Content Menu

● Introduction to Greg's Wade Extruder

>> Key Features of Greg's Wade Extruder

● Benefits for Prusa i3 Aluminum Frame

>> Improved Print Quality

>> Reduced Motor Heat

>> Compatibility and Versatility

>> Enhanced Reliability

>> Community Support

● Considerations and Challenges

>> Compatibility Issues

>> Maintenance and Upgrades

>> Cost and Availability

>> Comparison with Other Extruders

● Advanced Printing Techniques

● Conclusion

● FAQs

>> 1. What are the main benefits of using Greg's Wade Extruder on a Prusa i3?

>> 2. How does the geared system in Greg's Wade Extruder improve print quality?

>> 3. Are there any compatibility issues with the Prusa i3 aluminum frame?

>> 4. What maintenance is required for Greg's Wade Extruder?

>> 5. Where can I find parts for Greg's Wade Extruder?

The Prusa i3 is one of the most popular DIY 3D printer designs, known for its versatility and upgradeability. Among the various upgrades available, the extruder is a crucial component that can significantly impact print quality and reliability. Greg's Wade Extruder is a well-regarded option for the Prusa i3, particularly when paired with an aluminum frame. This article will delve into the benefits and considerations of using Greg's Wade Extruder on a Prusa i3 with an aluminum frame.

