Content Menu

● Introduction to Aluminum Alloy Extruders

>> Benefits of Aluminum Alloy Extruders

● Preparing for the Upgrade

● Step-by-Step Installation Guide

>> 1. Power Off and Unplug Your Printer

>> 2. Remove Filament

>> 3. Detach the Bowden Tube

>> 4. Remove the Old Extruder

>> 5. Prepare the New Aluminum Extruder

>> 6. Install the New Extruder

>> 7. Reattach the Bowden Tube

>> 8. Load Filament and Test Print

● Troubleshooting Common Issues

● Advanced Extruder Upgrades

>> Features of Advanced Extruders

● Maintenance and Calibration

>> Maintenance Tips

>> Calibration

● Applications and Benefits

● Handling Flexible Filaments

● Conclusion

● FAQ

>> 1. What are the benefits of using an aluminum alloy extruder?

>> 2. How do I know if my extruder needs an upgrade?

>> 3. Can aluminum alloy extruders be used with all types of filaments?

>> 4. How do I prevent over-extrusion after installing a new extruder?

>> 5. Are aluminum alloy extruders more expensive than plastic ones?

● Citations:

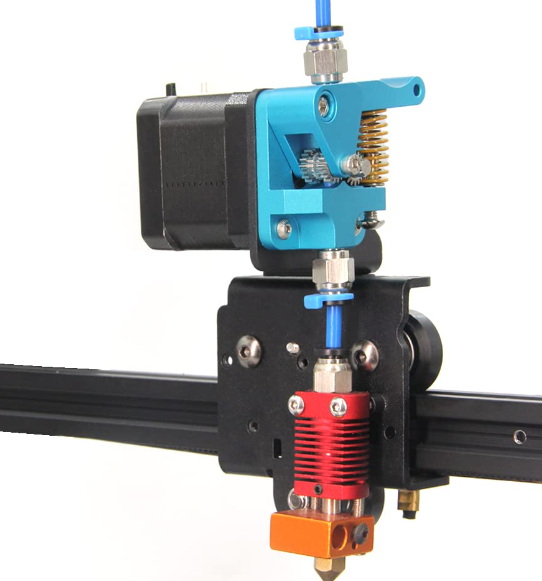

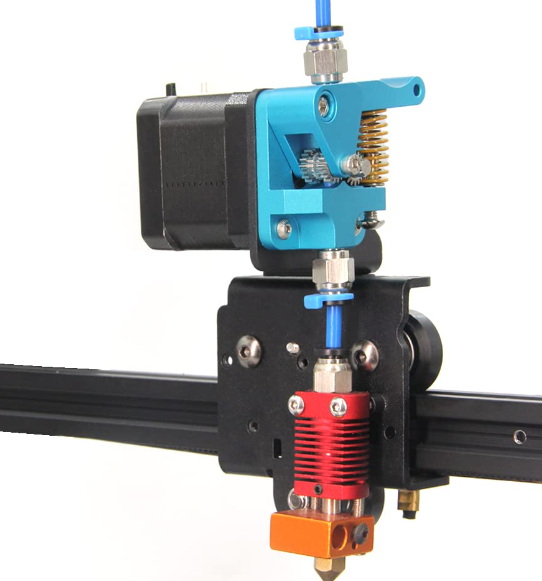

Upgrading your 3D printer with an extruder aluminum alloy can significantly enhance its performance, durability, and print quality. This guide will walk you through the process of installing an aluminum alloy extruder, highlighting the benefits and providing step-by-step instructions.

Introduction to Aluminum Alloy Extruders

Aluminum alloy extruders have become a popular choice among 3D printing enthusiasts due to their durability, lightweight nature, and ability to maintain stability during printing. Unlike traditional plastic extruders, which can flex and wear down over time, aluminum alloy extruders provide a consistent and reliable filament flow, ensuring better print quality.

Benefits of Aluminum Alloy Extruders

1. Durability and Resistance to Wear: Aluminum alloy extruders are more resistant to wear and tear compared to plastic ones, reducing the need for frequent replacements and minimizing overall costs.

