Content Menu

● Introduction

● Understanding 4040 Aluminum Extrusion Dimensions

>> Key Features of 4040 Aluminum Extrusion Dimensions

>> Comparison with Other Common Extrusion Sizes

● Applications of 4040 Aluminum Extrusion

>> Robotics

>> 3D Printing

>> Machine Guarding

>> Workstations and Assembly Lines

>> Display and Signage

● Benefits of Using 4040 Aluminum Extrusion

>> Strength and Durability

>> Easy Assembly and Customization

>> Cost-Effectiveness

>> Aesthetic Appeal

● Choosing the Right Supplier for 4040 Aluminum Extrusion

>> Quality Assurance

>> Customization Options

>> Customer Support

>> Reputation and Reviews

>> Pricing and Lead Times

● Conclusion

● Related Questions

>> 1. What are the standard lengths available for 4040 aluminum extrusion?

>> 2. Can 4040 aluminum extrusion be used for outdoor applications?

>> 3. How do I cut 4040 aluminum extrusion to the desired length?

>> 4. What types of fasteners are compatible with 4040 aluminum extrusion?

>> 5. Is it possible to connect 4040 aluminum extrusion with other sizes?

Introduction

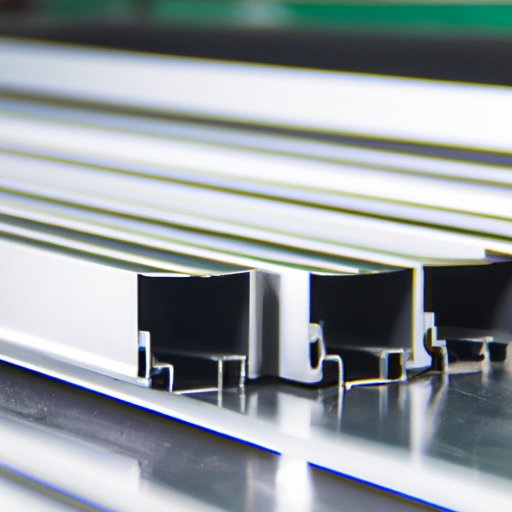

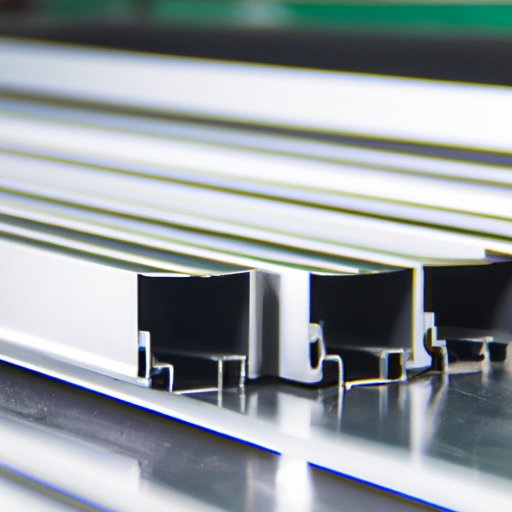

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to its versatility, strength, and lightweight properties. Among the many profiles available, the 4040 aluminum extrusion stands out for its unique dimensions and applications. This article will delve into the key dimensions of 4040 aluminum extrusion, its applications, benefits, and how to choose the right supplier.

