Content Menu

● Introduction

● Understanding Aluminum Extrusion Profiles

>> The Manufacturing Process

● Types of Aluminum Extrusion Profiles

>> Standard Profiles

>> Custom Profiles

● Applications Across Industries

>> Construction and Architecture

>> Automotive Industry

>> Industrial Applications

● Benefits of Aluminum Extrusion Profiles

>> Structural Advantages

>> Design Flexibility

>> Economic Benefits

● Design Considerations

>> Material Selection

>> Profile Design

● Future Trends

>> Technological Advancements

>> Sustainability Focus

● Conclusion

● Frequently Asked Questions

>> Q1: What are the main advantages of using aluminum extrusion profiles?

>> Q2: How long do aluminum extrusion profiles typically last?

>> Q3: Can aluminum extrusion profiles be customized for specific applications?

>> Q4: What industries commonly use aluminum extrusion profiles?

>> Q5: Are aluminum extrusion profiles environmentally friendly?

Introduction

Aluminum extrusion profiles represent one of the most versatile and widely-used manufacturing solutions in modern industry. These precisely engineered components have revolutionized various sectors, from construction to automotive, offering unprecedented flexibility in design and application. This comprehensive guide explores the world of aluminum extrusion profiles, their manufacturing processes, applications, and significance in contemporary engineering.

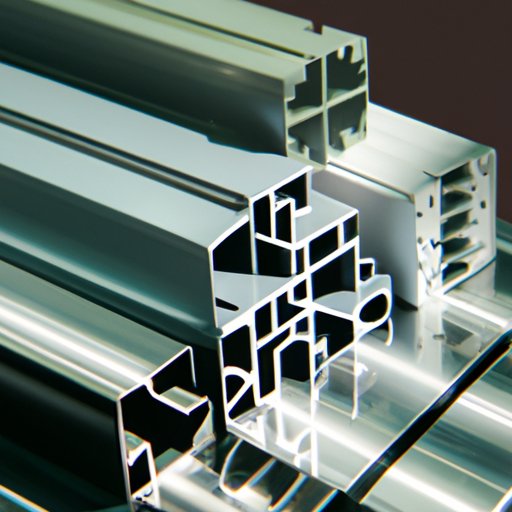

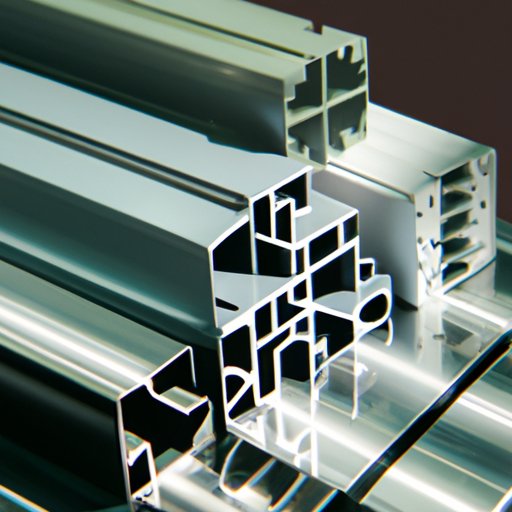

Understanding Aluminum Extrusion Profiles

Aluminum extrusion profiles are created through a sophisticated manufacturing process where aluminum billets are heated and forced through specially designed dies to create specific shapes and profiles. This process allows for the production of complex cross-sectional profiles that would be impossible or impractical to achieve through other manufacturing methods.

