Content Menu

● Understanding Aluminum Extrusions

● Advantages of Custom Aluminum Extrusions

● Industries That Benefit from Custom Aluminum Extrusions

>> Automotive Industry

>> Aerospace Industry

>> Construction and Architecture

>> Electronics and Electrical Industry

>> Marine Industry

>> Furniture and Interior Design

>> Renewable Energy

>> Medical Equipment

● Innovations in Custom Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What are the main benefits of using custom aluminum extrusions?

>> 2. Which industries primarily use custom aluminum extrusions?

>> 3. How does the aluminum extrusion process work?

>> 4. What are some common applications of aluminum extrusions in construction?

>> 5. Can custom aluminum extrusions be recycled?

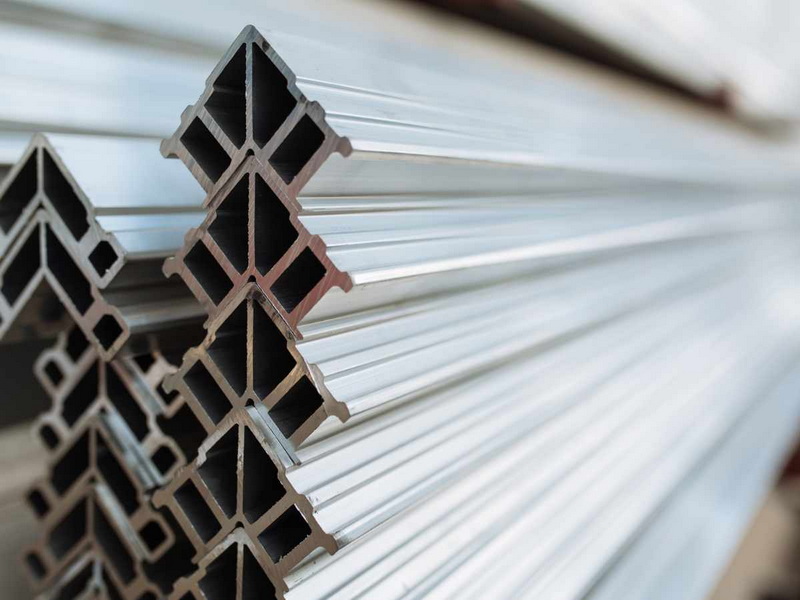

Understanding Aluminum Extrusions

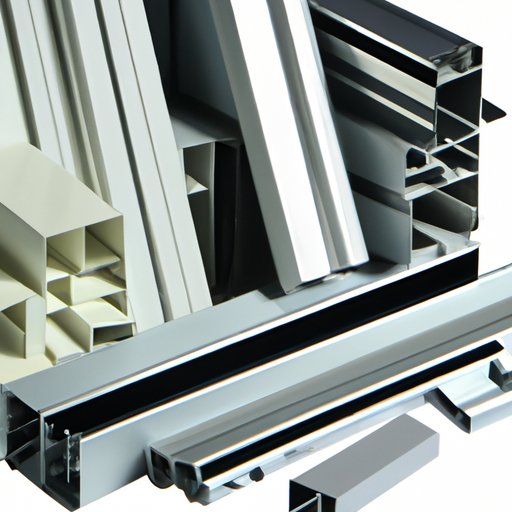

Custom aluminum extrusions are a vital component in various industries, providing unique solutions tailored to specific needs. The versatility of aluminum as a material, combined with the ability to create custom shapes and sizes, makes it an ideal choice for many applications. Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process allows for the creation of complex shapes and profiles that can be used in a wide range of applications. The resulting extrusions can be cut to length, finished, and assembled into various products.

