Content Menu

● Design Flexibility

● Material Efficiency

● Cost-Effectiveness

● Sustainability

● Wide Range of Applications

● Technological Advancements

● Quality Control Measures

● Market Trends Influencing Investment

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. What are the main advantages of using aluminum extrusions?

>> 3. How does investing in aluminum extrusion equipment contribute to sustainability?

>> 4. In which industries is aluminum extrusion commonly used?

>> 5. What technological advancements are impacting the aluminum extrusion process?

● Citations:

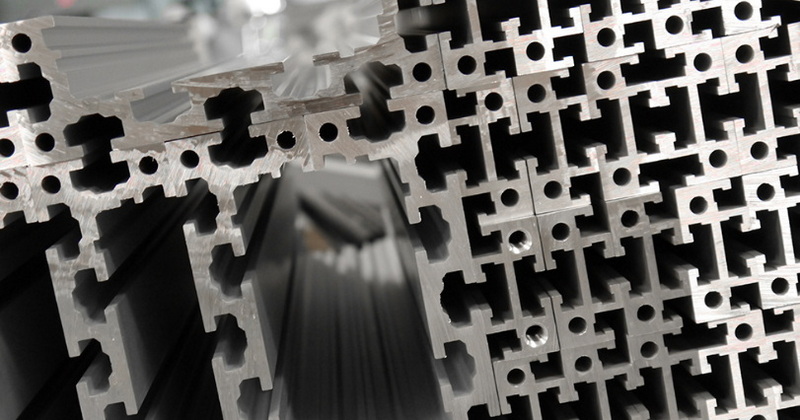

Aluminum extrusion is a manufacturing process that shapes aluminum by forcing it through a die to create various profiles. This method has gained immense popularity across different industries due to its versatility and efficiency. Investing in aluminum extrusion equipment can yield significant benefits for manufacturers, making it a strategic choice for businesses aiming to enhance their production capabilities. In this article, we will explore the key advantages of investing in aluminum extrusion equipment, covering aspects such as design flexibility, material efficiency, cost-effectiveness, sustainability, and technological advancements.

Design Flexibility

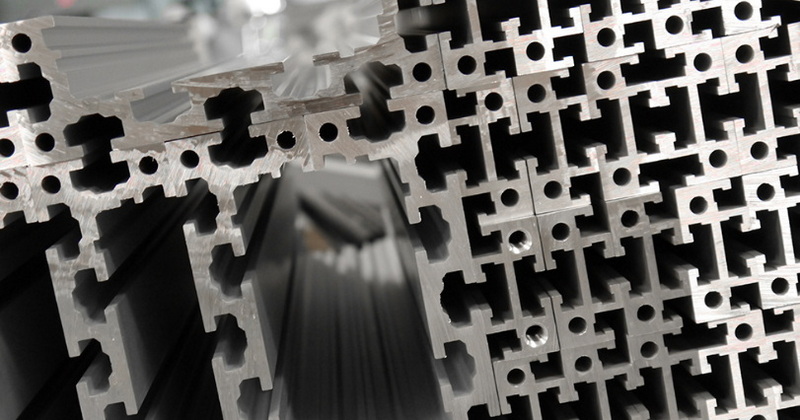

One of the primary benefits of aluminum extrusion equipment is the design flexibility it offers. Manufacturers can create complex shapes and profiles that might be challenging or impossible to achieve with other manufacturing methods. This flexibility allows for:

- Custom Profiles: The ability to produce tailored shapes that meet specific application requirements. This customization is particularly beneficial in industries such as automotive and aerospace, where unique designs can lead to improved performance and functionality.

- Variety of Applications: Aluminum extrusions are utilized in various industries, including automotive, aerospace, construction, and electronics. This wide applicability ensures that manufacturers can cater to diverse market needs.

- Innovative Designs: Engineers can push the boundaries of creativity, leading to innovative product designs that enhance functionality and aesthetics. The ability to experiment with different profiles encourages innovation and can result in competitive advantages.

Material Efficiency

Investing in aluminum extrusion equipment promotes material efficiency, which is crucial for reducing production costs and minimizing waste. This efficiency is achieved through:

- Optimized Material Usage: The extrusion process uses only the necessary amount of material to create the desired shape, significantly reducing scrap. This optimization not only saves costs but also aligns with sustainable manufacturing practices.

- Recyclability: Any scrap generated during production can often be recycled and reused, contributing to sustainable manufacturing practices. Aluminum is one of the most recycled materials globally, making it an environmentally friendly choice.

- Lightweight Components: Aluminum's lightweight nature allows manufacturers to design products that require less material while still meeting strength requirements. This quality is particularly important in industries like aerospace, where weight reduction translates directly into fuel savings.

Cost-Effectiveness

While the initial investment in aluminum extrusion equipment may seem substantial, the long-term savings can be significant. Key factors contributing to cost-effectiveness include:

- Reduced Labor Costs: Automation in the extrusion process minimizes labor requirements, leading to lower operational costs. Automated systems can handle repetitive tasks more efficiently than human laborers, allowing personnel to focus on more complex operations.

- Lower Shipping Costs: The lightweight nature of aluminum extrusions reduces transportation costs, making them more economical to ship. This aspect is particularly advantageous for companies that operate on a global scale.

- Durability and Low Maintenance: Aluminum products are known for their durability and resistance to corrosion, which means they require less maintenance over their lifespan. This longevity reduces replacement costs and enhances overall profitability.

Sustainability

Sustainability is increasingly becoming a priority for manufacturers. Aluminum extrusion equipment supports eco-friendly practices through:

- Energy Efficiency: Modern extrusion processes are designed to consume less energy compared to traditional manufacturing methods. Energy-efficient machinery not only lowers operational costs but also reduces the carbon footprint associated with production.

