Content Menu

● Introduction

● Understanding Aluminum Extrusion

● Types of Aluminum Extrusion Profiles

>> Standard Profiles

>> Custom Profiles

>> Hollow vs. Solid Profiles

● Applications of Aluminum Extrusion Profiles

>> Use in the Automotive Industry

>> Applications in Construction and Architecture

>> Role in Electronics and Consumer Goods

● Benefits of Using Aluminum Extrusions

>> Lightweight and Strength Advantages

>> Design Flexibility and Customization Options

>> Cost-Effectiveness in Production

● Conclusion

● Related Questions

>> 1. What are the most common types of aluminum extrusion profiles?

>> 2. How does the aluminum extrusion process work?

>> 3. What are the advantages of using custom aluminum extrusions?

>> 4. In which industries are aluminum extrusions commonly used?

>> 5. What are the benefits of using aluminum over other materials?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to the unique properties of aluminum, such as its lightweight, strength, and corrosion resistance. Understanding the different types of aluminum extrusion profiles and their uses is essential for engineers, designers, and manufacturers looking to leverage aluminum's advantages in their projects. This article will explore the various aluminum extrusion types, their applications, and the benefits they offer.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum alloy through a die to create a specific shape. The process begins with heating the aluminum billets to a malleable state, after which they are pushed through a die using a hydraulic press. The resulting extruded aluminum can be cut to length and further processed to meet specific requirements.

The materials used in aluminum extrusion are typically aluminum alloys, which are categorized into series based on their primary alloying elements. Common series include 1000 (pure aluminum), 2000 (copper), 3000 (manganese), 4000 (silicon), 5000 (magnesium), 6000 (magnesium and silicon), and 7000 (zinc). Each series has unique properties that make it suitable for different applications.

