Content Menu

● Introduction

● Understanding Rexroth Aluminum Profiles

● Key Benefits of Rexroth Aluminum Profiles

>> Lightweight and Durable

>> Versatility in Applications

>> Customization Options

● Modular Aluminum Framing Systems

>> Case Studies of Successful Implementations

● Cost-Effectiveness and Sustainability

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum profiles in construction?

>> 2. How can I customize Rexroth aluminum profiles for my project?

>> 3. Are Rexroth aluminum profiles suitable for outdoor use?

>> 4. What industries benefit the most from using Bosch Rexroth aluminum systems?

>> 5. How do modular aluminum framing systems reduce construction time?

Introduction

In the realm of modern manufacturing and construction, the choice of materials plays a pivotal role in determining the efficiency, durability, and overall success of a project. Among the various materials available, aluminum has emerged as a preferred choice due to its lightweight nature, strength, and versatility. Bosch Rexroth, a leader in drive and control technologies, offers a range of aluminum extrusion solutions that cater to diverse industrial needs. This article explores the custom aluminum structures that can be created using Bosch Rexroth systems, highlighting the benefits and applications of Rexroth aluminum extrusion.

Understanding Rexroth Aluminum Profiles

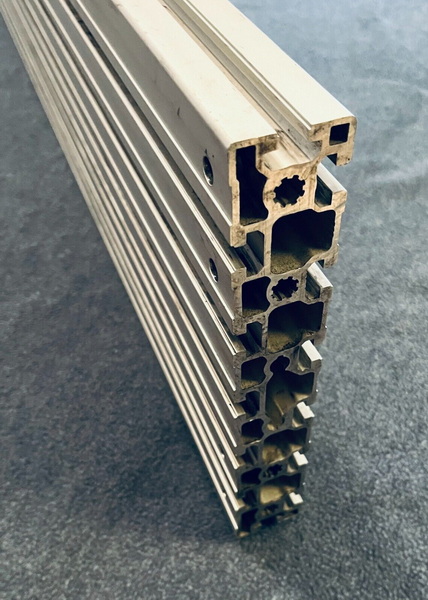

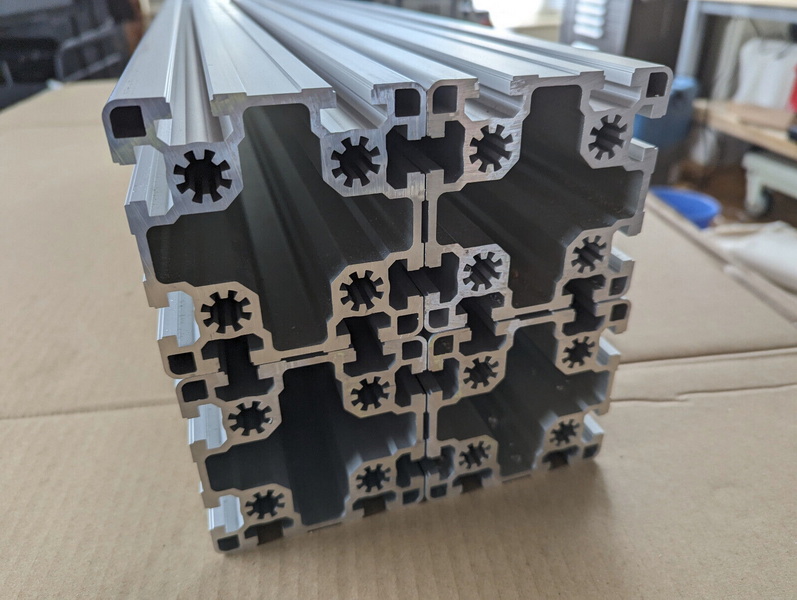

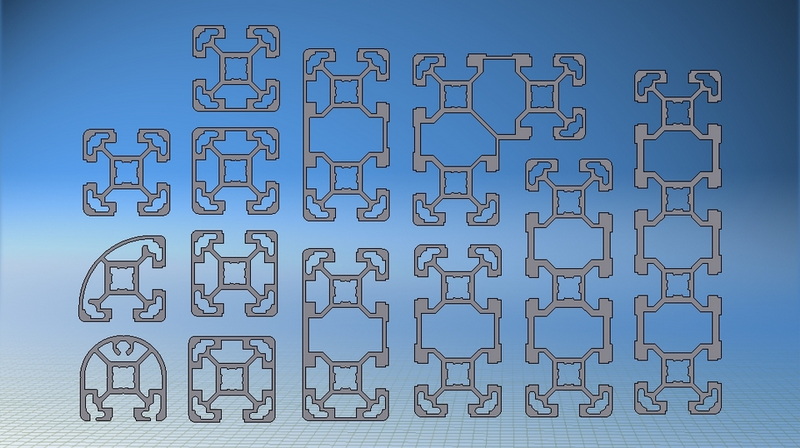

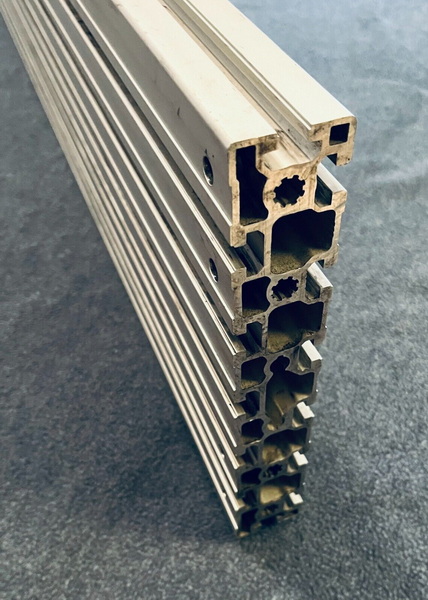

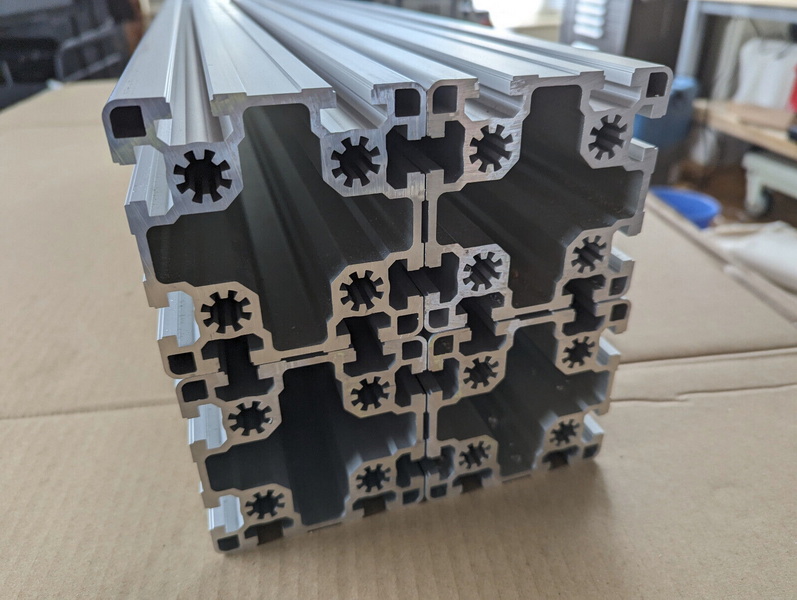

Rexroth aluminum profiles are engineered to provide robust solutions for various applications. These profiles are manufactured through an extrusion process, where aluminum is forced through a die to create specific shapes and sizes. The result is a lightweight yet strong material that can be easily manipulated to meet the requirements of different projects.

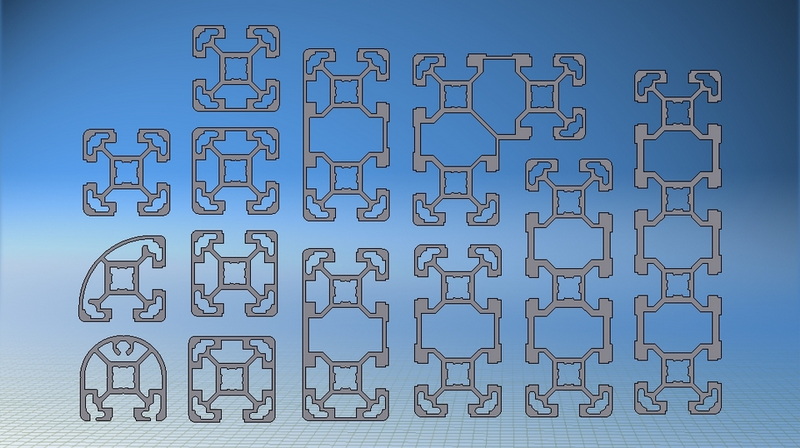

Rexroth aluminum profiles come in various designs, including T-slot profiles, which allow for easy assembly and disassembly. This modularity is a significant advantage in industries where flexibility and adaptability are crucial. The profiles can be combined with a range of accessories, such as connectors, brackets, and fasteners, to create custom structures tailored to specific needs.