2. Improved Stability: Despite being lightweight, aluminum provides sufficient strength to maintain the stability of the extruder assembly, minimizing vibrations during printing.

3. Compatibility with Various Filaments: Aluminum alloy extruders are compatible with a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon, allowing users to experiment with different materials without needing to switch extruders.

4. Heat Dissipation: Aluminum's excellent thermal conductivity helps dissipate heat generated by friction and motor operation, preventing heat creep and potential clogging issues.

Preparing for the Upgrade

Before starting the upgrade, ensure you have the necessary tools and parts:

- Aluminum Alloy Extruder Kit: This typically includes the main extruder base plate, extruder arm, spring, screws, extruder gear, bearing, and PTFE tube connector.

- Tools: Hex wrenches (2mm, 2.5mm, 3mm), screwdrivers, and Allen wrenches may be required depending on your printer model.

Step-by-Step Installation Guide

1. Power Off and Unplug Your Printer

Ensure your printer is turned off and unplugged to avoid electrical hazards.

2. Remove Filament

Heat up the hotend to soften the filament, then unload it from the printer.

3. Detach the Bowden Tube

Unscrew the fitting with the Bowden tube from the extruder and set it aside.

4. Remove the Old Extruder

Use the appropriate screwdriver or Allen wrench to remove the screws securing the old extruder. Be careful to support the extruder motor as you remove it.

5. Prepare the New Aluminum Extruder

Unpack the new extruder and ensure all parts are included in the kit.

6. Install the New Extruder

Mount the new extruder by aligning it with the motor and base plate, then secure it with screws. Ensure all screws are tightened evenly.

7. Reattach the Bowden Tube

Screw the fitting with the Bowden tube back into the new extruder.

8. Load Filament and Test Print

Turn the printer back on, load filament into the new extruder, and run a test print to ensure everything is functioning correctly.

Troubleshooting Common Issues

After upgrading, you might encounter some common issues:

- Over-Extrusion: Check calibration settings and adjust the extrusion multiplier as needed.

- Under-Extrusion: Ensure there are no obstructions and adjust print speeds if necessary.

Advanced Extruder Upgrades

Some advanced extruder upgrades, like the Bondtech Mini Geared (BMG) extruder, incorporate DualDrive systems. These systems ensure that the extruder maintains a consistent grip on the filament, preventing slipping and grinding, which can be particularly beneficial for printing with flexible filaments[1].

Features of Advanced Extruders

1. Dual Gear System: Provides better grip on the filament, minimizing slippage and ensuring consistent extrusion.

2. Adjustable Tension: Allows users to fine-tune the pressure on the filament for optimal feeding.

3. Direct Drive Conversion: Some kits offer the option to convert to a direct drive system, which can further improve print quality with flexible filaments[5].

Maintenance and Calibration

Regular maintenance is essential for ensuring the optimal performance and longevity of aluminum extrusion components in 3D printers.

Maintenance Tips

- Regular Cleaning: Keep aluminum components clean to prevent the buildup of dust and debris, which can affect performance[3].

- Check for Wear: Regularly inspect aluminum extrusions for signs of wear or damage.

- Ensure Secure Connections: Verify that all connections are secure and properly tightened.

Calibration

Calibration is crucial after installing a new extruder. Update your printer's firmware settings to accommodate the new extruder specifications. Conduct a series of test prints to verify the performance and make any necessary adjustments to the extruder and printer settings[2].

Applications and Benefits

Upgrading to an aluminum extruder can significantly enhance your printing experience across various applications:

- Prototyping: Improved filament handling and durability ensure consistent results, even with complex prototypes.

- Model Making: Enhanced thermal performance and reduced under-extrusion issues result in smoother, more detailed models.

- Educational Settings: The reliability and ease of use of aluminum extruders make them ideal for educational environments where printers are frequently used[1].

