Content Menu

● Introduction

● Understanding 15 Series Aluminum Profiles

● Advantages of 15 Series Aluminum Profiles

>> Strength and Durability

>> Versatility in Applications

>> Ease of Assembly

● Customization Options

● Accessories and Complementary Products

● Case Studies

● Conclusion

● Related Questions

>> 1. What industries commonly use 15 series aluminum profiles?

>> 2. How do I assemble 15 series aluminum profiles?

>> 3. Can I customize 15 series aluminum profiles?

>> 4. What are the advantages of using aluminum over other materials?

>> 5. Are there any limitations to using 15 series aluminum profiles?

Introduction

Aluminum extrusion has become a cornerstone in modern manufacturing and construction, offering a versatile and efficient solution for a wide range of applications. Among the various types of aluminum profiles available, the 15 series aluminum profiles stand out due to their unique design and functionality. These profiles are particularly favored in modular construction, robotics, and various industrial applications. This article delves into the benefits of using 15 series aluminum profiles in your projects, exploring their features, advantages, and practical applications.

Understanding 15 Series Aluminum Profiles

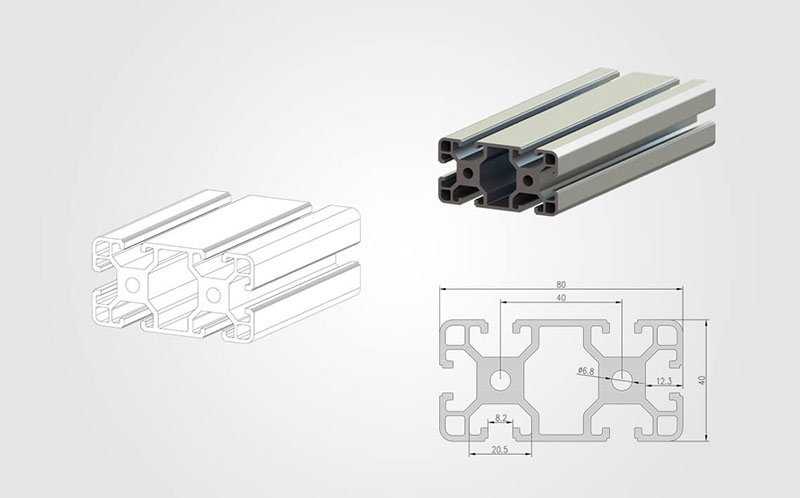

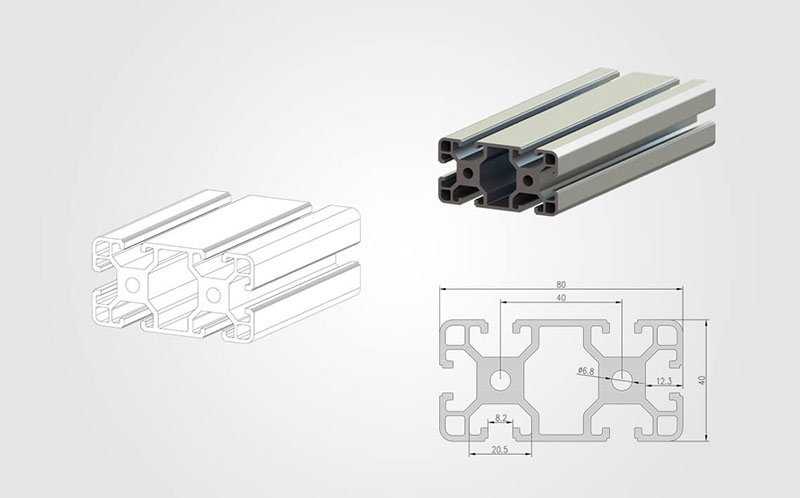

15 series aluminum profiles are characterized by their T-slot design, which allows for easy assembly and customization. Typically, these profiles have a width of 15mm, making them ideal for lightweight structures that require strength and stability. The T-slot design enables users to attach various components and accessories, facilitating the creation of complex structures without the need for welding or extensive machining.

The 15 series profiles are available in various lengths and can be cut to size, making them adaptable to different project requirements. Their compatibility with a wide range of accessories, such as brackets, connectors, and fasteners, enhances their versatility, allowing for innovative designs and configurations.

Advantages of 15 Series Aluminum Profiles

Strength and Durability

One of the primary benefits of using 15 series aluminum profiles is their strength and durability. Aluminum is known for its excellent strength-to-weight ratio, making it an ideal material for structural applications. The 15 series profiles are designed to withstand significant loads while remaining lightweight, which is crucial in applications where weight is a concern.

