Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process:

>> Types of Aluminum Extrusion Processes:

● Key Parameters in Aluminum Extrusion

● Industries Utilizing Aluminum Extruders in China

>> Construction

>> Automotive

>> Transportation

>> Electronics

>> Machinery and Industrial Equipment

● Advantages of Using Aluminum Extruders in China

● Market Trends and Future Outlook

● Conclusion

● FAQ

>> 1. What are the most common aluminum alloys used in extrusion in China?

>> 2. What surface treatments are typically available for aluminum extrusions?

>> 3. What is the typical minimum order quantity (MOQ) for custom aluminum extrusions?

>> 4. How long does it typically take to produce custom aluminum extrusions?

>> 5. How do I source high-quality aluminum extrusions from China?

● Citations:

China has become a global hub for aluminum extrusion, with its industry playing a pivotal role in various sectors. The country's dominance in this market is due to its extensive industrial base, technological advancements, skilled workforce, and cost-competitiveness[2][4]. Aluminum extrusion is a manufacturing process where aluminum billets are forced through a die to create specific profiles, which are used in a wide array of applications[5]. This article explores the diverse industries that utilize aluminum extruders in China, highlighting the significance of this process and its impact on the global market.

Understanding Aluminum Extrusion

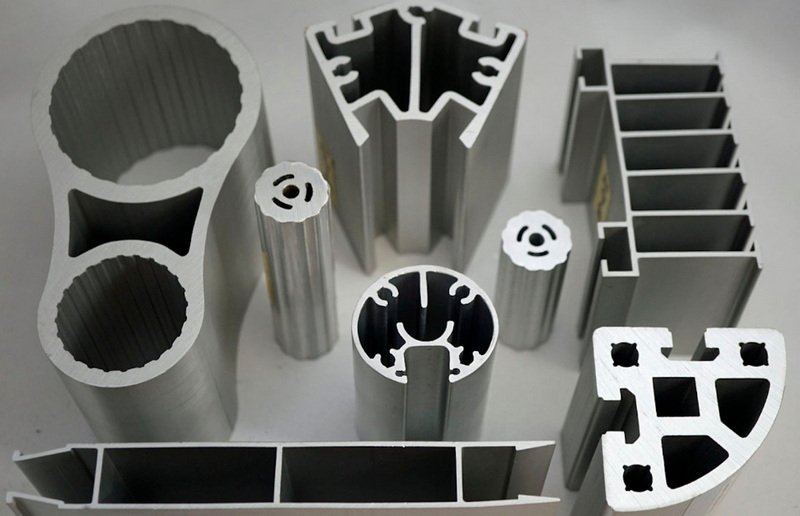

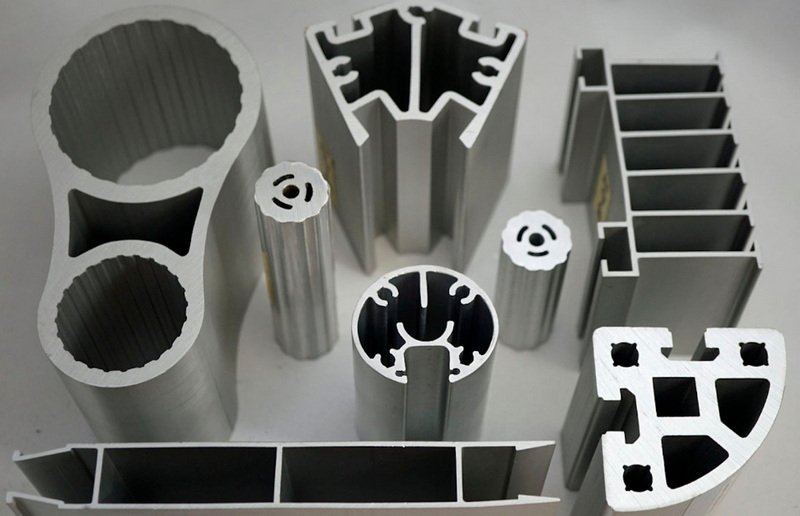

Aluminum extrusion is a versatile metal forming process that involves shaping aluminum into specific profiles by forcing a heated aluminum billet through a die[5]. The process is akin to squeezing toothpaste from a tube, where the aluminum is pushed through a die to create continuous shapes[6]. These shapes can be solid, hollow, or semi-hollow, depending on the design of the die[7].

