Content Menu

● Introduction to PVC Tube Extrusion

● Factors Affecting the Price of PVC Tube Extrusion Equipment

>> 1. Material Quality and Raw Material Costs

>> 2. Machinery Specifications

>> 3. Production Line Configuration

>> 4. Market Dynamics

>> 5. Regional Considerations

● Best PVC Tube Extrusion Equipment Price Considerations

● Cost Reduction Strategies for PVC Extrusion Plants

● Technological Advancements and Market Trends

● Future Outlook and Challenges

● Conclusion

● FAQ

>> 1. What is the typical price range for PVC tube extrusion equipment?

>> 2. How does the type of extruder affect the price?

>> 3. What role does automation play in pricing?

>> 4. How do regional factors influence equipment pricing?

>> 5. What are the benefits of investing in energy-efficient machinery?

● Citations:

The cost of PVC tube extrusion equipment can vary significantly based on several key factors. Understanding these factors is crucial for manufacturers looking to invest in the best PVC tube extrusion equipment at the optimal price. This article will delve into the main elements that influence the pricing of PVC tube extrusion machinery, including material quality, machinery specifications, production line configuration, market dynamics, and regional considerations.

Introduction to PVC Tube Extrusion

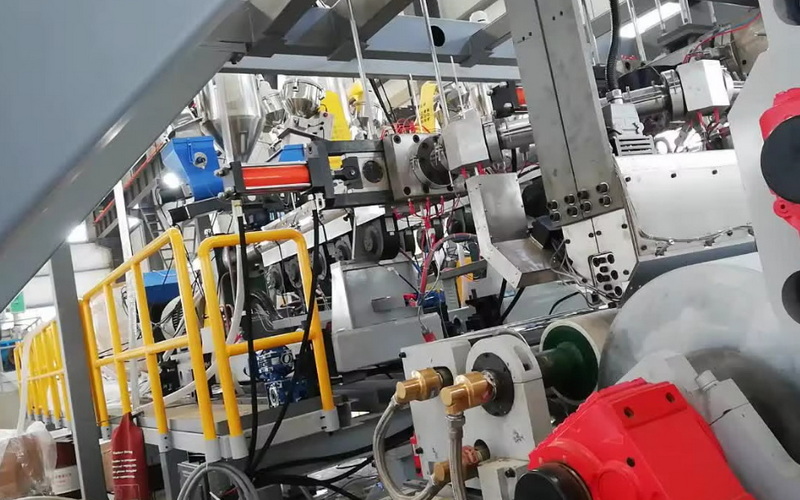

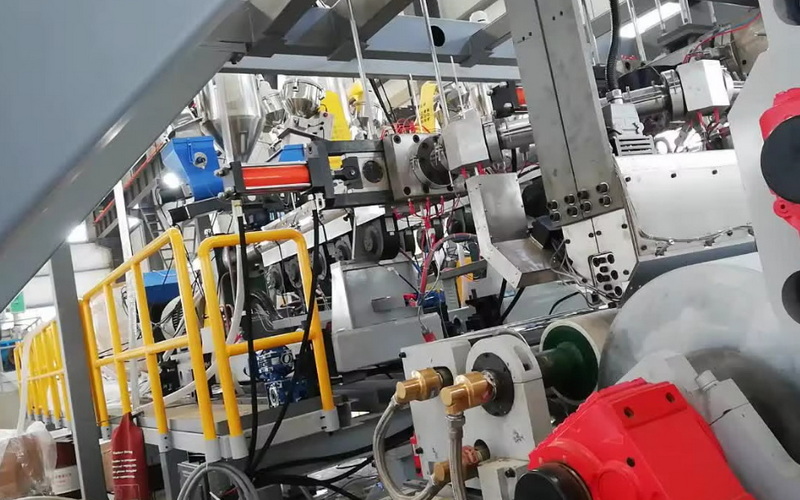

PVC tube extrusion is a process used to manufacture PVC tubes and pipes for various applications, such as plumbing, electrical conduits, and medical devices. The process involves melting PVC resin and shaping it into tubes through an extruder. The quality and efficiency of the extrusion equipment play a significant role in determining the final product's quality and the overall cost-effectiveness of the production process.

