Content Menu

● Understanding Aluminum Extrusion

● Key Factors Influencing Cost

>> Material Selection

>> Design Complexity

>> Die Costs

>> Production Volume

>> Surface Finishing

>> Machining and Fabrication

>> Lead Time

>> Supplier Relationships

>> Market Conditions

>> Regulatory Compliance

● Conclusion

● Frequently Asked Questions

>> 1. What is the average cost of custom aluminum extrusions?

>> 2. How can I reduce the cost of my custom aluminum extrusions?

>> 3. What is the typical lead time for custom aluminum extrusions?

>> 4. Are there any hidden costs associated with custom aluminum extrusions?

>> 5. How do I choose the right supplier for custom aluminum extrusions?

Understanding Aluminum Extrusion

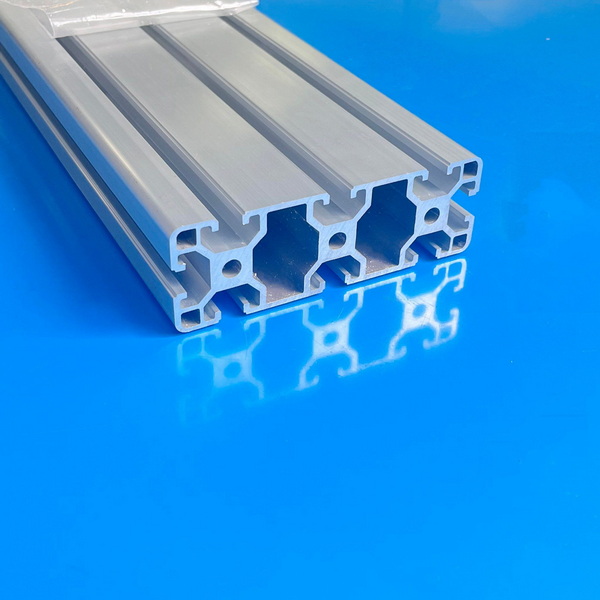

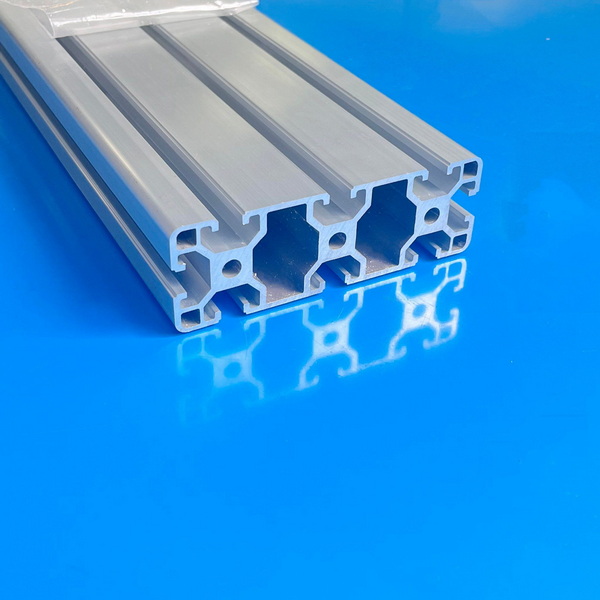

Custom aluminum extrusions are widely used in various industries due to their versatility, lightweight nature, and strength. However, the cost of these extrusions can vary significantly based on several factors. Understanding these factors is crucial for businesses and individuals looking to invest in custom aluminum solutions. This article will explore the key elements that influence the cost of custom aluminum extrusions, providing insights into how to manage and optimize these costs effectively.

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which gives it the specific shape required for various applications. The process can produce a wide range of profiles, from simple shapes to complex designs, making it a popular choice in industries such as construction, automotive, aerospace, and consumer goods.

Key Factors Influencing Cost

Material Selection

The type of aluminum alloy chosen for the extrusion significantly impacts the cost. Different alloys have varying properties, such as strength, corrosion resistance, and machinability. Common alloys used in extrusions include 6061, 6063, and 7075, each with its unique characteristics and price points. For instance, 6061 is often used for structural applications due to its strength, while 6063 is favored for architectural applications due to its excellent finish. The choice of alloy not only affects the initial cost but also influences the long-term performance and durability of the extrusions.

Design Complexity

The complexity of the design plays a crucial role in determining the cost of custom aluminum extrusions. More intricate designs require specialized dies and longer production times, which can increase costs. Simple shapes may be produced more quickly and with less expensive tooling, while complex profiles may necessitate additional engineering and design work. Additionally, the design must consider factors such as weight distribution and structural integrity, which can further complicate the manufacturing process.

