Content Menu

● Nano-Coating Technologies for Enhanced Durability

● Precision Control Through Artificial Intelligence

● Hybrid Extrusion Techniques for Improved Strength and Formability

● Environmentally Conscious Extrusion Practices

● Smart Extrusion Lines for Increased Efficiency

● Customization through 3D Printing

● High-Pressure Extrusion

● Automation, Robotics, and AI in Extrusion

● Rapid Extrusion Profile Inspection

● Rapid Quench Systems

● Higher Strength Aluminum Alloys

● Market Growth

● Reducing Carbon Emissions

● The Effect of Extrusion and Heat Treatment

● Automotive industry

● Conclusion

● FAQ

>> What are the primary benefits of using nano-coating technologies on aluminum extrusions?

>> How does AI contribute to improving the aluminum extrusion process?

>> What role does sustainability play in the latest aluminum extrusion innovations?

>> How does 3D printing enhance customization in aluminum extrusion?

>> What is the significance of high-pressure extrusion in modern applications?

● Citations:

The aluminum extrusion industry is experiencing a period of rapid innovation, driven by the need for greater efficiency, sustainability, and customization. In 2024, several key advancements are reshaping the landscape of aluminum extrusion technology, offering new possibilities for design, manufacturing, and application across various sectors[1].

Nano-Coating Technologies for Enhanced Durability

Recent developments in nano-coating technologies have revolutionized the durability of aluminum extruded profiles[1]. These ultra-thin coatings provide an extra layer of protection against corrosion and abrasion, significantly extending the lifespan of extruded products in diverse applications, from construction to automotive manufacturing[1].

Precision Control Through Artificial Intelligence

The integration of artificial intelligence (AI) in the extrusion process has ushered in a new era of precision control[1]. AI algorithms analyze real-time data from the extrusion machinery, allowing for immediate adjustments and ensuring that each profile meets exact specifications[1]. This not only enhances product quality but also contributes to resource efficiency[1]. AI is also being incorporated into various aspects of the extrusion process, including predictive maintenance, die design, and die correction processes[4]. AI and machine learning are being used to optimize plant operations, from quoting to process development for aluminum extruder 2024[4].