The Aluminum Extrusion Process:

1. Die Preparation: The process starts with designing and preparing the die, which is crafted from robust materials like H13 steel to withstand high pressures and temperatures[6].

2. Billet Preheating: Aluminum billets are heated to between 400–500°C to ensure the metal is malleable yet solid for extrusion[6].

3. Loading the Billet: The heated billet is transferred to the press, and a lubricant is applied to prevent sticking and facilitate smoother extrusion[6].

4. Extrusion: The billet is forced through the die using a ram, either through direct extrusion (billet moves forward) or indirect extrusion (die moves towards a stationary billet)[6].

5. Cooling (Quenching): Immediately after extrusion, the profiles are cooled to set the properties of the aluminum, enhancing its strength and durability[6].

6. Stretching: Post-cooling, the profiles may be stretched to correct any distortions and improve straightness[6].

7. Heat Treatment: The extruded profiles may undergo heat treatment to achieve the desired temper and increase mechanical strength[6].

Types of Aluminum Extrusion Processes:

- Direct Extrusion: The ram pushes the aluminum billet through a stationary die[6]. This method is flexible and widely used for producing standard and custom aluminum extrusion shapes[6].

- Indirect Extrusion: The die moves towards a stationary billet, reducing friction compared to direct extrusion[6]. This is advantageous for manufacturing complex or thin-walled aluminum profiles where precise temperature control is crucial[6].

Key Parameters in Aluminum Extrusion

Several parameters govern the aluminum extrusion process, influencing the quality and efficiency of the extruded products[6]. These include:

- Extrusion Speed: The rate at which aluminum is pushed through the die affects productivity and quality[6].

- Extrusion Temperature: Maintaining the right temperature for the billet, die, and container ensures proper aluminum flow without defects[6].

- Extrusion Pressure: The force applied to the billet affects the material's deformation and final strength[6].

- Extrusion Ratio: The ratio of the billet's cross-sectional area to the extruded profile's cross-sectional area determines the feasibility and quality of the extrusion[6].

- Cooling Rate: This affects the mechanical properties and microstructure of the aluminum after extrusion[6].

Industries Utilizing Aluminum Extruders in China

China's aluminum extrusion industry supports a diverse range of sectors, each benefiting from the unique properties of aluminum extrusions[4].

Construction

The construction industry is one of the largest consumers of aluminum extrusions in China[1]. Aluminum profiles are used in various applications, including:

- Structural Components: Aluminum extrusions provide lightweight yet strong support for buildings, reducing the overall load on the foundation.

- Window and Door Frames: Aluminum's corrosion resistance and durability make it ideal for window and door frames, ensuring long-lasting performance.

- Curtain Walls: Aluminum extrusions are used in curtain wall systems, offering aesthetic appeal and energy efficiency.

- Solar Panel Frames: With the increasing focus on renewable energy, aluminum extrusions are used to frame solar panels, providing structural support and weather resistance.

Automotive

The automotive industry is another significant consumer of aluminum extrusions, driven by the need for lightweight materials to improve fuel efficiency and reduce emissions[1]. Key applications include:

- Chassis Components: Aluminum extrusions are used in chassis construction, reducing the vehicle's weight and improving handling.

- Body Panels: Aluminum body panels offer a lighter alternative to steel, enhancing fuel economy and performance.

- Heat Sinks: Aluminum's excellent thermal conductivity makes it ideal for heat sinks in automotive electronics.

- Electric Vehicle Components: With the rise of electric vehicles, aluminum extrusions are used in battery housings and other components, contributing to weight reduction and improved range.

Transportation

The transportation sector, including railways, aerospace, and marine applications, relies on aluminum extrusions for their strength, lightweight, and corrosion resistance[4]. Uses include:

- Railway Carriages: Aluminum extrusions are used in the construction of railway carriages, reducing weight and increasing energy efficiency.

- Aircraft Components: In the aerospace industry, aluminum extrusions are used for wing structures, fuselage components, and interior parts.

- Marine Applications: Aluminum's corrosion resistance makes it suitable for marine applications, such as boat hulls and structural components for ships.

Electronics

The electronics industry utilizes aluminum extrusions for their thermal conductivity and shielding properties[3]. Common applications include:

- Heat Sinks: Aluminum extrusions are used to dissipate heat from electronic components, ensuring reliable performance.

