Content Menu

● Introduction to Plastic Extrusion Machinery

● Factors to Consider When Choosing a Supplier

>> 1. Expertise and Experience

>> 2. Customization Capabilities

>> 3. Quality and Reliability

>> 4. After-Sales Support and Service

>> 5. Customer Experience and Values

● Evaluating Plastic Extrusion Machinery Suppliers

● Understanding the Sales Approach

● Product Deep-Dive

● Company Credibility

● Material Compatibility and Production Requirements

● Innovation and Sustainability

● Global Footprint and Supply Chain

● Cost Efficiency and Return on Investment

● Training and Operator Skills

● Safety Features and Compliance

● Future Scalability

● Choosing the Right Extrusion Machine Type

● Small Extrusion Machines

● Conclusion

● Frequently Asked Questions

>> 1. What are the key factors to consider when selecting a plastic extrusion machinery supplier?

>> 2. How does customization impact the choice of a plastic extrusion machinery supplier?

>> 3. What role does after-sales support play in the selection of a supplier?

>> 4. How important is the customer experience when evaluating plastic extrusion machinery suppliers?

>> 5. What steps should be taken to evaluate potential plastic extrusion machinery suppliers?

● Citations:

Choosing the right plastic extrusion machinery supplier is a critical decision for any business involved in the production of plastic products. This decision can significantly impact the efficiency, quality, and profitability of your operations. In this article, we will explore the key factors to consider when selecting a plastic extrusion machinery supplier and provide insights into how to make an informed choice.

Introduction to Plastic Extrusion Machinery

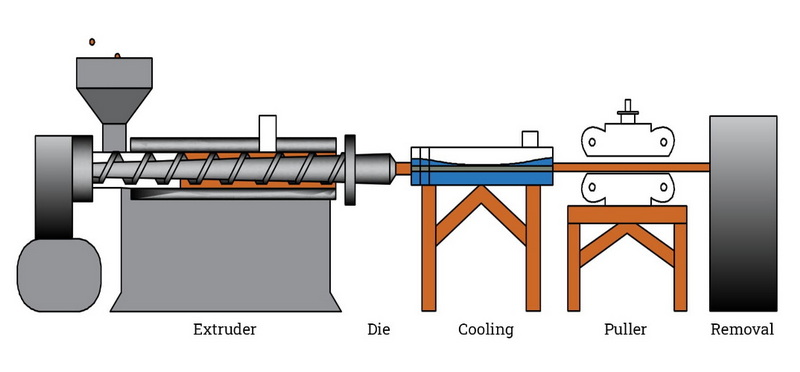

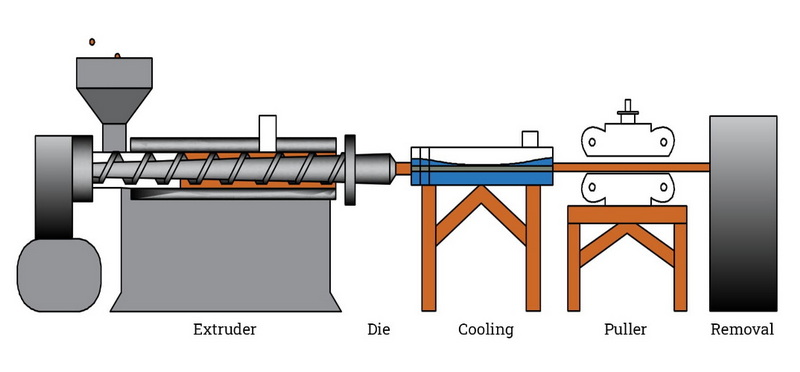

Plastic extrusion is a continuous process that transforms thermoplastic feedstock into a molten viscous fluid, which is then shaped and cooled into various forms such as tubes, pipes, profiles, sheets, and films. The machinery involved in this process includes extruders, dies, cooling tanks, haul-off systems, and cutting tools.

Factors to Consider When Choosing a Supplier

1. Expertise and Experience

When selecting a plastic extrusion machinery supplier, it is essential to assess their expertise and experience in the industry. Established suppliers with a proven track record can offer valuable insights and solutions tailored to specific applications. They are more likely to have invested in research and development, providing access to cutting-edge technology that enhances productivity and efficiency.