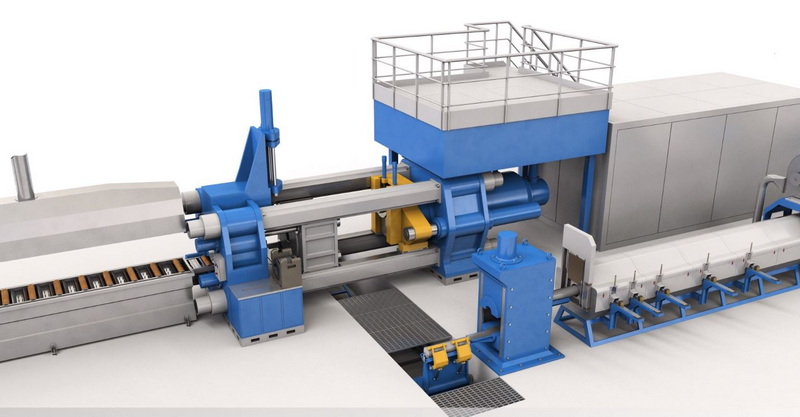

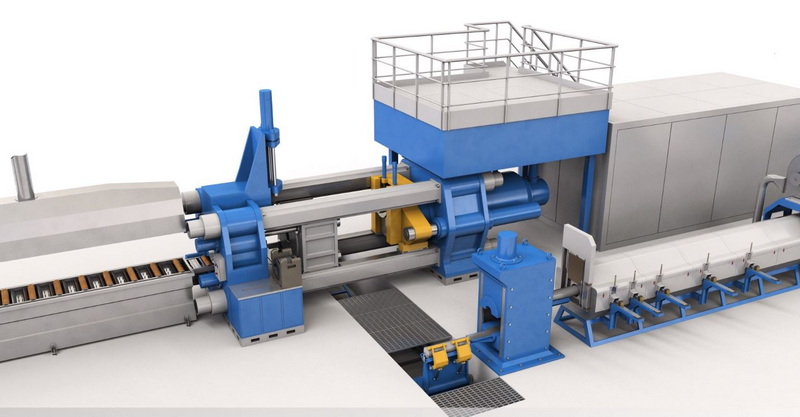

The Manufacturing Process

The manufacturing process involves several critical steps:

1. Billet Preparation

2. Heating Process

3. Extrusion

4. Cooling

5. Stretching

6. Aging

7. Final Processing

Types of Aluminum Extrusion Profiles

Standard Profiles

Standard aluminum extrusion profiles include:

- T-slots

- L-angles

- U-channels

- Box sections

- Round tubes

- Square tubes

Custom Profiles

Custom aluminum extrusion profiles are designed to meet specific application requirements, offering:

- Unique cross-sections

- Special features

- Integrated functionality

- Application-specific solutions

Applications Across Industries

Construction and Architecture

In the construction industry, aluminum extrusion profiles are essential for:

- Window frames

- Door systems

- Curtain walls

- Solar panel mounting systems

- Structural frameworks

- Decorative elements

Automotive Industry

The automotive sector utilizes aluminum extrusion profiles for:

- Body frame components

- Crash management systems

- Heat exchangers

- Interior trim

- Battery housings for electric vehicles

Industrial Applications

Industrial applications include:

- Machine guards

- Conveyor systems

- Workstation frameworks

- Equipment housing

- Pneumatic systems

- Robotic frameworks

Benefits of Aluminum Extrusion Profiles

Structural Advantages

- High strength-to-weight ratio

- Excellent corrosion resistance

- Superior thermal conductivity

- Dimensional stability

- Recyclability

Design Flexibility

- Complex shapes possible

- Custom solutions available

- Modular design capabilities

- Easy integration with other components

- Scalable production

Economic Benefits

- Cost-effective manufacturing

- Reduced maintenance requirements

- Long service life

- Energy efficiency

- Sustainable material choice

Design Considerations

Material Selection

Choosing the right aluminum alloy is crucial for:

- Strength requirements

- Surface finish needs

- Cost considerations

- Environmental conditions

- Manufacturing complexity

Profile Design

Key design considerations include:

- Wall thickness

- Cross-sectional area

- Structural requirements

- Assembly methods

- Surface treatment options

Future Trends

Technological Advancements

- Advanced alloy development

- Smart manufacturing integration

- Improved surface treatments

- Enhanced design software

- Automated quality control

Sustainability Focus

- Increased recycling initiatives

- Energy-efficient production

- Sustainable manufacturing practices

- Green building applications

- Circular economy integration

Conclusion

Aluminum extrusion profiles continue to play a crucial role in modern manufacturing and construction. Their versatility, durability, and sustainability make them an ideal choice for numerous applications across various industries. As technology advances and environmental concerns grow, the importance of aluminum extrusion profiles in creating innovative solutions will only increase.

Frequently Asked Questions

Q1: What are the main advantages of using aluminum extrusion profiles?

A1: Aluminum extrusion profiles offer exceptional strength-to-weight ratio, corrosion resistance, design flexibility, cost-effectiveness, and sustainability. They provide versatile solutions for various industries while maintaining high performance standards.

Q2: How long do aluminum extrusion profiles typically last?

A2: With proper maintenance and installation, aluminum extrusion profiles can last several decades. Their durability is enhanced by their natural corrosion resistance and the ability to apply protective surface treatments.

Q3: Can aluminum extrusion profiles be customized for specific applications?

A3: Yes, aluminum extrusion profiles can be fully customized to meet specific application requirements, including unique cross-sections, special features, and integrated functionality for particular industry needs.

Q4: What industries commonly use aluminum extrusion profiles?

A4: Aluminum extrusion profiles are widely used in construction, automotive, aerospace, solar energy, electronics, machinery, and furniture industries, among others. Their versatility makes them suitable for numerous applications across different sectors.

Q5: Are aluminum extrusion profiles environmentally friendly?

A5: Yes, aluminum extrusion profiles are environmentally friendly as they are 100% recyclable without loss of properties. They contribute to sustainable construction and manufacturing practices while reducing environmental impact.