Content Menu

● Introduction to Aluminium Extrusion Equipment

>> Key Components of Aluminium Extrusion Equipment

● How Aluminium Extrusion Equipment Works

● Benefits of Aluminium Extrusion Equipment

● Setting Up an Aluminium Extrusion Factory

● Recent Innovations in Aluminium Extrusion Technology

● Challenges in Aluminium Extrusion

● Maintenance Tips for Aluminium Extrusion Machines

● Conclusion

● FAQ

>> 1. What is the primary function of the extrusion head in aluminium extrusion equipment?

>> 2. How does the hydraulic system contribute to the aluminium extrusion process?

>> 3. What role does the control system play in aluminium extrusion equipment?

>> 4. What are some recent innovations in aluminium extrusion technology?

>> 5. What are the main challenges faced in the aluminium extrusion process?

● Citations:

Aluminium extrusion is a widely used manufacturing process that involves forcing heated aluminium alloy through a die to create profiles with specific cross-sectional shapes. This process is crucial in various industries, including construction, automotive, aerospace, and consumer products. The key to successful aluminium extrusion lies in the equipment used, which consists of several critical components. In this article, we will delve into the main parts of aluminium extrusion equipment and explore their functions.

Introduction to Aluminium Extrusion Equipment

Aluminium extrusion equipment is designed to handle the high pressures and temperatures required to shape aluminium into desired forms. The process begins with an aluminium billet, which is heated to a malleable state before being pushed through a die by a hydraulic ram. The result is a continuous profile that can be cut to desired lengths.

Key Components of Aluminium Extrusion Equipment

1. Extrusion Head: This is a crucial part of the aluminium extrusion machine, consisting of a mold, heater, pretreatment device, and extrusion cavity. The mold shapes the aluminium into the required profile, while the heater ensures the aluminium is at the appropriate temperature for extrusion.

2. Hydraulic System: This system generates the high pressure needed to push the aluminium through the die. It includes components like the main cylinder, oil pump, high-pressure cylinder, and valves.

3. Control System: This system controls the operation of the entire machine, ensuring precise control over temperature, pressure, and movement. It typically includes a PLC controller, human-machine interface, and various electrical components.

4. Main Cylinder: This is where hydraulic fluid is pumped to generate pressure for moving the ram. The ram applies force to push the heated aluminium billet through the die.

5. Die Holder and Die: The die holder secures the die assembly, which shapes the extruded profile. The die itself determines the final shape of the extruded material.

6. Press Platen and Tie Rods: The press platen consists of front and back sections that hold everything together, supported by tie rods that maintain alignment under high pressure.

7. Run Out Table and Cooling System: The run out table supports extrusions as they exit the die, guiding them for cooling and further processing. The cooling system uses water or air to achieve desired mechanical properties.

How Aluminium Extrusion Equipment Works

The process of aluminium extrusion involves several key steps:

1. Heating: The aluminium billet is heated to a temperature between 350°C and 500°C to make it soft and pliable.

2. Feeding: The heated billet is placed into the container of the extruder.

3. Extrusion: High pressure is applied to push the billet through the die, forming the required profile.

4. Cooling and Post-processing: The extruded profile is cooled and then undergoes post-processing such as stretching and cutting to ensure size and shape accuracy.

Benefits of Aluminium Extrusion Equipment

Aluminium extrusion equipment offers several benefits, including:

- Efficiency: It can produce large quantities of high-quality profiles quickly.

- Energy Efficiency: The hydraulic system reduces power consumption and costs.

- Flexibility: Different molds can be used to produce a wide range of shapes and sizes.

