Content Menu

● Understanding 1030 Aluminum Extrusion

>> Key Properties of 1030 Aluminum

● Applications of 1030 Aluminum Extrusion

>> Architectural Applications

>> Transportation Industry

>> Electrical and Electronics

>> Industrial Applications

>> Consumer Products

>> Marine Applications

>> Renewable Energy

>> Medical Equipment

>> Furniture and Interior Design

>> Aerospace Applications

● Conclusion

● Frequently Asked Questions

>> 1. What is 1030 aluminum extrusion?

>> 2. What are the benefits of using 1030 aluminum extrusion?

>> 3. In which industries is 1030 aluminum extrusion commonly used?

>> 4. Can 1030 aluminum extrusion be customized?

>> 5. How does 1030 aluminum extrusion compare to other aluminum alloys?

Understanding 1030 Aluminum Extrusion

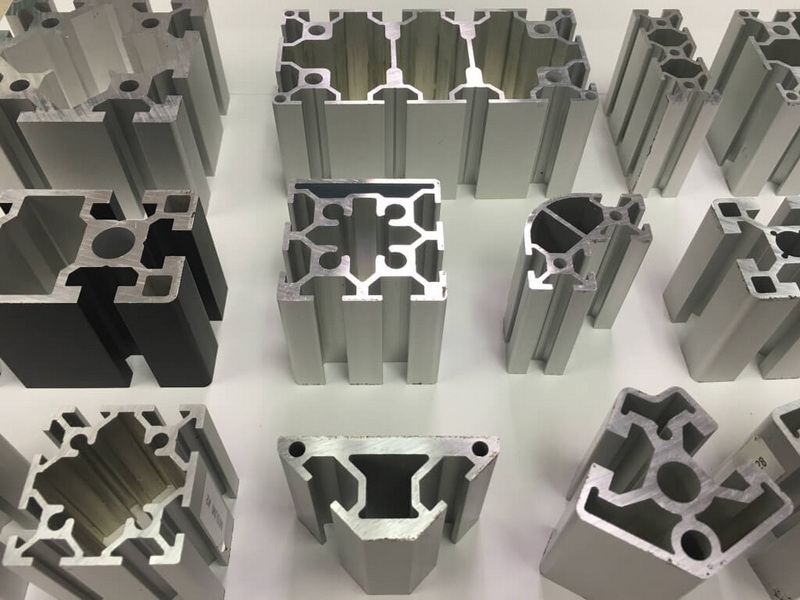

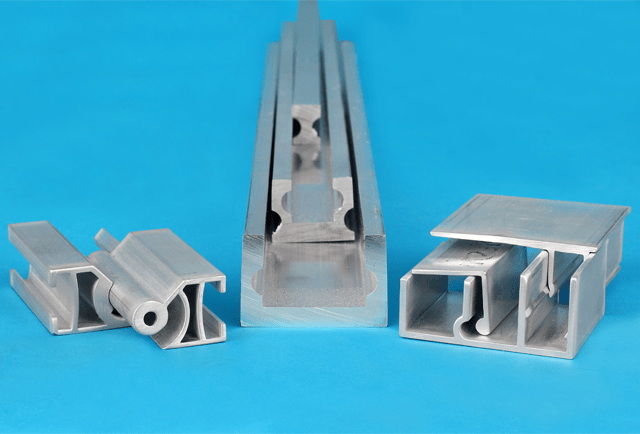

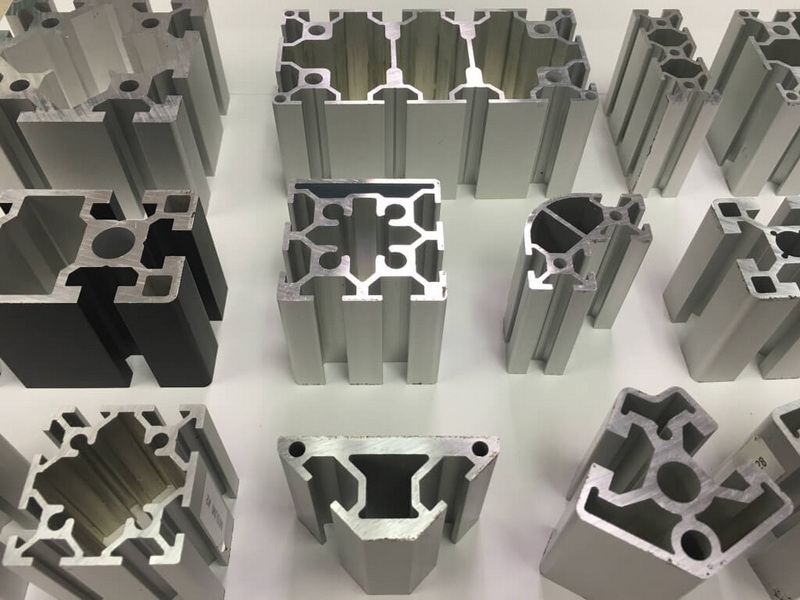

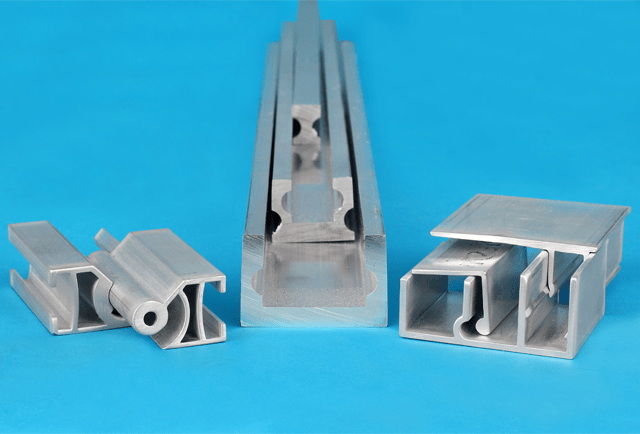

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. Among the various aluminum alloys available, 1030 aluminum extrusion is particularly notable for its unique properties and versatility. This article explores the applications best suited for 1030 aluminum extrusion, highlighting its benefits, characteristics, and the industries that utilize it.

1030 aluminum is a type of aluminum alloy that is primarily composed of aluminum with a small percentage of silicon and iron. This alloy is known for its excellent corrosion resistance, good machinability, and moderate strength. The extrusion process involves forcing the aluminum alloy through a die to create long shapes with a consistent cross-section. This method allows for the production of complex shapes that can be tailored to specific applications.

Key Properties of 1030 Aluminum

