Content Menu

● Introduction to FlashForge Extruder Aluminum Block

>> Importance of Maintenance

● Tools Needed for Maintenance

● Step-by-Step Cleaning Guide

>> Step 1: Disassemble the Extruder

>> Step 2: Clean the Nozzle and Aluminum Block

>> Step 3: Reassemble the Extruder

● Common Issues and Troubleshooting

>> Clogged Nozzle

>> Filament Residue on Aluminum Block

>> Extruder Gear Clogs

● Preventive Maintenance

● Conclusion

● FAQs

>> 1. How Often Should I Clean the Extruder Aluminum Block?

>> 2. What Tools Are Needed to Clean the FlashForge Extruder Aluminum Block?

>> 3. How Do I Remove a Clog from the Nozzle?

>> 4. Can I Use Steel Brushes to Clean the Nozzle?

>> 5. How Do I Prevent Filament Residue from Accumulating on the Aluminum Block?

● Citations:

Maintaining and cleaning the FlashForge extruder aluminum block is crucial for ensuring optimal performance and longevity of your 3D printer. This guide will walk you through the steps to keep your extruder in top condition, including disassembly, cleaning, and reassembly. We'll also cover common issues and troubleshooting tips.

Introduction to FlashForge Extruder Aluminum Block

The FlashForge extruder aluminum block, often referred to as the heater block, is a critical component of the 3D printing process. It houses the nozzle and is responsible for heating the filament to the appropriate temperature for extrusion. Over time, this area can become clogged with filament residue, leading to print failures and decreased printer performance.

Importance of Maintenance

Regular maintenance is essential to prevent clogs and ensure consistent print quality. Here are some reasons why cleaning the extruder aluminum block is important:

- Prevents Clogs: Filament residue can accumulate and cause blockages, leading to failed prints.

- Improves Print Quality: A clean extruder ensures consistent filament flow, resulting in better print quality.

- Extends Printer Life: Regular cleaning helps prevent damage to the extruder components.

Tools Needed for Maintenance

Before starting, gather the necessary tools:

- Allen Wrenches (2.5 mm and 3 mm)

- Socket Wrench (for nozzle removal)

- Padded Pliers or Vice Grips

- Soft Brass Brush

- Cotton Swabs or Paper Towels

- Acetone (for ABS and ASA filaments)

- Ethyl Acetate (for PLA filaments)

- Cleaning Filament (optional)

Step-by-Step Cleaning Guide

Step 1: Disassemble the Extruder

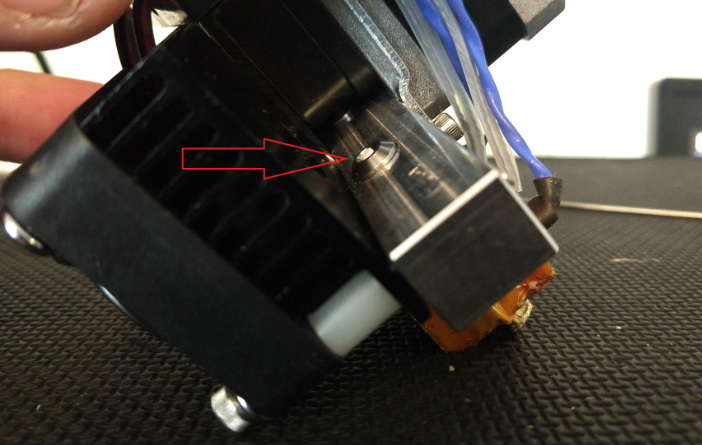

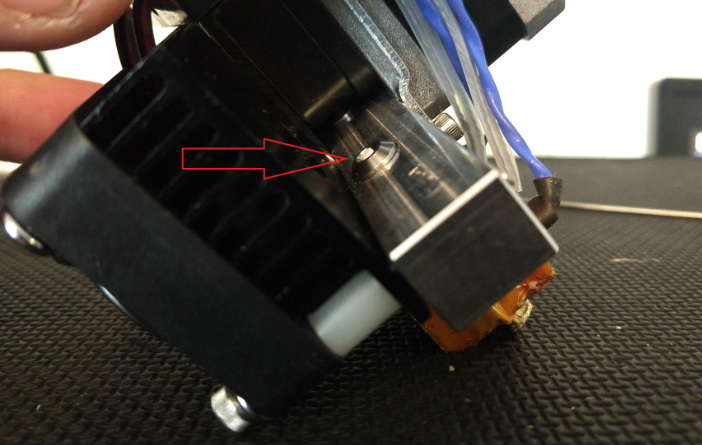

1. Remove the Extruder Assembly:

- Unscrew the two screws holding the extruder assembly to the X shuttle. This will allow you to lift the assembly away from the printer.

- Use a flashlight to locate the screws, as they are often hidden.

2. Loosen Top Screws:

- Loosen the screws holding the black plastic plate in place. This will give you access to the heat sinks and fans.

3. Remove Fans and Heat Sinks:

- Slide the screws out partially to remove the fans and heat sinks. Be careful not to lose the spacers.