Factors Affecting the Price of PVC Tube Extrusion Equipment

1. Material Quality and Raw Material Costs

The quality of the PVC resin and additives used in the extrusion process directly impacts the cost. Higher-quality materials often result in better-performing pipes but come at a higher cost. Fluctuations in raw material prices, influenced by supply chain issues or market demand, can significantly affect production expenses. For instance, increased demand for PVC products can lead to higher raw material prices, while supply chain disruptions can affect the availability and cost of vinyl chloride monomer (VCM), a key component in PVC production[1].

2. Machinery Specifications

The specifications of the extrusion machinery itself are a crucial factor in determining the price. Key specifications include:

- Type of Extruder: Single-screw and twin-screw extruders are the two main types. Twin-screw extruders are generally more expensive due to their greater processing capabilities and flexibility in handling various formulations[1][4].

- Output Capacity: The production capacity, typically measured in kilograms per hour (kg/h), directly influences the price. Higher output capacities require more robust machinery, leading to increased costs[1][4].

- Automation Level: Advanced automation features can enhance efficiency and reduce labor costs but may also raise initial investments[1][6].

3. Production Line Configuration

A complete PVC tube extrusion line includes several components:

- Feeding System: This system transports raw materials to the extruder.

- Extruder: The heart of the operation, where raw materials are melted and shaped into tubes.

- Cooling System: Essential for maintaining the shape and integrity of extruded tubes.

- Haul-off Unit: Pulls the finished tube from the extruder at a controlled speed.

- Cutting Equipment: Used to cut tubes to specified lengths.

Each additional component or advanced feature can increase overall costs[1].

4. Market Dynamics

Market conditions also play a significant role in pricing:

- Competitive Landscape: The presence of multiple manufacturers can drive prices down due to competition. Conversely, limited suppliers can lead to higher prices[1].

- Economic Factors: Inflation rates, currency fluctuations, and changes in trade policies can impact costs across the board[1].

The global PVC pipe extruder market is experiencing robust growth, driven by expanding construction and agricultural sectors. This growth is fueled by infrastructure development projects and agricultural demands for irrigation systems, which increases the demand for PVC pipes and extrusion machinery[2].

5. Regional Considerations

Geographical location affects pricing due to variations in:

- Transportation Costs: Shipping machinery and materials can add significant expenses based on distance and logistics challenges[1].

- Labor Costs: Labor rates vary by region, impacting overall production costs[1].

- Regulatory Environment: Stricter regulations in certain areas may necessitate additional investments in compliance technologies or processes[1].

Best PVC Tube Extrusion Equipment Price Considerations

When looking for the best PVC tube extrusion equipment price, manufacturers should consider the following:

- Quality vs. Cost: While higher-quality equipment may be more expensive upfront, it can lead to better product quality and longer machinery lifespan.

- Customization: Tailoring equipment to specific production needs can optimize efficiency and reduce long-term costs.

- Energy Efficiency: Investing in energy-efficient machines may have higher upfront costs but can result in significant savings over time[3][6].

Cost Reduction Strategies for PVC Extrusion Plants

Starting a PVC extrusion plant involves various expenses that can be strategically minimized to enhance profitability without compromising quality. Here are several areas where costs can be reduced:

- Machinery and Equipment: Consider investing in used extrusion machinery or leasing options to cut initial costs by up to 30%[3].

- Facility Costs: Leasing facilities instead of purchasing can lower initial outlays and operational flexibility, potentially reducing costs by up to 25%[3].

- Raw Materials: Building strong relationships with suppliers for bulk purchasing discounts can lead to savings of approximately 15% on raw materials[3].

- Utility Setup: Implementing energy-efficient systems can lower utility costs by up to 20%[3].

- Marketing Expenses: Utilizing social media and online platforms for marketing can reduce traditional advertising costs by around 40%[3].

Technological Advancements and Market Trends

The PVC pipe extruder market is experiencing steady growth, driven by sustained demand from the construction and infrastructure sectors. Technological advancements in extruder design, such as the adoption of twin-screw extruders for enhanced performance and the integration of advanced control systems, are shaping market trends. These advancements include features like improved energy efficiency, higher output rates, and better product quality[2].

The increasing adoption of automation in extrusion processes further contributes to the growth of the market by improving operational efficiency. Additionally, there is a rising focus on enhancing the durability and lifespan of PVC pipes, which increases their cost-effectiveness[2].

