Content Menu

● Introduction to Kerke Extrusion Equipment

>> Kerke's Twin Screw Extruder Models

>> Key Features of Kerke's Twin Screw Extruders

>> Applications of Kerke's Twin Screw Extruders

>> Auxiliary Equipment and Services

● Kerke Extrusion Equipment in Action

● Conclusion

● FAQs

>> 1. What are the primary applications of Kerke's twin screw extruders?

>> 2. What makes Kerke's twin screw extruders energy efficient?

>> 3. How does Kerke support its customers?

>> 4. Can Kerke's twin screw extruders be customized?

>> 5. What certifications do Kerke's products hold?

● Citations:

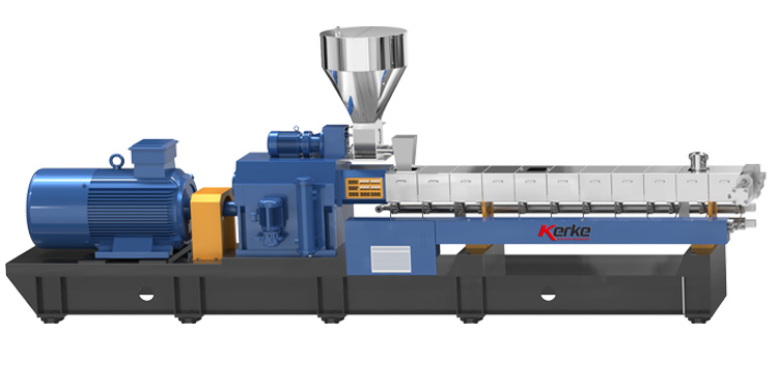

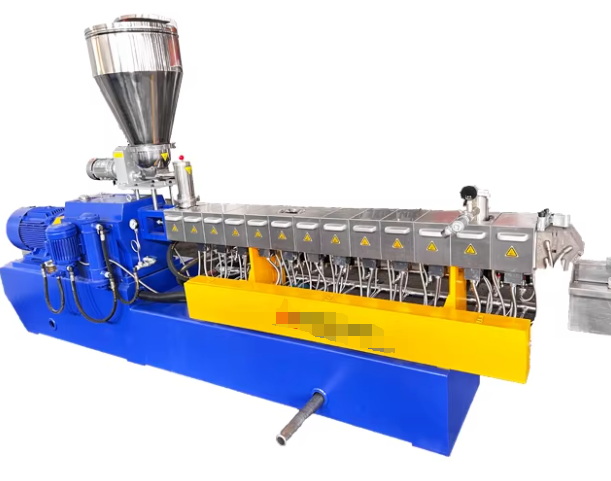

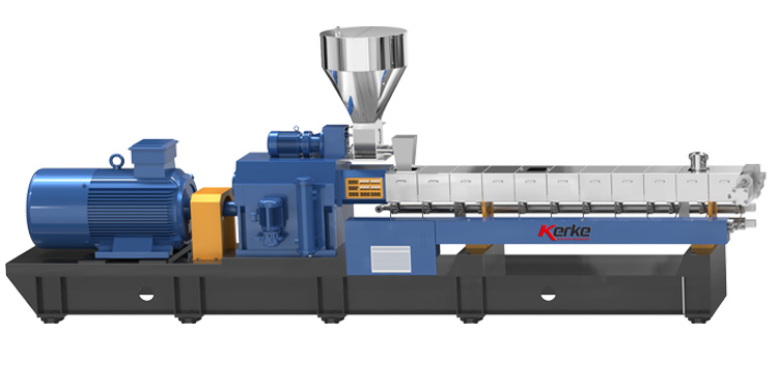

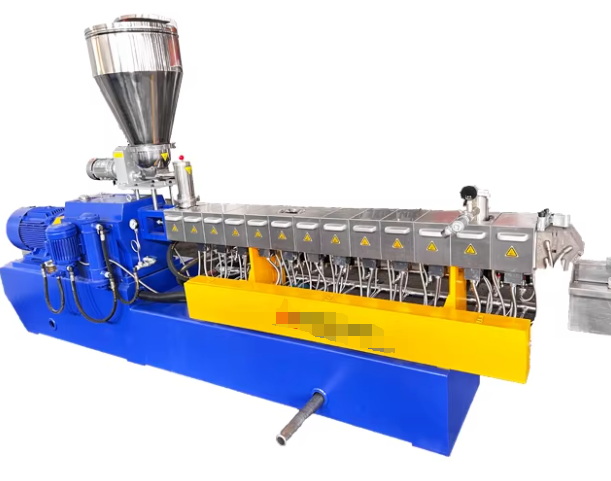

Kerke Extrusion Equipment Co., Ltd., a prominent player in the twin screw extruder industry, has been specializing in the design and manufacture of high-quality parallel co-rotating twin screw extruders for over a decade. These machines are widely used in various industries, including plastics, rubber, and food processing, due to their versatility and advanced technology. In this article, we will delve into the key features of Kerke's twin screw extruders, exploring their design, applications, and benefits.

Introduction to Kerke Extrusion Equipment

Nanjing Kerke Extrusion Equipment Co., Ltd. is part of the Wanplas Group, a high-tech company renowned for its expertise in R&D, manufacturing, and sales of twin screw extruders. Kerke's products include the KTE series parallel twin screw extruders, which are designed for compounding and masterbatch production with output capacities ranging from 30 kg/h to 4000 kg/h[1][2].

Kerke's Twin Screw Extruder Models