Additionally, aluminum is resistant to corrosion, which means that structures made from 15 series profiles can endure harsh environmental conditions without deteriorating. This durability translates to lower maintenance costs and longer service life, making it a cost-effective choice for many projects.

Versatility in Applications

The versatility of 15 series aluminum profiles is another significant advantage. These profiles are used in a wide range of industries, including manufacturing, automation, construction, and even furniture design. Their modular nature allows for easy modifications and expansions, making them suitable for both temporary and permanent structures.

For instance, in manufacturing, 15 series profiles can be used to create custom workstations, conveyor systems, and machine frames. In the construction industry, they are often employed in the assembly of modular buildings, providing a lightweight yet robust framework. The adaptability of these profiles means that they can be tailored to meet the specific needs of any project.

Ease of Assembly

The T-slot design of 15 series aluminum profiles significantly simplifies the assembly process. Users can easily connect profiles using standard fasteners, eliminating the need for specialized tools or skills. This ease of assembly not only saves time but also reduces labor costs, making it an attractive option for businesses looking to streamline their operations.

Moreover, the ability to disassemble and reconfigure structures without damage allows for flexibility in design. If project requirements change, users can easily modify their setups, making 15 series profiles a practical choice for dynamic environments.

Customization Options

One of the standout features of 15 series aluminum profiles is the extensive customization options available. Users can choose from a variety of lengths, finishes, and accessories to create a profile that meets their specific needs. Anodized finishes, for example, enhance the aesthetic appeal while providing additional protection against wear and corrosion.

Customizations can also include the addition of holes, slots, or other features that facilitate specific applications. This level of customization ensures that users can create solutions tailored to their unique project requirements, enhancing both functionality and appearance.

Accessories and Complementary Products

To maximize the functionality of 15 series aluminum profiles, a wide range of accessories is available. These include brackets, connectors, end caps, and fasteners, all designed to work seamlessly with the profiles. By utilizing these accessories, users can enhance the stability and versatility of their structures.

For example, corner brackets can be used to create strong joints between profiles, while connectors allow for the easy addition of new sections. End caps provide a finished look and protect the ends of the profiles from damage. The availability of these accessories makes it easy to build complex structures that are both functional and aesthetically pleasing.

Case Studies

Real-world applications of 15 series aluminum profiles illustrate their effectiveness and versatility. In one case, a manufacturing company utilized these profiles to create a custom assembly line. The lightweight yet sturdy design allowed for easy adjustments and modifications as production needs changed. The T-slot design facilitated quick assembly, reducing downtime and increasing productivity.

In another instance, a construction firm used 15 series profiles to build a modular office space. The ability to easily reconfigure the layout allowed the company to adapt to changing workforce needs. The durability of the aluminum ensured that the structure would withstand the test of time, providing a reliable workspace for years to come.

Conclusion

In conclusion, the benefits of using 15 series aluminum profiles in your projects are numerous. Their strength, durability, versatility, and ease of assembly make them an ideal choice for a wide range of applications. The extensive customization options and availability of complementary accessories further enhance their appeal, allowing users to create tailored solutions that meet their specific needs.

As industries continue to evolve, the demand for efficient and adaptable materials will only grow. The 15 series aluminum profiles stand ready to meet this demand, providing a reliable and innovative solution for modern construction and manufacturing challenges.

Related Questions

1. What industries commonly use 15 series aluminum profiles?

15 series aluminum profiles are widely used in manufacturing, automation, construction, and furniture design due to their versatility and strength.

2. How do I assemble 15 series aluminum profiles?

Assembling 15 series aluminum profiles is straightforward. Use standard fasteners to connect the profiles at the T-slots, allowing for quick and easy assembly without specialized tools.

3. Can I customize 15 series aluminum profiles?

Yes, 15 series aluminum profiles can be customized in terms of length, finish, and additional features to meet specific project requirements.

4. What are the advantages of using aluminum over other materials?

Aluminum offers a superior strength-to-weight ratio, corrosion resistance, and ease of fabrication compared to many other materials, making it an excellent choice for structural applications.

5. Are there any limitations to using 15 series aluminum profiles?

While 15 series aluminum profiles are highly versatile, they may not be suitable for extremely heavy-duty applications where higher strength materials are required. However, they excel in most standard applications.