Content Menu

● Introduction

● Current Market Size and Growth Rate

● Key Trends in the Aluminum Extrusion Market

>> Increasing Demand in the Automotive and Construction Sectors

>> Technological Advancements in Aluminum Extrusion Processes

>> Sustainability and Recycling Trends in Aluminum Usage

● Major Applications of Aluminum Extrusion

>> Building & Construction

>> Automotive

>> Electrical

>> Consumer Goods

● Challenges Facing the Aluminum Extrusion Industry

>> Supply Chain Issues and Material Costs

>> Competition from Alternative Materials

● Future Outlook and Innovations

>> Predictions for Market Trends Over the Next Decade

>> Emerging Technologies and Their Potential Impact on the Industry

● Conclusion

● Related Questions

>> 1. What are the main benefits of using aluminum extrusions in construction?

>> 2. How does aluminum recycling impact the environment?

>> 3. What role does technology play in the aluminum extrusion process?

>> 4. What are the challenges faced by the aluminum extrusion industry?

>> 5. What are the future trends expected in the aluminum extrusion market?

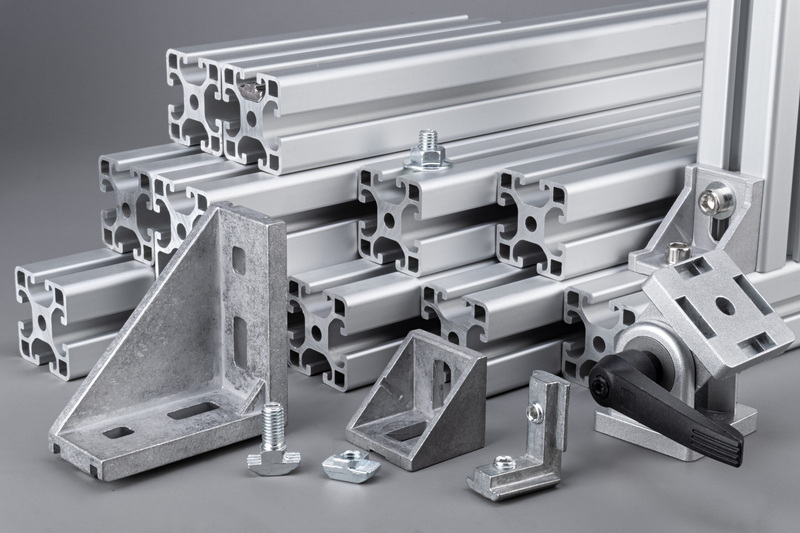

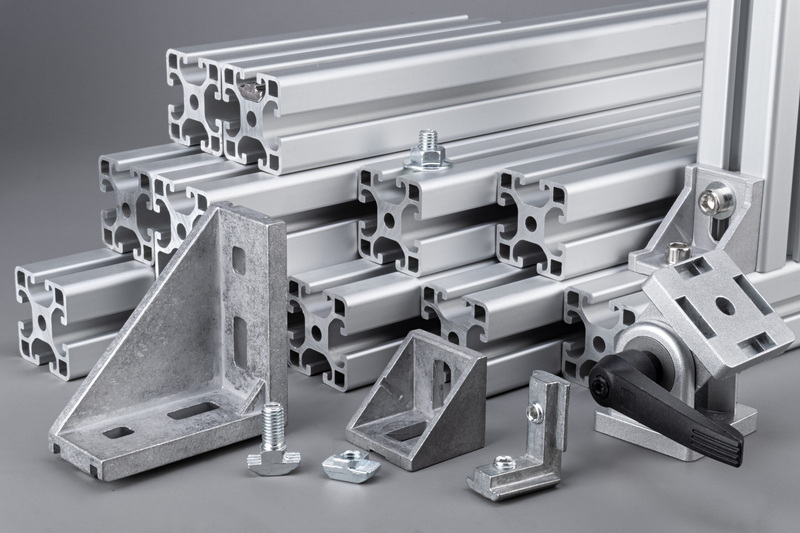

Introduction

The aluminum extrusion market has witnessed significant growth and transformation over the past few decades. As industries increasingly seek lightweight, durable, and corrosion-resistant materials, aluminum extrusion has emerged as a preferred choice across various sectors, including automotive, construction, and consumer goods. This article explores the key trends shaping the aluminum extrusion market today, highlighting the factors driving its growth, the major applications, and the challenges faced by the industry.

Current Market Size and Growth Rate

The aluminum extrusion market is currently valued at billions of dollars and is projected to continue its upward trajectory. The demand for aluminum extrusions is primarily driven by the automotive and construction industries, where lightweight materials are essential for improving fuel efficiency and reducing overall structural weight. The market is expected to grow at a robust rate, fueled by technological advancements and increasing applications in various sectors.

