Content Menu

● Introduction

● The Aluminum Extrusion Process

● Advantages of Custom Aluminum Profiles

>> Enhanced Product Performance

>> Cost Reduction

>> Design Flexibility

>> Lightweight and Strong

>> Corrosion Resistance

● Applications of Aluminum Profiles in Various Industries

>> Construction and Architecture

>> Automotive Industry

>> Electronics

>> Aerospace

>> Other Industrial Applications

● Choosing an Aluminum Extrusion Service Provider

>> Quality Control

>> Lead Times

>> Customer Service and Support

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum profiles in manufacturing?

>> 2. How does the aluminum extrusion process work?

>> 3. What industries benefit from custom aluminum profiles?

>> 4. Why is design flexibility important in manufacturing?

>> 5. How can I choose the right aluminum extrusion service provider?

Introduction

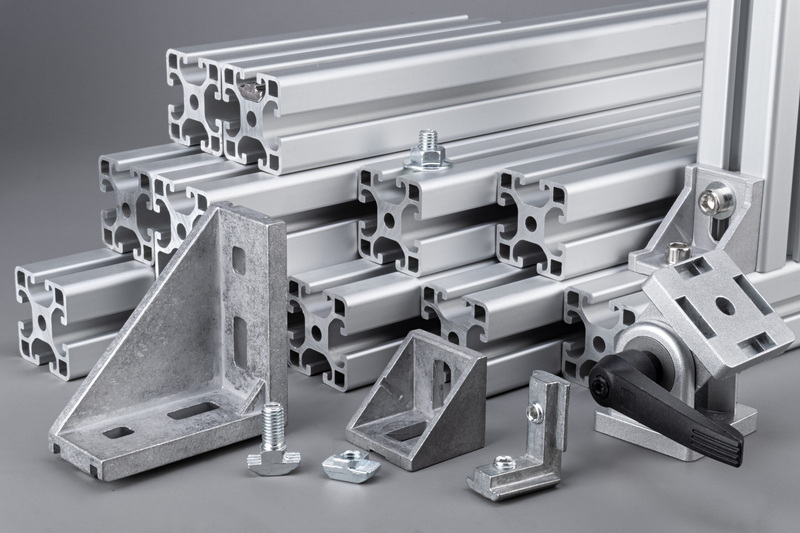

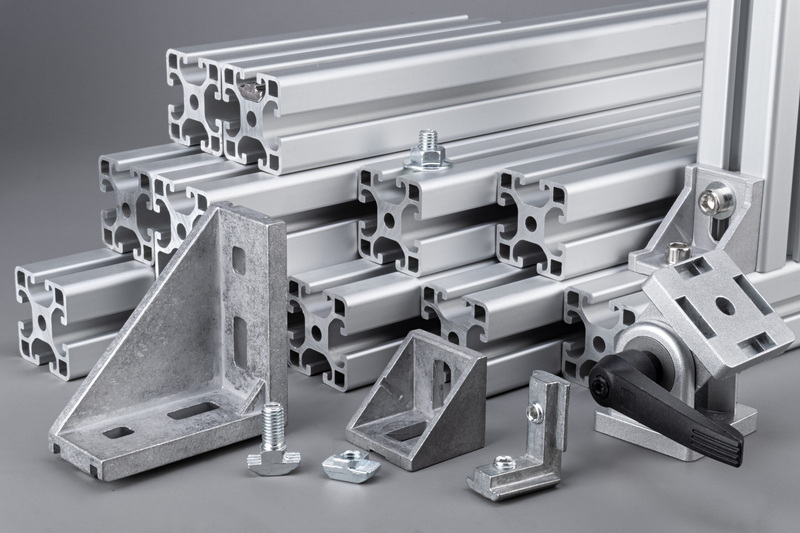

In the ever-evolving landscape of modern manufacturing, the demand for materials that offer both versatility and efficiency has never been higher. Among these materials, aluminum stands out due to its unique properties, making it an ideal choice for a wide range of applications. Custom aluminum profiles, particularly those produced by companies like Can Art Aluminum Extrusion Inc., have become increasingly popular. These profiles not only enhance product performance but also provide manufacturers with the flexibility needed to innovate and adapt to market demands.

The Aluminum Extrusion Process

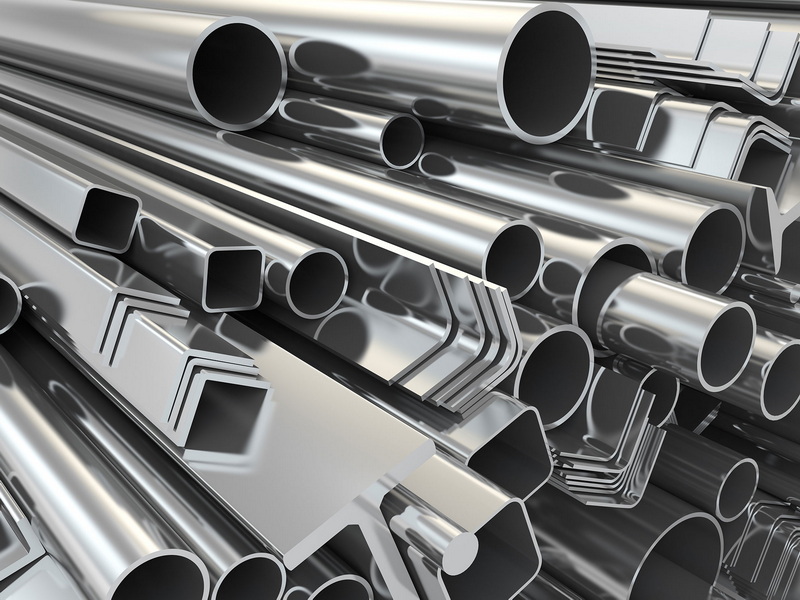

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process allows for the creation of complex shapes and profiles that can be tailored to specific applications. The extrusion process begins with heating aluminum billets, which are then pushed through a die using a hydraulic press. The result is a continuous length of aluminum profile that can be cut to desired lengths.