Kerke offers a wide range of twin screw extruder models, each designed to cater to different production needs. The KTE series includes models such as KTE-16, KTE-20, KTE-25D, KTE-36B, KTE-36D, KTE-50B, KTE-50D, KTE-52B, KTE-52D, KTE-65B, KTE-65D, KTE-75B, KTE-75D, KTE-85B, KTE-95B, KTE-95D, KTE-135B, and KTE-135D[1][3].

| Model | Screw Diameter [mm] | D/d [mm] | Maximum Speed [rpm] | Motor [Kw] | Torque [Nm] | Output [Kg/h] |

| KTE-16 | 15.6 | 1.71 | 500 | 2.2 | 2X18 | 1~5 |

| KTE-20 | 21.7 | 1.55 | 500 | 4 | 2X30 | 2~15 |

| KTE-25D | 26 | 1.55 | 500 | 7.5~11 | 2X85 | 5~20 |

| KTE-36B | 35.6 | 1.51 | 500~600 | 18.5~22 | 2X210 | 20~100 |

| KTE-36D | 35.6 | 1.51 | 500~600 | 22~37 | 2X352 | 20~150 |

| KTE-50B | 50.5 | 1.55 | 500~600 | 55~75 | 2X525 | 80~200 |

| KTE-50D | 50.5 | 1.55 | 300~800 | 75~90 | 2X860 | 100~300 |

| KTE-52B | 51.4 | 1.58 | 500~600 | 55~75 | 2X720 | 80~200 |

| KTE-52D | 51.4 | 1.58 | 500~600 | 75~110 | 2X1050 | 100~400 |

| KTE-65B | 62.4 | 1.55 | 500~600 | 90~110 | 2X860 | 200~450 |

| KTE-65D | 62.4 | 1.55 | 300~800 | 132~160 | 2X1530 | 350~600 |

| KTE-75B | 71 | 1.51 | 500~600 | 132~160 | 2X1530 | 300~800 |

| KTE-75D | 71 | 1.51 | 300~800 | 200~315 | 2X2100 | 500~1000 |

| KTE-85B | 85 | 1.54 | 500~600 | 220~315 | 2X2100 | 550~1000 |

| KTE-95B | 93 | 1.52 | 500~600 | 250~315 | 2X3000 | 800~1500 |

| KTE-95D | 93 | 1.52 | 500~800 | 315~500 | 2X4800 | 1000~2000 |

| KTE-135B | 135 | 1.55 | 500~600 | 315~500 | 2X4800 | 1500~3000 |

| KTE-135D | 135 | 1.55 | 500~800 | 500~1000 | 2X7800 | 1500~4000 |

Key Features of Kerke's Twin Screw Extruders

1. Advanced Technology and Innovation: Kerke's twin screw extruders incorporate the latest technological advancements, ensuring they meet current industry standards and set new benchmarks for performance and reliability. These machines are designed to handle a wide range of materials, including plastics, rubber, and food products[1].

