Content Menu

● Understanding the Aluminum Extrusion Process

● Key Components of an Aluminum Extrusion Press

● Essential Elements of an Aluminum Extrusion Press JSA

>> 1. Identification of Job Steps

>> 2. Identification of Potential Hazards

>> 3. Recommended Safe Job Procedures

>> 4. Required Personal Protective Equipment (PPE)

>> 5. Training Requirements

>> 6. Emergency Procedures

● Importance of Temperature Control in Aluminum Extrusion Press JSA

● Continuous Improvement of the Aluminum Extrusion Press JSA

● Conclusion

● FAQ

>> 1. What is the purpose of a Job Safety Analysis (JSA) for an aluminum extrusion press?

>> 2. How often should an aluminum extrusion press JSA be updated?

>> 3. What are some common hazards associated with aluminum extrusion press operations?

>> 4. Why is temperature control important in an aluminum extrusion press JSA?

>> 5. What role do workers play in the development and implementation of an aluminum extrusion press JSA?

● Citations:

Job Safety Analysis (JSA) is a crucial aspect of ensuring worker safety in the aluminum extrusion industry. When it comes to operating an aluminum extrusion press, understanding the key components of a JSA is essential for maintaining a safe work environment. This article will delve into the critical elements of an aluminum extrusion press JSA, exploring the various aspects that contribute to a comprehensive safety analysis.

Understanding the Aluminum Extrusion Process

Before we dive into the specifics of the JSA, it's important to have a clear understanding of the aluminum extrusion process. The process of extruding aluminum begins with a solid, cylindrical block, or billet of metal. It is heated until softened and then forced through a steel die to produce lightweight, strong and corrosion-resistant components that are shaped like the opening of the die.[4]

There are two conventional methods of extruding aluminum:

1. Direct extrusion: This is the most common method. The billet is placed in a stationary container while a hydraulic ram moves through to push it through the die opening. The aluminum flows in the same direction as the ram travels.

2. Indirect extrusion: In this method, the die stays in place while the aluminum billet and the container move in unison. The pressure of the ram forces the soft metal to flow through the die opening in the opposite direction of the ram. This is also called backwards extrusion.[4]