One of the key advantages of aluminum extrusion is its ability to produce lightweight yet strong components. This is particularly beneficial in industries where weight reduction is critical, such as aerospace and automotive. Additionally, the extrusion process allows for the incorporation of various features, such as grooves and channels, which can enhance the functionality of the final product.

Advantages of Custom Aluminum Profiles

Custom aluminum profiles offer numerous advantages that make them an attractive option for manufacturers. Here are some of the key benefits:

Enhanced Product Performance

Custom aluminum profiles are designed to meet specific performance requirements. By tailoring the shape and dimensions of the profile, manufacturers can optimize the strength-to-weight ratio, thermal conductivity, and corrosion resistance of their products. This level of customization ensures that the final product performs optimally in its intended application.

Cost Reduction

While the initial investment in custom aluminum profiles may be higher than standard options, the long-term cost savings can be significant. Custom profiles can reduce material waste, as they are designed to fit specific applications without the need for additional machining or fabrication. This efficiency not only lowers production costs but also minimizes lead times, allowing manufacturers to respond quickly to market demands.

Design Flexibility

One of the most significant advantages of custom aluminum profiles is the design flexibility they offer. Manufacturers can create profiles that meet their exact specifications, allowing for innovative designs that may not be possible with standard materials. This flexibility is particularly valuable in industries such as architecture and construction, where unique designs can set a product apart from the competition.

Lightweight and Strong

Aluminum is known for its lightweight properties, making it an ideal choice for applications where weight is a concern. Custom aluminum profiles maintain this lightweight characteristic while providing exceptional strength. This combination is particularly beneficial in industries such as automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This property is especially important in applications where components are exposed to harsh environments, such as marine or industrial settings. Custom aluminum profiles can be further enhanced with anodizing or other surface treatments to improve their corrosion resistance, ensuring longevity and reliability.

Applications of Aluminum Profiles in Various Industries

Custom aluminum profiles are utilized across a wide range of industries, each benefiting from the unique properties of aluminum. Here are some notable applications:

Construction and Architecture

In the construction industry, custom aluminum profiles are used for window frames, curtain walls, and structural components. Their lightweight nature and design flexibility allow architects to create innovative designs that enhance the aesthetic appeal of buildings while maintaining structural integrity.

Automotive Industry

The automotive industry has increasingly turned to custom aluminum profiles to reduce vehicle weight and improve fuel efficiency. Components such as chassis, body panels, and interior fittings can be manufactured using aluminum profiles, contributing to overall vehicle performance.

Electronics

In the electronics sector, custom aluminum profiles are used for heat sinks, enclosures, and structural supports. The excellent thermal conductivity of aluminum helps dissipate heat effectively, ensuring the longevity and reliability of electronic devices.

Aerospace

The aerospace industry demands materials that are both lightweight and strong. Custom aluminum profiles are used in aircraft structures, components, and interiors, contributing to improved fuel efficiency and performance.

Other Industrial Applications

Custom aluminum profiles are also used in various industrial applications, including machinery, equipment, and transportation. Their versatility and adaptability make them suitable for a wide range of manufacturing needs.

Choosing an Aluminum Extrusion Service Provider

When selecting a provider for custom aluminum profiles, several factors should be considered to ensure quality and reliability:

Quality Control

A reputable aluminum extrusion service provider, such as Can Art Aluminum Extrusion Inc., should have stringent quality control measures in place. This includes regular inspections and testing of materials to ensure that they meet industry standards and customer specifications.

Lead Times

Timely delivery is crucial in manufacturing. Choose a provider that can meet your production schedules without compromising on quality. Efficient production processes and logistics are essential for minimizing lead times.

Customer Service and Support

A strong customer service team can make a significant difference in the overall experience. Look for a provider that offers support throughout the design and manufacturing process, ensuring that your needs are met at every stage.

Conclusion

Custom aluminum profiles play a vital role in modern manufacturing, offering numerous benefits that enhance product performance, reduce costs, and provide design flexibility. Industries ranging from construction to aerospace are leveraging the advantages of aluminum extrusion to create innovative solutions that meet the demands of today's market. By choosing a reliable provider like Can Art Aluminum Extrusion Inc., manufacturers can ensure they receive high-quality custom profiles that contribute to their success.

Related Questions

1. What are the main advantages of using aluminum profiles in manufacturing?

Aluminum profiles offer lightweight strength, corrosion resistance, design flexibility, and cost efficiency, making them ideal for various applications.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum billets and forcing them through a die to create custom shapes and profiles.

3. What industries benefit from custom aluminum profiles?

Industries such as construction, automotive, electronics, and aerospace benefit significantly from custom aluminum profiles due to their unique properties.

4. Why is design flexibility important in manufacturing?

Design flexibility allows manufacturers to create innovative products tailored to specific applications, enhancing competitiveness and market appeal.

5. How can I choose the right aluminum extrusion service provider?

Consider factors such as quality control, lead times, and customer service when selecting an aluminum extrusion service provider to ensure a successful partnership.