Content Menu

● Introduction

● What is Aluminum Extrusion?

● Key Techniques in Aluminum Extrusion

>> Direct Extrusion

>> Indirect Extrusion

>> Role of Dies and Machinery

>> Innovations in Extrusion Technology

● Benefits of Aluminum Extrusion

>> Design Flexibility and Complexity

>> Cost-Effectiveness and Efficiency

>> Strength and Lightweight Properties

>> Corrosion Resistance

>> Sustainability

● Applications of Aluminum Extrusion

>> Construction

>> Automotive

>> Electronics

>> Aerospace

>> Consumer Products

● Factors Influencing the Cost of Aluminum Extrusion

>> Material Costs and Sourcing

>> Production Scale and Complexity

>> Quality Control and Finishing Processes

● Conclusion

● Related Questions

>> 1. What materials are commonly used in the aluminum extrusion process?

>> 2. How does the aluminum extrusion process compare to other manufacturing methods?

>> 3. What industries benefit the most from aluminum extrusion?

>> 4. Can aluminum extrusions be recycled?

>> 5. What are the common finishing processes for aluminum extrusions?

Introduction

The aluminum extrusion process is a manufacturing technique that involves shaping aluminum alloy into desired profiles by forcing it through a die. This method has gained immense popularity across various industries due to its versatility, efficiency, and cost-effectiveness. In this article, we will explore the key benefits of the aluminum extrusion process, its applications, and the techniques involved, providing a comprehensive understanding of why this process is favored in modern manufacturing.

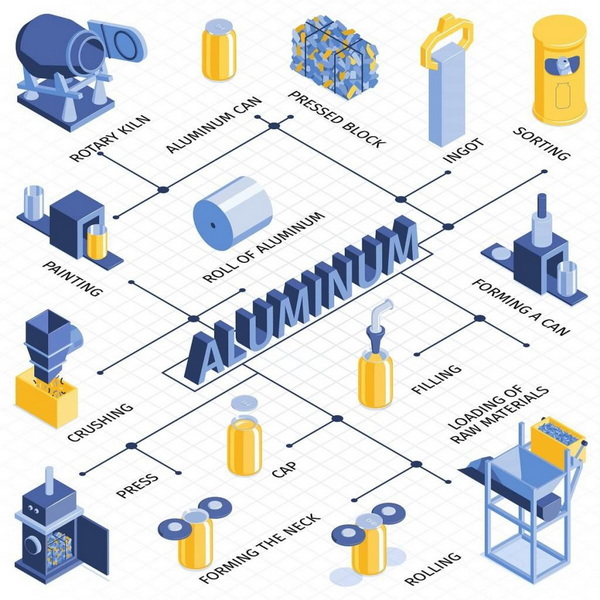

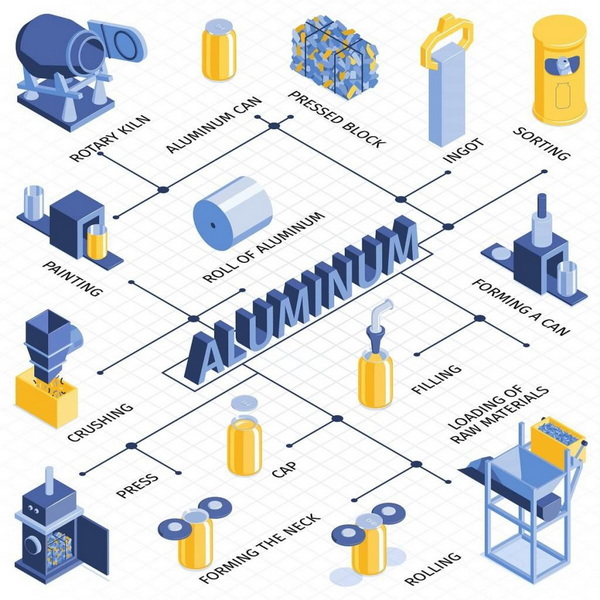

What is Aluminum Extrusion?

Aluminum extrusion is a process that transforms aluminum alloy into specific shapes and profiles. The process begins with heating the aluminum billets until they reach a malleable state. Once heated, the aluminum is placed in a press, where it is forced through a die, creating a continuous profile. This profile can be cut to length and further processed to meet specific requirements.