- Completely remove the screws to separate the fans and heat sinks from the aluminum bar.

4. Remove the Nozzle:

- Turn the aluminum bar upside down and unscrew the nozzle. If it's stiff, apply some lubricant to the threads.

- Carefully slide the PTFE tube out of the nozzle.

Step 2: Clean the Nozzle and Aluminum Block

1. Use a Soft Brass Brush:

- Heat the nozzle to around 220°C. Use a soft brass brush to gently scrub away any filament residue from the nozzle and aluminum block.

2. Clean with Cotton Swabs or Paper Towels:

- While the nozzle is still warm, use cotton swabs or paper towels to wipe away any remaining residue.

3. Use Acetone or Ethyl Acetate (if necessary):

- For ABS or ASA filaments, soak the nozzle in acetone. For PLA, use ethyl acetate. Always wear protective gloves and work in a well-ventilated area.

Step 3: Reassemble the Extruder

1. Reinsert the PTFE Tube:

- Carefully slide the PTFE tube back into the nozzle.

2. Reattach the Nozzle:

- Screw the nozzle back into place. Ensure it's securely tightened but avoid over-tightening.

3. Reattach Fans and Heat Sinks:

- Slide the screws back in partially to reattach the fans and heat sinks. Tighten them evenly.

4. Reattach the Extruder Assembly:

- Place the extruder assembly back onto the X shuttle and secure it with the screws.

Common Issues and Troubleshooting

Clogged Nozzle

- Symptoms: Filament not extruding or under-extrusion.

- Solution: Use a cleaning filament or perform a cold pull with nylon filament.

Filament Residue on Aluminum Block

- Symptoms: Visible residue on the heater block.

- Solution: Use a brass brush and cotton swabs to clean while heated.

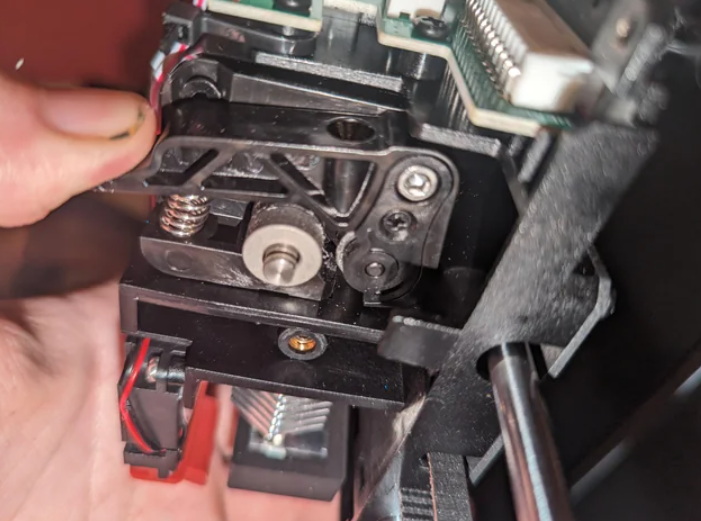

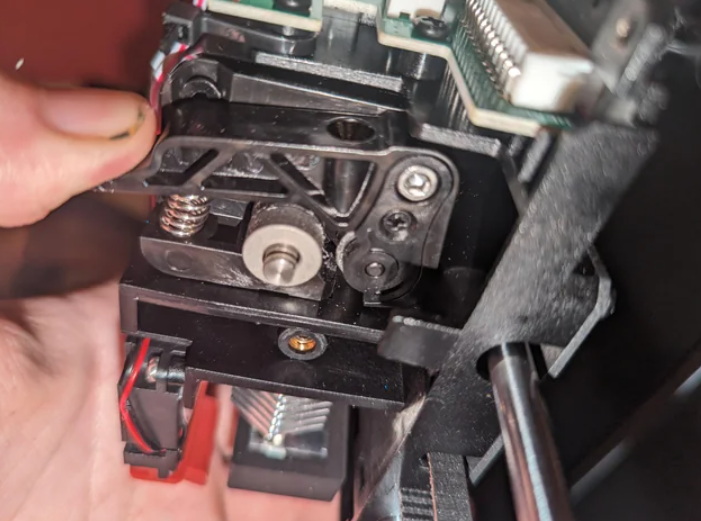

Extruder Gear Clogs

- Symptoms: Filament not feeding properly.

- Solution: Disassemble the extruder to clean the gears with tweezers and a toothbrush.

Preventive Maintenance

Regular cleaning and maintenance can prevent many issues. Here are some tips:

- Regularly Brush the Nozzle: Use a soft brass brush to remove filament residue.

- Use Cleaning Filament: Especially when switching between different types of filaments.

- Lubricate Moving Parts: Regularly apply lubricant to moving parts to prevent wear.

Conclusion

Maintaining the FlashForge extruder aluminum block is essential for ensuring your 3D printer operates efficiently and effectively. By following these steps and tips, you can prevent common issues like clogs and residue buildup, extending the life of your printer and improving print quality.

