Content Menu

● Superior Thermal Management

● Lightweight and Durable

● Aesthetic Versatility

● Energy Efficiency

● Customization Options

● Cost-Effectiveness

● Eco-Friendly Choice

● Easy Installation

● Compatibility with Smart Lighting Systems

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. How does aluminum help with LED heat dissipation?

>> 3. Can aluminum extrusions be customized for specific projects?

>> 4. Are aluminum LED fixtures environmentally friendly?

>> 5. What are the installation advantages of aluminum extrusions?

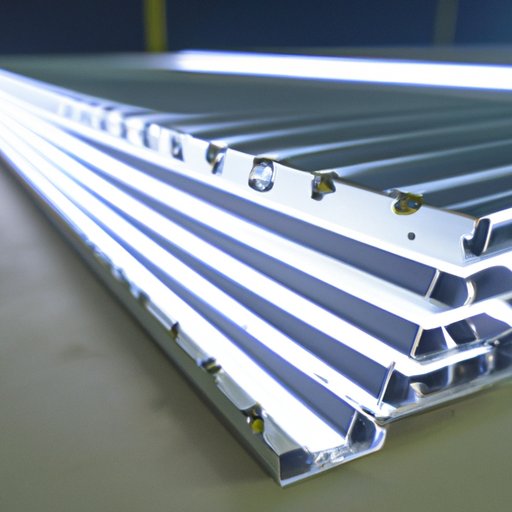

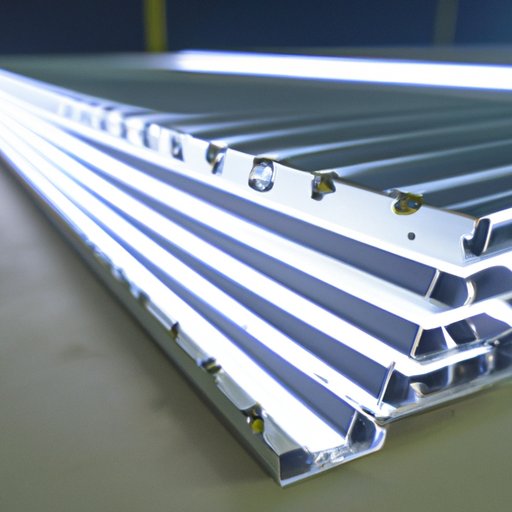

Aluminum extrusion has become a popular choice in the design and manufacturing of LED lighting solutions. This process involves shaping aluminum into specific profiles, which can then be used to house LED lights. The benefits of using aluminum extrusion for LED lighting are numerous, ranging from improved thermal management to aesthetic versatility. In this article, we will explore these benefits in detail, providing insights into why aluminum extrusion is an excellent choice for LED lighting applications.