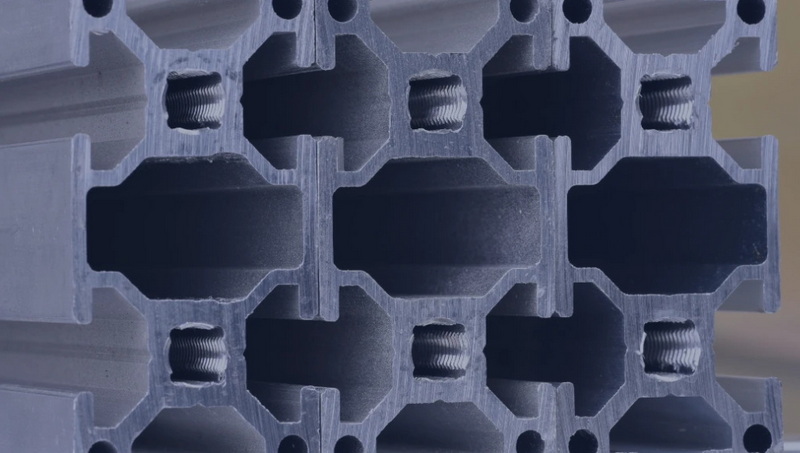

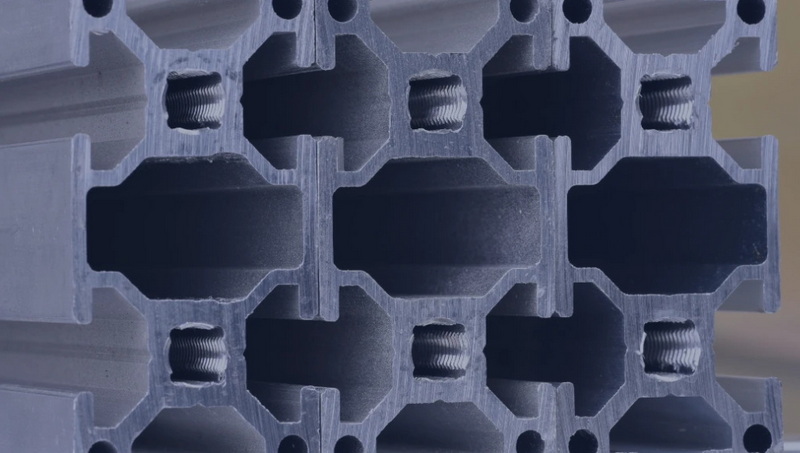

Hybrid Extrusion Techniques for Improved Strength and Formability

Hybrid extrusion techniques, combining traditional methods with advanced processes, have emerged to address the demand for aluminum profiles with enhanced strength and formability[1]. These methods optimize the material's properties, opening up new possibilities for applications in aerospace, automotive, and other industries where both strength and malleability are critical[1].

Environmentally Conscious Extrusion Practices

Sustainability is at the forefront of recent innovations. From energy-efficient extrusion processes to the use of recycled aluminum, the industry is embracing environmentally conscious practices[1]. These advancements not only reduce the carbon footprint of aluminum production but also align with global efforts to create more sustainable manufacturing solutions[1]. Aluminum companies are increasingly focused on high-performance billets to enable quicker and more efficient extrusion operations[5]. Aluminum extrusion firms prioritize sustainability by integrating closed-loop recycling and local sourcing[5]. This change intends to minimize emissions and lessen the carbon footprint, in line with environmental goals[5]. The emphasis on eco-friendly products and ethical sourcing indicates the industry's dedication to greener practices while also appealing to environmentally conscious consumers[5].

Smart Extrusion Lines for Increased Efficiency

The rise of smart extrusion lines equipped with IoT (Internet of Things) technology allows for seamless monitoring and control of the entire production process[1]. This connectivity optimizes efficiency, minimizes downtime, and facilitates predictive maintenance, ensuring that extrusion lines operate at peak performance[1].

Customization through 3D Printing

The marriage of aluminum extruder 2024 with 3D printing technology has opened up new frontiers in customization[1]. This combination allows for the creation of intricate and tailored designs, offering architects, engineers, and designers unparalleled freedom in realizing their visions[1]. Another trend reshaping the aluminum extrusion market is the integration of 3D printing and additive manufacturing technologies[2]. These processes are allowing for even more complex aluminum profiles to be produced, offering opportunities for design innovation and customization that were not possible with traditional extrusion methods[2].

High-Pressure Extrusion

High-pressure extrusion allows for the production of complex, high-strength profiles necessary for critical industries like aerospace and defense[7]. This process results in stronger, more durable profiles that meet exact specifications[7]. By applying substantial pressure, aluminum can be extruded into complex shapes with minimal deformation, which is crucial for aerospace components requiring high precision and resilience[7].

Automation, Robotics, and AI in Extrusion

Today's extrusion lines leverage robotics, AI, and IoT to streamline the process, reduce errors, and maximize efficiency[7]. AI-driven systems provide real-time feedback, adjusting parameters automatically to maintain product consistency and quality[7]. Robotics handles material transport and positioning with unmatched precision, reducing human error and improving safety[7]. Fully automated extrusion lines highlight how automation can reduce lead times and enhance output quality, providing customers with consistent and reliable products[7].

Rapid Extrusion Profile Inspection

Advances in rapid extrusion profile inspection using Computerized Topology (CAT) X-ray scanning are being developed[4]. This technology has the potential to eliminate time-consuming sample preparation and can be performed directly at the extrusion press, enhancing efficiency and accuracy in quality control[4].

