Content Menu

● The Evolution of Cereal Extrusion Technology

>> From Single to Twin Screw Extruders

>> Precision Control Systems

● Key Features of Advanced Cereal Extrusion Machinery

>> 1. Versatility in Raw Material Processing

>> 2. Energy Efficiency

>> 3. Customizable Die Designs

>> 4. Integrated Fortification Systems

>> 5. High-Temperature Short-Time (HTST) Processing

>> 6. Modular Design for Flexibility

>> 7. Enhanced Sanitation Features

>> 8. Automated Process Control

>> 9. Real-Time Monitoring and Data Analytics

>> 10. Sustainability Features

● The Impact on Product Quality and Innovation

>> Texture and Sensory Experience

>> Nutritional Enhancement

>> Product Innovation

● Challenges and Future Developments

>> Energy Optimization

>> Material Science Advancements

>> AI and Machine Learning Integration

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is cereal extrusion machinery?

>> 2. How does twin screw extrusion improve cereal production?

>> 3. Can cereal extrusion machinery process gluten-free ingredients?

>> 4. What role does automation play in cereal extrusion processes?

>> 5. How does cereal extrusion machinery contribute to product innovation?

● Citations:

In the ever-evolving world of food processing, cereal extrusion machinery has become a cornerstone of the breakfast cereal industry. This advanced technology has revolutionized the way we produce and consume our favorite morning staples. From corn flakes to puffed rice, the versatility and efficiency of cereal extrusion machinery have made it an indispensable tool for manufacturers worldwide. In this comprehensive exploration, we'll delve into the key features that make modern cereal extrusion machinery a marvel of engineering and a game-changer in food production.

The Evolution of Cereal Extrusion Technology

Cereal extrusion technology has come a long way since its inception. What began as a simple process has evolved into a sophisticated system capable of producing a wide array of breakfast cereals with varying textures, shapes, and nutritional profiles. The journey of cereal extrusion machinery is a testament to human ingenuity and the constant drive for innovation in the food industry.

From Single to Twin Screw Extruders

One of the most significant advancements in cereal extrusion machinery has been the transition from single screw to twin screw extruders. Twin screw extruders offer superior mixing, kneading, and conveying characteristics, resulting in more consistent product quality[1]. This technology allows for better control over the extrusion process, leading to improved texture and flavor in the final product.

Precision Control Systems

Modern cereal extrusion machinery is equipped with advanced control systems that allow for precise manipulation of various parameters. These systems enable operators to fine-tune temperature, pressure, and screw speed, ensuring optimal processing conditions for each type of cereal product[2].

Key Features of Advanced Cereal Extrusion Machinery

1. Versatility in Raw Material Processing

One of the standout features of modern cereal extrusion machinery is its ability to handle a wide range of raw materials. From maize and wheat to rice and oats, these machines can process various grains and ingredients to create diverse breakfast cereal products[2]. This versatility allows manufacturers to expand their product lines and cater to different consumer preferences.

2. Energy Efficiency

Advanced cereal extrusion machinery is designed with energy efficiency in mind. These machines operate at relatively low moisture levels while cooking food products, reducing the need for extensive re-drying. This feature not only saves energy but also contributes to lower processing costs[1].

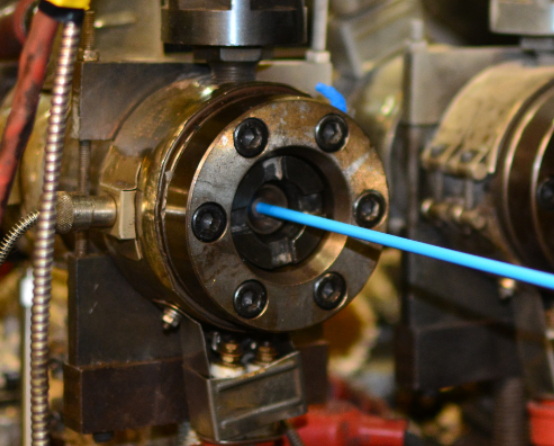

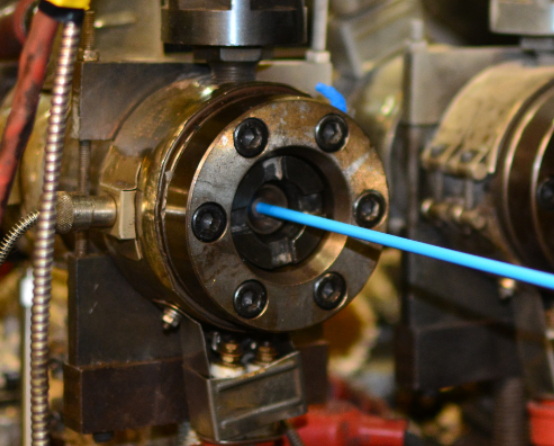

3. Customizable Die Designs

The die is a crucial component of cereal extrusion machinery, as it determines the final shape of the product. Modern extruders come with customizable die designs that allow for the creation of various shapes, from traditional flakes to fun and appealing forms that attract consumers[3].

