high strength-to-weight ratio.

- Electronics: Aluminum housings and heat sinks are used in electronic devices for thermal management and protection.

- Renewable Energy: Aluminum is used in solar panel frames and wind turbine components[1].

- Furniture: Aluminum extrusions are used in modern furniture designs for their lightweight and stylish appearance.

Key Companies in Michigan's Aluminum Extrusion Industry

Michigan Extruded Aluminum

Michigan Extruded Aluminum is a company specializing in custom aluminum extrusions, precision cutting, machining, fabrication, finishing, engineering, design assistance, tooling, packaging, and shipping[3][5]. They prioritize quality and sustainability by using recycled billet for extrusions[3]. With over 40 years of experience, their engineers assist in creating optimal extrusion designs[3]. They supply various industries including office furniture, marine, architectural products, construction equipment, medical, solar power, and LED lighting[3].

Hydro Aluminum Cassopolis

Hydro Aluminum Cassopolis produces 120,000 metric tonnes (265 million pounds) of aluminum extrusion ingot per year[7]. Applications for the aluminum produced in Cassopolis include critical automotive applications as well as other transportation uses, consumer and building system applications[7].

Extruded Aluminum Corporation

Extruded Aluminum Corporation, established in Otisco Township in 1987, processes extruded aluminum products for a variety of industries, including solar energy, material handling, truck/trailer, military and automotive[10][11].

Offshore Direct Metals

Offshore Direct Metals is a leading aluminum extrusion supplier in Michigan that offers design flexibility and dimensional control to develop unique, custom, and precise shapes and features for the best performance[2].

Huppert Engineering

Huppert Engineering offers top-of-the-line aluminum extrusion services designed for businesses and automotive experts in North America and Mexico[6]. Their custom aluminum extrusions provide the perfect solution for applications in automotive, construction, rail, mining, and commercial diesel industries[6].

Bonnell Aluminum

Bonnell Aluminum is a custom manufacturer of aluminum extrusions including fabricated and finished parts[1]. Capabilities include T-Slots, precision cutting, drilling, tapping, forming, bending and welding of custom and standard profiles[1]. Additional services such as packaging, painting and anodizing are provided[1].

Kaiser Aluminum

Kaiser Aluminum manufactures extrusions including hard alloys shapes, rods, bars and tubes[1].

Advantages of Using Aluminum Extrusions

- Lightweight: Aluminum's low density reduces the weight of the final product, which is particularly important in the automotive and aerospace industries[2][6].

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion in various environments[2].

- High Strength-to-Weight Ratio: Aluminum extrusions offer excellent strength for their weight, making them suitable for structural applications[2][6].

- Design Flexibility: The extrusion process allows for the creation of complex shapes and profiles tailored to specific needs[2].

- Recyclability: Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly material[3][7].

- Thermal Conductivity: Aluminum's excellent thermal conductivity makes it ideal for heat exchangers and cooling applications.

- Cost-Effectiveness: Aluminum extrusions can be a cost-effective manufacturing solution, especially for large production runs[6].

Conclusion

Aluminum extruders in Michigan play a vital role in supporting a wide array of industries, from automotive and construction to marine and medical[2][6][7]. The versatility, durability, and cost-effectiveness of aluminum extrusions make them an indispensable component in numerous applications[2]. As technology advances and industries continue to innovate, the demand for custom and high-quality aluminum extrusions is expected to grow, further solidifying Michigan's position as a key hub for aluminum extrusion manufacturing[1][3][5].

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die of a specific cross-section. This produces long pieces of aluminum with the desired profile, which can then be cut and used for various applications[4].

2. What are the main advantages of using aluminum extrusions?

The main advantages include its lightweight nature, corrosion resistance, high strength-to-weight ratio, design flexibility, recyclability, and thermal conductivity[2][6].

3. Which industries benefit the most from aluminum extrusions in Michigan?

Key industries include automotive, construction, marine, medical, retail, aerospace, electronics, and renewable energy[2][6][7].

4. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be highly customized in terms of shapes, sizes, finishes, wall thickness, and material/alloy selection[2]. This makes them suitable for a wide range of specific applications.

5. How does aluminum extrusion contribute to sustainability?

Aluminum is 100% recyclable without any loss of quality. Recycling aluminum requires only about 5% of the energy needed to produce primary aluminum, significantly reducing energy consumption and greenhouse gas emissions[3][7].

Citations:

[1] https://www.thomasnet.com/suppliers/michigan/all-cities/aluminum-extrusions-26890400

[2] https://www.odmetals.com/pages/custom-aluminum-extrusions-michigan

[3] https://www.explorium.ai/manufacturing/companies/michigan-extruded-aluminum

[4] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[5] https://aluminum-extrusions.net/michigan-extruded-aluminum/

[6] https://www.huppertengineeringusa.com/aluminum-extrusion-services

[7] https://www.hydro.com/en/global/about-hydro/hydro-worldwide/americas/united-states/midwest/hydro-aluminum-cassopolis/

[8] https://dajcor.com/extrusion

[9] https://michiganextruded.com/capabilities/machining-fabrication-assembly/

[10] https://www.areadevelopment.com/newsitems/11-22-2021/extruded-aluminum-corporation-otisco-township-ionia-county-michigan.shtml

[11] https://aluminummanufacturers.org/extruded-aluminum-corporation/

[12] https://www.iqsdirectory.com/extruded-aluminum/michigan/

[13] https://www.indeed.com/q-aluminum-extrusion-l-michigan-jobs.html

[14] https://www.belcoind.com

[15] https://www.hydro.com/profiles/aluminum-extrusions-manufacturer-in-michigan

[16] https://www.hydro.com/profiles/custom-aluminum-extrusions-in-michigan

[17] https://www.dnb.com/business-directory/company-profiles.michigan_aluminum_extrusion__window_corp.b0fcd174433f7063743c1c52be0bc269.html

[18] https://ensun.io/search/aluminium-extrusion/united-states

[19] https://www.ziprecruiter.com/Jobs/Aluminum-Extrusion/--in-Michigan

[20] https://www.grandviewresearch.com/industry-analysis/us-aluminum-extrusion-market-report

[21] https://www.whitehallindustries.com/capabilities/custom-precision-aluminum-extrusion-services/

[22] https://www.indeed.com/q-extrusion-l-michigan-jobs.html

[23] https://www.industryselect.com/blog/top-aluminum-extrusion-companies-in-the-us

[24] https://www.amcautomation.com/aluminum-extrusion-profile/

[25] https://www.facebook.com/michiganextrudedaluminum/

[26] https://www.youtube.com/watch?v=xOFb3m954lA

[27] https://www.ubemachinery.com

[28] https://www.extrusion.net/publications

[29] https://www.youtube.com/watch?v=at9MNEWU32E

[30] https://www.grancoclark.com

[31] https://www.extrusion.net

[32] https://www.youtube.com/watch?v=rhWppNC5IPA

[33] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[34] https://www.minalex.com/2021/06/08/4-questions-to-ask-when-starting-your-first-aluminum-extrusion-project/

[35] https://www.newsweek.com/trade-cheaters-are-killing-americas-aluminum-industry-jobs-opinion-1883839

[36] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[37] https://deepblue.lib.umich.edu/bitstream/handle/2027.42/177714/oberhg_1.pdf?sequence=1&isAllowed=y

[38] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[39] https://www.thomasnet.com/company/michigan-extruded-aluminum-700122/profile

[40] https://www.wkw-group.com/en/subsidiaries/north-america/erbsloeh-aluminum-solutions-inc/company

[41] https://aluminum-extrusions.net/category/michigan/

[42] https://tubeliteusa.com/tubelites-michigan-facility-expands-extrusion-capacity/

[43] https://www.youtube.com/watch?v=E5LKcduOiME

[44] https://www.belcoind.com/quench-system-increases-production-for-extruded-aluminum-corporation/

[45] https://aec.org/extrusion-die-rd