Content Menu

● Understanding Pipe Production Extrusion

>> Key Components of Pipe Production Extrusion Line

● Factors Affecting Efficiency

>> Importance of Material Selection

● Strategies to Improve Efficiency

>> 1. Optimize Material Selection

>> 2. Regular Maintenance of Equipment

>> 3. Enhance Process Control

>> 4. Train Operators

>> 5. Implement Lean Manufacturing Principles

>> 6. Upgrade Technology

>> 7. Monitor Energy Consumption

>> 8. Quality Control Measures

>> 9. Data Analytics for Continuous Improvement

>> 10. Gravimetric Control Systems

● Visual Aids to Enhance Understanding

>> Diagram of Pipe Production Extrusion Line Components

● Conclusion

● FAQ

>> 1. What types of materials are commonly used in pipe extrusion?

>> 2. How often should maintenance be performed on an extrusion line?

>> 3. What role does temperature play in the extrusion process?

>> 4. How can lean manufacturing principles benefit pipe production?

>> 5. What are some common defects in extruded pipes?

● Citations:

The pipe production extrusion line is a crucial component in the manufacturing of pipes for various applications, including plumbing, construction, and industrial uses. Improving the efficiency of this line not only enhances productivity but also reduces costs and waste. This article explores various strategies and techniques to optimize the efficiency of a pipe production extrusion line.

Understanding Pipe Production Extrusion

Extrusion is a manufacturing process where materials are pushed through a die to create long shapes with a fixed cross-section. In the case of pipe production, thermoplastics such as PVC, HDPE, and PP are commonly used. The extrusion line consists of several key components:

- Extruder: Melts the plastic and pushes it through the die.

- Die: Shapes the molten plastic into the desired pipe profile.

- Cooling System: Cools down the extruded pipe to solidify it.

- Cutting System: Cuts the pipe into specified lengths.

- Winding/Stacking System: Prepares finished pipes for storage or shipping.

Key Components of Pipe Production Extrusion Line

1. Extruder: The heart of the extrusion line, responsible for melting and conveying the material.

2. Die Head: Determines the shape and dimensions of the pipe.

3. Cooling Tank: Ensures that the extruded pipe is cooled uniformly to prevent deformation.

4. Haul-off Unit: Pulls the pipe from the die at a consistent speed to maintain uniformity.

5. Cutting Unit: Cuts pipes to desired lengths, which is critical for efficiency.

Factors Affecting Efficiency

To improve efficiency in a pipe production extrusion line, it is essential to understand the factors that can impact performance:

- Material Quality: The type and quality of raw materials used can significantly affect the extrusion process.

- Machine Calibration: Proper calibration of machines ensures optimal operation and reduces downtime.

- Temperature Control: Maintaining appropriate temperatures throughout the extrusion process is crucial for product quality.

- Operator Skill Level: Skilled operators can identify issues quickly and make necessary adjustments.

Importance of Material Selection

Selecting high-quality materials is fundamental to achieving efficient production. For instance, using *homogeneous* materials ensures that melting occurs evenly, leading to consistent product quality. Additionally, different materials have varying thermal properties that affect processing speeds and energy consumption.

Strategies to Improve Efficiency

1. Optimize Material Selection

Choosing the right materials for your pipe production is vital. High-quality resins with consistent properties can lead to smoother processing and better end products. Consider using additives that enhance flow properties or reduce processing temperatures.

2. Regular Maintenance of Equipment

Implementing a regular maintenance schedule for all machinery in the extrusion line helps prevent unexpected breakdowns. Key maintenance activities include:

- Lubricating moving parts

- Checking alignment and calibration

- Inspecting heating elements

- Cleaning dies and cooling systems

3. Enhance Process Control

Utilizing advanced process control systems can significantly improve efficiency. These systems allow for real-time monitoring and adjustments, ensuring optimal conditions throughout production. Key technologies include:

- Automated Temperature Control: Ensures consistent melting and cooling processes.

- Pressure Sensors: Monitor pressure levels to prevent blockages or defects.

4. Train Operators

Investing in training programs for operators can lead to improved efficiency. Skilled operators are more adept at troubleshooting issues, adjusting settings, and ensuring that production runs smoothly.

5. Implement Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste without sacrificing productivity. Techniques include:

- Streamlining workflows

- Reducing setup times

- Implementing just-in-time inventory practices

6. Upgrade Technology

Investing in modern extrusion technology can yield significant efficiency gains. Considerations include:

- High-efficiency extruders that consume less energy

- Advanced cooling systems that reduce cycle times

- Automated cutting systems that enhance precision

7. Monitor Energy Consumption

Energy costs can be a significant portion of operational expenses in a pipe production extrusion line. Monitoring energy consumption helps identify areas where savings can be made, such as:

- Using energy-efficient motors

- Optimizing heating elements to reduce energy waste

8. Quality Control Measures

Implementing stringent quality control measures ensures that defects are caught early in the process, reducing waste and rework. Techniques include:

- Regular sampling and testing of extruded pipes

- Visual inspections during production

- Utilizing non-destructive testing methods

9. Data Analytics for Continuous Improvement

Utilizing data analytics tools allows manufacturers to analyze production data for patterns and trends that indicate inefficiencies. By addressing these issues, companies can continuously improve their processes.

10. Gravimetric Control Systems

Integrating gravimetric control systems can greatly enhance material handling efficiency by allowing real-time monitoring of material flow rates and automatically adjusting downstream processes accordingly[1]. This leads to reduced waste and improved consistency in product quality.

