Content Menu

● Introduction to Aluminum Extruders

>> Benefits of Aluminum Extruders

>> Types of Extruders

● Upgrading to an Aluminum Extruder

>> Step-by-Step Upgrade Guide

>> Choosing the Right Aluminum Extruder

● Maintenance and Troubleshooting

● Conclusion

● FAQs

>> 1. What are the primary benefits of using an aluminum extruder?

>> 2. How do I install an aluminum extruder on my Ender 3?

>> 3. Is an aluminum extruder compatible with flexible filaments?

>> 4. How often should I maintain my aluminum extruder?

>> 5. Will upgrading to an aluminum extruder affect my printer's warranty?

● Citations:

In the world of 3D printing, the extruder is a crucial component that plays a pivotal role in the quality and reliability of your prints. Among various materials used for extruders, aluminum has emerged as a popular choice due to its unique properties and benefits. This article delves into the advantages of using an aluminum extruder, its compatibility with different 3D printers, and whether it's worth the investment.

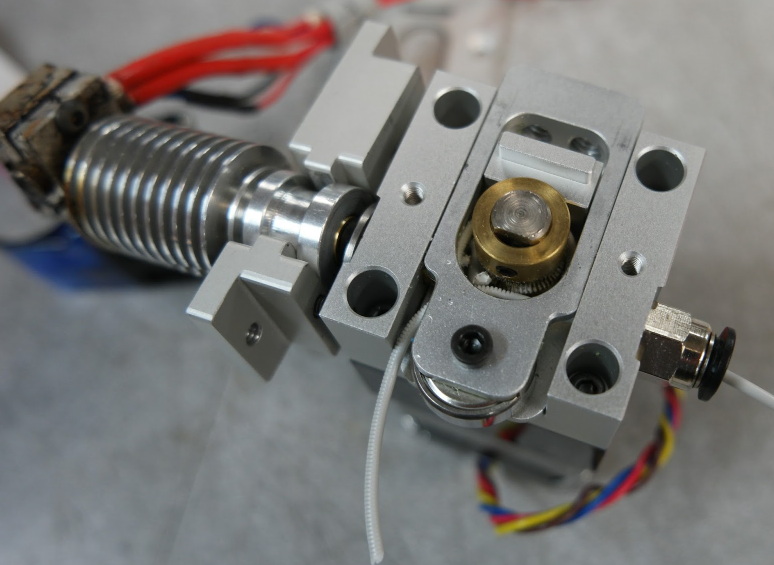

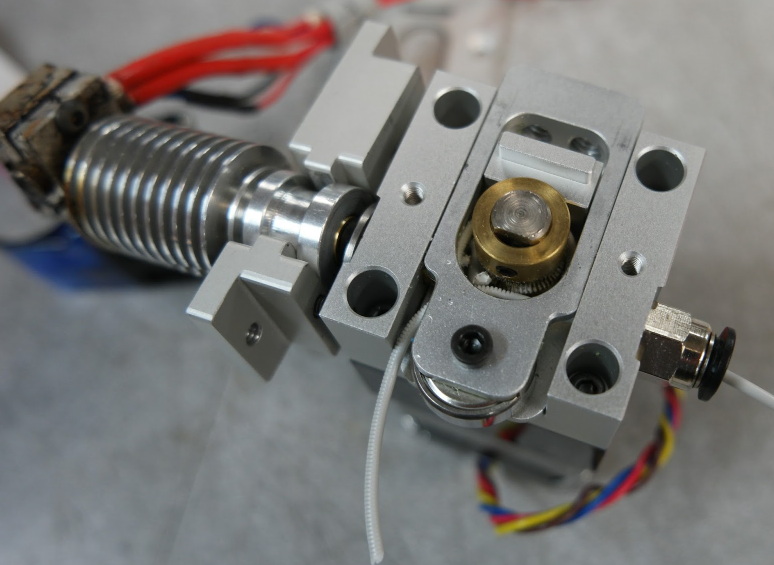

Introduction to Aluminum Extruders

Aluminum extruders have gained popularity in recent years due to their lightweight strength, durability, and cost-effectiveness. Unlike plastic extruders, which are prone to wear and tear, aluminum extruders offer a robust solution that can withstand the mechanical stress of continuous filament feeding. This results in more consistent and reliable prints, making them an attractive upgrade for both hobbyists and professionals.