Innovation in material formulations, including the use of recycled PVC, aims to minimize environmental impact while maintaining product quality. This trend is driven by environmental concerns surrounding PVC production and disposal, leading manufacturers to explore more sustainable manufacturing processes[2].

Future Outlook and Challenges

The future of the PVC pipe extruder market is expected to witness strategic mergers and acquisitions, intensifying competition and further driving innovation. The focus on customization and providing tailored solutions for specific applications will also be a key driver for success in this dynamic market. Continued investment in research and development aimed at creating more energy-efficient and sustainable extrusion processes is crucial for long-term market leadership[2].

However, the market also faces challenges such as fluctuating raw material prices and environmental concerns regarding PVC. These challenges necessitate proactive adaptation by manufacturers to maintain competitiveness and sustainability in the market[2].

Conclusion

The price of PVC tube extrusion equipment is influenced by a complex interplay of factors, including material quality, machinery specifications, production line configuration, market dynamics, and regional considerations. By understanding these factors, manufacturers can make informed decisions to find the best PVC tube extrusion equipment price that meets their production needs and budget constraints.

FAQ

1. What is the typical price range for PVC tube extrusion equipment?

The cost of PVC tube extrusion equipment can vary widely, typically ranging from $25,000 to $150,000 for basic setups, depending on specifications like capacity and technology used[1].

2. How does the type of extruder affect the price?

Twin-screw extruders are generally more expensive than single-screw extruders due to their greater processing capabilities and flexibility[1][4].

3. What role does automation play in pricing?

Advanced automation features can enhance efficiency but may increase initial investments. However, they can lead to long-term savings through reduced labor costs[1][6].

4. How do regional factors influence equipment pricing?

Regional factors such as transportation costs, labor rates, and regulatory environments can significantly impact the overall cost of equipment and production[1].

5. What are the benefits of investing in energy-efficient machinery?

Energy-efficient machines may have higher upfront costs but can provide significant long-term savings through reduced energy consumption[3][6].

Citations:

[1] https://www.yjing-extrusion.com/what-factors-affect-the-price-of-a-pvc-pipe-extrusion-production-line.html

[2] https://www.datainsightsmarket.com/reports/pvc-pipe-extruder-60118

[3] https://businessplan-templates.com/blogs/startup-costs/pvc-extrusion-plant

[4] https://plastic-extrusionmachines.com/plastic-extrusion-machine-cost/

[5] https://www.futuremarketinsights.com/reports/plastic-extrusion-machine-market

[6] https://www.inplexllc.com/blog/reducing-production-costs-with-custom-plastic-extrusion-solutions/

[7] https://deltaplastik.com/blog/plastic-extrusion-machine-prices-2024-choosing-the-right-machine-for-your-needs

[8] https://www.globenewswire.com/news-release/2025/02/05/3021359/0/en/Plastic-Extrusion-Machine-Market-to-Grow-at-4-7-CAGR-During-2025-2035-Boosting-Global-Industry-to-USD-12-343-2-Million-by-2035-Future-Market-Insights-Inc.html

[9] https://rollepaal.com/knowledge/optimization-of-raw-material-selection-for-cost-effectiveness-in-pipe-extrusion/

[10] https://www.qiangshengplas.com/news/what-determines-the-price-of-a-pvc-extruder-machine/

[11] https://www.imarcgroup.com/plastic-extrusion-machines-market

[12] https://www.plasticstoday.com/plastics-processing/reducing-energy-costs-focus-on-extrusion

[13] https://www.twinscrew.net/en/article/How-to-Choose-the-Best-PVC-Pipe-Extrusion-Line.html

[14] https://www.cognitivemarketresearch.com/plastic-extrusion-equipment-market-report

[15] https://www.bausano.com/en/press-and-news/reducing-energy-costs-focus-on-extrusion

[16] https://www.yjing-extrusion.com/what-factors-affect-the-price-of-medical-tube-plastic-extrusion-machinery.html

[17] https://www.linkedin.com/pulse/tube-extrusion-line-market-size-analysis-2025-2032-projected-0qa0e

[18] https://jydjx.com/optimizing-production-with-pvc-pipe-extrusion-machine-lines/

[19] https://europlas.com.vn/en-US/blog-1/how-much-does-plastic-injection-cost

[20] https://www.plasticsmachinerymanufacturing.com/manufacturing/article/55250477/will-the-plastics-machinery-market-rebound-in-2025