2. Superior Mixing and Homogenization: The co-rotating twin-screw design provides exceptional mixing and homogenization capabilities, ensuring consistent and uniform output. This is crucial for applications where product quality and consistency are paramount[1].

3. Energy Efficiency and Cost-Effectiveness: Kerke's extruders are engineered to be energy efficient, reducing operational costs and minimizing environmental impact. They achieve high throughput rates while consuming less energy, aligning with sustainable manufacturing practices[1].

4. Versatility and Customization: Kerke offers customizable solutions tailored to specific production needs. Their extruders can be configured with different screw elements, barrel designs, and auxiliary equipment to adapt to various applications[1][2].

5. Robust Construction and Durability: The machines are constructed with high-quality materials and components, ensuring long-term reliability and reduced downtime. This robust construction allows them to withstand demanding production conditions[1].

6. Comprehensive Support and Service: Kerke provides exceptional customer service and support, from initial consultation and installation to ongoing maintenance and technical assistance. This commitment helps maintain optimal machine performance and addresses any issues promptly[1].

Applications of Kerke's Twin Screw Extruders

Kerke's twin screw extruders are used in a variety of applications:

- Color Masterbatch: Used for producing color masterbatches that enhance the color consistency and vibrancy of final products[1][5].

- Filler Masterbatch: Designed for creating filler masterbatches that improve the physical properties of plastics[1][5].

- Engineering Plastics: Suitable for compounding engineering plastics that require high strength and durability[1][5].

- Biodegradable Plastics: Used in the production of biodegradable plastics, contributing to sustainable manufacturing practices[1][5].

- TPU/EVA Elastomers: Ideal for processing thermoplastic polyurethane (TPU) and ethylene-vinyl acetate (EVA) elastomers[1][5].

- Food Industry: Can be applied in the food industry for processing and extruding food products[5].

Auxiliary Equipment and Services

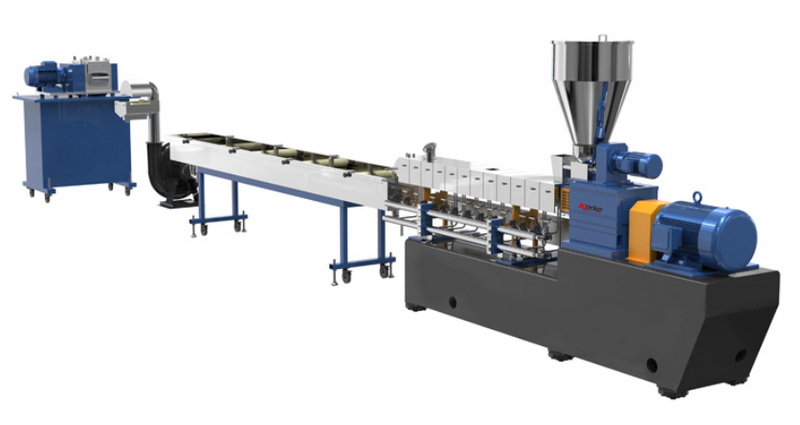

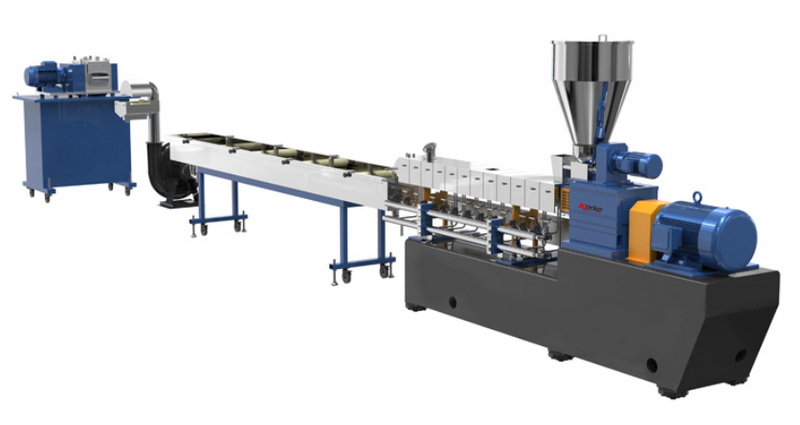

Kerke provides a range of auxiliary equipment to support their twin screw extruders, including high-speed mixers, plastic granulators, pulverizers, and water chillers. They also offer comprehensive services such as installation, training, and maintenance support[2][3].

