Content Menu

● Introduction to Aluminum Extrusion Press Manufacturing in Portugal

● Why Portugal? The Strategic Advantage

● Top Aluminum Extrusion Press Manufacturers And Suppliers in Portugal

>> Exlabesa Portugal

>>> Key Features

>>> Production Highlights

>> STRUGAL

>>> Key Features

>>> Production Strengths

>> GAP Aluminium

>>> Key Features

>>> Service Highlights

● The Aluminum Extrusion Process: Step-by-Step

>> Step 1: Die Preparation

>> Step 2: Billet Preheating

>> Step 3: Loading the Press

>> Step 4: Extrusion

>> Step 5: Profile Emergence

>> Step 6: Cooling and Quenching

>> Step 7: Cutting to Length

● Technological Advancements in Portuguese Aluminum Extrusion

● Sustainability and Environmental Responsibility

● Market Trends and Future Outlook

● Partnering with Portuguese Aluminum Extrusion Press Manufacturers And Suppliers

● Comparison Table: Leading Aluminum Extrusion Press Manufacturers And Suppliers in Portugal

● Conclusion

● Frequently Asked Questions

>> Q1: What alloys can Portuguese extrusion press manufacturers process?

>> Q2: How do Portuguese suppliers ensure sustainability in aluminum extrusion?

>> Q3: What is the typical production capacity of a modern extrusion facility in Portugal?

>> Q4: Are OEM and custom extrusion services available?

>> Q5: What are the main industries served by Portuguese aluminum extrusion press manufacturers?

Portugal has rapidly emerged as a strategic hub for aluminum extrusion press manufacturers and suppliers, serving both domestic and international markets. The country's central location in southern Europe, advanced industrial infrastructure, and commitment to sustainability have attracted global players and fostered the growth of local expertise. This article provides a comprehensive overview of the top aluminum extrusion press manufacturers and suppliers in Portugal, their technological capabilities, and the dynamic market landscape. The article also explores the aluminum extrusion process, key benefits of Portuguese suppliers, and the future of the industry.

Introduction to Aluminum Extrusion Press Manufacturing in Portugal

Aluminum extrusion is a process where aluminum alloy material is forced through a die to create objects of a fixed cross-sectional profile. This technique is essential for producing lightweight, strong, and corrosion-resistant components used in construction, transportation, infrastructure, and renewable energy sectors. Portugal's manufacturers and suppliers are renowned for their advanced technologies, high production capacities, and commitment to sustainability, making them key partners for OEMs, wholesalers, and producers worldwide.

Why Portugal? The Strategic Advantage

Portugal's rise as a leader in aluminum extrusion press manufacturing is driven by several key factors:

- Strategic Location: Portugal's central position in southern Europe enables efficient distribution to Spain, France, and other European markets, making it a prime location for international trade.

- Industrial Expertise: The country has decades of investment in advanced technology and skilled labor, fostering a highly capable manufacturing sector.

- Sustainability Focus: Portuguese manufacturers emphasize the use of recycled aluminum and adhere to stringent environmental standards, aligning with global sustainability goals.

- Robust Logistics: Portugal boasts extensive networks for fast and reliable delivery across Europe, ensuring timely fulfillment of orders.

Top Aluminum Extrusion Press Manufacturers And Suppliers in Portugal

Exlabesa Portugal

Exlabesa is a multinational leader in the aluminum extrusion industry, recently inaugurating a €25 million state-of-the-art facility in João Rui Ferreira, Portugal. This plant marks a significant milestone in consolidating Exlabesa's presence in southern Europe.

Key Features

- Facility Size: 86,000 sq m plot, with 10,000 sq m under roof.

- Production Capacity: Two 2,800 tonne press lines, vertical powder coating line for profiles up to 7,200 mm, annual capacity of 16,000 tonnes.

- Sustainability: Uses RE-local recycled aluminum with a carbon footprint of only 2.95 kg CO₂e/kg Al, certified by Bureau Veritas.

- Certifications: ISO 9001, CE marking, Qualicoat, and Alu+C- environmental label.

- Expansion Plans: Aiming to add three more presses (two 3,500 tonnes, one 4,500 tonnes), increasing annual output to over 45,000 tonnes.

- Industries Served: Construction, transport, infrastructure, renewable energy.

Production Highlights

Exlabesa's facility is equipped with advanced SMS Group extrusion lines capable of processing all 6000 series alloys (6005, 6060, 6061, 6063, 6082, 6101, 6106). The vertical coating line allows for high-quality, long-length profiles, and the company's extensive logistics network ensures rapid delivery to Iberia and wider Europe. Exlabesa's commitment to sustainability is evident through its use of recycled aluminum and adherence to internationally recognized certifications.

STRUGAL

STRUGAL operates some of the most modern extrusion plants in Europe and Africa, including significant operations in Portugal.

Key Features

- Production Capacity: 42,000 tonnes of aluminum profiles per year.

- Extrusion Presses: Multiple presses ranging from 1,400 to 2,200 tonnes.

