Content Menu

● Understanding Plastic Extrusion

>> The Basic Process

>> Key Components of an Extrusion Machine

● Types of Plastic Extrusion Machines

>> Single Screw Extruders

>> Twin Screw Extruders

>> Other Specialized Extruders

● Factors to Consider When Choosing a Plastic Extrusion Machine

>> Material Compatibility

>> Production Capacity

>> Size and Space Requirements

>> Energy Efficiency

>> Maintenance and Serviceability

>> Budget

>> Supplier Reputation

>> Compliance with Safety Standards

>> Level of Automation

● Key Specifications to Evaluate

● The Importance of Customization

>> Screw Design

>> Die Design

>> Heating and Cooling System

>> Feeding System

>> Control System

● Downstream Equipment

>> Cooling Tanks

>> Pullers

>> Cutters

>> Coilers or Winders

>> Screen Printers

● Installation and Training

>> Professional Installation

>> Comprehensive Training Programs

● Maintenance and Troubleshooting

>> Regular Inspection

>> Lubrication

>> Cleaning

>> Prompt Repairs

● Conclusion

● FAQ

>> 1. What is a plastic extrusion machine?

>> 2. How does an extrusion line work?

>> 3. What are the main types of plastic used in extrusion?

>> 4. What are some typical applications of plastic extrusion machines?

>> 5. What is the difference between single-screw and two-screw extruders?

● Citations:

Choosing the right plastic extrusion machine is a critical decision for any business involved in manufacturing plastic products. The right machine can significantly impact production efficiency, product quality, and overall profitability. With a wide array of options available in the market, it's essential to understand the key factors that influence this decision. This guide provides a comprehensive overview of how to select the best plastic extrusion equipment for sale to meet your specific needs.

Understanding Plastic Extrusion

Plastic extrusion is a high-volume manufacturing process in which raw plastic material is melted and formed into a continuous profile[5]. Extrusion produces items such as tubing, pipes, plastic sheeting, and films[5].

The Basic Process

1. Feeding the Material: Raw plastic, typically in the form of pellets, is fed into the extruder through a hopper[5].

2. Melting: The plastic pellets are moved forward by a rotating screw inside a heated barrel, where they are melted into a viscous liquid[5].

3. Shaping: The molten plastic is forced through a die, which shapes the plastic into the desired profile[5].

4. Cooling: The newly formed plastic product is cooled and solidified, maintaining its shape[5].

5. Cutting: The continuous plastic product is cut into the required lengths[5].

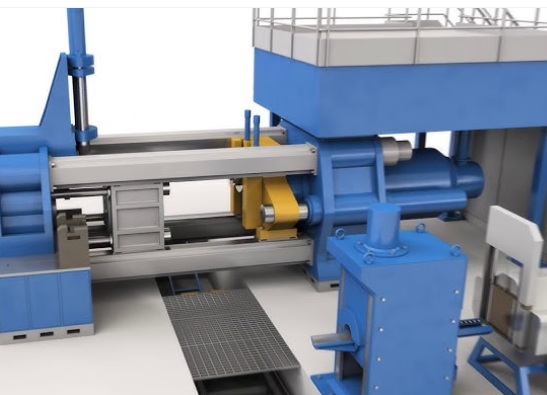

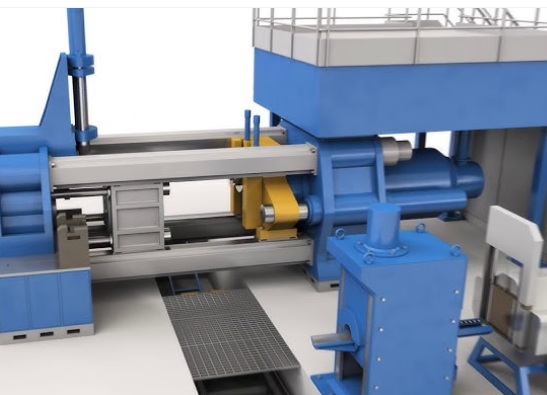

Key Components of an Extrusion Machine

- Hopper: Where raw plastic material is loaded[5].

- Barrel: Houses the extruder screw and heaters to melt the plastic[5].

- Extruder Screw: Carries plastic pellets and generates heat through friction[5].

- Heaters: Maintain optimal processing temperatures[5].

- Die: Shapes the molten plastic[5].

- Cooling System: Solidifies the plastic[5].

- Cutter: Cuts the plastic into desired lengths[5].