Kerke Extrusion Equipment in Action

To better understand how Kerke's twin screw extruders operate and their applications, let's look at some examples:

Conclusion

Kerke Extrusion Equipment Co., Ltd. stands out in the twin screw extruder market due to its commitment to innovation, quality, and customer satisfaction. Their machines offer superior mixing capabilities, energy efficiency, and customization options, making them ideal for various industrial applications. With a strong focus on customer support and a wide range of auxiliary equipment, Kerke continues to be a preferred choice for businesses seeking reliable and efficient compounding solutions.

FAQs

1. What are the primary applications of Kerke's twin screw extruders?

Kerke's twin screw extruders are primarily used for compounding and masterbatch production, including color masterbatches, filler masterbatches, engineering plastics, biodegradable plastics, and TPU/EVA elastomers[1][5].

2. What makes Kerke's twin screw extruders energy efficient?

Kerke's extruders are designed with advanced screw designs and optimized processing parameters to achieve high throughput rates while consuming less energy, aligning with sustainable manufacturing practices[1].

3. How does Kerke support its customers?

Kerke provides comprehensive customer support, including initial consultation, installation, ongoing maintenance, and technical assistance to ensure optimal machine performance and address any issues promptly[1].

4. Can Kerke's twin screw extruders be customized?

Yes, Kerke offers customizable solutions tailored to specific production needs. Their extruders can be configured with different screw elements, barrel designs, and auxiliary equipment[1][2].

5. What certifications do Kerke's products hold?

Kerke's products are certified by CE, SGS, Bureau Veritas, and TUV Rheinland, ensuring they meet international quality standards[6].

Citations:

[1] https://www.kerkeextruder.com/products/compounding/kte-series-twin-screw-extruder/

[2] https://www.kerkeextruder.com

[3] https://www.wanplas.com/group-factory/kerke-factory/

[4] https://www.linkedin.com/pulse/plastic-extruder-tips-7-twin-screw-design-function-kerke-extruder

[5] https://www.kerkepm.com/products/co-rotating-twin-screw-extruder/

[6] https://www.kerkepm.com

[7] https://www.kerkeextruder.com/contact/

[8] https://bbb.edouniversity.edu.ng/23340283/remain/protect/rush/compounding+in+co+rotating+twin+screw+extruders.pdf

[9] https://kerkeextrusion.en.made-in-china.com

[10] https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300047685?opendocument&ln=en

[11] https://www.plastemart.com/used-50-mm-kerke-twin-screw-extruder-europe/21625/um

[12] https://www.chinaplasonline.com/eMarketplace/exhibitorinfo/eng/Nanjing_Kerke_Extrusion_Equipment_Co,Ltd?compid=1007511

[13] https://www.alibaba.com/product-detail/Kerke-KTE-36-Co-rotating-twin_60147007888.html

[14] https://www.tradekey.com/product-free/Twin-screw-Extruder-1832009.html

[15] https://www.youtube.com/watch?v=jqxzawognNo

[16] https://www.youtube.com/@Kerkeextruderequipment

[17] https://www.alibaba.com/product-detail/KTE-75B-Twin-Screw-Extruder-Recycle_60286931710.html

[18] https://www.kerkepm.com/products/laboratory-twin-screw-extruder/

[19] https://www.youtube.com/@kerke

[20] https://www.youtube.com/watch?v=tDZ56iakizA

[21] https://www.kerkeextruder.com/products/kneader-extruder/

[22] https://www.kerkeextruder.com/fr/about-us/videos/

[23] https://www.youtube.com/c/Kerkeextruderequipment