Key Benefits of Rexroth Aluminum Profiles

Lightweight and Durable

One of the most significant advantages of using Rexroth aluminum profiles is their lightweight nature. Aluminum has a high strength-to-weight ratio, making it an ideal choice for applications where weight reduction is essential. This characteristic is particularly beneficial in industries such as aerospace, automotive, and manufacturing, where every ounce counts.

Moreover, aluminum is resistant to corrosion, which enhances the durability of structures made from Rexroth aluminum profiles. This resistance ensures that the structures maintain their integrity over time, even in harsh environments.

Versatility in Applications

Rexroth aluminum profiles are incredibly versatile and can be used in a wide range of applications. From industrial automation to custom machinery, the possibilities are virtually limitless.

For instance, in manufacturing settings, these profiles can be used to create assembly lines, workstations, and safety barriers. In the construction industry, they can be utilized for building frames, scaffolding, and even architectural features. The adaptability of Rexroth aluminum profiles allows engineers and designers to innovate and create solutions that meet specific project requirements.

Customization Options

One of the standout features of Bosch Rexroth systems is the ability to customize aluminum structures. The modular nature of Rexroth aluminum profiles means that they can be easily modified to suit unique project specifications.

Designers can choose from a variety of profile sizes, shapes, and finishes to create structures that not only meet functional requirements but also align with aesthetic preferences. This level of customization is particularly valuable in industries where branding and visual appeal are essential.

Modular Aluminum Framing Systems

Modular aluminum framing systems are a hallmark of Bosch Rexroth's offerings. These systems allow for the rapid assembly of structures using standard components, significantly reducing construction time and labor costs.

The modularity of these systems means that they can be easily reconfigured or expanded as project needs change. For example, a manufacturing facility may start with a specific layout but later require modifications to accommodate new machinery or processes. With Rexroth aluminum profiles, such changes can be implemented quickly and efficiently.

Case Studies of Successful Implementations

Numerous industries have successfully implemented Rexroth aluminum profiles in their operations. For instance, in the automotive industry, manufacturers have used these profiles to create assembly lines that enhance productivity and streamline workflows.

In the aerospace sector, companies have utilized Rexroth aluminum structures to build lightweight components that contribute to fuel efficiency. These case studies highlight the adaptability and effectiveness of Rexroth aluminum profiles in meeting the demands of various industries.

Cost-Effectiveness and Sustainability

In addition to their functional benefits, Rexroth aluminum profiles offer significant cost savings. The lightweight nature of aluminum reduces transportation costs, while the durability of the material minimizes maintenance and replacement expenses.

Furthermore, aluminum is a sustainable material. It is 100% recyclable, and the recycling process requires only a fraction of the energy needed to produce new aluminum. By choosing Rexroth aluminum profiles, companies can not only reduce their environmental impact but also enhance their sustainability credentials.

Conclusion

Bosch Rexroth systems provide a comprehensive solution for creating custom aluminum structures that meet the diverse needs of modern industries. The lightweight, durable, and versatile nature of Rexroth aluminum profiles makes them an ideal choice for a wide range of applications. With the ability to customize designs and the benefits of modularity, these profiles empower engineers and designers to innovate and create efficient solutions. As industries continue to evolve, the role of Rexroth aluminum extrusion will undoubtedly remain pivotal in shaping the future of manufacturing and construction.

Related Questions

1. What are the main advantages of using aluminum profiles in construction?

Aluminum profiles offer lightweight strength, corrosion resistance, and versatility, making them ideal for various construction applications.

2. How can I customize Rexroth aluminum profiles for my project?

Customization can be achieved by selecting different profile sizes, shapes, and finishes, along with various accessories to meet specific project requirements.

3. Are Rexroth aluminum profiles suitable for outdoor use?

Yes, Rexroth aluminum profiles are resistant to corrosion, making them suitable for outdoor applications where exposure to the elements is a concern.

4. What industries benefit the most from using Bosch Rexroth aluminum systems?

Industries such as automotive, aerospace, manufacturing, and construction benefit significantly from the lightweight and versatile nature of Bosch Rexroth aluminum systems.

5. How do modular aluminum framing systems reduce construction time?

Modular aluminum framing systems allow for rapid assembly using standard components, enabling quick reconfiguration and expansion as project needs change.