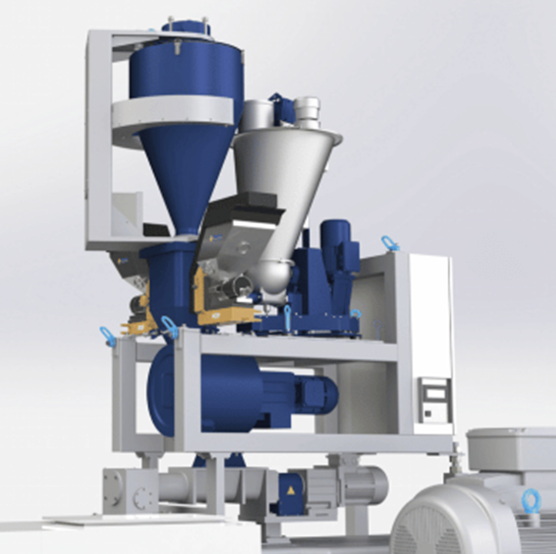

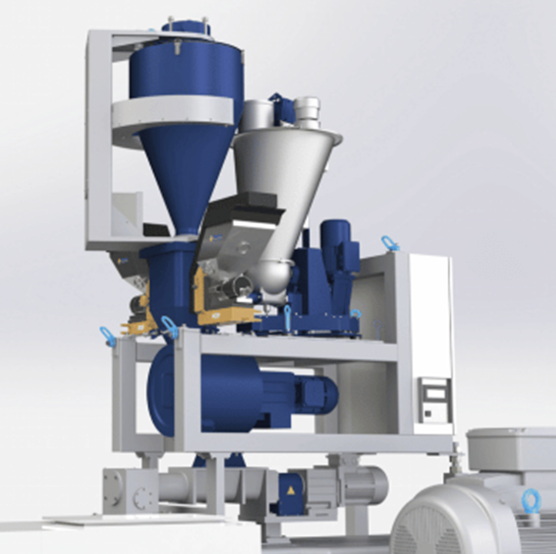

Visual Aids to Enhance Understanding

Incorporating visuals such as diagrams, flowcharts, and videos can significantly enhance comprehension of complex processes involved in pipe production extrusion lines.

Diagram of Pipe Production Extrusion Line Components

Pipe Production Extrusion Line Diagram

Conclusion

Improving efficiency in a pipe production extrusion line requires a multi-faceted approach that includes optimizing material selection, maintaining equipment, enhancing operator skills, implementing lean practices, upgrading technology, monitoring energy consumption, enforcing quality control measures, and utilizing data analytics for continuous improvement.

By focusing on these strategies, manufacturers can achieve higher productivity levels while reducing costs and waste associated with pipe production.

FAQ

1. What types of materials are commonly used in pipe extrusion?

Common materials used in pipe extrusion include PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), and PP (Polypropylene). Each material has unique properties suitable for different applications.

2. How often should maintenance be performed on an extrusion line?

Regular maintenance should be performed based on manufacturer recommendations but typically ranges from weekly inspections to monthly comprehensive checks to ensure optimal performance.

3. What role does temperature play in the extrusion process?

Temperature is critical in the extrusion process as it affects material flow properties. Maintaining appropriate temperatures helps ensure smooth processing and high-quality end products.

4. How can lean manufacturing principles benefit pipe production?

Lean manufacturing principles help minimize waste by streamlining workflows, reducing setup times, and improving overall operational efficiency, resulting in cost savings.

5. What are some common defects in extruded pipes?

Common defects include inconsistent wall thickness, surface imperfections, color variations, and dimensional inaccuracies. Implementing quality control measures can help identify these issues early on.

Citations:

[1] https://rollepaal.com/knowledge/explore-how-gravimetric-control-can-improve-your-pipe-extrusion-production

[2] https://plastic-extrusionmachines.com/the-basic-principles-of-pipes-extrusion/

[3] https://www.bausano.com/en/press-and-news/reducing-energy-costs-focus-on-extrusion

[4] https://www.ptonline.com/articles/how-to-get-peak-performance-efficiency-out-of-your-extrusion-line---part-i

[5] https://rollepaal.com/knowledge/optimization-of-raw-material-selection-for-cost-effectiveness-in-pipe-extrusion/

[6] https://jieyatwinscrew.com/blog/the-ultimate-guide-to-pipe-extrusion/

[7] https://drts.com/five-ways-upgrade-plastic-pipe-extruder-machine/

[8] https://www.medicalplasticsnews.com/news/the-best-approach/

[9] https://www.ptonline.com/articles/tips-and-techniques-boosting-extrusion-productivitypart-iii-of-iii-trim-your-material-energy-costs

[10] https://jydjx.com/maximizing-efficiency-and-quality-a-comprehensive-guide-to-plastic-pipe-extrusion-lines/

[11] https://www.bausano.com/en/press-and-news/pipe-extrusion-energy-consumption-and-efficiency

[12] https://www.xinrongplas.com/news/how-to-improve-production-efficiency-of-pe-pipe-production-equipment.html

[13] https://jydjx.com/optimizing-production-with-pvc-pipe-extrusion-machine-lines/

[14] https://www.qiangshengplas.com/news/maximizing-efficiency-in-your-pvc-extrusion-line-tips-for-improved-productivity-and-reduced-costs/

[15] https://www.linkedin.com/pulse/enhancing-pvc-pipe-extrusion-efficiency-maximelt-xighe

[16] https://jydjx.com/selecting-the-right-pipe-extruder-a-path-to-quality-and-efficiency/

[17] https://www.eng-tips.com/threads/hdpe-extrusion-what-mfi-value-for-best-production-efficiency.494518/