Handling Flexible Filaments

Aluminum extruders, especially those with direct drive systems, are well-suited for handling flexible filaments like TPU. To achieve the best results with flexible filaments, optimizing print settings is crucial:

- Print Speed: Slowing down the print speed can help prevent issues related to filament buckling and ensure better layer adhesion. A speed of 20-40 mm/s is generally recommended for flexible filaments[6].

- Temperature: Flexible filaments typically require higher printing temperatures than rigid materials. Refer to the filament manufacturer's recommendations for the optimal temperature range.

- Retraction: Adjusting retraction settings is essential for minimizing stringing and oozing. Lower retraction distances and speeds are generally recommended for flexible filaments[6].

Conclusion

Upgrading your 3D printer with an extruder aluminum alloy can significantly improve print quality, durability, and overall performance. By following these steps and understanding the benefits of aluminum alloy extruders, you can enhance your 3D printing experience.

FAQ

1. What are the benefits of using an aluminum alloy extruder?

Aluminum alloy extruders offer durability, improved stability, compatibility with various filaments, and enhanced heat dissipation, making them a superior choice over plastic extruders.

2. How do I know if my extruder needs an upgrade?

Signs that your extruder may need an upgrade include inconsistent filament feeding, slippage, wear and tear, and difficulty printing with flexible filaments.

3. Can aluminum alloy extruders be used with all types of filaments?

Yes, aluminum alloy extruders are compatible with a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon.

4. How do I prevent over-extrusion after installing a new extruder?

To prevent over-extrusion, carefully calibrate your extruder settings, ensure accurate filament diameter entry in your slicer, and adjust the extrusion multiplier as needed.

5. Are aluminum alloy extruders more expensive than plastic ones?

While aluminum alloy extruders may initially seem more expensive, their durability and long lifespan reduce the need for frequent replacements, making them a cost-effective option in the long run.

Citations:

[1] https://www.yjing-extrusion.com/why-upgrade-to-a-cr-10-aluminum-extruder-for-better-3d-printing.html

[2] https://blog.goldsupplier.com/metal-extruder/

[3] https://www.yjing-extrusion.com/how-does-aluminum-extrusion-improve-3d-printing-performance.html

[4] https://www.inorigin.eu/3d-printer-extruder/

[5] https://www.yjing-extrusion.com/is-the-upgraded-aluminum-extruder-v2-worth-the-investment-for-better-print-quality.html

[6] https://www.yjing-extrusion.com/can-an-aluminum-mk8-extruder-with-direct-drive-handle-flexible-filaments.html

[7] https://community.ultimaker.com/topic/32275-ultimaker-2-extruder-problems-needed-upgrade/

[8] https://additive-x.com/blog/essential-guide-3d-printer-calibration

[9] https://hotends.com/general/upgrading-your-3d-printer-the-hotend-upgrade/

[10] https://www.3djake.ch/en-CH/creality-3d-printers-spare-parts/metal-extruder-upgrade-kit

[11] https://www.matterhackers.com/articles/top-ten-advanced-3d-printer-upgrades

[12] https://www.reddit.com/r/3Dprinting/comments/1gqlhqd/new_to_3d_printing_what_are_some_mistakes_that/

[13] https://www.youtube.com/watch?v=v8SwY8yveqc

[14] https://www.reddit.com/r/ender3/comments/q6cojb/what_are_the_pros_and_cons_of_a_direct_drive/

[15] https://www.reddit.com/r/ender3/comments/eqeddp/the_all_aluminum_extruder_upgrade_is_only_ten/

[16] https://www.reddit.com/r/ender3v2/comments/193nzb0/i_upgraded_to_the_all_metal_extruder_and_now_the/

[17] https://www.linkedin.com/advice/1/what-youre-making-common-mistakes-when-responding-failure-l8pre

[18] https://all3dp.com/2/3d-printer-maintenance-fdm-3d-printer/

[19] http://www.soliforum.com/topic/5711/the-benefits-of-upgrading-to-a-geared-extruder/

[20] https://www.researchgate.net/publication/287594463_Review_of_past_innovations_and_recent_improvements_in_aluminum_extrusion_from_alloy_to_process_development