Advantages of Custom Aluminum Extrusions

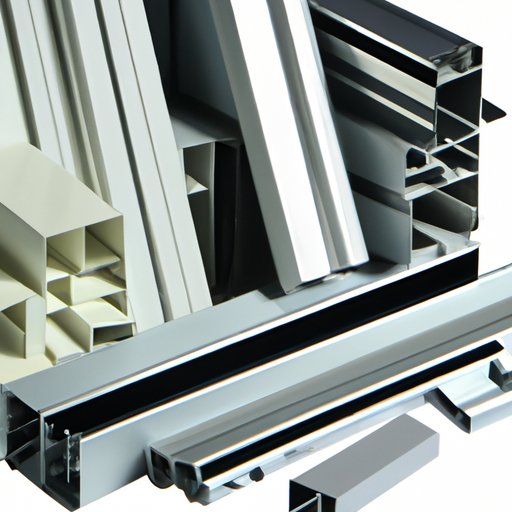

1. Lightweight and Strong: Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications where weight reduction is crucial without compromising strength. This property is particularly beneficial in industries such as aerospace and automotive, where every ounce counts.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This property is particularly beneficial in industries where exposure to harsh environments is common, such as marine and construction.

3. Design Flexibility: Custom aluminum extrusions can be designed to meet specific requirements, allowing for unique shapes and sizes that standard materials cannot provide. This flexibility enables engineers and designers to innovate and create products that stand out in the market.

4. Cost-Effectiveness: While the initial cost of custom extrusions may be higher than standard materials, the long-term savings in weight, durability, and maintenance often outweigh these costs. Additionally, the efficiency of the manufacturing process can lead to reduced labor costs.

5. Sustainability: Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice for manufacturers looking to reduce their carbon footprint. The recycling process requires only a fraction of the energy needed to produce new aluminum, further enhancing its sustainability profile.

Industries That Benefit from Custom Aluminum Extrusions

Automotive Industry

The automotive industry is one of the largest consumers of aluminum extrusions. Manufacturers use custom extrusions for various components, including structural parts, chassis, and body panels. The lightweight nature of aluminum helps improve fuel efficiency and reduce emissions, making it an attractive option for modern vehicles. Additionally, custom extrusions can be designed to meet specific safety standards and performance requirements, ensuring that vehicles are both efficient and safe.

Aerospace Industry

In aerospace, weight reduction is critical for performance and fuel efficiency. Custom aluminum extrusions are used in aircraft frames, wings, and other structural components. The ability to create complex shapes allows for optimized designs that enhance aerodynamics and reduce drag. Furthermore, the high strength-to-weight ratio of aluminum makes it suitable for high-stress applications, contributing to the overall safety and reliability of aircraft.

Construction and Architecture

Aluminum extrusions are widely used in the construction industry for window frames, curtain walls, and roofing systems. Their durability and resistance to corrosion make them ideal for both residential and commercial buildings. Custom extrusions can be designed to meet specific architectural requirements, allowing for innovative designs and energy-efficient solutions. The aesthetic appeal of aluminum also allows architects to create visually striking buildings that stand out in urban environments.

Electronics and Electrical Industry

Custom aluminum extrusions are commonly used in the electronics industry for heat sinks, enclosures, and structural components. The excellent thermal conductivity of aluminum helps dissipate heat effectively, ensuring the longevity and performance of electronic devices. Additionally, custom extrusions can be designed to accommodate various electronic components, providing a streamlined and efficient solution for manufacturers.

Marine Industry

In the marine industry, aluminum extrusions are used for boat frames, railings, and other structural components. The lightweight and corrosion-resistant properties of aluminum make it an ideal choice for marine applications, where exposure to saltwater can lead to rapid deterioration of other materials. Custom extrusions can be designed to meet specific marine standards, ensuring safety and performance in challenging environments.

Furniture and Interior Design

Custom aluminum extrusions are increasingly used in furniture design, providing modern and sleek aesthetics. They can be found in tables, chairs, and shelving units, offering both functionality and style. The ability to create unique shapes allows designers to push the boundaries of traditional furniture design, resulting in innovative products that appeal to contemporary consumers.

Renewable Energy

The renewable energy sector, particularly solar energy, benefits from custom aluminum extrusions used in solar panel frames and mounting systems. The lightweight and durable nature of aluminum allows for easy installation and long-term performance in various environmental conditions. Custom extrusions can be designed to optimize the angle and positioning of solar panels, maximizing energy capture and efficiency.