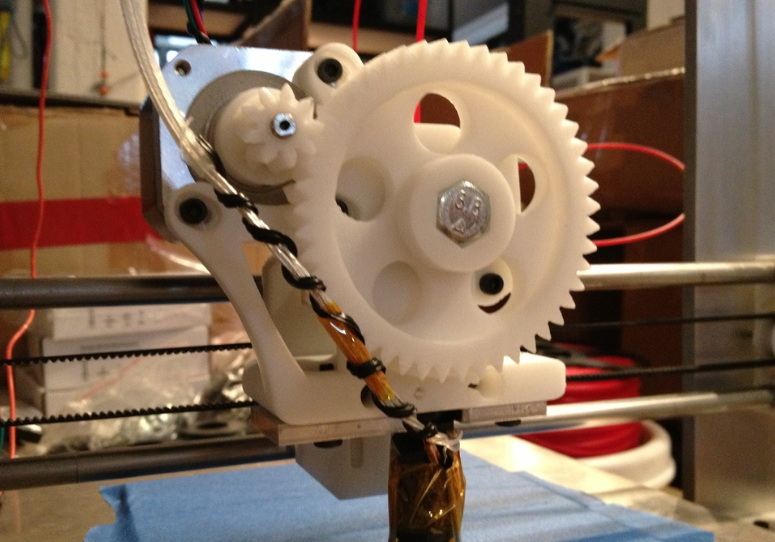

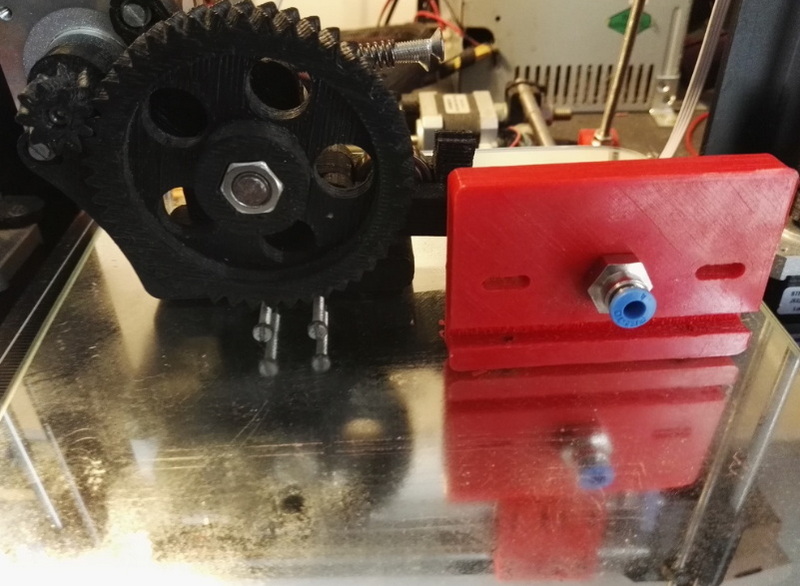

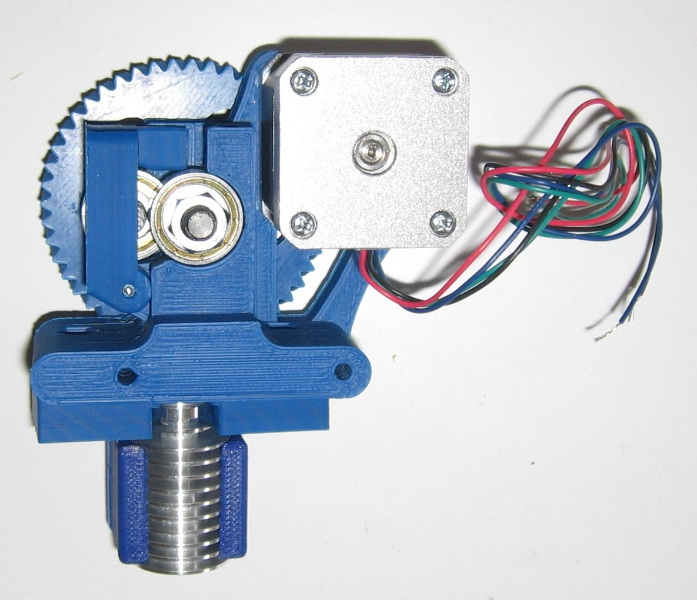

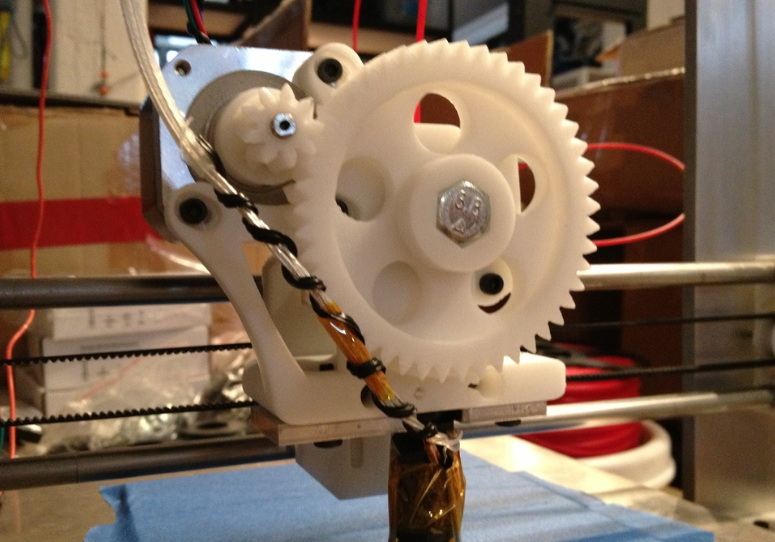

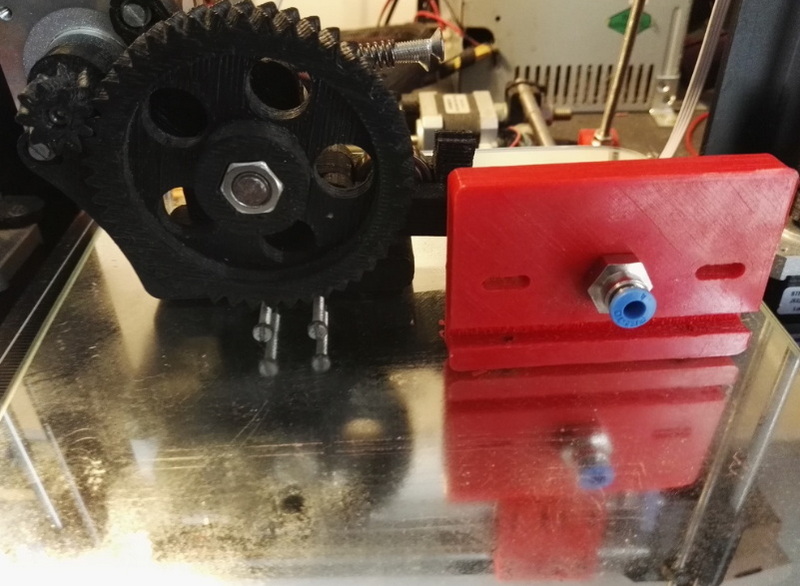

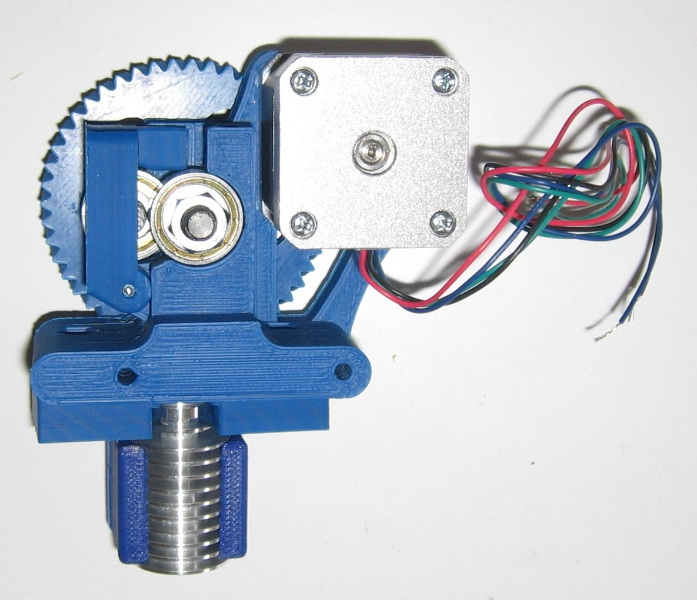

Introduction to Greg's Wade Extruder

Greg's Wade Extruder is a geared extruder design that has been widely adopted in the 3D printing community. It features a NEMA 17 stepper motor driving a small gear that turns a larger gear, which is connected to a hobbed bolt. This setup provides a high gear ratio, allowing for precise filament control and reduced motor torque requirements, which can lead to less heat generation and improved print quality.

