Content Menu

● Introduction to Jwell Extrusion Machinery

>> Production Bases and Global Reach

● Key Features of Jwell Extrusion Machinery

>> Technological Advancements

>>> Twin-Screw Extruders

>>> Multi-Screw Extruders

>> Product Range

>> Customer Support

● Applications of Jwell Extrusion Machinery

>> Automotive

>> Medical

>> Building Materials

>> Packaging

● Technological Innovations

● Quality Certifications and Standards

● Conclusion

● FAQ

>> 1. What Types of Extrusion Lines Does Jwell Offer?

>> 2. What Are the Key Features of Jwell's Twin-Screw Extruders?

>> 3. How Does Jwell Support Its Customers Globally?

>> 4. What Quality Certifications Does Jwell Machinery Hold?

>> 5. How Long Does It Take for Jwell to Deliver Their Machinery?

● Citations:

Jwell Extrusion Machinery, a leading manufacturer in China, specializes in producing high-quality plastic extrusion lines for various industries. With over four decades of experience, Jwell has become a premier supplier of extrusion machinery globally. This article will delve into the key features of Jwell extrusion machinery, highlighting its technological advancements, product range, and customer support.

Introduction to Jwell Extrusion Machinery

Jwell Machinery was founded in 1997, building on the legacy of Jinhailuo, China's first screw and barrel manufacturer established in 1978. Today, Jwell operates multiple production bases across China and Thailand, employing over 3000 staff, including 300 design and test engineers. The company's commitment to innovation and quality has earned it a strong reputation in the global market.

Production Bases and Global Reach

Jwell's manufacturing facilities are strategically located in Shanghai, Suzhou, Changzhou, Zhejiang, and Dongguan, China, as well as in Thailand. This extensive network enables Jwell to serve customers worldwide efficiently. Their products have been exported to over 120 countries, including India, Korea, Thailand, Indonesia, Iran, Turkey, Egypt, Syria, Argentina, and Italy.

Jwell's global presence is supported by its strong research and development capabilities. The company continuously invests in technological innovation, enhancing its products to meet evolving market demands. This focus on R&D ensures that Jwell remains at the forefront of the plastic extrusion industry.

Key Features of Jwell Extrusion Machinery

Technological Advancements

Jwell extrusion machinery incorporates advanced technology to ensure high-quality production. Their machines are designed with European standards and utilize components from renowned brands like Siemens, Schneider, and ABB. This integration enhances the efficiency and reliability of their extrusion lines.

Twin-Screw Extruders

Jwell's twin-screw extruders are particularly notable for their forced extrusion capabilities, offering high-quality output with wide adaptability. These machines are ideal for processing materials with poor thermal stability and provide excellent mixing, exhaust, and self-cleaning functions. The twin-screw design allows for better heat management and material handling compared to single-screw extruders, making them suitable for complex plastic formulations.

Multi-Screw Extruders

In addition to twin-screw extruders, Jwell also offers multi-screw extruders for more complex applications. These machines are designed to handle blends with poor thermal stability, providing superior mixing and processing capabilities.

Product Range

Jwell offers a diverse range of extrusion lines catering to various industries:

- PVC Profile Production Lines: These lines are designed for producing PVC profiles with high precision and efficiency. Models like SJZ55/110 and SJZ65/132 are popular choices, offering capacities of up to 180 kg/h.

| Type | Max. Width of Product (mm) | Extruder Model | Max. Extrusion Capacity (kg/h) |

| YF108 | 108 | SJZ55/110 | 110 |

| YF240 | 240 | SJZ65/132 | 180 |

- PS Plastic Foamed Picture Frame Extrusion Line: This line combines a single screw extruder with a special co-extruder, featuring imported ABB AC inverter control for stable performance.