- Enclosures: Aluminum enclosures provide protection for sensitive electronic equipment, shielding it from electromagnetic interference.

- LED Lighting: Aluminum extrusions are used in LED lighting fixtures, providing heat dissipation and structural support.

Machinery and Industrial Equipment

Aluminum extrusions are essential in the machinery and industrial equipment sectors for their strength, durability, and design flexibility[1]. Applications include:

- Machine Frames: Aluminum extrusions provide a stable and lightweight frame for various types of machinery.

- Conveyor Systems: Aluminum profiles are used in conveyor systems for their ease of assembly and ability to handle heavy loads.

- Workstations: Aluminum extrusions are used to create ergonomic workstations that can be easily customized to meet specific needs.

Advantages of Using Aluminum Extruders in China

Several factors contribute to China's prominence in aluminum extrusion manufacturing:

- Extensive Industrial Base: China's vast network of factories is equipped with advanced machinery and cutting-edge technologies, enabling the production of various extruded aluminum profiles[2].

- Technological Advancements: The rise of automated systems and digital manufacturing techniques has significantly increased efficiency and precision in aluminum extrusion processes[2].

- Skilled Workforce: China has cultivated a pool of engineers, technicians, and operators specializing in aluminum extrusion manufacturing[2].

- Cost-Competitiveness: Chinese manufacturers offer competitive pricing without compromising quality through economies of scale and streamlined production processes[2].

- Rapid Prototyping and Flexibility: Chinese manufacturers can quickly produce prototypes and adapt to changing customer requirements[2].

Market Trends and Future Outlook

The aluminum extrusion market in China is experiencing significant growth, driven by demands from end-user industries such as automotive, aviation, and construction[1]. In 2020, aluminum extrusion in China reached a historic high of 21,380 kt, an increase of 6.8% year-on-year[1]. The rise of emerging industries such as lightweight automobiles, photovoltaics, wind power stations, and ultra-high voltage is also driving demand for processed aluminum products[3].

Analysts predict that China's extruded aluminum output will reach 22.47 million tons in 2023[3]. The battery aluminum foil segment is also experiencing rapid growth, with production expected to reach 560,000 tons in 2023[3].

Despite the positive outlook, there are challenges to consider. Trade duties and investigations into aluminum extrusions may impact the market[10]. Importers need to review the components of their products to determine if any aluminum extrusions were used and understand the applicable duties[10].

Conclusion

China's aluminum extrusion industry is a vital component of its manufacturing sector, supporting a wide range of industries from construction to electronics[4]. The country's extensive industrial base, technological advancements, skilled workforce, and cost-competitiveness have propelled it to the forefront of the global market[2]. As demand for lightweight, durable, and corrosion-resistant materials continues to grow, aluminum extruders in China are well-positioned to meet the needs of various industries, shaping the future of manufacturing and construction worldwide[3][4].

FAQ

1. What are the most common aluminum alloys used in extrusion in China?

The 6000 series alloys, particularly 6063, are most commonly used due to their good combination of strength, corrosion resistance, and workability[5][12]. Other series like 3000, 5000, and 7000 are also used depending on specific application requirements[5].

2. What surface treatments are typically available for aluminum extrusions?

Common surface treatments include anodizing (for corrosion resistance and color), powder coating (for durability and a wide range of colors), electrophoresis (for smooth, even coatings), and PVDF coating (for superior weather resistance)[5].

3. What is the typical minimum order quantity (MOQ) for custom aluminum extrusions?

MOQs vary among manufacturers but generally range from 500kg to several tons, depending on the complexity of the extrusion and the manufacturer's capacity[5].

4. How long does it typically take to produce custom aluminum extrusions?

The production time for custom aluminum extrusions depends on factors such as the complexity of the design, the quantity required, and the manufacturer's production schedule[5]. It can range from a few weeks to several months[5].

5. How do I source high-quality aluminum extrusions from China?

To source high-quality aluminum extrusions from China, it is essential to conduct thorough research, obtain samples, and verify the manufacturer's certifications and quality control processes[12]. Consider using sourcing services to find reliable Chinese manufacturers and ensure that the products meet your specifications[12].