Key Trends in the Aluminum Extrusion Market

Increasing Demand in the Automotive and Construction Sectors

One of the most significant trends in the aluminum extrusion market is the rising demand from the automotive and construction sectors. In the automotive industry, manufacturers are increasingly using aluminum extrusions to produce lightweight components that enhance fuel efficiency and reduce emissions. The shift towards electric vehicles (EVs) has further accelerated this trend, as EVs require lightweight materials to maximize battery efficiency.

In construction, aluminum extrusions are favored for their strength-to-weight ratio, making them ideal for structural applications, window frames, and roofing systems. The growing emphasis on sustainable building practices has also led to an increased adoption of aluminum, as it is 100% recyclable and can contribute to green building certifications.

Technological Advancements in Aluminum Extrusion Processes

Technological innovations are playing a crucial role in shaping the aluminum extrusion market. Advanced extrusion techniques, such as direct and indirect extrusion, have improved the efficiency and quality of aluminum products. Additionally, the integration of automation and robotics in the extrusion process has enhanced production capabilities, reduced labor costs, and minimized waste.

Moreover, the development of new alloys and surface treatment technologies has expanded the range of applications for aluminum extrusions. These advancements enable manufacturers to produce customized solutions that meet specific performance requirements, further driving market growth.

Sustainability and Recycling Trends in Aluminum Usage

Sustainability is a key focus for many industries today, and the aluminum extrusion market is no exception. Aluminum is one of the most sustainable materials available, as it can be recycled indefinitely without losing its properties. The recycling process requires only a fraction of the energy needed to produce new aluminum, making it an environmentally friendly choice.

As consumers and businesses become more environmentally conscious, the demand for recycled aluminum extrusions is on the rise. Many manufacturers are now incorporating recycled materials into their production processes, contributing to a circular economy and reducing their carbon footprint.

Major Applications of Aluminum Extrusion

Aluminum extrusions are used in a wide range of applications across various industries. Some of the most notable applications include:

Building & Construction

In the building and construction sector, aluminum extrusions are used for window frames, doors, curtain walls, and roofing systems. Their lightweight nature and resistance to corrosion make them ideal for both residential and commercial buildings. Additionally, aluminum extrusions can be easily customized to meet specific design requirements, allowing architects and builders to create innovative structures.

Automotive

The automotive industry is one of the largest consumers of aluminum extrusions. Lightweight aluminum components are used in vehicle frames, bumpers, and interior parts to improve fuel efficiency and performance. As the industry shifts towards electric vehicles, the demand for aluminum extrusions is expected to grow even further, as manufacturers seek to reduce weight and enhance battery performance.

Electrical

Aluminum extrusions are widely used in the electrical industry for applications such as heat sinks, electrical enclosures, and cable trays. Their excellent thermal conductivity and lightweight properties make them ideal for managing heat in electronic devices and ensuring efficient electrical performance.

Consumer Goods

In the consumer goods sector, aluminum extrusions are used in a variety of products, including furniture, appliances, and sporting goods. The versatility of aluminum allows manufacturers to create aesthetically pleasing and functional designs that appeal to consumers.

Challenges Facing the Aluminum Extrusion Industry

Despite the positive trends in the aluminum extrusion market, several challenges must be addressed.

Supply Chain Issues and Material Costs

The aluminum extrusion industry faces supply chain challenges, particularly in sourcing raw materials. Fluctuations in aluminum prices can impact production costs and profitability. Additionally, global supply chain disruptions, such as those caused by the COVID-19 pandemic, have highlighted the need for manufacturers to diversify their supply sources and improve inventory management.