| Model | Extruder | Co-extruder | Products Width |

| YF1 | JWS65 | JWS35 | 3 inch |

| YF2 | JWS90 | JWS45 | 4 inch |

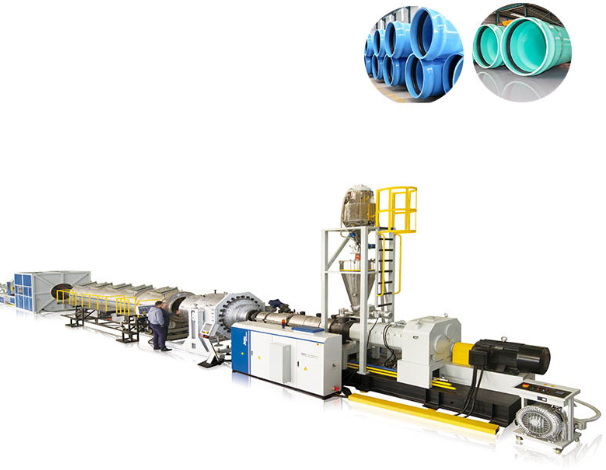

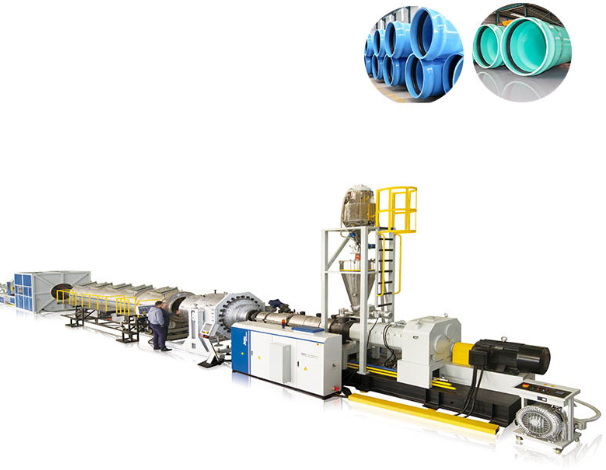

- Pipe Extrusion Machines: Jwell's pipe extrusion machines are designed for high yield and low energy consumption, suitable for producing PP, PVC, ABS, and composite pipes.

- Polymer Composite Waterproof Roll Extrusion Line: This line is designed for producing multi-layer waterproof coils with various materials and structures. It features a five-roll calendering machine, capable of handling PVC, TPO, PE, and other materials.

Customer Support

Jwell provides comprehensive after-sales support, including installation, training, and maintenance services. Their technical team is available worldwide to ensure prompt solutions to any operational issues. This commitment to customer satisfaction has earned Jwell a loyal client base across the globe.

Applications of Jwell Extrusion Machinery

Jwell's plastic extrusion lines are widely used in various industries:

Automotive

Jwell cooperates with many well-known automobile manufacturers, providing flexible and efficient plastic extrusion production lines. Their equipment helps customers achieve significant improvements in production efficiency and meets the automotive industry's stringent requirements for product quality and production efficiency.

Medical

In the medical industry, Jwell's plastic extrusion production lines are used for producing medical pipes, packaging materials, and other medical products. These lines provide reliable production solutions, ensuring high-quality output that meets medical standards.

Building Materials

Jwell's extrusion lines are also used in the building materials industry, offering efficient and reliable production solutions for various building materials, pipes, and decorative materials.

Packaging

For the plastic packaging industry, Jwell provides customized extrusion production line solutions. From ordinary packaging materials to high-tech special packaging products, they support customers in achieving innovative and sustainable production processes.

Technological Innovations

Jwell continuously invests in research and development, focusing on technological innovations that enhance the performance and efficiency of their extrusion machinery. This includes developing specialized equipment like the CJWS 75 Plus, designed for high-end customers seeking higher quality and stronger performance.

The CJWS 75 Plus features advanced components such as a domestic ultra-high torque transmission box or an original imported transmission box, ensuring low energy consumption and high production capabilities. The screw material is made from WR5PM + HIP (powder metallurgy hot isostatic pressing technology), providing superior durability and performance.

Quality Certifications and Standards

Jwell machinery adheres to CE certification and IS09001 quality management system standards. This ensures that all products meet international quality requirements, providing customers with reliable and efficient extrusion solutions.

Conclusion

Jwell extrusion machinery stands out in the industry due to its technological advancements, diverse product range, and commitment to customer satisfaction. With a strong global presence and adherence to international quality standards, Jwell continues to be a reliable partner for businesses seeking high-quality extrusion solutions.

FAQ

1. What Types of Extrusion Lines Does Jwell Offer?

Jwell offers a wide range of extrusion lines, including PVC profile production lines, PS plastic foamed picture frame extrusion lines, pipe extrusion machines, and more. These lines cater to various industries such as construction, packaging, and consumer goods.

2. What Are the Key Features of Jwell's Twin-Screw Extruders?

Jwell's twin-screw extruders are known for their forced extrusion capabilities, providing high-quality output with wide adaptability. They offer excellent mixing, exhaust, and self-cleaning functions, making them ideal for processing materials with poor thermal stability.

3. How Does Jwell Support Its Customers Globally?

Jwell provides comprehensive after-sales support, including installation, training, and maintenance services. Their technical team is available worldwide to ensure prompt solutions to any operational issues, ensuring smooth production for their customers.

4. What Quality Certifications Does Jwell Machinery Hold?

Jwell machinery adheres to CE certification and IS09001 quality management system standards. This ensures that all products meet international quality requirements, providing customers with reliable and efficient extrusion solutions.