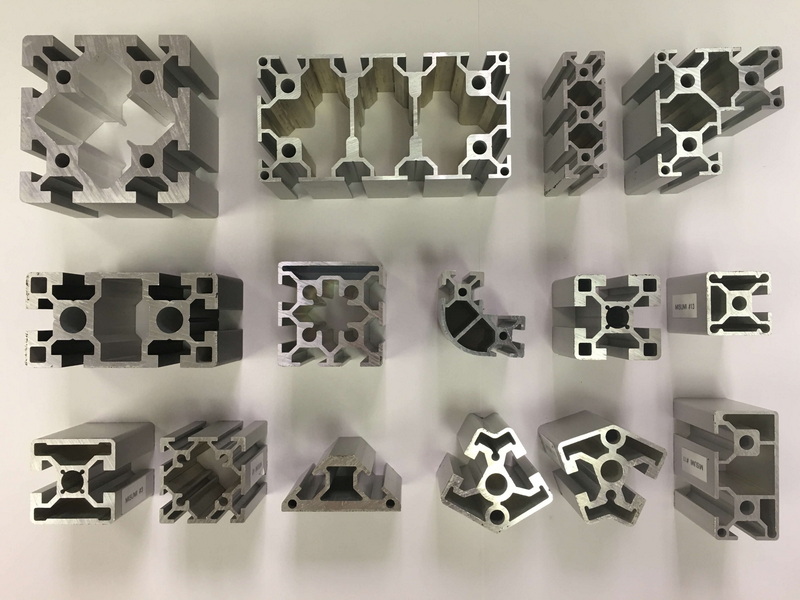

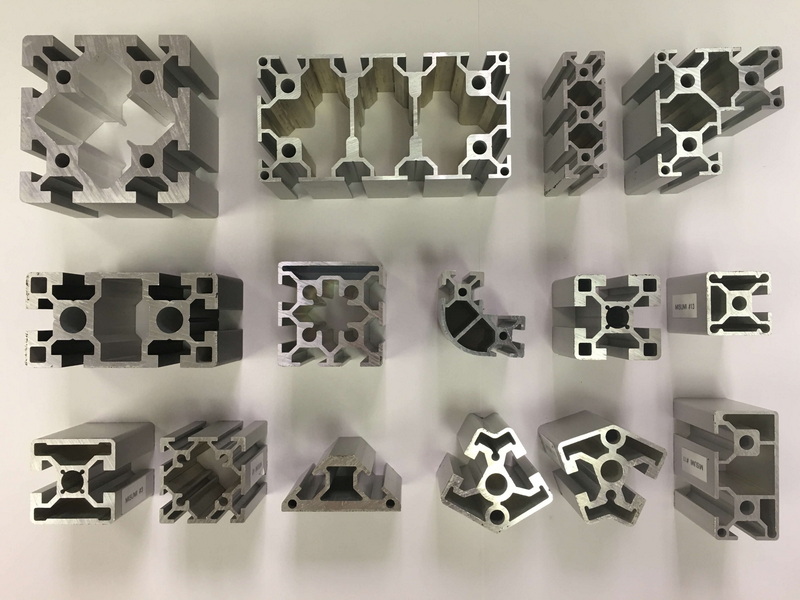

Types of Aluminum Extrusion Profiles

Standard Profiles

Standard aluminum extrusion profiles are pre-defined shapes that are commonly used in various applications. These profiles include:

- T-Profiles: Shaped like the letter "T," these profiles are often used in structural applications, providing support and stability.

- U-Profiles: Resembling the letter "U," these profiles are ideal for creating channels or frames.

- L-Profiles: Shaped like the letter "L," these profiles are commonly used for brackets and supports.

- Z-Profiles: These profiles are used in applications requiring a unique shape for specific structural needs.

Standard profiles are readily available and can be sourced from various manufacturers, making them a popular choice for many projects.