4. Integrated Fortification Systems

Nutrition is a key concern for consumers, and cereal extrusion machinery has adapted to meet this demand. Many advanced systems now include integrated fortification capabilities, allowing for the seamless addition of vitamins, minerals, and other nutrients during the extrusion process[4].

5. High-Temperature Short-Time (HTST) Processing

HTST processing is a hallmark of modern cereal extrusion machinery. This technique allows for rapid cooking at high temperatures, which not only ensures food safety but also helps preserve heat-sensitive nutrients. The short processing times minimize nutrient losses, particularly for vitamins and minerals[3].

6. Modular Design for Flexibility

Advanced cereal extrusion machinery often features a modular design, allowing for easy customization and upgrades. This flexibility enables manufacturers to adapt their production lines to changing market demands without the need for complete system overhauls[4].

7. Enhanced Sanitation Features

Food safety is paramount in cereal production. Modern extrusion machinery incorporates enhanced sanitation features, such as easy-to-clean surfaces and CIP (Clean-in-Place) systems, ensuring that hygiene standards are consistently met[2].

8. Automated Process Control

Automation is at the heart of advanced cereal extrusion machinery. From raw material handling to final product packaging, these systems can be fully automated, reducing labor costs and minimizing human error[5].

9. Real-Time Monitoring and Data Analytics

The integration of IoT (Internet of Things) technology allows for real-time monitoring of the extrusion process. Advanced sensors collect data on various parameters, which can be analyzed to optimize production and ensure consistent quality[4].

10. Sustainability Features

As environmental concerns grow, cereal extrusion machinery manufacturers are incorporating sustainability features into their designs. These may include reduced water consumption, improved energy efficiency, and the ability to process sustainable ingredients[5].

The Impact on Product Quality and Innovation

The advanced features of modern cereal extrusion machinery have a profound impact on product quality and innovation in the breakfast cereal industry.

Texture and Sensory Experience

The precise control offered by advanced extruders allows manufacturers to create cereals with a wide range of textures, from crunchy to crispy to airy. This versatility enhances the sensory experience for consumers, leading to more enjoyable and satisfying breakfast options[1].

Nutritional Enhancement

With integrated fortification systems and the ability to preserve heat-sensitive nutrients, cereal extrusion machinery plays a crucial role in enhancing the nutritional profile of breakfast cereals. This aligns with consumer demand for healthier food options and allows manufacturers to create products that cater to specific dietary needs[3].

Product Innovation

The flexibility and customization options offered by modern cereal extrusion machinery open up new avenues for product innovation. Manufacturers can experiment with novel ingredients, unique shapes, and exciting flavor combinations, keeping their product lines fresh and appealing to consumers[2].

Challenges and Future Developments

While cereal extrusion machinery has come a long way, there are still challenges to overcome and exciting developments on the horizon.

Energy Optimization

Despite improvements in energy efficiency, there is ongoing research to further optimize energy consumption in cereal extrusion processes. Future machinery may incorporate even more advanced energy recovery systems and alternative power sources[4].

Material Science Advancements

As new, sustainable ingredients enter the market, cereal extrusion machinery will need to adapt to process these materials effectively. This may lead to innovations in screw design and extrusion techniques[5].

AI and Machine Learning Integration

The future of cereal extrusion machinery is likely to see increased integration of artificial intelligence and machine learning. These technologies could enable predictive maintenance, further process optimization, and even autonomous operation of extrusion lines[4].

Conclusion

Advanced cereal extrusion machinery stands at the forefront of food processing technology, offering a myriad of features that enhance product quality, efficiency, and innovation in the breakfast cereal industry. From twin screw extruders to integrated fortification systems, these machines have transformed the way we produce and consume cereals.

The key features of modern cereal extrusion machinery, including versatility in raw material processing, energy efficiency, customizable die designs, and advanced control systems, have enabled manufacturers to meet the ever-changing demands of consumers. As we look to the future, continued advancements in this technology promise even greater possibilities for nutritious, sustainable, and exciting breakfast options.