- Alloys Processed: All 6000 series, with heat treatments T4, T5, T6, and T66, under ISO 9001 certification.

- Profile Dimensions: Raw profiles from 3 to 14 meters, weights from 0.04 kg/m to 35 kg/m, thicknesses from 1 mm to 70 mm.

Production Strengths

STRUGAL's facilities are characterized by high efficiency, reliable delivery, and consistent quality. With over 20,000 die matrices, the company is well-equipped to handle a wide range of custom extrusion requirements. Their experience and technical expertise make them a preferred partner for architectural and industrial projects across Europe.

GAP Aluminium

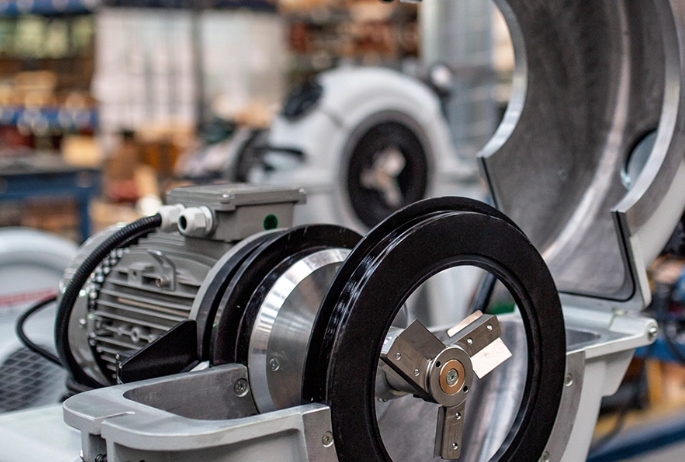

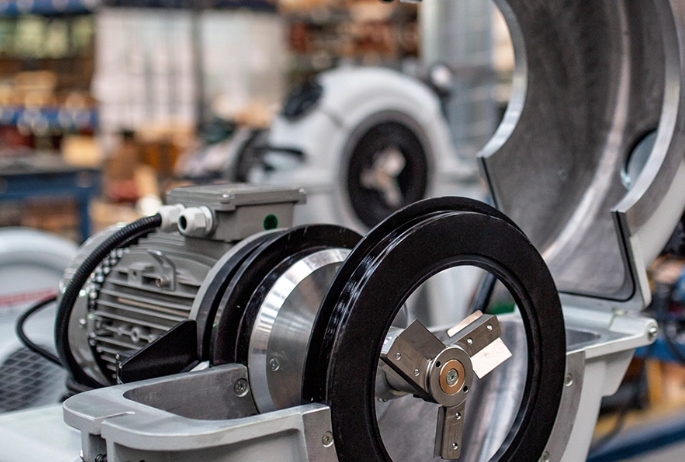

GAP Aluminium specializes in the repair, maintenance, and refurbishment of extrusion lines, serving both local and international clients.

Key Features

- Expertise: Over 25 years of experience with all major extrusion line manufacturers (SMS, Turla, Tecalex, GIA, Sutton, etc.).

- Services: Mechanical repairs, hydraulics, programming, furnace maintenance, lacquering, and anodizing equipment upgrades.

- Custom Solutions: Equipment upgrades to improve energy efficiency and productivity.

Service Highlights

GAP Aluminium offers personalized technical advice and immediate solutions for extrusion line challenges. Their focus on customer satisfaction, timely delivery, and competitive pricing has earned them a strong reputation among OEMs, factories, and suppliers.

The Aluminum Extrusion Process: Step-by-Step

Understanding the extrusion process is crucial for buyers and engineers. Below is a detailed walkthrough of the typical aluminum extrusion press operation:

Step 1: Die Preparation

The extrusion die is carefully prepared and moved to the press. The die's design determines the final shape of the extruded profile, making this step critical for quality and precision.

Step 2: Billet Preheating

Aluminum billets are preheated to the optimal temperature, typically between 400°C and 500°C. Proper preheating ensures the material flows smoothly through the die and achieves the desired mechanical properties.

Step 3: Loading the Press

The preheated billet is transferred to the extrusion press and lubricated. Lubrication minimizes friction and wear on both the billet and the die, extending the lifespan of the equipment.

Step 4: Extrusion

Hydraulic cylinders apply immense pressure, forcing the billet through the die. The aluminum takes on the cross-sectional shape defined by the die, emerging as a continuous profile.

Step 5: Profile Emergence

The extruded aluminum profile emerges from the die in the desired shape. Operators monitor the process closely to ensure consistency and quality.

Step 6: Cooling and Quenching

The profile is guided along a runout table and quenched, typically with air or water, for uniform cooling. Controlled cooling is essential to achieve the required mechanical properties and prevent warping.

Step 7: Cutting to Length

Extrusions are sheared to the required length and further processed as needed. Additional steps may include straightening, aging (heat treatment), surface finishing, and quality inspection.