Medical Equipment

In the medical field, custom aluminum extrusions are used in various equipment and devices, including hospital beds, diagnostic machines, and surgical instruments. The lightweight and corrosion-resistant properties of aluminum make it suitable for medical applications, where hygiene and durability are paramount. Custom designs can also accommodate specific medical technologies, enhancing the functionality and usability of medical devices.

Innovations in Custom Aluminum Extrusions

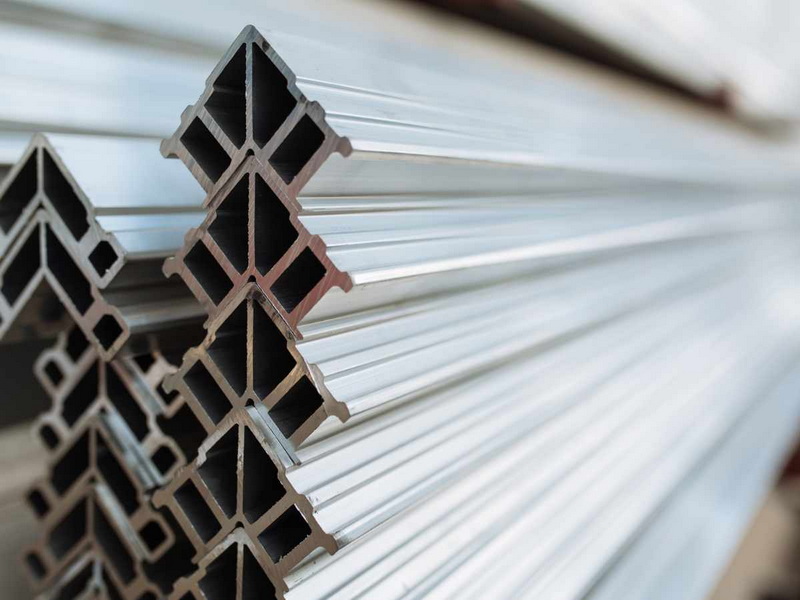

The advancements in technology have led to innovative designs and applications for custom aluminum extrusions. Manufacturers are now able to create more complex shapes and profiles, allowing for greater customization and functionality. Some of the latest innovations include:

- 3D Printing of Aluminum Extrusions: This technology allows for rapid prototyping and the creation of intricate designs that were previously impossible with traditional methods. 3D printing can significantly reduce lead times and costs associated with developing new products.

- Integrated Features: Manufacturers are now designing extrusions with integrated features, such as channels for wiring or built-in mounting points, reducing assembly time and improving overall efficiency. This integration can streamline the manufacturing process and enhance the final product's performance.

- Enhanced Finishing Options: New finishing techniques, such as anodizing and powder coating, provide additional protection and aesthetic appeal, allowing for a wider range of applications. These finishes can improve the durability of aluminum extrusions and enhance their visual appeal, making them suitable for consumer-facing products.

Conclusion

Custom aluminum extrusions play a crucial role in various industries, providing tailored solutions that enhance performance, durability, and aesthetics. From automotive to aerospace, construction to electronics, the versatility of aluminum makes it an ideal choice for a wide range of applications. As technology continues to advance, the potential for custom aluminum extrusions will only grow, leading to even more innovative designs and uses.

Frequently Asked Questions

1. What are the main benefits of using custom aluminum extrusions?

- Custom aluminum extrusions offer lightweight strength, corrosion resistance, design flexibility, cost-effectiveness, and sustainability.

2. Which industries primarily use custom aluminum extrusions?

- Industries such as automotive, aerospace, construction, electronics, marine, furniture, renewable energy, and medical equipment benefit from custom aluminum extrusions.

3. How does the aluminum extrusion process work?

- The aluminum extrusion process involves heating aluminum alloy and forcing it through a die to create specific shapes and profiles.

4. What are some common applications of aluminum extrusions in construction?

- Common applications include window frames, curtain walls, roofing systems, and structural components.

5. Can custom aluminum extrusions be recycled?

- Yes, aluminum is 100% recyclable without loss of quality, making it an environmentally friendly material choice.