Content Menu

● Introduction

● Understanding Aluminum Extrusion Strength

● Key Strength Characteristics of 2020 Aluminum Extrusions

>> Material Properties

>> Comparison with Other Profiles

>> Fatigue Resistance

● Applications of 2020 Aluminum Extrusions

● Factors Influencing the Strength of Aluminum Extrusions

>> Design Considerations

>> Manufacturing Processes

>> Environmental Factors

● Conclusion

● Related Questions

>> 1. What is the tensile strength of 2020 aluminum extrusions?

>> 2. How does the T-slot design enhance the strength of 2020 aluminum extrusions?

>> 3. What industries commonly use 2020 aluminum extrusions?

>> 4. How can the strength of aluminum extrusions be improved through design?

>> 5. What environmental factors can affect the strength of aluminum extrusions?

Introduction

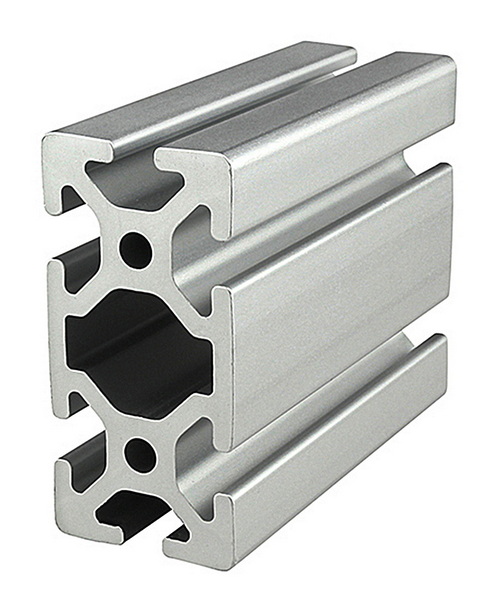

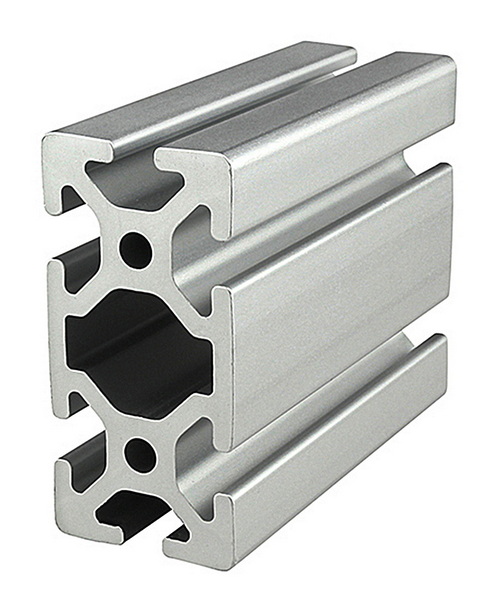

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This technique is widely used in various industries due to its versatility, lightweight nature, and excellent strength-to-weight ratio. Among the many profiles available, the 2020 aluminum extrusion stands out for its unique properties and applications. This article delves into the key strength characteristics of 2020 aluminum extrusions, exploring their material properties, applications, and the factors that influence their strength.

Understanding Aluminum Extrusion Strength

Strength in the context of aluminum extrusions refers to the material's ability to withstand applied forces without failure. This characteristic is crucial for structural applications where safety and durability are paramount. The strength of aluminum extrusions is typically measured in terms of tensile strength and yield strength.

Tensile strength is the maximum amount of tensile (pulling) stress that a material can withstand before failure, while yield strength is the amount of stress at which a material begins to deform plastically. For 2020 aluminum extrusions, these strength characteristics are influenced by the alloy composition, manufacturing processes, and design considerations.

Key Strength Characteristics of 2020 Aluminum Extrusions

Material Properties

The 2020 aluminum extrusion is made from a specific aluminum alloy, typically 6063 or 6061, which is known for its excellent mechanical properties. The alloy composition significantly impacts the strength of the extrusion.

- Tensile Strength: The tensile strength of 2020 aluminum extrusions can range from 200 to 300 MPa, depending on the specific alloy and temper. This strength makes it suitable for various structural applications where high strength is required.

- Yield Strength: The yield strength of 2020 aluminum extrusions is also impressive, often exceeding 200 MPa. This characteristic ensures that the material can withstand significant loads without permanent deformation.

Comparison with Other Profiles

When comparing the strength of 2020 aluminum extrusions to other profiles, such as 8020 or 4040, it is essential to consider the cross-sectional design and dimensions. The 2020 profile, with its T-slot design, allows for easy assembly and versatility in applications.