Die Costs

The die used in the extrusion process is one of the most significant upfront costs. Custom dies can be expensive to manufacture, especially for complex shapes. The cost of the die is typically amortized over the production run, meaning that larger production volumes can help reduce the per-unit cost. However, for small runs, the die cost can significantly impact the overall price. It is essential to work closely with manufacturers to understand the die-making process and explore options for reducing costs, such as using standard dies for simpler designs.

Production Volume

The quantity of extrusions ordered can greatly influence the cost. Generally, higher production volumes lead to lower per-unit costs due to economies of scale. This is because the fixed costs associated with die production and setup are spread over a larger number of units. Conversely, small orders may incur higher costs per unit due to the initial setup and die costs. Businesses should carefully evaluate their production needs and consider placing larger orders to take advantage of lower pricing.

Surface Finishing

The surface finish of the aluminum extrusion can also affect the overall cost. Various finishing processes, such as anodizing, painting, or powder coating, can enhance the appearance and durability of the extrusions but add to the cost. The choice of finish will depend on the intended application and aesthetic requirements. For example, anodizing not only improves corrosion resistance but also provides a decorative finish, making it a popular choice for architectural applications. Understanding the benefits and costs associated with different finishing options is crucial for making informed decisions.

Machining and Fabrication

In many cases, custom aluminum extrusions require additional machining or fabrication to meet specific design requirements. This can include cutting, drilling, or milling the extrusions to achieve the desired dimensions or features. The complexity and extent of these additional processes will influence the overall cost. It is essential to factor in these costs when budgeting for a project, as they can significantly impact the final price of the extrusions.

Lead Time

The lead time for production can also impact costs. If a project requires a quick turnaround, manufacturers may charge a premium for expedited services. Planning ahead and allowing for longer lead times can help reduce costs, as manufacturers can schedule production more efficiently. Businesses should communicate their timelines clearly with suppliers to ensure that expectations are aligned and to avoid unexpected costs associated with rush orders.

Supplier Relationships

The choice of supplier can significantly affect the cost of custom aluminum extrusions. Established suppliers with a good reputation may offer better pricing due to their experience and efficiency. Additionally, building a long-term relationship with a supplier can lead to better pricing and service over time. It is beneficial to research potential suppliers, request quotes, and compare their offerings to find the best fit for your needs.

Market Conditions

Market conditions, including the price of raw aluminum and demand for extrusions, can also influence costs. Fluctuations in the price of aluminum can directly impact the cost of extrusions, as can changes in demand from various industries. Staying informed about market trends can help businesses anticipate cost changes. For instance, during periods of high demand, prices may rise, while a surplus of aluminum may lead to lower costs. Understanding these dynamics is essential for effective budgeting and planning.

Regulatory Compliance

Depending on the application, certain regulatory standards may need to be met, which can add to the cost. Industries such as aerospace and automotive often have stringent requirements for materials and manufacturing processes. Ensuring compliance with these regulations may require additional testing and documentation, increasing overall costs. Businesses should be aware of the relevant regulations in their industry and factor these into their project planning.

Conclusion

Understanding the factors that influence the cost of custom aluminum extrusions is essential for making informed decisions in manufacturing and procurement. By considering material selection, design complexity, die costs, production volume, surface finishing, machining, lead time, supplier relationships, market conditions, and regulatory compliance, businesses can better manage their costs and optimize their investments in aluminum solutions.

By taking a proactive approach to understanding these factors, companies can not only reduce costs but also improve the quality and performance of their aluminum extrusions. This knowledge empowers businesses to make strategic decisions that align with their operational goals and budgetary constraints.

Frequently Asked Questions

1. What is the average cost of custom aluminum extrusions?

The average cost can vary widely based on factors such as material, design complexity, and production volume. It's best to consult with suppliers for specific quotes tailored to your project requirements.

2. How can I reduce the cost of my custom aluminum extrusions?

To reduce costs, consider increasing production volume, simplifying designs, and choosing standard alloys. Additionally, working closely with suppliers to optimize the design and production process can lead to cost savings.

3. What is the typical lead time for custom aluminum extrusions?

Lead times can range from a few weeks to several months, depending on the complexity of the design and the supplier's capacity. Planning ahead and communicating your timeline with suppliers can help ensure timely delivery.

4. Are there any hidden costs associated with custom aluminum extrusions?

Yes, hidden costs can include tooling, finishing, and additional machining processes that may not be immediately apparent. It's essential to discuss all potential costs with your supplier upfront to avoid surprises.

5. How do I choose the right supplier for custom aluminum extrusions?

Look for suppliers with a good reputation, experience in your industry, and the ability to meet your specific requirements. Request quotes from multiple suppliers and compare their offerings to find the best fit for your needs.