Content Menu

● Understanding 135 Degree Aluminum Extrusions

● Applications in Construction

● Use in Automotive Manufacturing

● Furniture Design and Manufacturing

● Electronics and Technology

● Benefits of Using 135 Degree Aluminum Extrusions

● Conclusion

● Related Questions and Answers

>> 1. What are the typical costs associated with 135-degree aluminum extrusions?

>> 2. How do 135-degree aluminum extrusions compare in strength to other extrusion angles?

>> 3. What are the environmental impacts of producing 135-degree aluminum extrusions?

>> 4. Can 135-degree aluminum extrusions be used in outdoor applications?

>> 5. What industries are seeing increased demand for 135-degree aluminum extrusions?

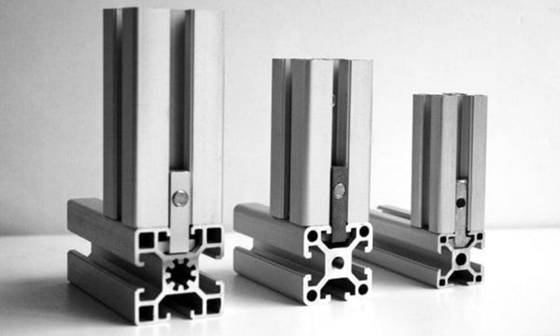

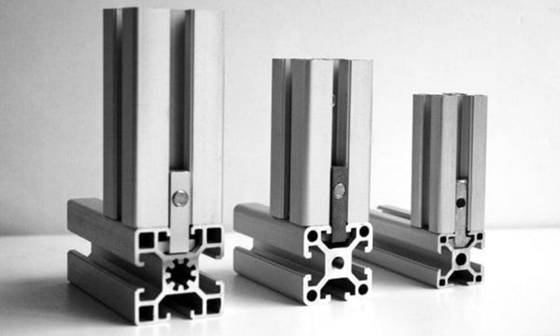

Aluminum extrusions are a vital component in various industries due to their lightweight, strength, and versatility. Among the different angles available, 135-degree aluminum extrusions have unique applications that make them particularly valuable. This article explores the best applications for 135-degree aluminum extrusions, highlighting their benefits and uses across various sectors.

Understanding 135 Degree Aluminum Extrusions

Aluminum extrusions are created by forcing aluminum alloy through a die, resulting in a specific cross-sectional shape. The 135-degree angle is particularly useful in applications where a change in direction is required without compromising structural integrity. This angle allows for seamless transitions in design, making it ideal for various construction and manufacturing needs.

Applications in Construction

In the construction industry, 135-degree aluminum extrusions are commonly used in window frames, curtain walls, and structural supports. Their ability to withstand environmental stressors while maintaining aesthetic appeal makes them a preferred choice for architects and builders. The extrusions can be easily integrated into various designs, providing both functionality and style.

Use in Automotive Manufacturing

The automotive industry also benefits from 135-degree aluminum extrusions. They are used in the production of lightweight vehicle components, contributing to fuel efficiency and performance. The strength-to-weight ratio of aluminum allows manufacturers to create durable parts that do not add excessive weight to the vehicle, enhancing overall efficiency.

Furniture Design and Manufacturing

In furniture design, 135-degree aluminum extrusions are utilized for creating modern and sleek furniture pieces. They are often found in the frames of chairs, tables, and shelving units. The versatility of aluminum allows designers to experiment with various shapes and configurations, resulting in innovative and functional furniture solutions.

Electronics and Technology

The electronics industry employs 135-degree aluminum extrusions in the production of enclosures and heat sinks. The excellent thermal conductivity of aluminum helps dissipate heat effectively, protecting sensitive electronic components. Additionally, the lightweight nature of aluminum makes it an ideal choice for portable devices, ensuring durability without adding unnecessary weight.

Benefits of Using 135 Degree Aluminum Extrusions

The advantages of using 135-degree aluminum extrusions extend beyond their applications. They offer several benefits, including:

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This property is particularly beneficial in outdoor applications where exposure to the elements is a concern.

- Customization: Aluminum extrusions can be easily customized to meet specific design requirements. Manufacturers can create unique shapes and sizes, allowing for greater flexibility in design.

- Sustainability: Aluminum is a recyclable material, making it an environmentally friendly choice. Using recycled aluminum reduces energy consumption and minimizes waste, contributing to sustainable manufacturing practices.

Conclusion

In summary, 135-degree aluminum extrusions play a crucial role in various industries, including construction, automotive, furniture design, and electronics. Their unique angle allows for versatile applications while providing numerous benefits such as corrosion resistance, customization, and sustainability. As industries continue to evolve, the demand for innovative materials like 135-degree aluminum extrusions will likely increase, paving the way for new applications and advancements.

Related Questions and Answers

1. What are the typical costs associated with 135-degree aluminum extrusions?

The cost of 135-degree aluminum extrusions can vary based on factors such as the alloy used, the complexity of the design, and the quantity ordered. Generally, prices range from $2 to $10 per pound, depending on these variables. Bulk orders often result in lower per-unit costs.

2. How do 135-degree aluminum extrusions compare in strength to other extrusion angles?

135-degree aluminum extrusions offer comparable strength to other angles, such as 90-degree or 45-degree extrusions. The choice of angle often depends on the specific application and design requirements. In many cases, the 135-degree angle provides better load distribution in certain structural applications.

3. What are the environmental impacts of producing 135-degree aluminum extrusions?

The production of aluminum extrusions, including 135-degree shapes, can have environmental impacts, primarily related to energy consumption and emissions. However, aluminum is highly recyclable, and using recycled materials significantly reduces the environmental footprint. Manufacturers are increasingly adopting sustainable practices to minimize these impacts.

4. Can 135-degree aluminum extrusions be used in outdoor applications?

Yes, 135-degree aluminum extrusions are suitable for outdoor applications due to their corrosion resistance. The natural oxide layer formed on aluminum protects it from environmental damage, making it an excellent choice for outdoor furniture, architectural elements, and structural components.

5. What industries are seeing increased demand for 135-degree aluminum extrusions?

Industries such as construction, automotive, and electronics are experiencing increased demand for 135-degree aluminum extrusions. As these sectors continue to innovate and seek lightweight, durable materials, the versatility of aluminum extrusions positions them as a preferred choice for various applications.