Before diving into its applications, it's essential to understand the key properties that make 1030 aluminum extrusion a preferred choice in various industries:

- Corrosion Resistance: 1030 aluminum exhibits excellent resistance to corrosion, making it suitable for outdoor and marine applications.

- Lightweight: Aluminum is significantly lighter than many other metals, which is advantageous in applications where weight reduction is critical.

- Machinability: This alloy can be easily machined, allowing for precise fabrication and assembly.

- Formability: The extrusion process enables the creation of intricate shapes and profiles that can meet specific design requirements.

- Cost-Effectiveness: Compared to other materials, aluminum extrusion can be a more economical choice, especially for large production runs.

Applications of 1030 Aluminum Extrusion

Architectural Applications

One of the most common uses of 1030 aluminum extrusion is in architectural applications. The alloy's lightweight nature and corrosion resistance make it ideal for window frames, door frames, and curtain walls. Architects and builders often choose aluminum extrusions for their aesthetic appeal and durability. The ability to create custom shapes allows for innovative designs that enhance the overall look of buildings while providing structural integrity.

Transportation Industry

The transportation industry benefits significantly from the use of 1030 aluminum extrusion. Components such as structural frames, chassis, and body panels for vehicles, trains, and aircraft are often made from this alloy. The lightweight properties of aluminum help improve fuel efficiency and reduce emissions. Additionally, the strength-to-weight ratio of 1030 aluminum makes it an ideal choice for high-performance vehicles, where every ounce counts.