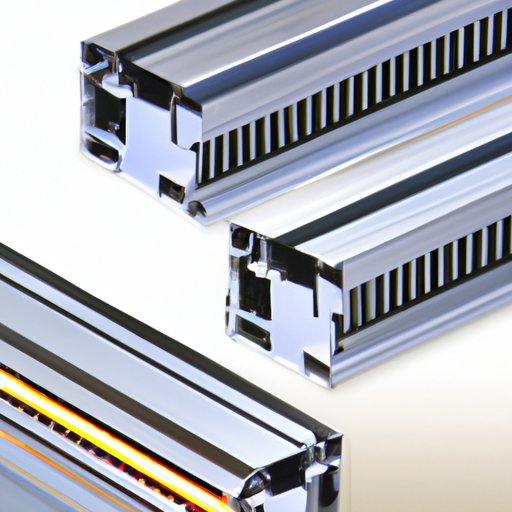

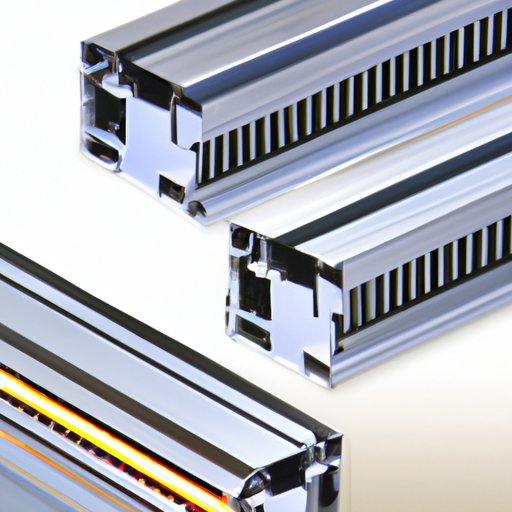

Superior Thermal Management

One of the most significant advantages of aluminum extrusion in LED lighting is its excellent thermal conductivity. LEDs generate heat during operation, and if this heat is not dissipated effectively, it can lead to reduced performance and a shorter lifespan for the lights. Aluminum, being a highly conductive material, allows for efficient heat dissipation, ensuring that the LEDs operate at optimal temperatures.

By using aluminum extrusions, manufacturers can design fixtures that maximize surface area for heat dissipation. This is particularly important in applications where LEDs are used continuously or in high-output scenarios, such as in commercial lighting or outdoor installations. The ability to maintain lower temperatures not only enhances the performance of the LEDs but also contributes to energy savings, as cooler LEDs consume less power.

Lightweight and Durable

Aluminum is known for its lightweight properties, making it an ideal material for LED lighting fixtures. This lightweight nature allows for easier installation and reduces the structural load on buildings and fixtures. Despite being lightweight, aluminum is also incredibly durable and resistant to corrosion, which is essential for outdoor applications where exposure to the elements can be a concern.

The durability of aluminum extrusions means that they can withstand harsh conditions without compromising their structural integrity. This longevity translates to lower maintenance costs and a longer lifespan for the lighting fixtures. In environments where lighting fixtures are subject to vibrations or impacts, such as in industrial settings, aluminum's resilience ensures that the fixtures remain intact and functional over time.

Aesthetic Versatility

Aluminum extrusions offer a wide range of design possibilities, allowing for creative and aesthetically pleasing lighting solutions. The extrusion process can create various shapes and sizes, enabling designers to develop unique fixtures that fit specific architectural styles and design themes. This versatility is particularly beneficial in modern architecture, where lighting plays a crucial role in enhancing the overall aesthetic of a space.

Additionally, aluminum can be finished in numerous ways, including anodizing, powder coating, and painting. These finishes not only enhance the appearance of the fixtures but also provide additional protection against wear and tear. The ability to customize colors and textures allows designers to create lighting solutions that seamlessly integrate with their surroundings, whether in residential, commercial, or public spaces.

Energy Efficiency

LED lighting is already known for its energy efficiency compared to traditional lighting solutions. However, the use of aluminum extrusion can further enhance this efficiency. The effective thermal management provided by aluminum helps maintain the optimal operating temperature for LEDs, which in turn maximizes their energy efficiency.

By keeping LEDs cooler, aluminum extrusions help reduce energy consumption, leading to lower electricity bills and a smaller carbon footprint. This makes aluminum extrusion an environmentally friendly choice for lighting solutions. As energy costs continue to rise, the demand for energy-efficient lighting solutions will only increase, making aluminum extrusion a smart investment for the future.

Customization Options

Aluminum extrusion allows for a high degree of customization, which is particularly beneficial for manufacturers and designers. Custom profiles can be created to meet specific project requirements, whether for residential, commercial, or industrial applications. This flexibility means that lighting solutions can be tailored to fit unique spaces and design needs.

Manufacturers can also incorporate features such as integrated diffusers, lenses, and mounting options directly into the extrusion, streamlining the production process and reducing assembly time. This level of customization not only enhances the functionality of the lighting fixtures but also allows for innovative designs that can set a project apart from the competition.