Setting Up an Aluminium Extrusion Factory

To set up an aluminium extrusion factory, several pieces of equipment are necessary:

1. Billet Heating and Shearing Equipment: This includes billet racks, furnaces, and hot shearing machines.

2. Aluminium Extrusion Press: The main machine for forming profiles.

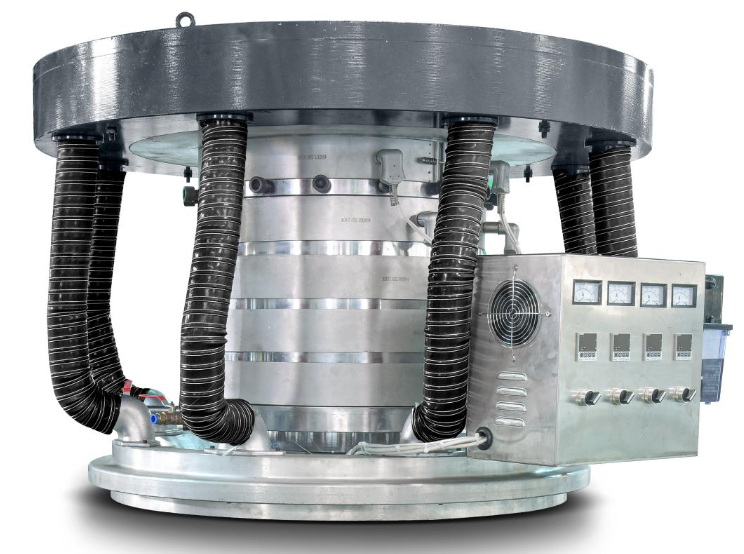

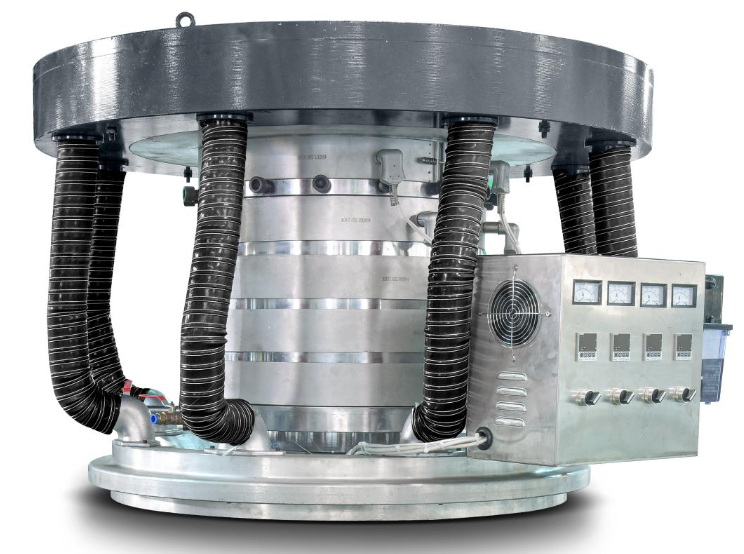

3. Mold Heating Oven: For heating molds before extrusion.

4. Puller Machine: For pulling, sawing, and cutting extrusions to length.

5. Cooling Bed: For cooling extrusions after they exit the die.

Recent Innovations in Aluminium Extrusion Technology

The aluminium extrusion industry is continuously evolving with new technologies and innovations. Some of the recent advancements include:

- Nano-Coating Technologies: These enhance the durability of aluminium extrusions by providing an extra layer of protection against corrosion and abrasion[2][5][8].

- Rapid Extrusion Profile Inspection: Advances in rapid extrusion profile inspection using Computerized Topology (CAT) X-ray scanning are being developed to enhance efficiency and accuracy in quality control[1].

- Smart Extrusion Lines: Equipped with IoT technology, these lines optimize efficiency, minimize downtime, and facilitate predictive maintenance[2][5][8].

- Artificial Intelligence Integration: AI is being used for predictive maintenance, die design, and die correction processes, optimizing plant operations[1][8].

- Hybrid Extrusion Techniques: These combine traditional methods with advanced processes to produce profiles with enhanced strength and formability[8].

- 3D Printing Integration: This allows for the creation of intricate and tailored designs, offering unparalleled freedom in realizing complex profiles[2][8].

Challenges in Aluminium Extrusion

Despite the advancements, the aluminium extrusion process faces several challenges:

- Die Wear and Tear: Caused by prolonged use or improper alignment, this can lead to reduced profile quality and inconsistent dimensions[3].