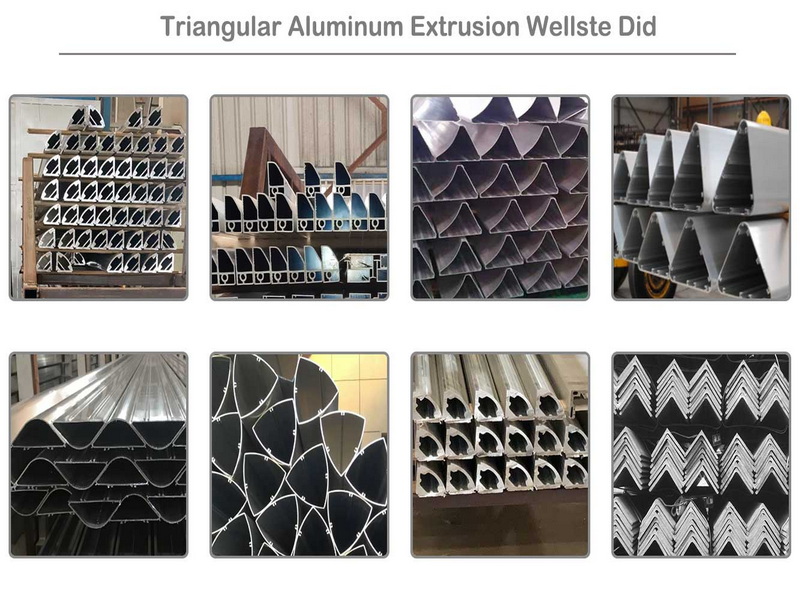

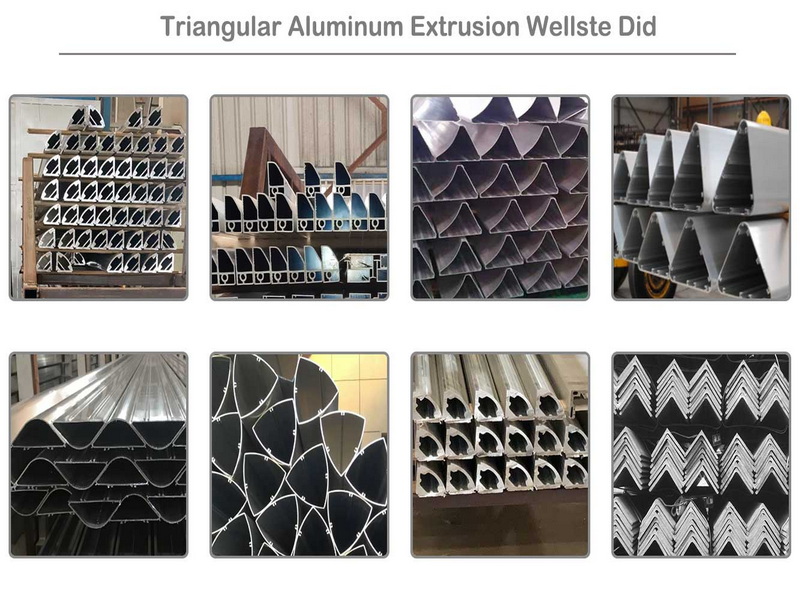

Custom Profiles

Custom aluminum extrusions are tailored to meet specific design requirements. These profiles are created based on the unique needs of a project, allowing for greater flexibility in design. Custom profiles can be designed to fit specific dimensions, shapes, and functionalities, making them ideal for specialized applications.

Industries such as aerospace, automotive, and construction often require custom aluminum extrusions to meet their unique specifications. For example, a custom profile may be designed to fit a specific component in an aircraft, ensuring optimal performance and safety.

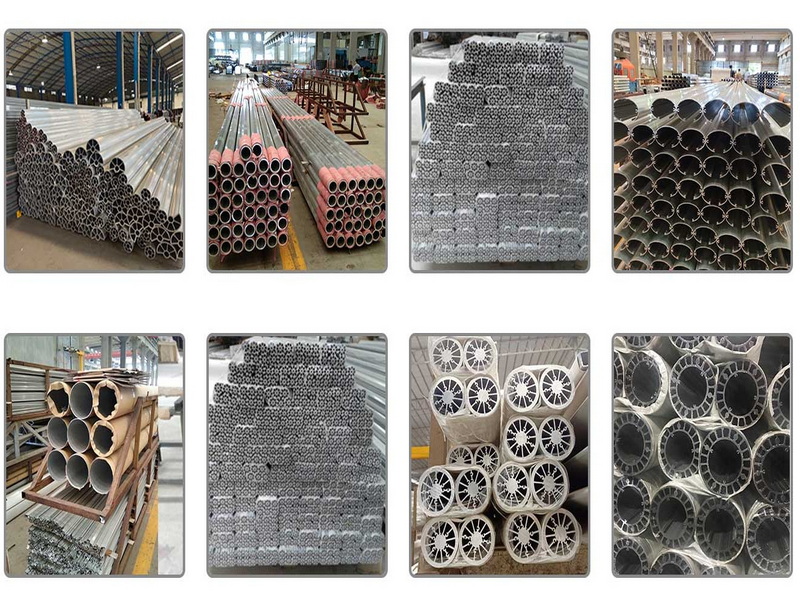

Hollow vs. Solid Profiles

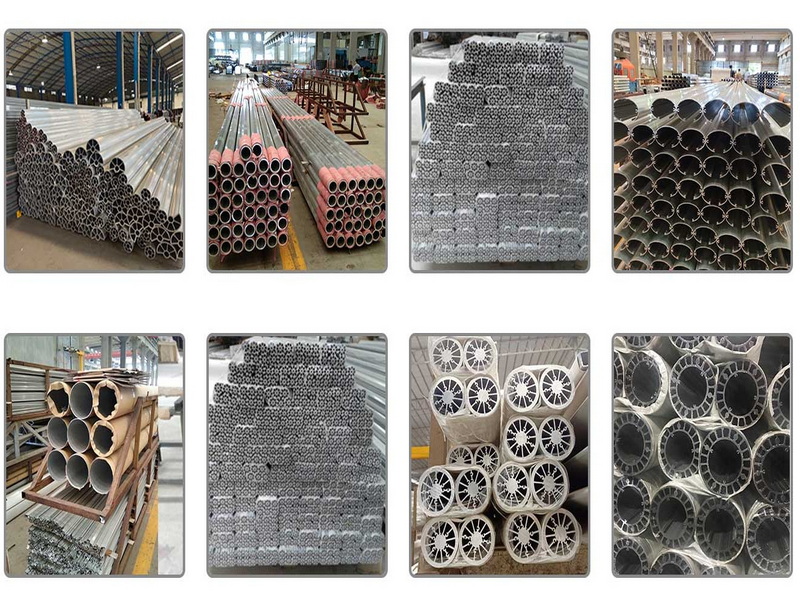

Aluminum extrusions can be categorized into hollow and solid profiles.