The T-slot design not only enhances the strength of the extrusion but also provides flexibility in connecting various components. This feature is particularly beneficial in modular construction, where components can be easily added or removed without compromising structural integrity.

Fatigue Resistance

Fatigue resistance is another critical aspect of the strength characteristics of 2020 aluminum extrusions. Fatigue failure occurs when a material is subjected to repeated loading and unloading cycles, leading to the development of cracks over time.

2020 aluminum extrusions exhibit excellent fatigue resistance, making them suitable for dynamic applications such as machinery frames and robotic structures. The ability to withstand cyclic loading without failure is a significant advantage in industries where equipment is frequently in motion.

Applications of 2020 Aluminum Extrusions

The unique strength characteristics of 2020 aluminum extrusions make them ideal for various applications across multiple industries. Some common uses include:

- Industrial Machinery: The strength and lightweight nature of 2020 aluminum extrusions make them perfect for constructing machine frames, supports, and enclosures. Their ability to withstand heavy loads while remaining lightweight enhances the overall efficiency of machinery.

- Workstations and Assembly Lines: In manufacturing environments, 2020 aluminum extrusions are often used to create workstations and assembly lines. The modular design allows for easy customization and reconfiguration, accommodating changing production needs.

- Robotics and Automation: The strength and versatility of 2020 aluminum extrusions make them a popular choice in robotics and automation. They can be used to build robotic arms, frames, and other structural components that require both strength and flexibility.

- Furniture and Displays: The aesthetic appeal of aluminum, combined with its strength, makes 2020 aluminum extrusions suitable for furniture and display systems. They can be used to create sleek, modern designs that are both functional and visually appealing.

Factors Influencing the Strength of Aluminum Extrusions

Several factors influence the strength of 2020 aluminum extrusions, including design considerations, manufacturing processes, and environmental factors.

Design Considerations

The design of the aluminum extrusion plays a crucial role in its strength. Cross-sectional shapes and dimensions can significantly impact the load-bearing capacity of the profile. For instance, a larger cross-sectional area can distribute loads more effectively, enhancing overall strength.

Additionally, incorporating features such as ribs or gussets can improve the structural integrity of the extrusion. These design elements help to resist bending and twisting forces, making the extrusion more robust in applications where stability is critical.

Manufacturing Processes

The manufacturing process used to create aluminum extrusions also affects their strength characteristics. The extrusion process involves heating the aluminum alloy and forcing it through a die to create the desired shape.

The temperature and speed of the extrusion process can influence the grain structure of the aluminum, impacting its mechanical properties. Proper control of these parameters is essential to ensure that the final product meets the required strength specifications.

Environmental Factors

Environmental factors, such as exposure to moisture and temperature fluctuations, can also affect the strength of aluminum extrusions. While aluminum is naturally resistant to corrosion, prolonged exposure to harsh environments can lead to degradation over time.

To mitigate these effects, it is essential to consider protective coatings or treatments that enhance the corrosion resistance of the extrusion. Additionally, understanding the operating environment can help in selecting the appropriate alloy and temper for specific applications.

Conclusion

In summary, the key strength characteristics of 2020 aluminum extrusions make them a valuable choice for various applications across multiple industries. Their impressive tensile and yield strength, combined with excellent fatigue resistance, ensure that they can withstand significant loads and dynamic conditions.

The versatility of the T-slot design allows for easy assembly and customization, making 2020 aluminum extrusions ideal for modular construction. By understanding the factors that influence their strength, manufacturers and engineers can make informed decisions when selecting aluminum extrusions for their projects.

Related Questions

1. What is the tensile strength of 2020 aluminum extrusions?

The tensile strength of 2020 aluminum extrusions typically ranges from 200 to 300 MPa, depending on the specific alloy and temper.

2. How does the T-slot design enhance the strength of 2020 aluminum extrusions?

The T-slot design allows for easy assembly and connection of components, enhancing the overall structural integrity and versatility of the extrusion.

3. What industries commonly use 2020 aluminum extrusions?

2020 aluminum extrusions are commonly used in industrial machinery, workstations, robotics, and furniture design due to their strength and lightweight nature.

4. How can the strength of aluminum extrusions be improved through design?

Incorporating features such as ribs or gussets can improve the structural integrity of aluminum extrusions, helping them resist bending and twisting forces.

5. What environmental factors can affect the strength of aluminum extrusions?

Environmental factors such as moisture exposure and temperature fluctuations can impact the strength of aluminum extrusions, making protective coatings essential for long-term durability.