Content Menu

● Introduction

● Advantages of Triangular Aluminum Tubing

>> Structural Strength

>> Lightweight

>> Corrosion Resistance

>> Aesthetic Appeal

● Applications of Triangular Aluminum Tubing

>> Architectural Structures

>> Furniture Design

>> Industrial Applications

>> Transportation

>> Sports and Recreation

>> Custom Applications

● Customizing Triangular Aluminum Tubing

>> Case Studies of Successful Custom Applications

● Conclusion

● Related Questions

>> 1. What are the key benefits of using triangular aluminum tubing in construction?

>> 2. How does triangular aluminum tubing compare to traditional tubing materials?

>> 3. Can triangular aluminum tubing be customized for specific applications?

>> 4. What industries benefit the most from triangular aluminum tubing?

>> 5. How does the weight of triangular aluminum tubing impact its applications?

Introduction

Triangular aluminum tubing is a versatile and innovative material that has gained popularity in various industries due to its unique shape and properties. Unlike traditional round or square tubing, triangular aluminum extrusion offers distinct advantages in terms of strength, weight, and aesthetic appeal. This article explores the various applications best suited for triangular aluminum tubing, highlighting its benefits and showcasing its potential in modern design and construction.

Advantages of Triangular Aluminum Tubing

Triangular aluminum tubing boasts several advantages that make it an ideal choice for various applications.

Structural Strength

One of the primary benefits of triangular aluminum tubing is its structural strength. The triangular shape provides excellent load-bearing capabilities, making it suitable for applications where stability and support are crucial. The geometry of the triangle distributes weight evenly, reducing the risk of bending or deformation under stress. This makes triangular aluminum tubing an excellent choice for construction projects, where structural integrity is paramount.

Lightweight

Another significant advantage of triangular aluminum tubing is its lightweight nature. Aluminum is known for being a lightweight material, and when combined with the triangular design, it results in a product that is easy to handle and transport. This lightweight characteristic is particularly beneficial in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance.

Corrosion Resistance

Aluminum is naturally resistant to corrosion, which makes triangular aluminum tubing an excellent choice for outdoor applications. The material can withstand harsh weather conditions without deteriorating, ensuring longevity and durability. This property is especially important in construction and architectural applications, where exposure to the elements is inevitable.

Aesthetic Appeal

The unique shape of triangular aluminum tubing also adds an aesthetic element to designs. Its sleek lines and modern appearance can enhance the visual appeal of structures and products. Designers and architects often seek out triangular aluminum tubing for its ability to create striking visual elements while maintaining functionality.

Applications of Triangular Aluminum Tubing

Triangular aluminum tubing finds applications across various industries, each benefiting from its unique properties. Here are some of the most common applications:

Architectural Structures

In the realm of architecture, triangular aluminum tubing is increasingly used in the construction of modern buildings. Its strength and lightweight nature make it an ideal choice for framing and support structures. Architects can create innovative designs that incorporate triangular aluminum tubing, allowing for open spaces and unique shapes that traditional materials may not support.

Furniture Design

Triangular aluminum tubing is also making waves in furniture design. Its modern aesthetic and structural integrity allow designers to create stylish and functional pieces. From tables and chairs to shelving units, triangular aluminum tubing can be used to craft furniture that is not only visually appealing but also durable and lightweight. This is particularly advantageous for modular furniture systems that require easy assembly and disassembly.

Industrial Applications

In industrial settings, triangular aluminum tubing is utilized for various purposes, including the construction of frames for machinery and equipment. Its strength and resistance to corrosion make it suitable for environments where heavy loads and exposure to chemicals are common. Additionally, triangular aluminum tubing can be used in conveyor systems, providing a lightweight yet robust solution for transporting goods.

Transportation

The transportation industry benefits significantly from the use of triangular aluminum tubing. In automotive and aerospace applications, reducing weight is crucial for improving fuel efficiency and performance. Triangular aluminum tubing can be used in the construction of vehicle frames, support structures, and even in the design of aircraft components. Its strength-to-weight ratio makes it an ideal choice for manufacturers looking to enhance their products' performance.

Sports and Recreation

Triangular aluminum tubing is also popular in the sports and recreation industry. It is commonly used in the construction of lightweight and durable equipment, such as bicycle frames, tents, and outdoor structures. The ability to create strong yet lightweight designs allows for improved performance and ease of use in various recreational activities.