Benefits of Aluminum Extruders

1. Durability and Resistance to Wear: Aluminum extruders are significantly more durable than their plastic counterparts. They can withstand prolonged use without degrading, ensuring long-term reliability and reducing the need for frequent replacements[1][2].

2. Improved Filament Feeding: The rigid construction of aluminum extruders provides a more secure grip on the filament, minimizing slippage and ensuring consistent extrusion. This leads to better layer adhesion and overall print quality[1][3].

3. Enhanced Heat Dissipation: Aluminum's excellent thermal conductivity helps dissipate heat generated by the motor and friction, preventing heat creep and potential clogging issues. This is particularly beneficial when printing with temperature-sensitive filaments like PLA[1][2].

4. Compatibility with Various Filaments: Aluminum extruders are compatible with a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon. This versatility allows users to experiment with different materials and applications without needing to switch extruders[1][3].

5. Cost-Effectiveness: Despite offering superior performance and durability, aluminum extruders are generally more cost-effective than other metal options like stainless steel or titanium. Their efficient manufacturing process makes them accessible to a broader audience[1].

Types of Extruders

There are primarily two types of extruders used in 3D printing: Direct Drive Extruders and Bowden Extruders.

- Direct Drive Extruders: These mount the extruder motor and feeding mechanism directly on top of the hot end. This setup minimizes the distance the filament has to travel, offering better control, especially with flexible filaments[1].

- Bowden Extruders: In this configuration, the extruder motor is located remotely, typically on the printer frame, and the filament is fed to the hot end through a PTFE (Teflon) tube. Bowden extruders reduce the weight on the moving print head, allowing for faster printing speeds but may require more retraction tuning[1].

Upgrading to an Aluminum Extruder

Upgrading your 3D printer with an aluminum extruder can significantly enhance your printing experience. Here's a step-by-step guide on how to upgrade your Ender 3 to an aluminum extruder:

Step-by-Step Upgrade Guide

1. Gather Tools and Components:

- Allen wrenches (1.5mm, 2mm, 2.5mm)

- Screwdriver

- Pliers (optional)

- New aluminum extruder kit

2. Turn Off and Unload Filament:

- Ensure your printer is powered off.

- Remove any filament from the extruder by heating up the hotend and pulling it out gently.

3. Unscrew the Coupling:

- Use a 2mm Allen wrench to unscrew the coupling holding the Bowden tube in place.

4. Disconnect the Stepper Motor:

- Remove the screws attaching the stepper motor to the extruder body. Hold the motor while unscrewing to prevent it from falling.

5. Detach the Lever Arm:

- Unscrew and remove the lever arm from the old extruder assembly.

6. Attach the Base Plate:

- Place the new aluminum base plate onto the motor. Secure it using screws provided in your kit.

7. Install Gear:

- Slide on the new gear and ensure one of its grub screws aligns with the flat part of the motor shaft for a secure fit.

8. Assemble Lever Arm:

- Attach the lever arm and idler pulley using screws, ensuring that it can pivot freely.

9. Reconnect Bowden Tube:

- Insert and secure the Bowden tube into its new coupling on the aluminum extruder.

10. Reconnect Wiring:

- Plug back in any electrical connectors that were disconnected during disassembly.

11. Power On Your Printer:

- Turn on your Ender 3 and perform a test print to ensure everything is functioning correctly.

12. Calibrate E-Steps:

- After changing your extruder, it's crucial to recalibrate your e-steps for accurate filament extrusion[6].

Choosing the Right Aluminum Extruder

When deciding to buy an aluminum extruder, consider the following factors:

- Compatibility: Ensure the extruder is compatible with your specific 3D printer model.

- Type of Filament Used: If you frequently use flexible filaments, consider a dual-gear or direct drive system for optimal performance.

- Installation Difficulty: Choose a kit that matches your comfort level with DIY projects.

- Cost: While more expensive than plastic extruders, aluminum extruders offer long-term benefits.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure optimal performance from your aluminum extruder:

1. Regular Cleaning: Periodically clean the extruder gear to remove any accumulated debris or filament residue. Use a brush or compressed air to dislodge any particles.

2. Check Tension: Ensure that tension on the extruder arm is properly adjusted. Too little tension can cause filament slippage, while too much tension can deform it.

3. Inspect for Wear: Regularly inspect for signs of wear or damage; replace any worn parts promptly to prevent further issues.