The aluminum extrusion process is characterized by its ability to produce complex shapes with high precision. The resulting products are lightweight yet strong, making them ideal for a wide range of applications, from construction to automotive components.

Key Techniques in Aluminum Extrusion

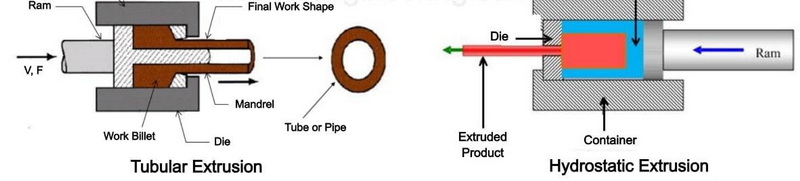

The aluminum extrusion process employs several techniques to achieve optimal results. The two primary methods are direct extrusion and indirect extrusion.

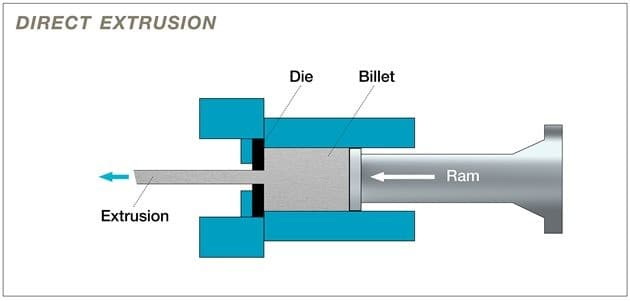

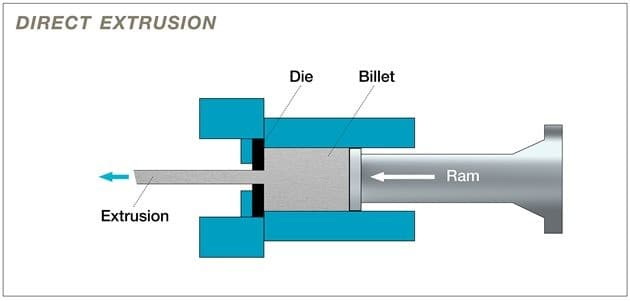

Direct Extrusion

In direct extrusion, the aluminum billet is heated and placed in a chamber. A ram pushes the billet through the die, creating the desired profile. This method is widely used due to its simplicity and efficiency. The direct extrusion process allows for the production of long lengths of aluminum profiles, which can be cut to size as needed.

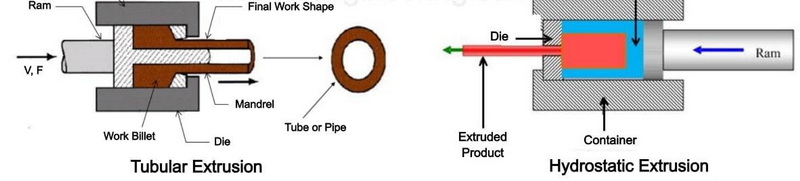

Indirect Extrusion

Indirect extrusion, on the other hand, involves the die moving towards the billet rather than the billet moving towards the die. This method is beneficial for producing more complex shapes and profiles. Indirect extrusion can also reduce the friction between the billet and the die, leading to improved surface quality and dimensional accuracy.

Role of Dies and Machinery

The design of the die is crucial in the aluminum extrusion process. Dies can be customized to create a wide variety of shapes, from simple rectangles to intricate designs. The machinery used in the extrusion process, including presses and cooling systems, also plays a significant role in determining the quality and efficiency of the final product.

Innovations in Extrusion Technology

Recent advancements in extrusion technology have further enhanced the capabilities of the aluminum extrusion process. Innovations such as computer-aided design (CAD) and simulation software allow manufacturers to optimize die designs and extrusion parameters before production begins. This leads to reduced waste, improved quality, and faster turnaround times.

Benefits of Aluminum Extrusion

The aluminum extrusion process offers numerous benefits that make it a preferred choice for manufacturers. Here are some of the key advantages:

Design Flexibility and Complexity

One of the most significant benefits of the aluminum extrusion process is its design flexibility. Manufacturers can create complex shapes and profiles that would be challenging or impossible to achieve with other manufacturing methods. This flexibility allows for innovative designs that can enhance the functionality and aesthetics of products.