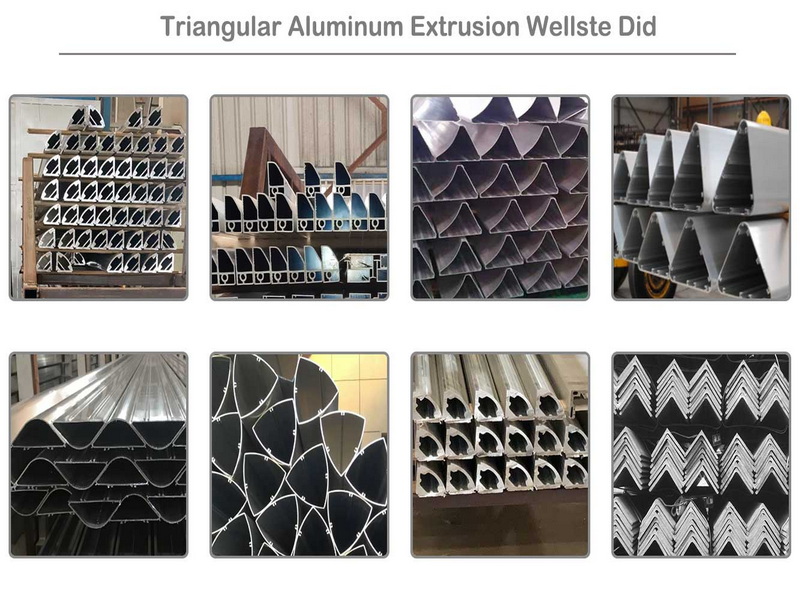

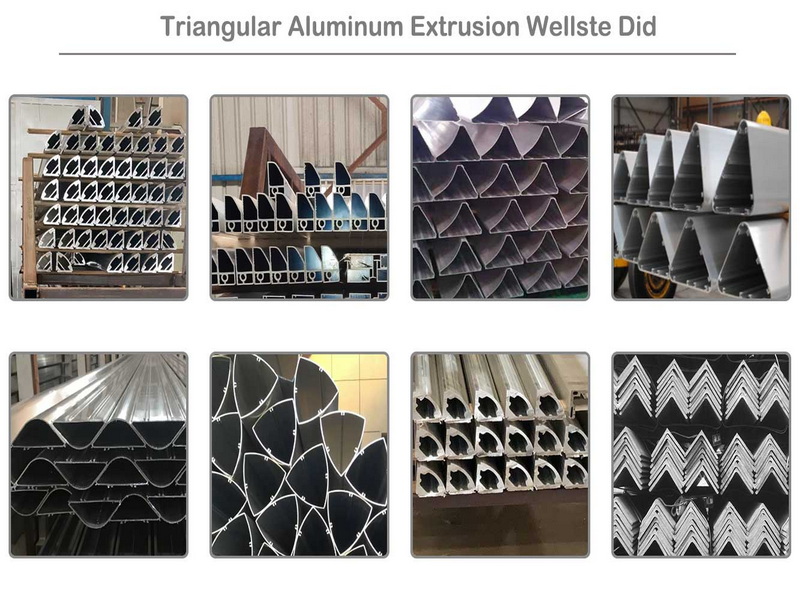

Custom Applications

One of the most significant advantages of triangular aluminum tubing is its versatility. Manufacturers can create custom extrusions tailored to specific needs, allowing for unique applications across different industries. Whether it's a specialized frame for a piece of machinery or a custom design for a piece of furniture, the possibilities are endless.

Customizing Triangular Aluminum Tubing

The ability to customize triangular aluminum tubing is a game-changer for many industries. Manufacturers can work with clients to develop specific shapes, sizes, and finishes that meet their unique requirements. This customization process allows for greater flexibility in design and functionality, ensuring that the final product aligns perfectly with the intended application.

Case Studies of Successful Custom Applications

Several companies have successfully utilized custom triangular aluminum tubing in their projects. For instance, a furniture manufacturer created a line of modular shelving units using triangular aluminum tubing, allowing customers to easily configure their storage solutions. The lightweight nature of the tubing made it easy to transport and assemble, while the modern design appealed to a wide range of consumers.

In another example, an aerospace company developed a new aircraft component using triangular aluminum tubing. The custom extrusion provided the necessary strength while significantly reducing weight, leading to improved fuel efficiency and performance.

Conclusion

Triangular aluminum tubing is a versatile and innovative material that offers numerous advantages across various applications. Its structural strength, lightweight nature, corrosion resistance, and aesthetic appeal make it an ideal choice for industries ranging from architecture to transportation. As manufacturers continue to explore the potential of triangular aluminum tubing, we can expect to see even more creative and functional applications in the future.

Related Questions

1. What are the key benefits of using triangular aluminum tubing in construction?

Triangular aluminum tubing offers structural strength, lightweight properties, corrosion resistance, and aesthetic appeal, making it ideal for modern architectural designs.

2. How does triangular aluminum tubing compare to traditional tubing materials?

Triangular aluminum tubing is lighter and more corrosion-resistant than traditional materials like steel, while also providing unique design opportunities due to its shape.

3. Can triangular aluminum tubing be customized for specific applications?

Yes, triangular aluminum tubing can be customized in terms of shape, size, and finish to meet the specific needs of various industries and applications.

4. What industries benefit the most from triangular aluminum tubing?

Industries such as construction, furniture design, transportation, and sports and recreation benefit significantly from the use of triangular aluminum tubing.

5. How does the weight of triangular aluminum tubing impact its applications?

The lightweight nature of triangular aluminum tubing allows for easier handling, transportation, and assembly, making it particularly advantageous in industries where weight reduction is critical.