Technological Advancements in Portuguese Aluminum Extrusion

Portuguese aluminum extrusion press manufacturers and suppliers are at the forefront of technological innovation. Some of the latest advancements include:

- Automated Press Controls: Modern presses are equipped with advanced control systems that monitor pressure, temperature, and speed, ensuring precise and repeatable results.

- Energy Efficiency: Newer presses and process optimizations have significantly reduced energy consumption, lowering operational costs and environmental impact.

- Advanced Alloys: The ability to process a wide range of aluminum alloys, including high-strength and specialty grades, allows manufacturers to serve diverse industries.

- Surface Finishing Technologies: Vertical powder coating lines and anodizing facilities enable manufacturers to offer a variety of surface finishes, improving aesthetics and corrosion resistance.

Sustainability and Environmental Responsibility

Sustainability is a core value among Portuguese aluminum extrusion press manufacturers and suppliers. Key initiatives include:

- Use of Recycled Aluminum: Companies like Exlabesa prioritize the use of recycled aluminum billets, which significantly reduce carbon emissions compared to primary aluminum.

- Waste Management: Advanced recycling and waste management systems ensure that scrap aluminum is efficiently reused in the production process.

- Certifications: Adherence to international standards such as ISO 9001, Qualicoat, and environmental labels like Alu+C- demonstrates a commitment to quality and sustainability.

- Energy Recovery: Heat recovery systems and renewable energy sources are increasingly integrated into production facilities to minimize environmental impact.

Market Trends and Future Outlook

The aluminum extrusion industry in Portugal is poised for continued growth, driven by several key trends:

- Rising Demand for Lightweight Materials: The automotive, aerospace, and construction industries are increasingly seeking lightweight, durable materials to improve efficiency and reduce emissions.

- Customization and OEM Services: Manufacturers are offering more custom solutions and OEM services to meet the specific needs of global clients.

- Digitalization: The adoption of Industry 4.0 technologies, such as IoT sensors and data analytics, is enhancing production efficiency and quality control.

- Global Expansion: Portuguese manufacturers are expanding their reach into new markets, leveraging their strategic location and advanced capabilities.

Partnering with Portuguese Aluminum Extrusion Press Manufacturers And Suppliers

For OEMs, wholesalers, and producers seeking reliable partners, Portugal offers:

- OEM Services: Custom design and production to meet specific requirements, including unique profiles, finishes, and mechanical properties.

- Technical Support: Comprehensive after-sales service, maintenance, and upgrades ensure long-term performance and reliability.

- Competitive Pricing: Efficient production processes and logistics translate to cost savings for customers.

- Innovation: Ongoing investment in research and development keeps Portuguese manufacturers at the cutting edge of the industry.

Comparison Table: Leading Aluminum Extrusion Press Manufacturers And Suppliers in Portugal

| Company | Facility Size | Annual Capacity | Key Technologies | Main Markets Served | Certifications |

| Exlabesa | 86,000 sq m | 16,000–45,000 t | SMS Group presses, vertical coating | Construction, transport, infra | ISO 9001, CE, Qualicoat |

| STRUGAL | Multi-site | 42,000 t | Multiple presses (1,400–2,200 t) | Architecture, industry | ISO 9001, EN 755-9, 12020-2 |

| GAP Aluminium | N/A (Service) | N/A | All major brand refurb/maintenance | OEMs, factories, suppliers | N/A |

Conclusion

Portugal has firmly established itself as a leading center for aluminum extrusion press manufacturers and suppliers, offering advanced technology, sustainable production, and extensive OEM services. Companies like Exlabesa, STRUGAL, and GAP Aluminium deliver high-quality solutions for a wide range of industries, including construction, transportation, infrastructure, and renewable energy. Their commitment to innovation, sustainability, and customer satisfaction makes them valuable partners for businesses worldwide. As the demand for lightweight, durable, and environmentally friendly materials continues to grow, Portuguese manufacturers are well-positioned to meet the evolving needs of the global market.

Frequently Asked Questions

Q1: What alloys can Portuguese extrusion press manufacturers process?

A1: Most leading manufacturers, such as Exlabesa and STRUGAL, can process all 6000 series aluminum alloys, including 6005, 6060, 6061, 6063, 6082, 6101, and 6106.

Q2: How do Portuguese suppliers ensure sustainability in aluminum extrusion?

A2: Companies like Exlabesa use recycled aluminum billets with a low carbon footprint and invest in energy-efficient technologies. They also hold certifications such as ISO 9001 and environmental labels like Alu+C-.

Q3: What is the typical production capacity of a modern extrusion facility in Portugal?

A3: State-of-the-art plants like Exlabesa's can produce between 16,000 and 45,000 tonnes of extruded profiles annually, depending on expansion stages.

Q4: Are OEM and custom extrusion services available?

A4: Yes, Portuguese manufacturers and suppliers offer comprehensive OEM services, including custom die design, tailored profiles, and specialized finishing processes.

Q5: What are the main industries served by Portuguese aluminum extrusion press manufacturers?

A5: Key sectors include construction, transportation, infrastructure, renewable energy, and industrial machinery.