Content Menu

● Introduction to Aluminum MK8 Extruders

>> Benefits of Aluminum MK8 Extruders

>> Installation Process

● Compatibility and Compatibility Issues

>> Real-World Examples

>> Compatibility Considerations

● Cost and Long-Term Benefits

>> Cost Analysis

● Troubleshooting Common Issues

>> Advanced Troubleshooting Techniques

● Advanced Features and Upgrades

>> Customization Options

● Community Feedback and Reviews

>> Community Tips

● Conclusion

● FAQ

>> 1. What are the main benefits of upgrading to an aluminum MK8 extruder?

>> 2. Is the aluminum MK8 extruder compatible with all 3D printers?

>> 3. Do I need to calibrate my extruder after upgrading?

>> 4. Can the aluminum MK8 extruder handle flexible filaments like TPU?

>> 5. Is it difficult to install the aluminum MK8 extruder?

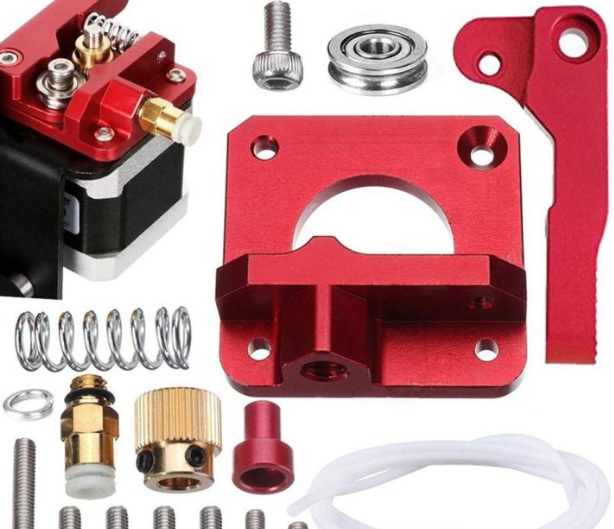

Upgrading your 3D printer with an aluminum MK8 extruder is a popular choice among enthusiasts seeking improved performance and reliability. This article will delve into the benefits, installation process, and compatibility of the extruder upgraded replacement aluminum MK8, helping you decide if this upgrade is right for your printing needs.

Introduction to Aluminum MK8 Extruders

Aluminum MK8 extruders are designed to replace stock plastic extruders, offering enhanced durability, better filament control, and improved heat resistance. These upgrades are particularly beneficial for users who frequently print with high-temperature filaments or require consistent extrusion for complex models.

Benefits of Aluminum MK8 Extruders

1. Durability: Aluminum extruders are more robust than plastic ones, withstanding mechanical stress without cracking or warping. This ensures consistent performance over time and reduces the need for frequent replacements.

2. Improved Filament Control: The aggressive grip on the filament minimizes slippage, leading to smoother feeding and more accurate prints. This is especially important for flexible filaments like TPU, which can be challenging to handle with stock extruders.

3. Higher Temperature Resistance: Aluminum can handle higher temperatures than plastic, making it suitable for printing with ABS, nylon, and other high-performance materials.

4. Precision Printing: The consistent filament flow and stable temperature control contribute to better layer adhesion, reduced stringing, and overall improved print quality.

5. Ease of Installation: Most MK8 aluminum extruder kits are designed for easy installation, requiring minimal technical expertise.

Installation Process

Installing an aluminum MK8 extruder is relatively straightforward:

1. Remove the Stock Extruder: Detach the existing plastic extruder from your printer by unscrewing it and disconnecting any wiring.

2. Install the New Extruder: Align the aluminum extruder with the mounting holes and secure it using the provided screws.

3. Connect Filament Path: Ensure the filament guide tube is properly connected to the hot end.

4. Calibrate Your Printer: Adjust printer settings to accommodate the new extruder for optimal performance.

Compatibility and Compatibility Issues

While the aluminum MK8 extruder is compatible with many popular 3D printers, such as the Ender 3 and CR-10 series, it's crucial to ensure compatibility before purchasing. Some extruders may require slight modifications for specific printer models.

Real-World Examples

- Ender 3 Series: Users have reported significant improvements in print quality and reliability after upgrading to an aluminum extruder on their Ender 3 models.