Types of Plastic Extrusion Machines

There are several types of plastic extrusion equipment for sale, each designed for specific applications and materials. The most common types include:

Single Screw Extruders

Single screw extruders are the most common type, ideal for simple extrusion processes[3]. They are generally lower in cost and suitable for a range of materials[3].

Twin Screw Extruders

Twin screw extruders are more expensive but offer greater processing power and adaptability[3]. They are better suited for complex plastic materials and applications requiring intensive mixing[3].

Other Specialized Extruders

- Ram Extruders: Used for processing materials that cannot be processed continuously.

- Co-Extruders: Allow for the simultaneous extrusion of multiple layers of different materials.

- Blown Film Extruders: Specifically designed for producing plastic films and bags.

Factors to Consider When Choosing a Plastic Extrusion Machine

Selecting the right plastic extrusion equipment for sale requires careful consideration of several factors.

Material Compatibility

Different machines are designed to handle specific types of plastics[6]. It's crucial to ensure the machine is compatible with the materials you plan to use, considering factors like melting point and viscosity[5].

- PVC: Commonly used for pipes and profiles[5].

- HDPE: Suitable for containers and durable products[5].

- Polypropylene: Used in packaging and automotive parts[5].

- Polycarbonate: Ideal for applications requiring high strength and clarity[5].

Production Capacity

The machine's output rate should align with your production needs[5]. Consider the quantity of products needed and the timeframe for production[5]. Too high a capacity may result in wasted resources, while too low a capacity may limit production potential[3].

Size and Space Requirements

The machine should fit within your designated space, keeping in mind constraints such as ceiling height and floor space[5].

Energy Efficiency

Opt for machines that are energy-efficient to reduce operating costs and align with sustainability goals[5].

Maintenance and Serviceability

Consider the machine's maintenance requirements[5]. Machines that are easier to service reduce downtime and overall operational costs[5].

Budget

The cost of the machine should align with your budget without compromising on critical requirements[5]. Budget planning should take into account the price of the machine, shipping, installation, and possible additional costs[3].

Supplier Reputation

It's essential to choose a machine from a reputable supplier that provides excellent customer service, on-time delivery, and post-purchase support[5].

Compliance with Safety Standards

The machine should comply with all relevant safety standards to ensure a safe working environment[5].

Level of Automation

Consider the level of automation and control technology integrated into the machine[6]. Advanced extruders come equipped with sophisticated control systems that enable precise monitoring of temperature, pressure, and speed, enhancing the quality of the final product and reducing waste during production[6].

Key Specifications to Evaluate

When comparing different models of plastic extrusion equipment for sale, pay close attention to these specifications:

- Screw Design: Look for an extruder with a well-designed screw for consistent melt and high-quality output[1]. The screw should be suitable for the type of plastic you plan to process[5].

- Barrel Length and Diameter: Ensure the barrel dimensions match your production needs, affecting the output capacity and processing efficiency[1].

- Temperature Control: Verify that the machine has precise and reliable temperature control systems to maintain optimal processing conditions[1].

- Sheet Thickness Range: Check the machine's ability to produce sheets within the desired thickness range for your applications[1].

- Material Handling Capacity: Different types and qualities of plastic materials require different processing parameters and handling equipment[3].

The Importance of Customization

Customizable features offer flexibility and adaptability in the production process[5].

Screw Design

The design of the screw can be tailored to enhance processing capabilities and product quality[5]. Different techniques, such as barrier screws or mixing screws, are available to suit specific materials and applications[5].

Die Design

The die, which shapes the extruded plastic, can be customized based on the desired product shape and dimensions[5].

Heating and Cooling System

The temperature control system can be optimized to ensure consistent and ideal processing conditions for different plastics[5].

Feeding System

The feeding system can be adapted based on the type of raw material used, whether it's granules, powders, or liquids[5].

Control System

Advanced control systems can be incorporated to facilitate remote operation, real-time monitoring, and precise control over the entire extrusion process[5].

Downstream Equipment

Downstream equipment refers to the machinery used after the extrusion process to add the finishing touches to the final product[5].

Cooling Tanks

Cooling tanks cool down the extruded plastic to stabilize its shape using chilled water or air[5].

Pullers

Pullers help maintain the speed and tension of the extrusion to ensure uniform shape and size[5].

Cutters

Cutters or saws are used to slice the extruded product into the desired lengths[5].

Coilers or Winders

These are used to wind extruded products like tubes or profiles onto spools or reels for ease of handling and transportation[5].

Screen Printers

For products requiring printed information or branding, screen printers can be used to print directly onto the extruded plastic[5].

Installation and Training

Proper installation and training are crucial for the safe and efficient operation of plastic extrusion equipment for sale.