Understanding 4040 Aluminum Extrusion Dimensions

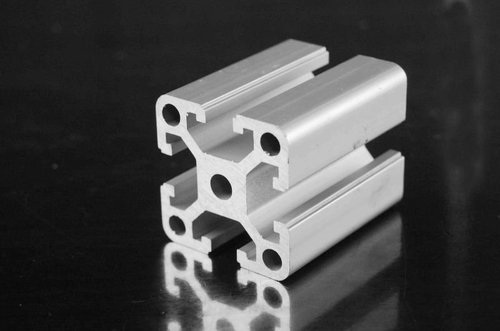

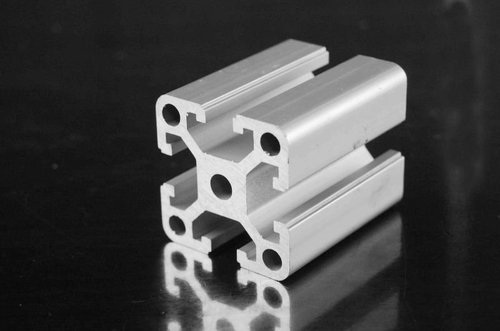

The term "4040" refers to the dimensions of the aluminum extrusion, specifically 40mm x 40mm. This square profile is characterized by its equal width and height, making it a popular choice for various structural applications. The dimensions of 4040 aluminum extrusion are crucial for ensuring compatibility with other components in a project.

Key Features of 4040 Aluminum Extrusion Dimensions

1. Cross-Sectional Area: The 4040 aluminum extrusion has a cross-sectional area of 1600 mm², which provides a good balance between strength and weight. This area is significant for load-bearing applications, ensuring that the structure can support the necessary weight without compromising stability.

2. Wall Thickness: The standard wall thickness of 4040 aluminum extrusion is typically around 3mm. This thickness contributes to the overall strength of the profile while keeping it lightweight. Variations in wall thickness can be customized based on specific project requirements.

3. T-Slot Design: One of the defining features of 4040 aluminum extrusion is its T-slot design. This design allows for easy assembly and disassembly of structures, making it ideal for modular systems. The T-slots enable the attachment of various components, such as brackets, panels, and other extrusions, without the need for complex fasteners.

4. Length Options: 4040 aluminum extrusions are available in various lengths, typically ranging from 1 meter to 6 meters. This flexibility allows for customization based on project needs, reducing waste and ensuring that the right amount of material is used.

5. Surface Finish: The surface finish of 4040 aluminum extrusion can vary, with options including mill finish, anodized, and powder-coated. Anodizing enhances corrosion resistance and provides a decorative finish, while powder coating offers a wide range of colors and additional protection.

Comparison with Other Common Extrusion Sizes

While 4040 aluminum extrusion is popular, it is essential to compare it with other common sizes, such as 2020 and 8020. The 2020 aluminum extrusion has dimensions of 20mm x 20mm, making it suitable for lighter applications, while the 8020 aluminum extrusion, measuring 80mm x 80mm, is designed for heavier loads. The choice between these profiles depends on the specific requirements of the project, including load capacity, space constraints, and assembly complexity.

Applications of 4040 Aluminum Extrusion

The versatility of 4040 aluminum extrusion makes it suitable for a wide range of applications across various industries. Here are some common uses:

Robotics

In the robotics industry, 4040 aluminum extrusion is often used to create frames and structures for robotic arms and mobile robots. Its lightweight nature allows for easy movement, while the strength ensures stability during operation. The T-slot design facilitates the attachment of motors, sensors, and other components, enabling quick modifications and upgrades.

3D Printing

The 4040 aluminum extrusion is a popular choice for building frames for 3D printers. Its dimensions provide a sturdy base that can support the weight of the printer components while allowing for precise alignment. Additionally, the modularity of the T-slot design enables users to customize their printer setups easily.

Machine Guarding

In manufacturing environments, 4040 aluminum extrusion is frequently used to create machine guarding systems. These systems protect operators from moving parts and hazardous areas while maintaining visibility. The ability to customize the height and configuration of the guarding using 4040 extrusions ensures compliance with safety regulations.

Workstations and Assembly Lines

Many companies utilize 4040 aluminum extrusion to build workstations and assembly lines. The modular nature of the T-slot design allows for easy reconfiguration as production needs change. This adaptability is crucial in modern manufacturing environments, where efficiency and flexibility are paramount.

Display and Signage

The aesthetic appeal of anodized or powder-coated 4040 aluminum extrusion makes it an excellent choice for display and signage applications. Retailers often use these extrusions to create attractive displays that can be easily modified or expanded as needed.

