Content Menu

● Introduction

● Understanding Modular Framing Systems

>> What is 20/80 Aluminum Extrusion?

● Benefits of Modular Framing Systems

>> Versatility

>> Ease of Assembly

>> Cost-Effectiveness

● Common Applications of Modular Framing Systems

>> Workstations

>> Industrial Racking Systems

>> Display Stands

>> Enclosures and Partitions

>> Custom Solutions

● Choosing the Right Profile

>> Factors to Consider

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using modular framing systems?

>> 2. How does 20/80 aluminum extrusion compare to other materials?

>> 3. Can modular framing systems be used outdoors?

>> 4. What types of projects are best suited for modular framing systems?

>> 5. How can I ensure the right profile is chosen for my project?

Introduction

Modular framing systems have revolutionized the way we approach construction and design in various industries. These systems, particularly those utilizing 20/80 aluminum extrusion, offer unparalleled versatility, ease of assembly, and cost-effectiveness. In this article, we will explore the best applications for modular framing systems, focusing on the benefits of 20/80 aluminum extrusion and how it enhances the functionality and aesthetics of various projects.

Understanding Modular Framing Systems

Modular framing systems are pre-engineered structures that can be easily assembled and disassembled. They are designed to be flexible, allowing for modifications and expansions as needed. The use of 20/80 aluminum extrusion in these systems provides a lightweight yet robust framework that can support a wide range of applications.

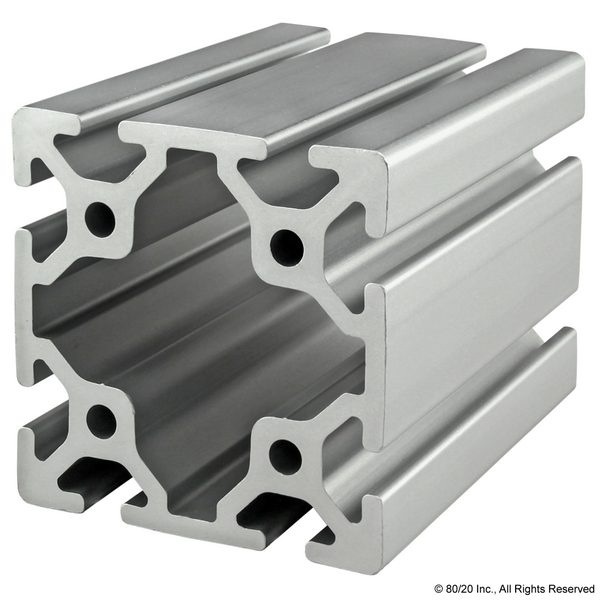

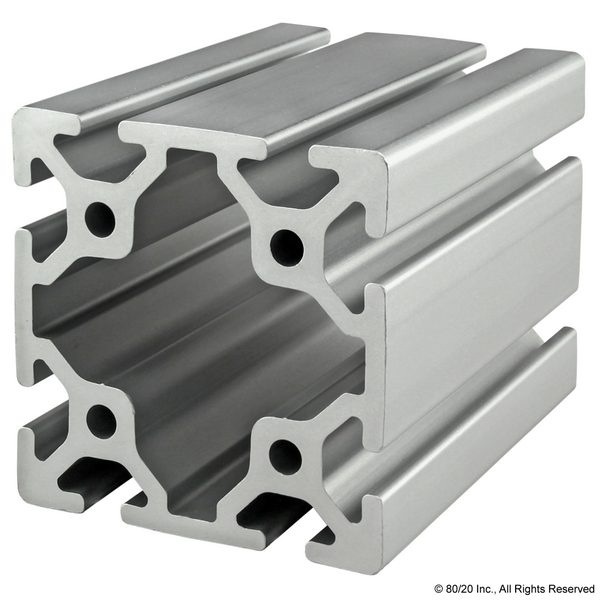

What is 20/80 Aluminum Extrusion?

20/80 aluminum extrusion refers to a specific profile size in the modular framing system, where the dimensions are measured in millimeters. This profile is characterized by its T-slot design, which allows for easy attachment of various components, making it ideal for creating custom structures. The aluminum material is not only lightweight but also resistant to corrosion, making it suitable for both indoor and outdoor applications.