- Hydraulic System Failures: These can be caused by contaminated hydraulic oil or pump malfunctions, resulting in inadequate pressure and machine downtime[3].

- Thermal Management Issues: Proper heating and cooling are critical to prevent defects and ensure consistent product quality[3].

- Profile Defects: Common defects include surface blemishes, dimensional inaccuracies, and structural weaknesses[6].

Maintenance Tips for Aluminium Extrusion Machines

To ensure peak performance and longevity of aluminium extrusion machines, regular maintenance is essential:

- Scheduled Inspections: Regularly inspect critical components like the hydraulic system and cooling systems for signs of wear or damage[4][7].

- Lubrication: Ensure all moving parts are well-lubricated to reduce friction and wear[4][7].

- Cleanliness: Maintain a clean environment around the machine to prevent blockages and damage[4].

- Training and Documentation: Invest in proper training for operators and maintain detailed records of maintenance activities[4].

Conclusion

Aluminium extrusion equipment is complex and consists of several critical components, each playing a vital role in the extrusion process. Understanding these components and how they work together is essential for efficient and high-quality production of aluminium profiles. The benefits of using aluminium extrusion equipment include efficiency, energy savings, and flexibility in producing various shapes and sizes. Recent innovations in the industry, such as nano-coating technologies and smart extrusion lines, further enhance the capabilities of aluminium extrusion.

FAQ

1. What is the primary function of the extrusion head in aluminium extrusion equipment?

- The extrusion head is responsible for shaping the aluminium into the required profile using a mold, while also heating the aluminium to the appropriate temperature for extrusion.

2. How does the hydraulic system contribute to the aluminium extrusion process?

- The hydraulic system generates the high pressure needed to push the aluminium through the die, using components like the main cylinder and oil pump.

3. What role does the control system play in aluminium extrusion equipment?

- The control system ensures precise control over temperature, pressure, and movement during the extrusion process, using components like PLC controllers and human-machine interfaces.

4. What are some recent innovations in aluminium extrusion technology?

- Recent innovations include nano-coating technologies for enhanced durability, smart extrusion lines with IoT technology, and the integration of artificial intelligence for precision control.

5. What are the main challenges faced in the aluminium extrusion process?

- Common challenges include die wear and tear, hydraulic system failures, thermal management issues, and profile defects such as surface blemishes and dimensional inaccuracies.

Citations:

[1] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[2] https://www.yjing-extrusion.com/what-are-the-latest-innovations-in-aluminum-extruder-technology-for-2024.html

[3] https://www.yjing-extrusion.com/what-are-the-challenges-in-the-aluminum-extrusion-press-line-process.html

[4] https://satimaco.wixsite.com/satimaco/post/aluminum-extrusion-machine-maintenance-tips-for-peak-performance

[5] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[6] https://hplmachining.com/blog/what-are-the-problems-with-aluminum-extrusion/

[7] https://www.yjing-extrusion.com/how-to-maintain-an-aluminum-extrusion-press-for-optimal-performance.html

[8] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[9] https://gloriaaluminium.com/blog/the-future-of-the-aluminum-extrusion-industry-trends-and-growth/

[10] https://www.alcirclebiz.com/blogs/innovations-in-aluminium-extrusion-meeting-modern-industry-demands

[11] https://www.fortune-alu.com/info-detail/future-trends-in-aluminum-extrusion

[12] https://www.kedagroup.com/news/index316.html

[13] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[14] https://www.otalum.com/future-developments-and-trends-in-industrial-aluminum-extrusion-technology.html

[15] https://www.linkedin.com/pulse/nine-main-points-aluminum-extrusion-press-machine-maintenance-

[16] https://www.atieuno.com/2023/11/29/aluminium-extrusion-die/

[17] https://jmaluminium.com/the-evolution-of-aluminium-extrusion-industry-challenges-and-future-outlook/

[18] https://americandouglasmetals.com/2023/12/20/global-aluminum-extrusion-market-2023-2030-growth-trends-key-players-and-industry-insights/

[19] https://aluminium-guide.com/extrusion-press-maintenance/

[20] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/