- CR-10 Series: The MK8 extruder is well-suited for CR-10 printers, offering enhanced filament control and durability.

Compatibility Considerations

Before purchasing an aluminum MK8 extruder, consider the following:

- Mounting System: Ensure the extruder's mounting system matches your printer's configuration.

- Filament Path Compatibility: Verify that the extruder's filament guide tube is compatible with your hot end.

- Electrical Connections: Check if the extruder requires any specific wiring modifications.

Cost and Long-Term Benefits

The cost of an aluminum MK8 extruder typically ranges from $20 to $50, depending on the brand and features. While this may seem like an additional expense, the long-term benefits include reduced maintenance costs and improved print quality, which can save you money on filament and replacement parts over time.

Cost Analysis

- Initial Investment: The upfront cost of the extruder.

- Long-Term Savings: Reduced waste from failed prints and less frequent replacements.

- Enhanced Print Quality: Improved layer adhesion and reduced defects lead to fewer reprints.

Troubleshooting Common Issues

After upgrading to an aluminum MK8 extruder, you might encounter issues such as under-extrusion or jamming. Here are some troubleshooting tips:

- Under-Extrusion: Check if the extruder temperature is correct and ensure the filament is properly seated.

- Jams: Verify that the filament path is clear and adjust tension settings as needed.

Advanced Troubleshooting Techniques

For more complex issues, consider the following:

- Calibration Checks: Ensure E-steps and extrusion multipliers are correctly set.

- Thermal Management: Monitor temperature fluctuations and adjust cooling settings if necessary.

- Filament Quality: Use high-quality filaments to minimize inconsistencies.

Advanced Features and Upgrades

Some aluminum MK8 extruders come with advanced features such as:

- Dual Gear System: Provides even more aggressive filament grip for improved control.

- Adjustable Tension: Allows for fine-tuning of filament tension to suit different materials.

- Integrated Cooling: Enhances thermal management for better performance.

Customization Options

For enthusiasts looking to further customize their setup, consider:

- Custom Mounts: Design or purchase custom mounts for unique printer configurations.

- Upgraded Cooling Systems: Add additional fans or heat sinks for enhanced thermal control.

- Filament Sensors: Install sensors to monitor filament usage and detect breaks.

Community Feedback and Reviews

Feedback from the 3D printing community is overwhelmingly positive, with many users reporting significant improvements in print quality and reliability. Online forums and review platforms are filled with testimonials from satisfied users who have upgraded to aluminum MK8 extruders.

Community Tips

- Join Online Forums: Engage with other users to share tips and learn from their experiences.

- Read Reviews: Check reviews on platforms like Amazon or Reddit to find the best options.

- Share Your Experience: Contribute to the community by sharing your own upgrade experiences.

Conclusion

Upgrading to an aluminum MK8 extruder is a worthwhile investment for anyone seeking improved print quality, reliability, and durability. While there are initial costs and potential compatibility issues to consider, the long-term benefits far outweigh these drawbacks. Whether you're a hobbyist or a professional, this upgrade can elevate your 3D printing experience.

FAQ

1. What are the main benefits of upgrading to an aluminum MK8 extruder?

Upgrading to an aluminum MK8 extruder offers several benefits, including enhanced durability, improved filament control, higher temperature resistance, and better print quality. These upgrades are particularly beneficial for users who print frequently or with high-temperature filaments.

2. Is the aluminum MK8 extruder compatible with all 3D printers?

The aluminum MK8 extruder is compatible with many popular 3D printers, such as the Ender 3 and CR-10 series. However, it's essential to check compatibility with your specific printer model before purchasing.

3. Do I need to calibrate my extruder after upgrading?

Yes, after installing an aluminum MK8 extruder, you should recalibrate your printer settings to ensure optimal performance. This includes adjusting extrusion parameters and E-steps.

4. Can the aluminum MK8 extruder handle flexible filaments like TPU?

Yes, the aluminum MK8 extruder is well-suited for printing flexible filaments like TPU. Its enhanced grip and consistent filament flow make it ideal for handling these materials.

5. Is it difficult to install the aluminum MK8 extruder?

No, installing an aluminum MK8 extruder is generally straightforward and requires minimal technical expertise. Most kits come with clear instructions and necessary components for a DIY installation.