Benefits of Modular Framing Systems

Versatility

One of the primary advantages of modular framing systems is their versatility. They can be used in a variety of settings, including industrial, commercial, and residential applications. The adaptability of 20/80 aluminum extrusion allows for the creation of custom solutions tailored to specific needs.

For instance, in industrial settings, modular framing systems can be used to construct workstations, assembly lines, and storage solutions. In commercial environments, they can be utilized for display stands, office partitions, and even entire office layouts. The possibilities are virtually endless.

Ease of Assembly

The T-slot design of 20/80 aluminum extrusion simplifies the assembly process. Components can be easily connected using standard fasteners, eliminating the need for specialized tools or skills. This ease of assembly not only saves time but also reduces labor costs, making it an attractive option for businesses looking to streamline their operations.

Cost-Effectiveness

Modular framing systems are often more cost-effective than traditional construction methods. The ability to reuse and reconfigure components means that businesses can adapt their spaces without incurring significant costs. Additionally, the lightweight nature of aluminum reduces shipping and handling expenses.

Common Applications of Modular Framing Systems

Workstations

One of the most common applications for modular framing systems is the creation of workstations. These can be tailored to fit specific tasks, whether in a manufacturing environment or an office setting. The flexibility of 20/80 aluminum extrusion allows for the integration of various accessories, such as shelving, lighting, and power supplies.

Industrial Racking Systems

Modular framing systems are ideal for constructing industrial racking systems. The strength of 20/80 aluminum extrusion can support heavy loads, making it suitable for warehouses and storage facilities. These racking systems can be easily adjusted to accommodate different products and inventory levels.

Display Stands

In retail environments, modular framing systems can be used to create eye-catching display stands. The sleek design of 20/80 aluminum extrusion enhances the aesthetic appeal of products while providing a sturdy structure. Retailers can easily modify their displays to keep up with changing trends and seasonal promotions.

Enclosures and Partitions

Modular framing systems can also be used to create enclosures and partitions. This is particularly useful in environments where space needs to be divided for different functions, such as in laboratories or manufacturing facilities. The transparency of materials like polycarbonate can be combined with aluminum framing to create safe and functional spaces.

Custom Solutions

One of the standout features of modular framing systems is the ability to create custom solutions. Whether it's a unique workstation, a specialized display, or a tailored storage solution, the flexibility of 20/80 aluminum extrusion allows designers and engineers to bring their visions to life.

Choosing the Right Profile

When selecting a modular framing system, it's essential to consider the specific requirements of your project. Factors such as load capacity, dimensions, and intended use will influence your choice of profile. The 20/80 aluminum extrusion is a popular choice due to its balance of strength and weight, making it suitable for a wide range of applications.

Factors to Consider

1. Load Capacity: Ensure that the chosen profile can support the intended weight and stress.

2. Dimensions: Consider the space available and the dimensions of the components needed.

3. Aesthetics: The appearance of the framing system can impact the overall design, especially in customer-facing environments.

Conclusion

Modular framing systems, particularly those utilizing 20/80 aluminum extrusion, offer a wealth of benefits across various applications. Their versatility, ease of assembly, and cost-effectiveness make them an ideal choice for businesses looking to optimize their spaces. From workstations to display stands, the possibilities are endless. As industries continue to evolve, the demand for adaptable and efficient solutions will only grow, making modular framing systems a key player in the future of construction and design.

Frequently Asked Questions

1. What are the main advantages of using modular framing systems?

Modular framing systems offer versatility, ease of assembly, and cost-effectiveness. They can be customized for various applications and are easy to modify or expand as needed.

2. How does 20/80 aluminum extrusion compare to other materials?

20/80 aluminum extrusion is lightweight, corrosion-resistant, and strong, making it an excellent choice for modular framing systems compared to heavier materials like steel.

3. Can modular framing systems be used outdoors?

Yes, modular framing systems made from aluminum, such as 20/80 extrusion, are suitable for outdoor use due to their resistance to corrosion and weathering.

4. What types of projects are best suited for modular framing systems?

Modular framing systems are ideal for workstations, industrial racking, display stands, enclosures, and custom solutions across various industries.

5. How can I ensure the right profile is chosen for my project?

Consider factors such as load capacity, dimensions, and aesthetics when selecting a profile. Consulting with a professional can also help ensure the best choice for your specific needs.