2. Customization Capabilities

Each industry and application has unique requirements, making customization a crucial factor. A reliable supplier should be able to tailor their machinery and equipment to suit specific production needs, optimizing the process and delivering superior end products.

3. Quality and Reliability

The quality and reliability of the machinery are paramount in ensuring smooth production lines and consistent product output. Selecting a supplier known for producing high-quality, reliable machinery reduces the risk of downtime, maintenance issues, and production delays.

4. After-Sales Support and Service

After-sales support and service play a significant role in the overall customer experience. A reputable supplier offers comprehensive support, including installation, training, maintenance, and spare parts availability. Responsive and dependable after-sales service ensures minimal disruptions to production and long-term satisfaction.

5. Customer Experience and Values

A good customer experience includes quick communication, competitive pricing, timely order confirmations, and shipments arriving on schedule. It is also important to select a supplier who operates with strong values and ethics, ensuring fairness and integrity in all transactions.

Evaluating Plastic Extrusion Machinery Suppliers

When evaluating potential suppliers, consider the following steps:

1. Research and Shortlisting: Research potential suppliers based on their reputation, expertise, and customer reviews. Shortlist suppliers that align with your production goals and industry-specific requirements.

2. Site Visits and Audits: Conduct site visits or audits to assess the supplier's facilities, equipment, and quality control processes.

3. Request for Quotations (RFQs): Send RFQs to shortlisted suppliers to compare pricing, delivery times, and customization options.

4. Trial Orders: Place trial orders to test the supplier's product quality, delivery reliability, and after-sales support.

5. Feedback and Reviews: Check for feedback and reviews from existing customers to gauge the supplier's performance and customer satisfaction.

Understanding the Sales Approach

When interacting with potential suppliers, pay attention to their sales approach. Top-tier sales professionals in the plastic extrusion machine industry should demonstrate a deep understanding of your unique needs and business model. They should exhibit unmatched professionalism, providing confidence in their expertise and guiding you in clarifying your requirements to ensure the machine aligns with your production goals[1].

Product Deep-Dive

Evaluating the machine's performance is crucial. Assess its ability to meet your production demands efficiently and ensure it comes equipped with solution-centric features that address specific challenges in your manufacturing process. Insist on comprehensive demonstrations and detailed breakdowns of each component to align with your expectations[1].

Company Credibility

The manufacturer's market standing and history of dependability are vital. Look for a supplier that collaborates closely with you to tailor machinery to your needs and offers robust after-sales support, reflecting their commitment to a long-term partnership[1].

Material Compatibility and Production Requirements

Material compatibility is essential when selecting an extruder. The thermal, mechanical, and chemical attributes of the materials should match those of the machine. Consider the production requirements, including output capacity, product specifications, and material compatibility, to ensure the machine aligns with your production goals[2][5].

Innovation and Sustainability

Leading plastic extruder machine manufacturers invest in R&D for new products that improve machine performance, product quality, and energy consumption. They also focus on sustainability by developing more energy-efficient machines and utilizing recycled materials[2].

Global Footprint and Supply Chain

A strong global presence combined with a reliable supply chain enables manufacturers to support their products worldwide, including quick access to parts and services. This is crucial for maintaining efficient operations across different regions[2].

Cost Efficiency and Return on Investment

While the initial purchase price is important, focus on the overall return on investment (ROI). Evaluate the machine's performance, durability, maintenance requirements, and potential for future upgrades to determine its long-term value for your business[5].

Training and Operator Skills

Ensure that your operators receive proper training on the operation and maintenance of the chosen plastic extrusion machine. Adequate training enhances productivity, minimizes errors, and extends the machine's lifespan[5].

Safety Features and Compliance

Consider the safety features integrated into the machine design. Look for certifications and compliance with industry standards to ensure the machine meets safety requirements and protects your operators and facility[5].

Future Scalability

Anticipate future business growth and evaluate the scalability of the chosen machine. Will it accommodate increased production demands or potential product expansions? Planning for scalability can save you from having to invest in new equipment sooner than necessary[5].