Cost-Effectiveness and Efficiency

Aluminum extrusion is a cost-effective manufacturing process. The ability to produce long lengths of profiles reduces material waste and minimizes production costs. Additionally, the efficiency of the extrusion process allows for high-volume production, making it suitable for large-scale manufacturing.

Strength and Lightweight Properties

Aluminum is known for its excellent strength-to-weight ratio. The aluminum extrusion process retains these properties, resulting in products that are both strong and lightweight. This characteristic is particularly advantageous in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that makes it highly resistant to corrosion. This property is especially beneficial for products exposed to harsh environments, such as marine applications or outdoor structures. The aluminum extrusion process can further enhance corrosion resistance through anodizing or other surface treatments.

Sustainability

The aluminum extrusion process is environmentally friendly. Aluminum is 100% recyclable, and the extrusion process generates minimal waste. Manufacturers can recycle scrap aluminum generated during production, contributing to a more sustainable manufacturing cycle.

Applications of Aluminum Extrusion

The versatility of the aluminum extrusion process allows it to be used in a wide range of applications across various industries. Some common applications include:

Construction

In the construction industry, aluminum extrusions are used for window frames, doors, curtain walls, and structural components. The lightweight nature of aluminum makes it an ideal choice for reducing the overall weight of buildings while maintaining structural integrity.

Automotive

Aluminum extrusions are increasingly used in the automotive industry to produce lightweight components such as chassis, bumpers, and heat exchangers. The use of aluminum helps manufacturers meet fuel efficiency standards while enhancing vehicle performance.

Electronics

In the electronics industry, aluminum extrusions are used for heat sinks, enclosures, and structural supports. The excellent thermal conductivity of aluminum makes it an ideal material for dissipating heat in electronic devices.

Aerospace

The aerospace industry relies heavily on aluminum extrusions for aircraft components, including frames, wings, and fuselage sections. The lightweight and strong properties of aluminum are critical for improving fuel efficiency and overall aircraft performance.

Consumer Products

Aluminum extrusions are also used in various consumer products, including furniture, appliances, and sporting goods. The design flexibility of the extrusion process allows manufacturers to create aesthetically pleasing and functional products.

Factors Influencing the Cost of Aluminum Extrusion

Several factors can influence the cost of the aluminum extrusion process. Understanding these factors can help manufacturers make informed decisions when planning their production.

Material Costs and Sourcing

The cost of aluminum raw materials can fluctuate based on market conditions. Manufacturers must consider these costs when budgeting for production. Sourcing high-quality aluminum from reliable suppliers can also impact overall costs.

Production Scale and Complexity

The scale of production plays a significant role in determining the cost of aluminum extrusion. Larger production runs can lead to lower per-unit costs due to economies of scale. Additionally, the complexity of the desired profiles can affect tooling and machining costs.

Quality Control and Finishing Processes

Ensuring high-quality standards throughout the aluminum extrusion process is essential. Implementing quality control measures can add to production costs but is necessary to maintain product integrity. Finishing processes, such as anodizing or painting, can also contribute to overall costs.

Conclusion

The aluminum extrusion process is a highly versatile and efficient manufacturing technique that offers numerous benefits. From design flexibility and cost-effectiveness to strength and sustainability, aluminum extrusion has become a preferred choice across various industries. As technology continues to advance, the capabilities of the aluminum extrusion process will only expand, paving the way for innovative applications and products.

Related Questions

1. What materials are commonly used in the aluminum extrusion process?

Aluminum alloys, particularly those in the 6000 series, are commonly used due to their excellent extrudability and strength.

2. How does the aluminum extrusion process compare to other manufacturing methods?

Aluminum extrusion offers unique advantages in terms of design flexibility, material efficiency, and the ability to produce complex shapes compared to methods like casting or machining.

3. What industries benefit the most from aluminum extrusion?

Industries such as construction, automotive, aerospace, and electronics benefit significantly from aluminum extrusion due to its lightweight and strong properties.

4. Can aluminum extrusions be recycled?

Yes, aluminum is 100% recyclable, and the recycling process does not degrade its quality, making it an environmentally friendly material choice.

5. What are the common finishing processes for aluminum extrusions?

Common finishing processes include anodizing, painting, and powder coating, which enhance the appearance and corrosion resistance of aluminum extrusions.