- Hollow Profiles: These profiles have a void or cavity within them, making them lightweight while maintaining strength. Hollow profiles are often used in applications where weight reduction is critical, such as in the automotive and aerospace industries. They can also provide insulation and reduce thermal conductivity.

- Solid Profiles: Solid aluminum extrusions are dense and robust, making them suitable for applications requiring high strength and durability. These profiles are commonly used in construction, machinery, and structural applications where load-bearing capacity is essential.

Applications of Aluminum Extrusion Profiles

Aluminum extrusion profiles are utilized in a wide range of industries due to their versatility and performance. Here are some key applications:

Use in the Automotive Industry

In the automotive sector, aluminum extrusions are used to manufacture lightweight components that enhance fuel efficiency and performance. Extruded aluminum is commonly found in vehicle frames, bumpers, and heat exchangers. The lightweight nature of aluminum helps reduce the overall weight of vehicles, leading to improved fuel economy and reduced emissions.

Applications in Construction and Architecture

Aluminum extrusions play a vital role in construction and architectural design. They are used in window frames, curtain walls, roofing systems, and structural supports. The corrosion resistance of aluminum ensures longevity and durability in outdoor applications, making it a preferred material for modern buildings.

Role in Electronics and Consumer Goods

In the electronics industry, aluminum extrusions are used to create heat sinks, enclosures, and structural components for various devices. The excellent thermal conductivity of aluminum helps dissipate heat, ensuring the efficient operation of electronic components. Additionally, aluminum extrusions are commonly found in consumer goods such as furniture, appliances, and sporting equipment, where aesthetics and functionality are essential.

Benefits of Using Aluminum Extrusions

The use of aluminum extrusions offers several advantages, making them a popular choice across various industries:

Lightweight and Strength Advantages

Aluminum is known for its lightweight properties, which make it an ideal material for applications where weight reduction is crucial. Despite being lightweight, aluminum extrusions maintain high strength, allowing them to support significant loads without compromising structural integrity.

Design Flexibility and Customization Options

Aluminum extrusion allows for a high degree of design flexibility. Manufacturers can create complex shapes and profiles that meet specific design requirements. This customization capability enables engineers and designers to innovate and develop unique solutions for their projects.

Cost-Effectiveness in Production

Aluminum extrusions are cost-effective due to their efficient manufacturing process. The ability to produce long lengths of extruded profiles reduces material waste and lowers production costs. Additionally, the durability and low maintenance requirements of aluminum contribute to long-term cost savings.

Conclusion

Understanding the different types of aluminum extrusion profiles and their uses is essential for anyone involved in manufacturing, engineering, or design. From standard profiles to custom solutions, aluminum extrusions offer versatility and performance across various industries. Their lightweight nature, strength, and corrosion resistance make them an ideal choice for applications in automotive, construction, electronics, and more. As technology advances, the potential for aluminum extrusions continues to grow, paving the way for innovative designs and applications.

Related Questions

1. What are the most common types of aluminum extrusion profiles?

The most common types of aluminum extrusion profiles include T-profiles, U-profiles, L-profiles, and Z-profiles. These standard shapes are widely used in various applications due to their availability and versatility.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum billets until they become malleable, then forcing them through a die using a hydraulic press to create a specific shape. The extruded aluminum is then cut to length and can be further processed.

3. What are the advantages of using custom aluminum extrusions?

Custom aluminum extrusions offer design flexibility, allowing manufacturers to create profiles tailored to specific project requirements. This customization can enhance functionality and aesthetics, making them ideal for specialized applications.

4. In which industries are aluminum extrusions commonly used?

Aluminum extrusions are commonly used in the automotive, construction, aerospace, electronics, and consumer goods industries. Their versatility and performance make them suitable for a wide range of applications.

5. What are the benefits of using aluminum over other materials?

Aluminum offers several benefits over other materials, including lightweight properties, high strength-to-weight ratio, corrosion resistance, and design flexibility. These advantages make aluminum a preferred choice for many applications across various industries.