Key Features of Greg's Wade Extruder

- Geared System: The extruder uses a gear system to increase the torque applied to the filament, allowing for more precise control over filament extrusion.

- Hobbed Bolt: The hobbed bolt provides a strong grip on the filament, ensuring consistent and reliable extrusion.

- Spring-Loaded Idler: The idler is spring-loaded, making it easy to adjust tension and change filaments.

Benefits for Prusa i3 Aluminum Frame

Improved Print Quality

The geared system in Greg's Wade Extruder allows for finer control over filament extrusion, which can lead to smoother prints and reduced layer shifting. This is particularly beneficial for the Prusa i3, as it can enhance the overall print quality by providing more consistent extrusion rates. For example, when printing with materials like PETG or ABS, which require precise temperature control and extrusion rates, Greg's Wade Extruder can help maintain a stable extrusion flow, resulting in better layer adhesion and reduced warping.

Reduced Motor Heat

By reducing the torque required from the motor, Greg's Wade Extruder helps minimize heat generation. This is advantageous for maintaining a stable printing environment, especially when using temperature-sensitive materials like PLA. Reduced motor heat also prolongs the lifespan of the motor and surrounding components, reducing the need for frequent replacements or repairs.

Compatibility and Versatility

Greg's Wade Extruder is widely supported and has been adapted for various Prusa i3 configurations, including aluminum frames. It can be used with different hotends and filament sizes (1.75mm and 3mm), making it a versatile upgrade option. This versatility allows users to experiment with different materials and printing techniques without needing to change the extruder.

Enhanced Reliability

The robust design of Greg's Wade Extruder ensures that it can handle demanding printing tasks without compromising performance. The spring-loaded idler and hobbed bolt work together to maintain a consistent grip on the filament, reducing the likelihood of jams or slips during printing.

Community Support

One of the significant advantages of using Greg's Wade Extruder is the extensive community support. There are numerous forums, tutorials, and user groups dedicated to troubleshooting and optimizing the extruder for various setups. This community support can be invaluable for beginners and experienced users alike, providing solutions to common issues and tips for maximizing performance.

Considerations and Challenges

Compatibility Issues

While Greg's Wade Extruder is popular, it may require modifications to fit certain Prusa i3 configurations, especially if you're using a specific X-carriage design. Ensuring compatibility before purchasing is crucial to avoid unnecessary modifications or returns.

Maintenance and Upgrades

The extruder's design allows for easy filament changes and maintenance. However, some users may find the assembly and adjustment process complex compared to simpler extruder designs. Regular maintenance includes checking and adjusting the idler tension and ensuring that the hobbed bolt remains clean and free of debris.

Cost and Availability

Greg's Wade Extruder is generally more affordable than some other geared extruders, but it may still be more expensive than basic extruder designs. Parts are widely available on platforms like eBay and Thingiverse, making it easy to source components for repairs or upgrades.

Comparison with Other Extruders

When comparing Greg's Wade Extruder to other options like the Bondtech BMG or the E3D Titan, several factors come into play:

- Gear Ratio: Greg's Wade Extruder offers a high gear ratio, which is beneficial for precise filament control.

- Material Compatibility: It supports a wide range of filaments, including flexible materials.

- Community Support: The extensive community support and documentation make it easier for users to troubleshoot and optimize the extruder.

Advanced Printing Techniques

Greg's Wade Extruder can also be used to explore advanced printing techniques, such as multi-material printing or printing with specialized filaments like carbon fiber or wood-infused materials. The extruder's ability to handle different filament types and sizes makes it an excellent choice for users looking to expand their printing capabilities.

Conclusion

Greg's Wade Extruder is a solid upgrade for the Prusa i3, particularly when paired with an aluminum frame. It offers improved print quality, reduced motor heat, and versatility in terms of compatibility with different hotends and filament sizes. However, users should consider potential compatibility issues and the complexity of assembly. With its robust design and extensive community support, Greg's Wade Extruder remains a popular choice among DIY enthusiasts and professional users alike.

FAQs

1. What are the main benefits of using Greg's Wade Extruder on a Prusa i3?

The main benefits include improved print quality due to finer filament control, reduced motor heat, and compatibility with various hotends and filament sizes.

2. How does the geared system in Greg's Wade Extruder improve print quality?

The geared system allows for more precise control over filament extrusion, leading to smoother prints and reduced layer shifting.

3. Are there any compatibility issues with the Prusa i3 aluminum frame?

Yes, compatibility issues may arise depending on the specific X-carriage design. It's essential to ensure that the extruder fits your frame before purchasing.

4. What maintenance is required for Greg's Wade Extruder?

Maintenance involves easy filament changes and occasional adjustments to the idler tension. However, some users may find the assembly and adjustment process complex.

5. Where can I find parts for Greg's Wade Extruder?

Parts are widely available on platforms like eBay, Thingiverse, and specialized 3D printing stores.