Content Menu

● Understanding Aluminum Extrusion

● The Importance of Choosing the Right Supplier

● Top Aluminum Extrusion Suppliers

>> Alcoa Corporation

>> Hydro Extrusion

>> Parker Hannifin

>> Aluminum Extrusions, Inc.

>> Bonnell Aluminum

● Benefits of Working with Local Suppliers

● Applications of Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. What industries use aluminum extrusions?

>> 3. How do I choose the right aluminum extrusion supplier?

>> 4. What are the benefits of using aluminum extrusions?

>> 5. Can I get custom aluminum extrusions?

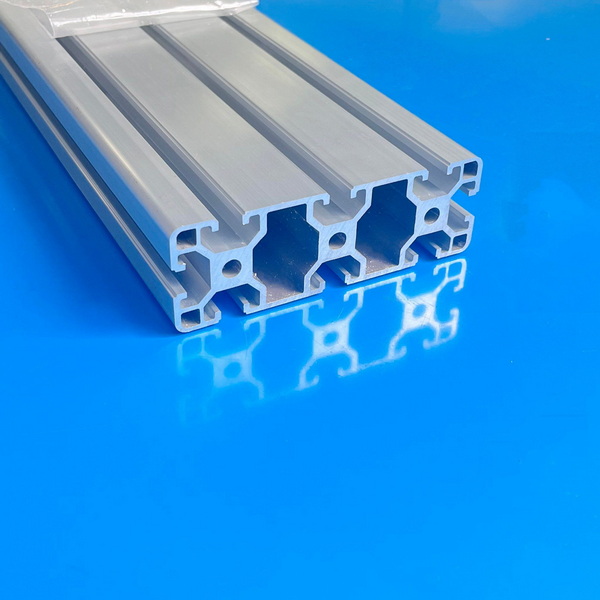

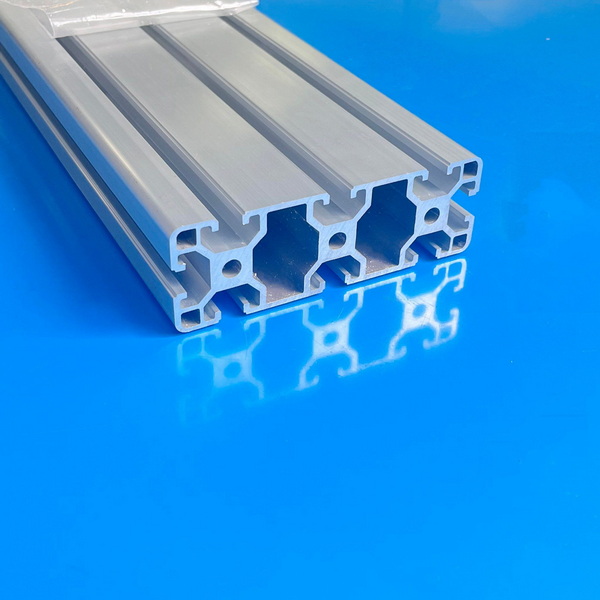

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This versatile process is widely used in various industries, including construction, automotive, aerospace, and consumer goods. As the demand for aluminum products continues to grow, finding reliable aluminum extrusion suppliers becomes crucial for businesses and individuals alike.

The aluminum extrusion process involves forcing aluminum alloy through a die to create a specific shape. This process allows for the production of complex profiles that can be used in a variety of applications. The benefits of aluminum extrusion include lightweight, high strength, corrosion resistance, and excellent thermal and electrical conductivity.

Aluminum is a popular choice for many applications due to its unique properties. It is lightweight yet strong, making it ideal for structural applications where weight savings are critical. Additionally, aluminum has excellent corrosion resistance, which is essential for products exposed to harsh environments. Its thermal and electrical conductivity makes it suitable for applications in the electrical and electronics industries.

The Importance of Choosing the Right Supplier

When it comes to sourcing aluminum extrusions, the choice of supplier can significantly impact the quality and cost of your products. Here are some key factors to consider when selecting an aluminum extrusion supplier:

1. Quality of Products: Ensure that the supplier adheres to industry standards and has a reputation for producing high-quality aluminum extrusions. Look for certifications such as ISO 9001, which indicates a commitment to quality management.

2. Range of Products: A good supplier should offer a wide range of aluminum profiles and custom solutions to meet your specific needs. This includes standard shapes as well as the ability to create custom designs.

3. Lead Times: Consider the supplier's lead times for production and delivery. Timely delivery is crucial for maintaining your project schedules.

4. Customer Service: A responsive and knowledgeable customer service team can make a significant difference in your experience. Look for suppliers who are willing to provide support and guidance throughout the purchasing process.