As the industry continues to evolve, cereal extrusion machinery will undoubtedly play a pivotal role in shaping the breakfast tables of tomorrow. With ongoing research and development, we can expect to see even more innovative features that will further revolutionize cereal production and contribute to a healthier, more diverse food landscape.

Frequently Asked Questions (FAQ)

1. What is cereal extrusion machinery?

Cereal extrusion machinery refers to the specialized equipment used in the food processing industry to produce breakfast cereals and snacks. These machines use a combination of heat, pressure, and mechanical shear to cook, shape, and texturize cereal ingredients into various forms such as flakes, puffs, and shapes.

2. How does twin screw extrusion improve cereal production?

Twin screw extrusion offers several advantages in cereal production, including better mixing and kneading capabilities, more precise control over processing parameters, and the ability to handle a wider range of ingredients. This results in improved product consistency, texture, and flavor, as well as increased production efficiency.

3. Can cereal extrusion machinery process gluten-free ingredients?

Yes, modern cereal extrusion machinery is capable of processing a wide variety of ingredients, including gluten-free options. Many manufacturers now offer dedicated gluten-free production lines that use specialized extrusion equipment designed to prevent cross-contamination and ensure the safety of gluten-free products.

4. What role does automation play in cereal extrusion processes?

Automation plays a crucial role in modern cereal extrusion processes. It helps maintain consistent product quality, reduces labor costs, and minimizes human error. Automated systems can control everything from ingredient dosing and mixing to extrusion parameters and packaging, ensuring efficient and reliable production.

5. How does cereal extrusion machinery contribute to product innovation?

Cereal extrusion machinery contributes to product innovation by offering flexibility in ingredient selection, customizable die designs for unique shapes, and the ability to create various textures. This versatility allows manufacturers to develop new and exciting cereal products that meet changing consumer preferences and dietary trends.

Citations:

[1] https://www.newfoodmagazine.com/article/2515/extrusion-of-cereals/

[2] https://www.eagleextruder.com/solutions/human-food-produciton-lines/breakfast-cereals-machine.html

[3] https://usetorg.com/blog/extruded-cereals

[4] https://www.buhlergroup.com/global/en/industries/Extrusion-solutions.html

[5] https://machine.goldsupplier.com/blog/corn-flakes-extrusion-technology/

[6] https://en.engormix.com/feed-machinery/extrusion/why-food-technology-extrusion_a54524/

[7] https://fstjournal.com.br/revista/article/view/44

[8] https://www.youtube.com/watch?v=R6KkTy6TPVo

[9] https://dayimachine.en.made-in-china.com/product/aSvJhEeTsMpu/China-High-Quality-Extruded-Crispy-Sweet-Corn-Flakes-Snack-Machine.html

[10] https://www.youtube.com/watch?v=jpwS9DnHWJs

[11] https://www.youtube.com/watch?v=sod2fxPAS7I

[12] https://www.businesswire.com/news/home/20120308006060/en/Research-and-Markets-Extrusion-Problems-Solved-Food-Pet-Food-and-Feed

[13] https://www.linkedin.com/pulse/common-problems-use-extruder-amisy-fish

[14] https://engitech.in/extrusion-machines-and-extruders-guide/

[15] https://www.eagleextruder.com/product/extruders/twin-screw-extruder.html

[16] https://www.mdpi.com/2076-2615/14/21/3144

[17] https://www.clextral.com/our-offer/

[18] https://m.loyalfoodmachine.com/news-3029-the-ultimate-guide-to-breakfast-cereal-manufacturing-equipment-in-2024.html

[19] https://www.youtube.com/watch?v=DdgPnnS4cyI

[20] https://www.foodextrusion.de/en/breakfast-cereals

[21] https://www.shutterstock.com/search/food-extruders

[22] https://www.youtube.com/watch?v=isurfvU044Q

[23] https://www.youtube.com/watch?v=gBEPYN3oXxk

[24] https://zirveextrusion.com/en/

[25] https://www.youtube.com/watch?v=TiaCrn23g1k

[26] https://dl.ojocv.gov.et/admin_/ttlm_/M12-Extrusion.pdf

[27] https://making.com/products/breakfast-cereal/extrusion

[28] https://www.andritz.com/resource/blob/325242/bb534737f6e6b9cf2a833d92724d6b30/sh-ffs-extruder-feed-and-biofuel-data.pdf

[29] https://making.com/extruded-cereals

[30] https://www.foodmachineryint.com/everything-you-need-to-know-about-breakfast-cereal-making-machine-equipment/

[31] https://www.eagleextruder.com/blog/how-do-you-manufacture-corn-flakes-from-extruder.html

[32] https://machine.goldsupplier.com/blog/food-extruder/