- Use of Recycled Materials: Many manufacturers utilize recycled aluminum in their extrusion processes, reducing the demand for virgin materials and lowering their carbon footprint. The recycling process for aluminum requires only about 5% of the energy needed to produce new aluminum from ore.

- Long Lifespan Products: The durability of aluminum products contributes to sustainability by reducing the need for replacements and minimizing waste. Products designed with longevity in mind help manufacturers meet increasing consumer demand for sustainable goods.

Wide Range of Applications

Aluminum extrusions find applications across various industries due to their unique properties. Some notable sectors include:

- Automotive Industry: Used in chassis and body structures, aluminum extrusions help reduce vehicle weight and improve fuel efficiency. As environmental regulations become stricter, the demand for lightweight materials in vehicles continues to grow.

- Construction Sector: Aluminum is widely used for window frames, facades, and structural components due to its strength and aesthetic appeal. Its resistance to corrosion makes it ideal for outdoor applications where exposure to elements is a concern.

- Electronics Industry: Extrusions serve as heat sinks and enclosures, benefiting from aluminum's excellent thermal conductivity. As electronic devices become smaller and more powerful, effective heat dissipation becomes critical.

Technological Advancements

The field of aluminum extrusion is continuously evolving with technological advancements. These innovations enhance both productivity and product quality. Key developments include:

- Computer-Aided Design (CAD): CAD software allows manufacturers to optimize die designs and extrusion parameters for improved outcomes. This technology enables rapid prototyping and testing of new designs before full-scale production begins.

- Automation and Robotics: Integrating automated systems into the extrusion process enhances efficiency by streamlining material handling and finishing operations. Robotics can perform tasks such as cutting, bending, and assembling components with precision.

- Advanced Die Technology: Innovations in die technology enable the production of more complex shapes with greater precision. Improved die materials and designs reduce wear and tear during production cycles, leading to longer-lasting equipment.

Quality Control Measures

Investing in aluminum extrusion equipment also involves implementing rigorous quality control measures throughout the manufacturing process. These measures ensure that products meet industry standards and customer expectations:

- In-Line Inspection Systems: Automated inspection systems can detect defects during production, allowing for immediate corrections before products are completed.

- Testing Protocols: Manufacturers often employ various testing protocols (such as tensile strength tests) on extruded products to ensure they meet specified performance criteria.

- Certifications: Obtaining industry certifications (like ISO standards) demonstrates a commitment to quality assurance and can enhance customer trust.

Market Trends Influencing Investment

Several market trends are influencing manufacturers' decisions to invest in aluminum extrusion equipment:

- Growing Demand for Lightweight Materials: As industries focus on improving energy efficiency, there's an increasing demand for lightweight materials like aluminum that contribute to overall performance improvements.

- Shift Towards Sustainable Practices: Consumers are becoming more environmentally conscious; therefore, manufacturers are compelled to adopt sustainable practices that include using recyclable materials like aluminum.

- Technological Integration: The rise of Industry 4.0 has led many manufacturers to explore smart manufacturing solutions that integrate advanced technologies into their processes for enhanced productivity.

Conclusion

Investing in aluminum extrusion equipment offers numerous benefits that can significantly enhance manufacturing capabilities. From design flexibility and material efficiency to cost-effectiveness and sustainability, these advantages make aluminum extrusion a vital component of modern manufacturing processes. As industries continue to evolve and demand lightweight yet durable materials increases, aluminum extrusion will play a pivotal role in meeting these challenges. Manufacturers who embrace this technology position themselves favorably in an increasingly competitive market by enhancing their product offerings while adhering to sustainable practices.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where solid aluminum billets are heated and forced through a die to create specific shapes or profiles. This method allows for high precision and versatility in design.

2. What are the main advantages of using aluminum extrusions?

The main advantages include design flexibility, material efficiency (minimizing waste), cost-effectiveness (lower operational costs), sustainability (use of recycled materials), and a wide range of applications across various industries.

3. How does investing in aluminum extrusion equipment contribute to sustainability?

Investing in aluminum extrusion equipment supports sustainability by using energy-efficient processes, allowing for the recycling of scrap materials, and producing durable products that reduce waste over time.

4. In which industries is aluminum extrusion commonly used?

Aluminum extrusion is commonly used in industries such as automotive (for chassis and body structures), construction (for window frames and facades), aerospace (for aircraft components), and electronics (for heat sinks).

5. What technological advancements are impacting the aluminum extrusion process?

Technological advancements impacting the aluminum extrusion process include computer-aided design (CAD) for optimizing die designs, automation for enhancing productivity, and innovations in die technology that allow for more complex shapes with greater precision.

Citations:

[1] https://proleantech.com/aluminum-extrusion-explained/

[2] https://www.news.market.us/aluminum-extrusion-market-news/

[3] https://www.linkedin.com/pulse/advantages-aluminum-extrusion-process-

[4] https://www.istockphoto.com/fr/photos/aluminum-extrusion

[5] https://www.freepik.com/free-photos-vectors/aluminum-extrusion

[6] https://www.youtube.com/watch?v=iiGlq7408ME

[7] https://www.yjing-extrusion.com/what-are-the-key-benefits-of-aluminum-extrusion-in-modern-manufacturing.html

[8] https://taberextrusions.com/how-taber-does-that-aluminum-extrusion-innovation-and-technology/

[9] https://www.alu4all.com/what-is-the-benefit-of-custom-aluminum-extrusions/

[10] https://www.youtube.com/watch?v=vHkwq_2yY9E