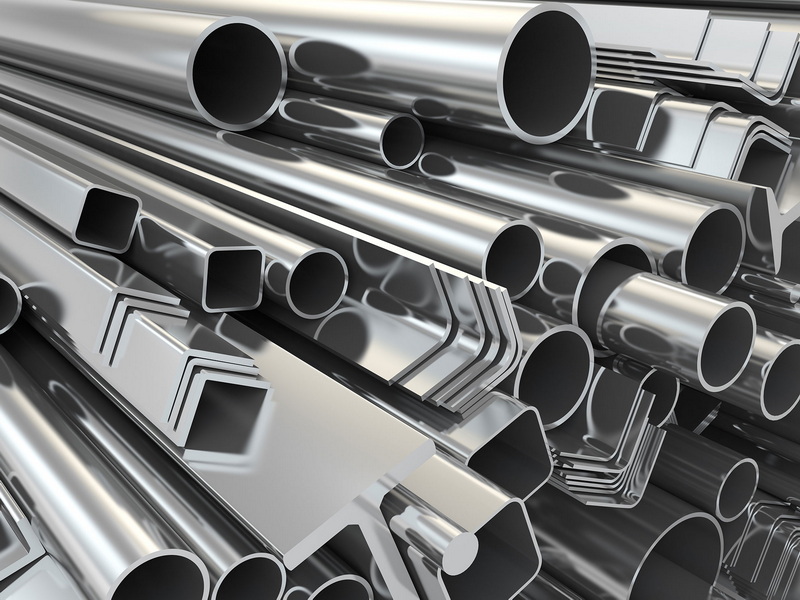

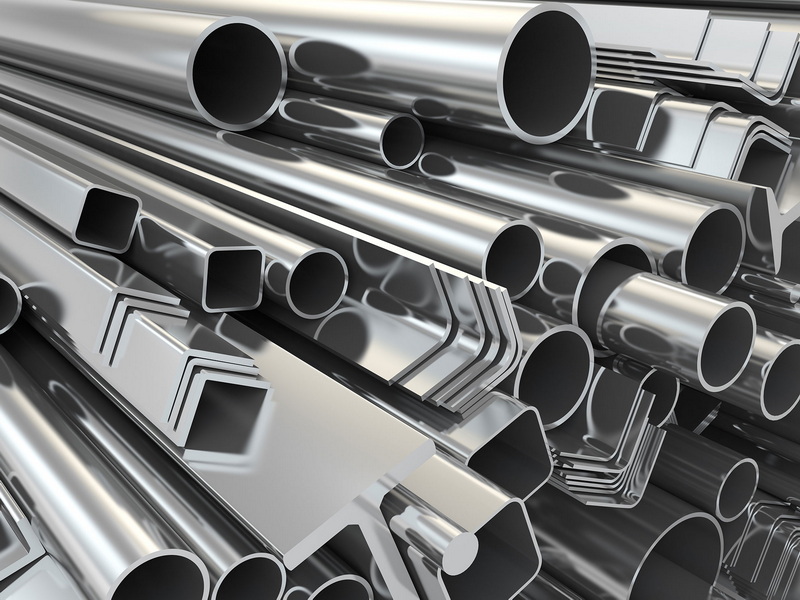

Competition from Alternative Materials

While aluminum is a popular choice for many applications, it faces competition from alternative materials such as steel, plastic, and composites. These materials may offer specific advantages in certain applications, prompting manufacturers to evaluate their material choices carefully. To remain competitive, the aluminum extrusion industry must continue to innovate and demonstrate the unique benefits of aluminum.

Future Outlook and Innovations

The future of the aluminum extrusion market looks promising, with several innovations on the horizon.

Predictions for Market Trends Over the Next Decade

As industries continue to prioritize sustainability and lightweight materials, the demand for aluminum extrusions is expected to grow. The market is likely to see increased investment in research and development, leading to the creation of new alloys and extrusion techniques that enhance performance and reduce costs.

Emerging Technologies and Their Potential Impact on the Industry

Emerging technologies, such as 3D printing and advanced manufacturing techniques, have the potential to revolutionize the aluminum extrusion market. These technologies can enable manufacturers to produce complex shapes and designs that were previously difficult or impossible to achieve with traditional extrusion methods. As these technologies mature, they may open up new opportunities for aluminum extrusions in various applications.

Conclusion

The aluminum extrusion market is undergoing significant changes driven by various trends, including increasing demand from the automotive and construction sectors, technological advancements, and a focus on sustainability. As the market continues to evolve, manufacturers must adapt to these trends and address the challenges they face to remain competitive. The future of the aluminum extrusion market looks bright, with numerous opportunities for growth and innovation.

Related Questions

1. What are the main benefits of using aluminum extrusions in construction?

Aluminum extrusions offer several benefits in construction, including lightweight properties, corrosion resistance, and design flexibility. They can be easily customized to meet specific architectural requirements and contribute to energy-efficient building designs.

2. How does aluminum recycling impact the environment?

Aluminum recycling significantly reduces energy consumption and greenhouse gas emissions compared to producing new aluminum. It conserves natural resources and minimizes waste, making it an environmentally friendly choice.

3. What role does technology play in the aluminum extrusion process?

Technology plays a crucial role in improving the efficiency and quality of aluminum extrusions. Advanced manufacturing techniques, automation, and robotics enhance production capabilities and reduce waste.

4. What are the challenges faced by the aluminum extrusion industry?

The aluminum extrusion industry faces challenges such as supply chain issues, fluctuating material costs, and competition from alternative materials. Addressing these challenges is essential for maintaining competitiveness.

5. What are the future trends expected in the aluminum extrusion market?

Future trends in the aluminum extrusion market include increased demand for lightweight materials, advancements in manufacturing technologies, and a focus on sustainability and recycling practices. These trends are expected to drive growth and innovation in the industry.