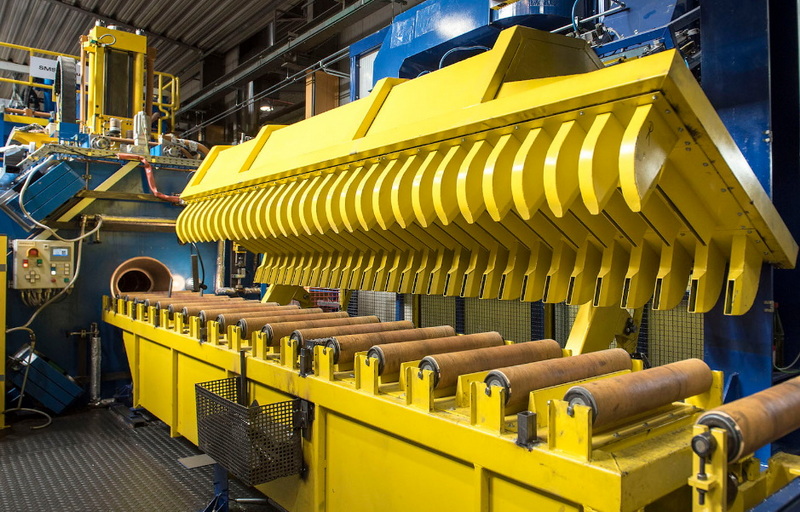

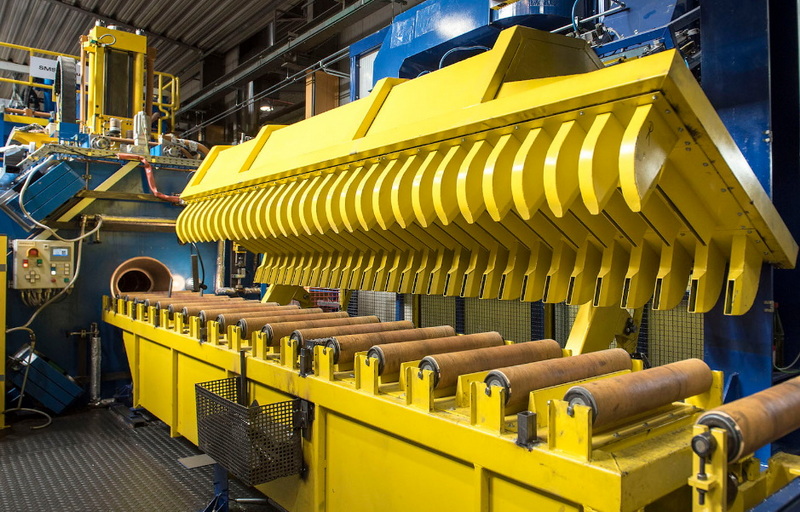

Key Components of an Aluminum Extrusion Press

To effectively create a JSA for an aluminum extrusion press, it's crucial to understand the main components of the equipment. The key parts of an aluminum extrusion press include:

1. Main Cylinder: Chamber and cylinder of an extrusion press into which hydraulic fluid is pumped to generate the desired ram pressure and movement.

2. Hydraulic Pressure: Pressure used to move the ram forward at the required Pounds per Square Inch.

3. Ram: A steel rod attached to the main cylinder with a dummy block on the end that enters the container and applies pressure to the billet.

4. Dummy Block: A tight fitting steel block attached to the ram stem on a press which seals the billet in the container and prevents metal from leaking backward.

5. Billet: Aluminum log cut to specific lengths which are fed into the press as extrusion materials.

6. Container: Holds the billet while it is being pushed into the extrusion press by the pressure from the ram.

7. Press Leadout Table: Table which supports extrusion between the die and run out table.

8. Run Out Table: Table at immediate exit of press leadout equipment which helps guide and support extrusions.

9. Back/Front Press Platen: The extrusion press consists of these two sections.

10. Tie Rods: Connects the back and front press platen.

11. Canister: Used to help guide the aluminum extrusions from the die.

12. Platen Pressure Ring[8]

Essential Elements of an Aluminum Extrusion Press JSA

Now that we understand the basic components and process of aluminum extrusion, let's explore the key elements that should be included in a comprehensive JSA for an aluminum extrusion press.

1. Identification of Job Steps

The first step in creating an effective aluminum extrusion press JSA is to break down the job into specific steps. This allows for a detailed analysis of each part of the process. Some key steps might include:

- Preheating the billet

- Loading the billet into the container

- Operating the hydraulic press

- Guiding the extruded profile along the runout table

- Quenching the extruded profile

For example, during the extrusion process:

1. As the alloy material fills the container, it is pressed against the extrusion die.

2. With continual pressure applied, the aluminum material is forced out through the opening(s) in the die.

3. It emerges from the die's opening in the shape of a fully-formed profile.

4. The extrusion is gripped by a puller, which guides it along the runout table at a speed that matches its exit from the press.

5. As it moves along the runout table, the profile is "quenched," or uniformly cooled by a water bath or by fans above the table.[6]

2. Identification of Potential Hazards

For each step identified, the JSA should list potential hazards that workers might face. Some common hazards in aluminum extrusion press operations include:

- Burns from hot metal or equipment

- Crushing injuries from moving press components

- Cuts from sharp edges on extruded profiles

- Slips and falls on wet surfaces near quenching areas

- Exposure to loud noise from machinery

3. Recommended Safe Job Procedures

After identifying potential hazards, the JSA should outline recommended safe job procedures to mitigate these risks. These procedures should be specific and actionable. For example:

- Wear appropriate Personal Protective Equipment (PPE) such as heat-resistant gloves, safety glasses with side shields, and steel-toed boots.

- Use proper lifting techniques when handling billets or finished extrusions.

- Maintain a safe distance from moving press components.

- Ensure proper guarding is in place on all machinery.

- Follow lockout/tagout procedures during maintenance or die changes.[3]

4. Required Personal Protective Equipment (PPE)

A crucial component of any aluminum extrusion press JSA is a detailed list of required PPE. This might include:

- Heavy gloves

- Kevlar sleeves

- Safety glasses with side shields

- Heavy work boots (steel toe optional)[3]

The JSA should specify when and how this PPE should be used during different stages of the extrusion process.

