Content Menu

● Introduction to Extrusion Welding Equipment

● How Extrusion Welding Works

● Key Features to Look for in Extrusion Welding Equipment

>> Temperature Control and Heating Systems

>> Extrusion Output and Feed Mechanism

>> Nozzle and Weld Shoe Design

>> Material Compatibility and Versatility

>> Ergonomics and User Interface

>> Portability and Weight

>> Safety Features and Certifications

>> Maintenance and Serviceability

>> Digital Controls and Display

>> Accessory and Spare Part Availability

● Applications of Extrusion Welding Equipment

● How to Choose the Right Extrusion Welding Equipment for Your Needs

● Conclusion

● FAQ

>> 1. What is extrusion welding equipment used for?

>> 2. Which thermoplastics can be welded using extrusion welding equipment?

>> 3. What are the main safety precautions when using extrusion welding equipment?

>> 4. How do I maintain and service extrusion welding equipment?

>> 5. How do I choose the right extrusion welding equipment for my project?

● Citations:

Extrusion welding equipment is indispensable in industries that require the joining of thermoplastic materials, such as plastic fabrication, construction, automotive, and electronics. Selecting the right extrusion welding equipment is crucial for achieving strong, reliable welds and ensuring efficiency, safety, and versatility in your operations. This comprehensive guide explores the essential features to consider when choosing extrusion welding equipment, delves into the technology behind the process, and answers frequently asked questions to help you make informed decisions.

Introduction to Extrusion Welding Equipment

Extrusion welding equipment is a specialized class of machinery designed to join thermoplastic materials by heating and extruding molten plastic along a seam or joint. This process is widely used for fabricating and repairing plastic components such as pipes, tanks, geomembranes, and more[1][2]. The reliability, speed, and versatility of extrusion welding make it a preferred method across various industries.

How Extrusion Welding Works

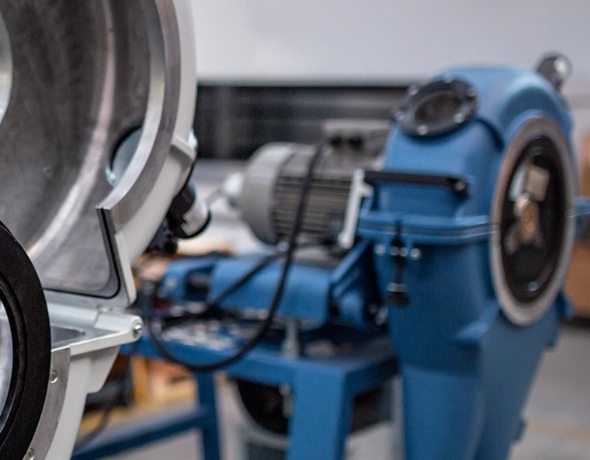

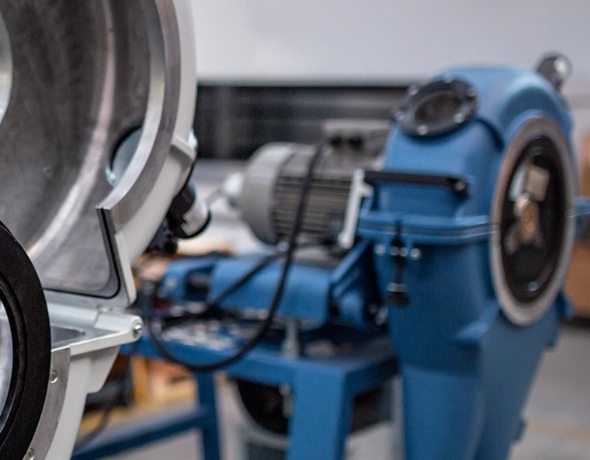

Extrusion welding involves three fundamental variables: heat, pressure, and time[2]. The process uses an extrusion welding gun or extruder that melts a plastic filler rod and the surfaces to be joined. The molten plastic is then forced through a nozzle (or weld shoe) and pressed into the joint, creating a strong, homogeneous weld seam as it cools[1][2].

The main components of extrusion welding equipment include:

- Hot Air Blower: Heats the surfaces to be welded.

- Extruder: Melts and delivers the filler rod material.

- Weld Shoe/Nozzle: Shapes and applies the molten plastic into the joint[2].

Key Features to Look for in Extrusion Welding Equipment

Choosing the right extrusion welding equipment involves evaluating several critical features. Below, we detail the most important aspects to consider:

Temperature Control and Heating Systems

Precise temperature control is essential for consistent, high-quality welds. Look for equipment with:

- Manual or digital temperature control for both the extruder and hot air blower, allowing you to set and maintain the optimal temperature for different thermoplastics[1][3].

- Dual independent heating systems that separately control the preheating of the base material and the melting of the filler rod, ensuring uniform fusion[3].