Cost-Effectiveness

While the initial investment in aluminum extrusion may be higher than other materials, the long-term cost savings are significant. The durability and low maintenance requirements of aluminum fixtures mean that they will not need to be replaced as frequently as other materials. Additionally, the energy savings associated with LED lighting further enhance the cost-effectiveness of using aluminum extrusion.

Over time, the combination of lower energy bills and reduced maintenance costs can lead to substantial savings, making aluminum extrusion a wise investment for lighting projects. Furthermore, the longevity of aluminum fixtures means that they contribute to a lower total cost of ownership, which is an essential consideration for businesses and organizations looking to manage their budgets effectively.

Eco-Friendly Choice

Aluminum is a highly recyclable material, making it an environmentally friendly option for LED lighting. The recycling process for aluminum requires only a fraction of the energy needed to produce new aluminum from raw materials. This means that using aluminum extrusions contributes to a more sustainable lighting solution.

By choosing aluminum extrusion for LED lighting, manufacturers and consumers can reduce their environmental impact and support a circular economy. The ability to recycle aluminum without degrading its quality ensures that it remains a viable material for future generations, aligning with the growing emphasis on sustainability in design and manufacturing.

Easy Installation

The design of aluminum extrusions often includes features that facilitate easy installation. Many extrusions come with pre-drilled holes or integrated mounting options, allowing for quick and straightforward installation. This ease of installation can save time and labor costs during the setup process.

Additionally, the lightweight nature of aluminum means that fewer personnel are required for installation, further reducing labor costs. In projects where time is of the essence, such as in commercial renovations or new construction, the ability to install lighting fixtures quickly can significantly impact project timelines and budgets.

Compatibility with Smart Lighting Systems

As the demand for smart lighting solutions continues to grow, aluminum extrusion provides a versatile platform for integrating smart technology. Many aluminum extrusions can accommodate smart LED modules, sensors, and control systems, allowing for the creation of advanced lighting solutions that can be controlled remotely.

This compatibility with smart systems enhances the functionality of LED lighting, providing users with greater control over their lighting environments. Features such as dimming, color changing, and scheduling can be easily integrated into aluminum extrusion designs, making them suitable for modern smart homes and commercial spaces.

Conclusion

In conclusion, the benefits of using aluminum extrusion for LED lighting are extensive. From superior thermal management and energy efficiency to aesthetic versatility and customization options, aluminum extrusions provide a robust solution for modern lighting needs. Their lightweight and durable nature, combined with cost-effectiveness and eco-friendliness, make them an ideal choice for a wide range of applications.

As the lighting industry continues to evolve, aluminum extrusion will undoubtedly play a crucial role in shaping the future of LED lighting solutions. Whether for residential, commercial, or industrial use, aluminum extrusions offer a combination of performance, design, and sustainability that is hard to beat.

Frequently Asked Questions

1. What is aluminum extrusion?

- Aluminum extrusion is a manufacturing process that shapes aluminum into specific profiles by forcing it through a die. This allows for the creation of complex shapes that can be used in various applications, including LED lighting.

2. How does aluminum help with LED heat dissipation?

- Aluminum has excellent thermal conductivity, which allows it to effectively dissipate heat generated by LEDs. This helps maintain optimal operating temperatures, improving performance and extending the lifespan of the lights.

3. Can aluminum extrusions be customized for specific projects?

- Yes, aluminum extrusions can be tailored to meet specific design and functional requirements, making them highly versatile for various lighting applications.

4. Are aluminum LED fixtures environmentally friendly?

- Yes, aluminum is recyclable and requires less energy to recycle than to produce new aluminum. This makes aluminum LED fixtures a more sustainable choice.

5. What are the installation advantages of aluminum extrusions?

- Aluminum extrusions are lightweight and often come with pre-drilled holes or integrated mounting options, making them easy to install and reducing labor costs.