Professional Installation

Ensure that the machine is installed by qualified technicians.

Comprehensive Training Programs

Operators should receive thorough training on machine operation, maintenance, and troubleshooting.

Maintenance and Troubleshooting

Regular maintenance is essential to keep the machine running smoothly and prevent costly downtime.

Regular Inspection

Conduct regular inspections to identify and address potential issues early.

Lubrication

Keep moving parts properly lubricated.

Cleaning

Clean the machine regularly to remove debris and contaminants.

Prompt Repairs

Address any issues promptly to prevent further damage.

Conclusion

Choosing the right plastic extrusion machine requires a comprehensive understanding of your production needs, the types of materials you'll be working with, and the key features and specifications of available machines. By carefully considering these factors, you can select plastic extrusion equipment for sale that will enhance your production efficiency, product quality, and overall profitability. Adequate research and consultation prior to making a decision will help you ensure that the machine you select will meet your production goals while achieving optimum performance and return on investment[3].

FAQ

1. What is a plastic extrusion machine?

A plastic extrusion machine is a type of machinery used to produce continuous lengths of plastic products with a cross-sectional profile[5]. It is commonly used in the production of items such as pipes, tubing, and plastic sheeting[5].

2. How does an extrusion line work?

An extrusion line works by melting raw plastic material and forcing it through a die to create the desired shape[5]. The plastic is heated and then compressed as it moves through the extruder machine, resulting in the formation of the product[5].

3. What are the main types of plastic used in extrusion?

The main types of plastic used in extrusion include PVC, HDPE, polypropylene, polycarbonate, and various other thermoplastics[5]. Each type of plastic has specific properties and applications within the extrusion process[5].

4. What are some typical applications of plastic extrusion machines?

Common applications of plastic extrusion machines include the production of pipes, tubing, film, profiles, and plastic sheeting[5]. These products are used in various industries, such as construction, packaging, and manufacturing[5].

5. What is the difference between single-screw and two-screw extruders?

Single-screw extruders have one rotating screw that creates the necessary pressure and heat to melt and shape the plastic, while two-screw extruders have two intermeshing screws that work together to carry out the extrusion process[5].

Citations:

[1] https://www.cnchaoxu.com/news-center/how-to-choose-a-good-plastic-sheet-extruder-machine

[2] https://reads.alibaba.com/your-ultimate-guide-to-sourcing-plastic-extruders/

[3] https://plastic-extrusionmachines.com/plastic-extrusion-machine-cost/

[4] https://www.alamy.com/stock-photo/extrusion-machine.html

[5] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[6] https://abhiplastics.com/the-ultimate-guide-to-choosing-the-right-plastic-extruder-machine-for-your-industrial-needs/

[7] https://www.cowinextrusion.com/all-about-plastic-extrusion-and-helpful-tips-for-buying-extruder-machinery/

[8] https://programminginsider.com/3-tips-you-should-consider-when-choosing-a-plastic-extrusion-machine/

[9] https://www.moldingmachinetepai.com/resources/the-ultimate-guide-to-plastic-extrusion-machines.html

[10] https://www.cowinextrusion.com/key-points-to-pay-attention-to-when-selecting-plastic-extruder/

[11] https://paulmurphyplastics.com/industry-news-blog/3-tips-you-should-consider-when-choosing-a-plastic-extrusion-machine/

[12] https://jydjx.com/how-to-choose-a-extrusion-machine/

[13] https://jydjx.com/important-things-to-consider-before-and-after-buying-a-plastic-profile-extrusion-line/

[14] https://www.cowellextrusion.com/key-points-when-choosing-a-plastic-extruder-machine/

[15] https://www.bausano.com/en/press-and-news/are-there-objective-parameters-to-choose-the-right-machine

[16] https://plastiwin.com/uncategorized/how-to-buy-plastic-extrusion-equipment/

[17] https://www.zatpatmachines.com/blog/view/how-to-choose-the-best-plastic-processing-machine-for-your-business/1069

[18] https://www.istockphoto.com/photos/extruder-machine

[19] https://www.istockphoto.com/photos/plastic-extrusion-machine

[20] https://www.youtube.com/watch?v=0daE1OcLDpw

[21] https://www.shutterstock.com/search/extrusion-machine

[22] https://www.youtube.com/channel/UCf6t2HsSOkVtJ5azgk_tPbQ

[23] https://www.youtube.com/watch?v=9Hmp4K3NwB0

[24] https://stock.adobe.com/search/images?k=plastic+extruder

[25] https://www.youtube.com/watch?v=08_f5BRYcyM