Citations:

[1] https://www.melchers-china.com/sectors/machinery-industrial/aluminium/

[2] https://proleantech.com/custom-aluminum-extrusion-manufacturer-china/

[3] https://www.aluminiumchina.com/en-gb/news-center/industry-news/2023/11yue/2.html

[4] https://www.goldapple-alu.com/how-chinese-aluminum-extrusions-are-shaping-the-global-market.html

[5] https://www.sourcifychina.com/aluminium-extrusion-guide-in-depth/

[6] https://www.3erp.com/blog/history-future-aluminum-extrusion/

[7] https://americandouglasmetals.com/2024/05/19/understanding-the-aluminum-extrusion-process/

[8] https://news.metal.com/newscontent/101761053/65-years-of-aluminum-extrusion-industry-in-china

[9] https://vmtcnc.com/guide-to-aluminum-extrusion/

[10] https://www.afslaw.com/perspectives/customs-import-compliance-blog/imported-products-containing-aluminum-extrusion-part-or

[11] https://www.zetwerk.com/aluminum-extrusions/

[12] https://www.sourcingallies.com/expertise/aluminum-extrusion-clear-anodized

[13] https://www.alu4all.com/aluminum-extrusion/

[14] https://www.alcircle.com/news/chinas-industrial-profits-hit-a-3-year-low-emulating-aluminium-extrusion-sector-can-fiscal-stimulus-measures-revive-growth-112380

[15] https://haomei-alu.en.made-in-china.com/product/wTGRYdcrsnkU/China-Aluminium-Extrusions-Applications-in-High-Precision-Instruments.html

[16] https://www.statista.com/statistics/269989/aluminum-extrusion-demand-in-china-by-sector/

[17] https://ensun.io/search/aluminum-extrusion/china

[18] https://www.alu4all.com/equipment-and-system/

[19] https://www.alufair.com/news-center/general-outlook-to-aluminum-extrusion-sector_168

[20] https://www.zp-aluminium.com/aluminum-extrusion/

[21] https://www.shengxinaluminium.com/aluminum-extrusion-profile-with-anodize-surface-in-china_p772.html

[22] https://www.alcircle.com/news/taking-the-lead-on-the-global-market-china-s-top-10-aluminium-profile-manufacturers-99165

[23] https://zjaluminum-cnc.com/top-10-aluminum-extrusion-product-manufacturers-from-china/

[24] https://www.sourcingallies.com/blog/manufacturing-aluminum-extrusions-in-china

[25] https://jma-aluminum.com

[26] https://www.grandviewresearch.com/industry-analysis/asia-pacific-aluminum-extrusion-market-report

[27] https://www.made-in-china.com/manufacturers/aluminum-extrusion.html

[28] http://en.zhongwang.com/products/extrusion.htm

[29] https://www.aixihardware.com/china-anodizing-extrusion-aluminum-extruded-aluminum-profiles-extruded-sections/

[30] https://www.wellste.com

[31] https://www.usitc.gov/sites/default/files/publications/701_731/pub5375.pdf

[32] https://www.ryerson.com/metal-resources/metal-market-intelligence/5-questions-on-aluminum-extrusions

[33] https://www.made-in-china.com/products-search/hot-china-products/Aluminum_Extrusion.html

[34] https://www.minalex.com/2021/10/29/10-questions-ask-aluminum-extruder/

[35] https://aec.org/faqs

[36] https://www.fonnovaluminium.com/faqs

[37] https://starext.com/frequently-asked-questions-about-aluminum-extrusions

[38] https://www.uniqueextrusions.com/aluminum-extrusion-faq/

[39] https://suntechaluminium.com/faq/

[40] https://www.reddit.com/r/manufacturing/comments/1eppadk/questions_about_buying_aluminum_extrusion/

[41] https://edmolimited.co.uk/education/frequently-asked-questions/aluminium-extrusion/

[42] https://www.sourcifychina.com/aluminum-extrusion-guide-in-depth/

[43] https://www.usitc.gov/sites/default/files/trade_remedy/731_ad_701_cvd/investigations/2010/Certain%20Aluminum%20Extrusions%20from%20China/Preliminary/us_importers_questionnaire_-_aluminum_extrusions_prelim_.pdf

[44] https://ncalu.com/products/aluminum-extrusion

[45] http://en.zhongwang.com/news/new-detail-11726.htm

[46] https://www.alcircle.com/news/update-top-five-aluminium-extrusion-companies-in-the-world-33870

[47] https://www.alcirclebiz.com/blogs/top-aluminum-extrusion-players-in-china

[48] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[49] https://www.impol.com/everything-you-need-to-know-about-aluminum-extrusion/