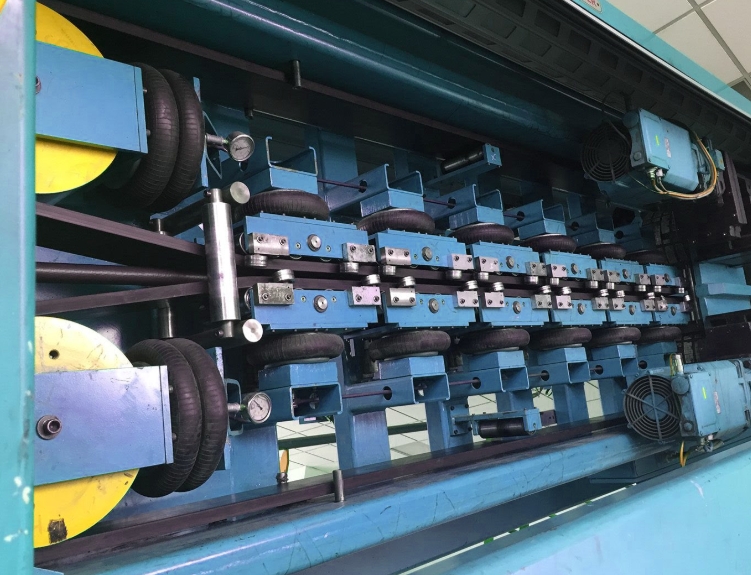

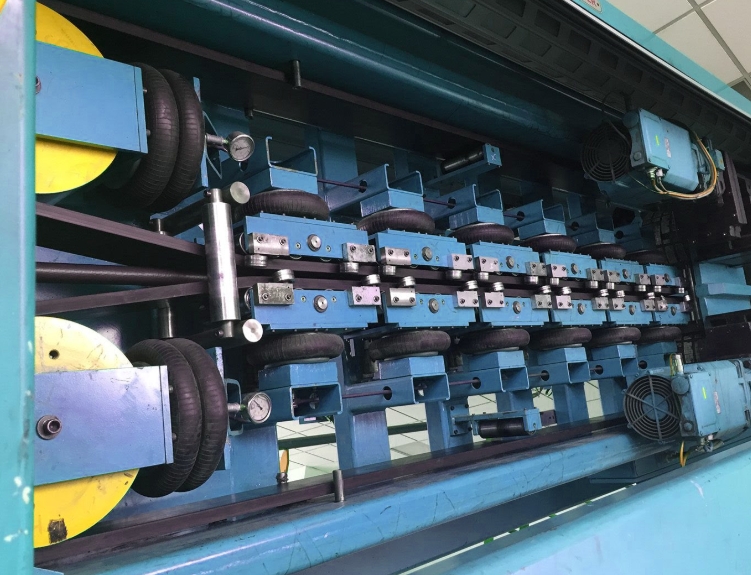

Extrusion Output and Feed Mechanism

The extrusion output, or the rate at which molten plastic is delivered, determines the speed and efficiency of the welding process.

- Adjustable extrusion volume: Allows you to match output to material thickness and application (e.g., 2.4–3.4 kg/h for certain models)[3].

- Consistent feed mechanism: Ensures uniform delivery of the filler material, which is critical for weld quality[1].

Nozzle and Weld Shoe Design

The nozzle or weld shoe shapes the molten plastic and applies it to the joint.

- Interchangeable nozzles: Enable different weld geometries and accommodate various joint types[1][2].

- Custom weld shoes: Allow adaptation to specific applications, such as fillet, lap, or butt welds[2].

- 360-degree rotating welding head: Increases flexibility for complex or hard-to-reach welds[3].

Material Compatibility and Versatility

Ensure the equipment can handle the types of thermoplastics you work with.

- Supported materials: Commonly welded plastics include HDPE, PP, PVC, PVDF, and LDPE[1][3][4].

- Welding rod compatibility: The equipment should accept different rod diameters and compositions (e.g., PE/PP φ 3–4 mm)[3].

Ergonomics and User Interface

Operator comfort and ease of use are vital, especially for prolonged welding tasks.

- Ergonomic design: Features such as comfortable grip handles reduce fatigue[4].

- User-friendly controls: Multifunctional display screens with adjustable temperature and air volume simplify operation[4].

Portability and Weight

Depending on your application, portability may be a key consideration.

- Lightweight construction: Handheld models typically weigh between 6–8 kg, making them suitable for fieldwork or overhead welding[1][3].

- Compact size: Facilitates use in confined spaces and enhances maneuverability[1].

Safety Features and Certifications

Safety should never be compromised.

- Electrical protection: Look for equipment with appropriate protection levels (e.g., Protection Level II)[3].

- Thermal insulation: Prevents accidental burns from hot surfaces.

- Certifications: Ensure compliance with relevant industry standards for electrical and mechanical safety.

Maintenance and Serviceability

Reliable equipment should be easy to maintain and service.

- Modular construction: Facilitates quick replacement of wear parts such as heating elements, nozzles, and motors[2].

- Availability of spare parts: Check for ready access to consumables and replacement components[2].

- Manufacturer support: Consider brands that offer calibration, repairs, and technical support[2].

Digital Controls and Display

Modern extrusion welding equipment often features digital interfaces.