5. Pricing: While cost should not be the only factor, it is essential to find a supplier that offers competitive pricing without compromising on quality.

6. Technical Support: Some projects may require technical assistance or engineering support. Suppliers that offer these services can help you optimize your designs and ensure that your products meet all necessary specifications.

7. Sustainability Practices: As environmental concerns grow, many businesses are looking for suppliers that prioritize sustainability. Consider suppliers that use recycled materials and have eco-friendly manufacturing processes.

Top Aluminum Extrusion Suppliers

Here are some of the top aluminum extrusion suppliers that you can consider:

Alcoa Corporation

Alcoa is one of the largest aluminum producers in the world, known for its high-quality aluminum products. They offer a wide range of extrusions for various applications, including automotive, aerospace, and construction. Alcoa's commitment to sustainability and innovation makes them a leader in the industry.

Hydro Extrusion

Hydro is a global leader in aluminum solutions, providing a comprehensive range of extruded aluminum products. They focus on sustainability and offer custom solutions tailored to their clients' needs. Hydro's extensive network of facilities ensures efficient production and delivery.

Parker Hannifin

Parker Hannifin is a well-known supplier of motion and control technologies, including aluminum extrusions. They provide a variety of profiles for different industries, with a focus on innovation and quality. Their extensive experience in the field makes them a reliable choice for aluminum extrusions.

Aluminum Extrusions, Inc.

Aluminum Extrusions, Inc. specializes in custom aluminum extrusions and offers a wide range of standard profiles. They pride themselves on their customer service and ability to meet tight deadlines. Their expertise in custom solutions makes them a popular choice for businesses looking for specific designs.

Bonnell Aluminum

Bonnell Aluminum is a leading manufacturer of aluminum extrusions, known for their high-quality products and exceptional customer service. They offer a wide range of standard and custom profiles, catering to various industries, including construction and transportation.

Benefits of Working with Local Suppliers

Choosing a local aluminum extrusion supplier has several advantages:

1. Faster Turnaround Times: Local suppliers can often provide quicker lead times, allowing you to receive your products faster and keep your projects on schedule.

2. Reduced Shipping Costs: Working with a nearby supplier can help minimize shipping costs, making it more economical for your business.

3. Personalized Service: Local suppliers are often more accessible, allowing for better communication and personalized service. This can lead to a more collaborative relationship.

4. Support for Local Economy: By choosing local suppliers, you contribute to the growth of your community and support local jobs.

5. Easier Quality Control: Proximity to your supplier allows for easier quality checks and inspections, ensuring that the products meet your specifications.

6. Flexibility in Orders: Local suppliers may be more willing to accommodate smaller orders or last-minute changes, which can be beneficial for businesses with fluctuating needs.

7. Building Relationships: Working with local suppliers allows you to build strong relationships, which can lead to better service and support over time.

Applications of Aluminum Extrusions

Aluminum extrusions are used in a wide variety of applications across different industries. Some common uses include:

- Construction: Aluminum extrusions are widely used in building facades, window frames, and structural components due to their strength and lightweight properties.

- Automotive: The automotive industry utilizes aluminum extrusions for lightweight structural components, improving fuel efficiency and performance.

- Aerospace: In aerospace applications, aluminum extrusions are used for aircraft frames and components, where weight reduction is critical.

- Consumer Products: Many consumer goods, such as furniture and appliances, incorporate aluminum extrusions for their durability and aesthetic appeal.

- Electronics: Aluminum extrusions are used in electronic enclosures and heat sinks, providing excellent thermal management.

Conclusion

Finding the right aluminum extrusion supplier is essential for the success of your projects. By considering factors such as product quality, range, lead times, customer service, and pricing, you can make an informed decision. The suppliers mentioned in this article are among the top choices in the industry, offering a variety of products and services to meet your needs. Additionally, working with local suppliers can provide numerous benefits, including faster turnaround times and personalized service.

Frequently Asked Questions

1. What is aluminum extrusion?

- Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific profiles by forcing it through a die.

2. What industries use aluminum extrusions?

- Aluminum extrusions are used in various industries, including construction, automotive, aerospace, and consumer goods.

3. How do I choose the right aluminum extrusion supplier?

- Consider factors such as product quality, range of products, lead times, customer service, and pricing when selecting a supplier.

4. What are the benefits of using aluminum extrusions?

- Aluminum extrusions are lightweight, strong, corrosion-resistant, and offer excellent thermal and electrical conductivity.

5. Can I get custom aluminum extrusions?

- Yes, many suppliers offer custom aluminum extrusion services to meet specific design requirements.