5. Training Requirements

The JSA should outline any specific training requirements for workers operating the aluminum extrusion press. This might include:

- General safety training

- Machine-specific operation training

- Emergency response procedures

- Proper use and maintenance of PPE

6. Emergency Procedures

An effective aluminum extrusion press JSA should include clear instructions for emergency situations. This might cover:

- Emergency shut-off procedures for the press

- Evacuation routes

- First aid locations

- Reporting procedures for accidents or near-misses

Importance of Temperature Control in Aluminum Extrusion Press JSA

When creating a JSA for an aluminum extrusion press, it's crucial to emphasize the importance of temperature control. During extrusion, maintaining temperature control is a crucial element of the process. The temperature of the container must remain constant at all times during the cycle, top to bottom and front to back. Temperature is limited by the alloy being used and by the shape being extruded. For example, lower extrusion temperatures will usually produce shapes with better quality surfaces and more accurate dimensions, while excessive temperatures may decrease the tensile strength.[4]

This aspect of the process should be carefully considered in the JSA, with specific procedures outlined for monitoring and maintaining appropriate temperatures throughout the extrusion process.

Continuous Improvement of the Aluminum Extrusion Press JSA

It's important to note that a JSA is not a static document. It should be regularly reviewed and updated to reflect changes in equipment, processes, or identified hazards. Some strategies for continuous improvement include:

1. Regular safety audits

2. Encouraging worker feedback on safety procedures

3. Analyzing accident and near-miss reports

4. Staying updated on industry best practices and new safety technologies

Conclusion

A comprehensive Job Safety Analysis for an aluminum extrusion press is a critical tool for ensuring worker safety in this complex manufacturing process. By carefully identifying job steps, potential hazards, and safe work procedures, companies can significantly reduce the risk of accidents and injuries.

The key components of an aluminum extrusion press JSA include a detailed breakdown of job steps, identification of potential hazards, recommended safe job procedures, required PPE, training requirements, and emergency procedures. Special attention should be paid to temperature control, as this is a crucial factor in the extrusion process that can significantly impact both product quality and worker safety.

Remember, safety is an ongoing process. Regularly reviewing and updating the JSA, incorporating worker feedback, and staying abreast of industry developments are all crucial for maintaining a safe work environment in aluminum extrusion operations.

FAQ

1. What is the purpose of a Job Safety Analysis (JSA) for an aluminum extrusion press?

The primary purpose of a JSA for an aluminum extrusion press is to identify potential hazards associated with each step of the extrusion process and to establish safe work procedures to mitigate these risks. It serves as a crucial tool for ensuring worker safety and preventing accidents in the aluminum extrusion industry.

2. How often should an aluminum extrusion press JSA be updated?

An aluminum extrusion press JSA should be reviewed and updated regularly, typically at least annually. However, it should also be revised whenever there are changes to equipment, processes, or when new hazards are identified. After any workplace incident or near-miss, the JSA should be reviewed to see if updates are necessary.

3. What are some common hazards associated with aluminum extrusion press operations?

Common hazards in aluminum extrusion press operations include burns from hot metal or equipment, crushing injuries from moving press components, cuts from sharp edges on extruded profiles, slips and falls on wet surfaces near quenching areas, and exposure to loud noise from machinery. The JSA should address each of these potential hazards and provide mitigation strategies.

4. Why is temperature control important in an aluminum extrusion press JSA?

Temperature control is crucial in aluminum extrusion because it affects both product quality and worker safety. The JSA should include procedures for monitoring and maintaining appropriate temperatures throughout the extrusion process. Proper temperature control ensures better quality surfaces, more accurate dimensions, and helps maintain the desired tensile strength of the extruded aluminum.

5. What role do workers play in the development and implementation of an aluminum extrusion press JSA?

Workers play a vital role in both the development and implementation of an aluminum extrusion press JSA. Their firsthand experience with the equipment and processes makes their input invaluable when identifying potential hazards and developing safe work procedures. Workers should be encouraged to provide feedback on the JSA and report any new hazards or safety concerns they observe during their work.

Citations:

[1] https://www.hydro.com/technicalspecificationsena

[2] https://geminigroup.net/understanding-aluminum-extrusion-dies/

[3] https://oem.msu.edu/images/abrasive_blasting/2018_Appendices/VII-A_MIOSHA-Job-Safety-Analysis.pdf

[4] https://www.hydro.com/profiles/what-are-aluminum-extrusions

[5] https://www.brightstaralu.com/parts-of-aluminium-extrusion-press-and-its-function/

[6] https://www.gabrian.com/what-is-aluminum-extrusion-process/

[7] https://bee.oregonstate.edu/sites/agsci/files/bee/hazardanalysis.pdf

[8] https://bonnellaluminum.com/tech-info-resources/aluminum-extrusion-process/