FAQs

1. How Often Should I Clean the Extruder Aluminum Block?

Cleaning should be done after every major print failure or when switching between different types of filaments. Regular maintenance can prevent clogs and improve print quality.

2. What Tools Are Needed to Clean the FlashForge Extruder Aluminum Block?

You will need Allen wrenches, a socket wrench, padded pliers, a soft brass brush, cotton swabs, and possibly acetone or ethyl acetate for solvent cleaning.

3. How Do I Remove a Clog from the Nozzle?

Use a cleaning filament or perform a cold pull with nylon filament. If the clog persists, consider using an acupuncture needle to break up the blockage.

4. Can I Use Steel Brushes to Clean the Nozzle?

No, steel brushes are too abrasive and can damage the nozzle. Always use a soft brass brush for cleaning.

5. How Do I Prevent Filament Residue from Accumulating on the Aluminum Block?

Regularly clean the nozzle and aluminum block with a brass brush and cotton swabs. Use cleaning filament when switching between different types of filaments.

Citations:

[1] https://www.instructables.com/Unclogging-Nozzle-on-Flashforge-Dreamer/

[2] https://www.hubs.com/talk/t/how-to-disassemble-flashforge-creator-extuder/2272/

[3] https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/special-cleanup-of-extruder-after-print-failure/

[4] https://www.youtube.com/watch?v=vmIY9_6s8Ss

[5] https://en.fss.flashforge.com/10000/software/300e2ae206fc33fa79735a1cc6f94671.pdf

[6] https://en.fss.flashforge.com/10000/software/61817cc4fa72e8e2d4654a6192d895f1.pdf

[7] https://www.youtube.com/watch?v=eqqtbiZGK7k

[8] https://www.hubs.com/talk/t/solved-flashforge-creator-pro-not-extruding-properly/11283/

[9] https://www.wevolver.com/article/how-to-clean-3d-printer-nozzle

[10] https://www.youtube.com/watch?v=FepYpYRethg

[11] https://www.reddit.com/r/FlashForge/comments/i01iiq/please_help_with_this_jam_in_my_flashforge/

[12] https://www.youtube.com/watch?v=Y8OikyBY8-s

[13] https://www.flashforge.com.hk/uploads/5/8/1/9/58196085/flashforge_creator_pro_user_manual_en_version04.29.2015.3.2._latest.pdf

[14] https://www.tiktok.com/discover/how-to-clean-you-nozzle-on-the-flashforge-5m

[15] https://www.reddit.com/r/FlashForge/comments/m2jkan/creator_pro_2_heater_block_and_nozzle_help/

[16] https://en.fss.flashforge.com/10000/software/692ef075fcb6db012b38a885dca0e057.pdf

[17] https://flashforge-usa.com/files/s/files/1/2510/7166/files/flashforge-guideriis-user-guide.v.20180410_v-1613178516.pdf

[18] https://www.reddit.com/r/FlashForge/comments/16l3dfd/clogged_flashforge_finder/

[19] https://wiki.flashforge.com/en/adventurer-series/maintenance

[20] https://www.youtube.com/watch?v=lAPjqjL16OY

[21] https://www.youtube.com/watch?v=ATs0Ob0qB7k

[22] https://www.reddit.com/r/3Dprinting/comments/cy7tid/flashforge_creator_pro_hotend_replacement_issues/

[23] https://www.youtube.com/watch?v=Pd7rWeeh8fE

[24] https://3dprinting.stackexchange.com/questions/6804/extruder-nozzle-keeps-clogging-up

[25] https://www.youtube.com/watch?v=DxbvzLBtlG0

[26] https://en.fss.flashforge.com/10000/software/5fed199886c6a9b740f002862063ea60.pdf

[27] https://www.tiktok.com/discover/how-to-clean-the-nozzle-on-flashforge-5

[28] https://www.flashforge.com.hk/uploads/5/8/1/9/58196085/dreamer_user_guide_en_v3.0_05.01.2015.pdf

[29] https://www.reddit.com/r/FlashForge/comments/g8qpbx/blocked_extruder_help_please/

[30] https://flashforgeeu.freshdesk.com/support/solutions/articles/24000012787-basic-maintenance-of-3d-printers-and-preventive-actions

[31] https://www.hubs.com/talk/t/flashforge-creator-pro-pla-extrusion-problem/5119/

[32] https://en.fss.flashforge.com/10000/software/899daf8848060aa85e584cda439514c0.pdf

[33] https://flashforge-germany.de/images/Bedienungsanleitungen/FlashForge-Creator_Pro-Users-Guide.V.20170824.pdf

[34] https://flashforge-germany.de/images/Bedienungsanleitungen/FlashForge-Inventor_II-User-Guide.V.20170816.pdf

[35] https://www.geekbuying.com/geekgiz/2024/01/flashfore-adventurer-5m-series-troubleshooting/

[36] https://creadil.com/wp-content/uploads/2023/06/manuel-Guider-3-Anglais.pdf

[37] https://www.instructables.com/Flashforge-Dual-Head-Printer-Print-Head-Repair/

[38] https://www.youtube.com/watch?v=2_EzsuLzMzA