5. How Long Does It Take for Jwell to Deliver Their Machinery?

The delivery time for Jwell's machinery varies depending on the type of production line. For profile and pipe production lines, the normal delivery time is 40-70 days. For sheet and plate production lines, it typically ranges from 90-120 days.

Citations:

[1] https://www.sourcifychina.com/plastic-extrusion-machine-guide-in-depth/

[2] https://www.jwellextrusions.com/research-development.html

[3] http://en.czjwell.com/newsinfo/3.html

[4] https://www.jwellmachine.com

[5] https://www.jwellmachine.com/application/

[6] https://www.jwellmachineryglobal.com

[7] https://www.jwellextrusions.com

[8] https://www.jwell-group.com/application/Jwell-extrusion-machinery

[9] https://www.jwellplate.com/service/

[10] https://www.jwellmachine.com/development-and-breakthrough-of-china-plastic-extrusion-machine/

[11] https://www.jwellplas.com/Importance-Of-Jwell-Extrusion-Machinery-In-Manufacturing.html

[12] https://www.jwellextrusions.com/video/jwell-machinerys-10-sheet-extrusion-lines-are-sent-to-the-middle-east-to-accurately-meet-the-diverse-needs-of-customers-combining-innovation-and-efficiency.html

[13] https://www.jwellmachine.com/npe-2024%EF%BD%9Cjwell-embraces-the-times-and-intersects-with-the-world/

[14] https://www.jwellmachine.com/es/what-is-a-pvc-panel-extrusion-line/

[15] https://hk.linkedin.com/company/jwell-extrusion-machinery-co-ltd

[16] https://www.jwellextrusions.com/video/jwell-product-series.html

[17] https://www.jwellextrusion.com/application/pp-sheet-extrusion-machine

[18] https://www.jwellmachine.com/analysis-of-plastic-extrusion-technology/

[19] https://www.linkedin.com/pulse/who-helped-jwell-machinery-rank-no1-chinas-plastic-10-lily-xu

[20] https://www.jwellplas.com/Why-Choose-High-Performance-Jwell-Extrusion-Machinery.html

[21] https://www.jwellextrusion.com/application/best-extrusion-machine

[22] https://www.jwell-machinery.com

[23] https://www.jwellmachine.com/product/

[24] https://jwellmachine.en.made-in-china.com

[25] https://jwellmachinery.en.made-in-china.com/product/xymnXDbAgBch/China-Jwell-HDPE-Plastic-Plate-Recycling-Making-Extrusion-Machine-for-Automobile-Application-Series-7-.html

[26] https://www.alibaba.com/showroom/jwell-extrusion-machinery.html

[27] https://www.jwellmachine.com/china-extruder-machine-knowledge-introduction/

[28] https://jwellmachinery.en.made-in-china.com/product/SCnQTMcEJBkf/China-Jwell-PVB-Plastic-Film-Recycling-Agricultural-Making-Extrusion-Machine-for-Automobile-Application-Series-3-.html

[29] https://www.jwellplate.com

[30] https://www.jwell-industry.com/solutions/profile-extrusion/industry-and-application/

[31] https://jwellmachine.en.made-in-china.com/product-list-1.html

[32] http://en.szjwell.cn/p-contact.html

[33] https://www.jwell.cn/en/contents/156/491.html

[34] https://www.jwellextrusions.com/after-sale-service.html

[35] https://www.jwellfactory.com

[36] https://www.jwellextrusions.com/services/

[37] https://www.jwellplast.com/after_sales.html

[38] https://www.jwellmech.com/service.html

[39] https://www.jwellmachine.com/contact-us/

[40] https://jwell1.goldsupplier.com

[41] https://www.jwell-machinery.com/contact/

[42] https://www.bloomberg.com/profile/company/8021534Z:CH

[43] https://www.jwellextrusions.com/twentyfive-years-of-turbulencejwell-builds-dreams-for-the-future.html

[44] https://www.jwellmachine.com/what-is-an-extruder-how-to-set-up-an-extruder/

[45] https://www.jwellplate.com/solution/hdpe-pipe-extrusion-machine/

[46] https://www.jwellextrusions.com/products/extrusion-line/

[47] https://www.machinepoint.com/machinepoint/inventory.nsf/bybrand?openform&cat_brand=jwell&ln=en

[48] https://www.jwellworld.com

[49] https://www.jwellextrusions.com/extrusion-application/

[50] https://www.jwellmachine.com/jwell-machinery-casting-machine-shutdown-and-maintenance-guide/

[51] https://www.jwell-industry.com/contact-us/

[52] https://www.jwellzj.com/en_contact.asp

[53] https://www.jwellextrusions.com/contact/