Choosing the Right Extrusion Machine Type

Different plastic extrusion processes require specific machine types. Consider whether you need a single screw, twin screw, or multi-screw extruder based on the materials and products you will be working with. Each machine type has its advantages and limitations, so choose accordingly[5].

Small Extrusion Machines

For smaller operations, consider machines with narrower screws and air cooling systems to save space. Assess the production capacity and throughput to ensure the machine meets your production targets while maintaining output quality[4].

Conclusion

Choosing the right plastic extrusion machinery supplier is a strategic decision that can significantly impact your business's efficiency and profitability. By evaluating factors such as expertise, customization capabilities, quality, after-sales support, and customer experience, you can partner with a supplier that aligns with your production goals and industry-specific requirements. With the right supplier by your side, you can enjoy optimized production lines, reduced downtime, and enhanced overall productivity.

Frequently Asked Questions

1. What are the key factors to consider when selecting a plastic extrusion machinery supplier?

When selecting a plastic extrusion machinery supplier, key factors include expertise and experience, customization capabilities, quality and reliability of machinery, after-sales support, and customer experience.

2. How does customization impact the choice of a plastic extrusion machinery supplier?

Customization is crucial as it allows suppliers to tailor machinery to specific production needs, optimizing processes and delivering superior end products. This capability ensures that the machinery meets the unique requirements of each industry or application.

3. What role does after-sales support play in the selection of a supplier?

After-sales support is vital as it ensures minimal disruptions to production. A reputable supplier provides comprehensive support, including installation, training, maintenance, and spare parts availability, leading to long-term customer satisfaction.

4. How important is the customer experience when evaluating plastic extrusion machinery suppliers?

A good customer experience is essential as it includes quick communication, competitive pricing, timely order confirmations, and shipments arriving on schedule. It also involves selecting a supplier with strong values and ethics, ensuring fairness and integrity in transactions.

5. What steps should be taken to evaluate potential plastic extrusion machinery suppliers?

To evaluate potential suppliers, conduct research and shortlist candidates, visit sites or conduct audits, send RFQs, place trial orders, and review customer feedback to assess performance and satisfaction.

Citations:

[1] https://www.linkedin.com/pulse/from-buyers-perspective-navigating-plastic-extrusion-machine-chan-1e7te

[2] https://jieyatwinscrew.com/blog/plastic-extruder-machine-manufacturers/

[3] https://www.fareastnetwork.co.jp/en/extruder/choosing-an-extruder-manufacturer-a-guide-with-a-comprehensive-list/

[4] https://jieyatwinscrew.com/blog/small-extrusion-machine/

[5] https://www.taizhengmachine.com/Howtochoosetherightplasticextrudermachine.html

[6] https://reads.alibaba.com/your-ultimate-guide-to-sourcing-plastic-extruders/

[7] https://paulmurphyplastics.com/industry-news-blog/what-is-plastic-extrusion-and-how-to-select-the-best-manufacturing-partner/

[8] https://jieyatwinscrew.com/blog/plastic-profile-extrusion-machine/

[9] https://www.cowellextrusion.com/key-points-when-choosing-a-plastic-extruder-machine/

[10] https://jydjx.com/how-to-choose-a-extrusion-machine/

[11] https://www.curbellplastics.com/resource-library/articles/how-to-choose-a-plastic-materials-supplier/

[12] https://blog.goldsupplier.com/plastic-extrusion-machines/

[13] https://www.siliconeplastics.com/post/enhancing-product-design-with-plastic-extrusion-tips-and-techniques-for-manufacturers

[14] https://www.bausano.com/en/press-and-news/are-there-objective-parameters-to-choose-the-right-machine

[15] https://www.cowinextrusion.com/all-about-plastic-extrusion-and-helpful-tips-for-buying-extruder-machinery/

[16] https://programminginsider.com/3-tips-you-should-consider-when-choosing-a-plastic-extrusion-machine/

[17] https://www.sourcifychina.com/plastic-extrusion-machine-guide-in-depth/