Electrical and Electronics

In the electrical and electronics sector, 1030 aluminum extrusion is used for heat sinks, enclosures, and other components. The alloy's excellent thermal conductivity helps dissipate heat effectively, making it suitable for electronic devices that generate heat during operation. This property is particularly important in applications such as LED lighting, where efficient heat management is crucial for performance and longevity.

Industrial Applications

1030 aluminum extrusion is widely used in various industrial applications, including manufacturing equipment, conveyor systems, and machine frames. Its strength and durability make it an excellent choice for components that must withstand heavy loads and harsh environments. The versatility of aluminum extrusions allows for the creation of modular systems that can be easily adapted to changing production needs.

Consumer Products

Many consumer products utilize 1030 aluminum extrusion, including furniture, appliances, and sporting goods. The alloy's versatility allows manufacturers to create stylish and functional designs that appeal to consumers. For instance, aluminum frames for bicycles and other sporting equipment benefit from the lightweight and durable nature of 1030 aluminum, enhancing performance and user experience.

Marine Applications

Due to its corrosion resistance, 1030 aluminum extrusion is an excellent choice for marine applications. Boat frames, railings, and other components exposed to saltwater environments benefit from the alloy's durability and resistance to corrosion. The lightweight nature of aluminum also contributes to improved performance and fuel efficiency in marine vessels.

Renewable Energy

The renewable energy sector, particularly solar energy, utilizes 1030 aluminum extrusion for mounting systems and frames for solar panels. The lightweight and corrosion-resistant properties of aluminum make it ideal for outdoor installations. Additionally, the ability to create custom profiles allows for optimized designs that enhance the efficiency of solar energy systems.

Medical Equipment

In the medical field, 1030 aluminum extrusion is used for various equipment and devices. Its lightweight and non-corrosive nature make it suitable for medical carts, frames, and other applications where hygiene and durability are essential. The ability to fabricate complex shapes also allows for the design of specialized medical devices that meet stringent industry standards.

Furniture and Interior Design

Aluminum extrusions are increasingly popular in furniture design. 1030 aluminum is used for table frames, shelving units, and decorative elements, providing a modern and sleek aesthetic. The versatility of aluminum allows designers to create innovative and functional furniture pieces that are both stylish and durable.

Aerospace Applications

The aerospace industry also benefits from 1030 aluminum extrusion. Components such as aircraft frames, wing structures, and fuselage parts are often made from this alloy due to its lightweight and high-strength properties. The use of aluminum in aerospace applications contributes to improved fuel efficiency and performance, making it a preferred material for manufacturers.

Conclusion

1030 aluminum extrusion is a versatile and valuable material used across various industries. Its unique properties, including corrosion resistance, lightweight nature, and machinability, make it suitable for numerous applications, from architecture to aerospace. As industries continue to seek lightweight and durable materials, the demand for 1030 aluminum extrusion is likely to grow.

Frequently Asked Questions

1. What is 1030 aluminum extrusion?

1030 aluminum extrusion is a type of aluminum alloy primarily composed of aluminum with small amounts of silicon and iron, known for its corrosion resistance and lightweight properties.

2. What are the benefits of using 1030 aluminum extrusion?

The benefits include excellent corrosion resistance, lightweight nature, good machinability, formability, and cost-effectiveness.

3. In which industries is 1030 aluminum extrusion commonly used?

It is commonly used in architecture, transportation, electrical and electronics, industrial applications, consumer products, marine applications, renewable energy, medical equipment, furniture design, and aerospace.

4. Can 1030 aluminum extrusion be customized?

Yes, 1030 aluminum extrusion can be customized to meet specific design requirements, including different shapes, sizes, and finishes.

5. How does 1030 aluminum extrusion compare to other aluminum alloys?

1030 aluminum extrusion offers a balance of strength, corrosion resistance, and machinability, making it suitable for various applications compared to other aluminum alloys. Its unique properties allow it to excel in specific applications where other alloys may not perform as well.

This comprehensive overview of 1030 aluminum extrusion highlights its diverse applications and benefits across multiple industries, showcasing its importance in modern manufacturing and design.