4. Lubricate Moving Parts: Apply a small amount of lubricant designed for 3D printer components to keep moving parts running smoothly[6].

Conclusion

Upgrading to an aluminum extruder can significantly enhance your 3D printing experience by offering improved durability, consistent filament feeding, and better heat dissipation. Whether you're a hobbyist or a professional, investing in an aluminum extruder is a worthwhile decision that can lead to higher-quality prints and reduced maintenance costs. If you're considering buying an aluminum extruder, weigh the benefits against your specific needs and printer compatibility.

FAQs

1. What are the primary benefits of using an aluminum extruder?

The primary benefits include increased durability, improved filament feeding consistency, enhanced heat dissipation, and compatibility with a wide range of filaments[1][2].

2. How do I install an aluminum extruder on my Ender 3?

Installation involves disassembling the stock extruder, attaching the new aluminum extruder components, and recalibrating your printer settings. Refer to the step-by-step guide provided earlier[6].

3. Is an aluminum extruder compatible with flexible filaments?

Yes, aluminum extruders can handle flexible filaments better than plastic ones. For optimal results, consider using a dual-gear or direct drive system[8].

4. How often should I maintain my aluminum extruder?

Regular maintenance should be performed every 1-3 months, depending on usage. This includes cleaning the extruder gear and checking tension[6].

5. Will upgrading to an aluminum extruder affect my printer's warranty?

Upgrading your printer may affect its warranty. It's best to check with the seller or manufacturer about their specific warranty policies regarding upgrades[8].

Citations:

[1] https://www.yjing-extrusion.com/why-should-you-choose-an-aluminum-extruder-for-3d-printing.html

[2] https://www.yjing-extrusion.com/is-the-ender-3-pro-aluminum-extruder-worth-the-upgrade.html

[3] https://www.yjing-extrusion.com/why-should-you-choose-an-mk8-extruder-aluminum-over-stock-extruders.html

[4] https://www.youtube.com/watch?v=UtemZqFJ5rY

[5] https://www.yjing-extrusion.com/how-does-aluminum-extrusion-improve-3d-printing-performance.html

[6] https://www.yjing-extrusion.com/how-to-upgrade-to-an-ender-3-aluminum-extruder.html

[7] https://www.yjing-extrusion.com/what-are-the-benefits-of-using-aluminum-extrusion-in-3d-printing.html

[8] https://www.yjing-extrusion.com/can-you-use-an-aluminum-extruder-on-ender-3.html

[9] https://www.yjing-extrusion.com/is-the-upgraded-aluminum-extruder-v2-worth-the-investment-for-better-print-quality.html

[10] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[11] https://makenica.com/everything-to-know-about-3d-printing-extruders/

[12] https://www.youtube.com/watch?v=ikVFselJO4Y

[13] https://www.wevolver.com/article/3d-print-aluminum

[14] https://forum.v1e.com/t/community-thoughts-on-3d-printed-extrusion-brackets-vs-aluminum/36919

[15] https://www.reddit.com/r/3Dprinting/comments/17xkiyp/is_it_better_to_use_extruded_aluminum_in_a/

[16] https://www.temu.com/ae/cr-10-extruder--replacement-aluminum-mk8-drive-feed-3d-printer-extruders-for---3-cr-10-cr-10s-cr-4-g-601099513760705.html

[17] https://all3dp.com/1/3d-printing-aluminum/

[18] https://top3dshop.com/blog/homemade-frame-pros-and-cons

[19] https://aluminumextrusions.net/prototyping-aluminum-extrusions/

[20] https://www.linkedin.com/pulse/what-advantages-aluminum-alloy-application-3d-printers-doman-agtor

[21] https://www.printables.com/model/499461-ultimaker-2-aluminum-extrusion-3d-printer

[22] https://www.pinterest.com/pin/pin-p-thingiverse--310748443051203268/

[23] https://hackaday.com/2018/05/08/how-to-build-anything-out-of-aluminum-extrusion-and-3d-printed-brackets/

[24] https://www.thingiverse.com/thing:811271

[25] https://reprap.org/forum/read.php?2%2C603480

[26] https://www.robotshop.com/collections/aluminum-extrusions-3d-printers

[27] https://www.youtube.com/watch?v=rzNmFK2zIWo

[28] https://www.solidprint3d.co.uk/prototyping-aluminium-extrusion-profiles-with-3d-printing/