Benefits of Using 4040 Aluminum Extrusion

The advantages of using 4040 aluminum extrusion are numerous, making it a preferred choice for many applications.

Strength and Durability

Aluminum is known for its strength-to-weight ratio, and 4040 aluminum extrusion is no exception. The profile can withstand significant loads while remaining lightweight, making it ideal for structural applications. Additionally, aluminum's natural resistance to corrosion ensures that the extrusion will maintain its integrity over time.

Easy Assembly and Customization

The T-slot design of 4040 aluminum extrusion allows for quick and easy assembly. Users can connect multiple extrusions using simple fasteners, eliminating the need for complex welding or machining. This ease of assembly also enables rapid prototyping and modifications, which is essential in fast-paced industries.

Cost-Effectiveness

Using 4040 aluminum extrusion can be cost-effective in the long run. The ability to customize lengths and configurations reduces material waste, while the durability of aluminum minimizes maintenance and replacement costs. Additionally, the lightweight nature of the material can lead to savings in shipping and handling.

Aesthetic Appeal

The various surface finishes available for 4040 aluminum extrusion enhance its aesthetic appeal. Anodized and powder-coated options provide a professional look that is suitable for both industrial and commercial applications. This versatility allows users to create visually appealing structures without sacrificing functionality.

Choosing the Right Supplier for 4040 Aluminum Extrusion

Selecting a reliable supplier for 4040 aluminum extrusion is crucial for ensuring quality and consistency in your projects. Here are some tips for choosing the right supplier:

Quality Assurance

Look for suppliers that adhere to strict quality control standards. Certifications such as ISO 9001 indicate that the supplier has implemented quality management systems to ensure consistent product quality.

Customization Options

Choose a supplier that offers customization options for dimensions, wall thickness, and surface finishes. This flexibility allows you to tailor the extrusions to meet your specific project requirements.

Customer Support

A good supplier should provide excellent customer support, including technical assistance and guidance on product selection. This support can be invaluable, especially for complex projects.

Reputation and Reviews

Research the supplier's reputation in the industry by reading customer reviews and testimonials. A supplier with a strong track record of delivering quality products and services is more likely to meet your expectations.

Pricing and Lead Times

Compare pricing and lead times among different suppliers. While cost is an important factor, it should not be the sole consideration. Ensure that you are getting a good balance of quality and price.

Conclusion

In conclusion, understanding the key dimensions of 4040 aluminum extrusion is essential for anyone involved in design and manufacturing. Its unique dimensions, combined with the benefits of strength, durability, and ease of assembly, make it a popular choice across various industries. Whether you are building a robotic frame, a workstation, or a display, 4040 aluminum extrusion offers the versatility and reliability needed for successful projects. By choosing the right supplier, you can ensure that your projects are completed efficiently and to the highest standards.

Related Questions

1. What are the standard lengths available for 4040 aluminum extrusion?

The standard lengths for 4040 aluminum extrusion typically range from 1 meter to 6 meters, allowing for customization based on project needs.

2. Can 4040 aluminum extrusion be used for outdoor applications?

Yes, 4040 aluminum extrusion can be used for outdoor applications, especially when anodized or powder-coated to enhance corrosion resistance.

3. How do I cut 4040 aluminum extrusion to the desired length?

4040 aluminum extrusion can be cut using a miter saw or a band saw with a suitable blade for aluminum. Ensure to measure accurately before cutting.

4. What types of fasteners are compatible with 4040 aluminum extrusion?

Common fasteners used with 4040 aluminum extrusion include T-nuts, bolts, and screws designed for T-slot profiles, allowing for easy assembly and disassembly.

5. Is it possible to connect 4040 aluminum extrusion with other sizes?

Yes, 4040 aluminum extrusion can be connected with other sizes, such as 2020 or 8020, using appropriate connectors and brackets designed for T-slot profiles.