- Digital display controllers: Allow precise monitoring and adjustment of parameters such as temperature, extrusion rate, and air flow[3][4].

- Programmable settings: Enable storage and recall of welding programs for repeatability and efficiency[4].

Accessory and Spare Part Availability

A comprehensive range of accessories enhances versatility.

- Welding shoes/nozzles: For different weld profiles and applications[2].

- Cleaning and preparation tools: Such as scrapers, rollers, and die grinders[2].

- Training and documentation: Access to user manuals, training, and technical resources is invaluable for both new and experienced operators[5].

Applications of Extrusion Welding Equipment

Extrusion welding equipment is used in a wide variety of applications, including:

- Plastic pipe and fitting fabrication

- Manufacture and repair of storage tanks and containers

- Geomembrane and liner installation for environmental protection

- Construction of water and gas distribution systems

- Automotive component assembly

- Electrical housing and enclosure manufacturing[1][2][4]

Its versatility, speed, and ability to produce strong, durable joints make extrusion welding equipment a go-to solution for thermoplastic joining tasks.

How to Choose the Right Extrusion Welding Equipment for Your Needs

Selecting the best extrusion welding equipment depends on your specific requirements. Consider the following steps:

- Identify the types of thermoplastics and thicknesses you will be welding.

- Determine the required extrusion output and welding speed for your projects.

- Assess the working environment (shop, field, confined spaces) to determine the importance of portability and ergonomics.

- Prioritize safety features and ensure compliance with relevant standards.

- Evaluate the availability of accessories, spare parts, and manufacturer support.

- Consider the level of operator training required and the user-friendliness of the equipment.

Consult with reputable suppliers and request demonstrations or samples when possible to ensure the equipment meets your expectations[2][3][4].

Conclusion

Choosing the right extrusion welding equipment is a critical decision that impacts the quality, efficiency, and safety of your plastic welding operations. By focusing on key features such as precise temperature control, adjustable extrusion output, ergonomic design, material compatibility, and robust safety provisions, you can ensure reliable performance and long-term value. Always consider the specific needs of your application, the skill level of your operators, and the support offered by equipment manufacturers. With the right extrusion welding equipment, you can achieve strong, durable welds and maximize productivity across a wide range of thermoplastic joining tasks.

FAQ

1. What is extrusion welding equipment used for?

Extrusion welding equipment is used to join thermoplastic materials by melting and extruding a plastic filler rod along a seam, creating a strong, homogeneous weld. Common applications include fabricating and repairing plastic pipes, tanks, geomembranes, and other components in industries such as construction, automotive, and environmental engineering[1][2][4].

2. Which thermoplastics can be welded using extrusion welding equipment?

Most extrusion welding equipment is compatible with a range of thermoplastics, including HDPE (high-density polyethylene), PP (polypropylene), PVC (polyvinyl chloride), PVDF (polyvinylidene fluoride), LDPE (low-density polyethylene), and others. Always verify the specific compatibility of your equipment with the materials you intend to weld[1][3][4].

3. What are the main safety precautions when using extrusion welding equipment?

Key safety precautions include wearing appropriate personal protective equipment (PPE), ensuring adequate ventilation, avoiding contact with hot surfaces, keeping the work area clean, and being mindful of electrical hazards. Always follow the manufacturer's safety guidelines and ensure equipment is properly maintained[2].

4. How do I maintain and service extrusion welding equipment?

Regular maintenance includes cleaning the equipment after use, inspecting and replacing worn parts such as heating elements and nozzles, and ensuring all moving parts are properly lubricated. Many manufacturers offer spare parts, calibration, and repair services. Always refer to the user manual for specific maintenance procedures[2][3].

5. How do I choose the right extrusion welding equipment for my project?

Consider the types of thermoplastics and thicknesses you will be welding, the required extrusion output, the working environment, and the level of operator experience. Evaluate features such as temperature control, extrusion rate, ergonomics, safety provisions, and accessory availability. Consult with suppliers and request demonstrations if possible to ensure the equipment meets your needs[2][4].

Citations:

[1] https://www.akuplastics.com/en/machines-appliances-plastics-locksmiths-fabricators-tank-builders/hsk26-gsx-welding-extruder/

[2] https://www.fhs.com.au/fusion-melding-blog/what-is-extrusion-welding

[3] https://sudabuttfusionwelder.en.made-in-china.com/product/MObteRudZGoJ/China-Extrusion-Welders-for-Plastic-Welding-Machine.html

[4] https://www.riyang-welding.com/products2115532/Extrusion-Welders.htm

[5] https://www.polyweldtech.com.au/training/extrusion-welding/

[6] https://www.leister.com/Extrusion-Welders

[7] https://www.yjing-extrusion.com/how-to-choose-the-right-china-extrusion-welding-equipment-for-my-needs.html

[8] https://bortte.com/hdpe-extrusion-welder/

[9] https://www.plastral.com.au/product/leister-weldplast-s4-extrusion-welding-machine-2/

[10] https://www.rothenbergertools.us/Rothenberger_roweld_extrusion_welding_welding_machines.htm