Rapid Quench Systems

New rapid quench systems, utilizing multiple nozzles and adjustable flow valves, are being developed to cool extrusions uniformly as they exit the press[4]. These systems ensure more consistent tempering along the length of the extrusion, reducing straightness and twist deformations, and improving overall product quality[4].

Higher Strength Aluminum Alloys

Higher strength 6000 series aluminum alloys are being developed, particularly for automotive applications where strength and durability are paramount[4].

Market Growth

The global aluminum extrusion market has been on a strong upward trajectory in recent years, and forecasts indicate it will continue to grow steadily in 2024 and beyond[2]. Market research estimates suggest that the market size could exceed USD 60 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.2%[2]. The global aluminum extruder 2024 market size was valued at USD 97.4 Billion in 2024, and it is expected to reach USD 185.2 Billion by 2033, exhibiting a growth rate (CAGR) of 7.4% during 2025 to 2033[5].

Reducing Carbon Emissions

The aluminum industry is making significant strides in reducing carbon emissions across the entire value stream, from mining bauxite to recycling aluminum scrap[4]. This initiative is crucial for promoting sustainability and reducing the environmental impact of aluminum production[4].

The Effect of Extrusion and Heat Treatment

Hot extrusion forming is one of the best cost-effective processing methods to obtain high-strength aluminum alloys[3]. In order to obtain high performance 2024 aluminum alloy for the aero and automobile industries, this research comprehensively uses heat treatment and reverse isothermal extrusion technology to prepare 2024 alloy[3].

Automotive industry

As electric vehicles continue to disrupt the automotive market, the demand for lightweight materials, especially for battery housings and EV body structures, is on the rise[2]. Aluminum extrusions are an ideal solution for these applications due to their lightweight and corrosion-resistant properties[2]. In 2024, the adoption of aluminum in EV production is expected to accelerate, opening new avenues for extruded aluminum manufacturers[2]. Uncover how aluminum extrusions can address the automotive industry's demand for solutions that minimize the environmental footprint[6].

Conclusion

The aluminum extruder 2024 industry is dynamic, with innovations spanning from material science to digital integration. These advancements collectively contribute to a more efficient, sustainable, and customizable future for aluminum extrusion, meeting the evolving demands of industries worldwide[1].

FAQ

What are the primary benefits of using nano-coating technologies on aluminum extrusions?

Nano-coating technologies enhance the durability of aluminum extrusions by providing an extra layer of protection against corrosion and abrasion, which extends the lifespan of the products[1].

How does AI contribute to improving the aluminum extrusion process?

AI algorithms analyze real-time data from extrusion machinery, enabling immediate adjustments to ensure that each profile meets exact specifications, enhancing product quality and resource efficiency[1].

What role does sustainability play in the latest aluminum extrusion innovations?

Sustainability is a key focus, with innovations including energy-efficient extrusion processes and the use of recycled aluminum to reduce the carbon footprint and align with global environmental efforts[1].

How does 3D printing enhance customization in aluminum extrusion?

The integration of aluminum extruder 2024 with 3D printing allows for the creation of intricate and tailored designs, providing architects, engineers, and designers with unparalleled freedom in realizing their visions[1].

What is the significance of high-pressure extrusion in modern applications?

High-pressure extrusion enables the production of complex, high-strength profiles essential for critical industries like aerospace and defense, resulting in stronger, more durable profiles that meet precise specifications[7].

Citations:

[1] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[2] https://www.marketresearchintellect.com/blog/shaping-the-future-how-the-aluminum-extrusion-market-is-reshaping-industries-in-2024/

[3] https://pmc.ncbi.nlm.nih.gov/articles/PMC9655778/

[4] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[5] https://www.imarcgroup.com/aluminium-extrusion-market-statistics

[6] https://aec.org/sites/default/files/2024-04/et24-best-papers.pdf

[7] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[8] https://www.precedenceresearch.com/aluminum-extrusion-market