Content Menu

● Understanding Cable Extrusion Machinery

● Key Factors to Consider When Choosing Cable Extrusion Machinery

>> 1. Production Capacity and Speed

>> 2. Material Compatibility

>> 3. Energy Efficiency

>> 4. Automation and Control Systems

>> 6. Quality Control Features

>> 7. Maintenance and Support

● Advanced Features in Modern Cable Extrusion Machinery

>> 1. IoT Integration

>> 2. Artificial Intelligence and Machine Learning

>> 3. Sustainable Manufacturing Features

● Assessing Your Business Needs

● Case Studies: Successful Implementation of Cable Extrusion Machinery

>> Case Study 1: Small-Scale Cable Manufacturer

>> Case Study 2: Large-Scale Power Cable Producer

● Future Trends in Cable Extrusion Machinery

● Tips for Successful Implementation of New Cable Extrusion Machinery

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the typical lifespan of cable extrusion machinery?

>> 2. How can I determine the right size of cable extrusion machinery for my business?

>> 3. What are the key maintenance requirements for cable extrusion machinery?

>> 4. How can I improve the energy efficiency of my cable extrusion process?

>> 5. What are the latest technological advancements in cable extrusion machinery?

● Citations:

Selecting the appropriate cable extrusion machinery is a critical decision that can significantly impact your business's productivity, efficiency, and overall success in the cable manufacturing industry. This comprehensive guide will walk you through the essential factors to consider when choosing cable extrusion machinery, helping you make an informed decision that aligns with your production needs and business goals.

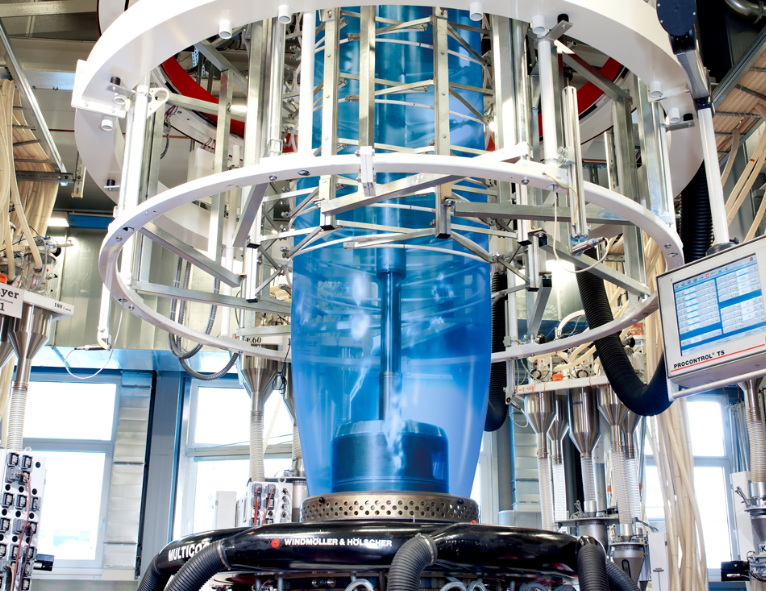

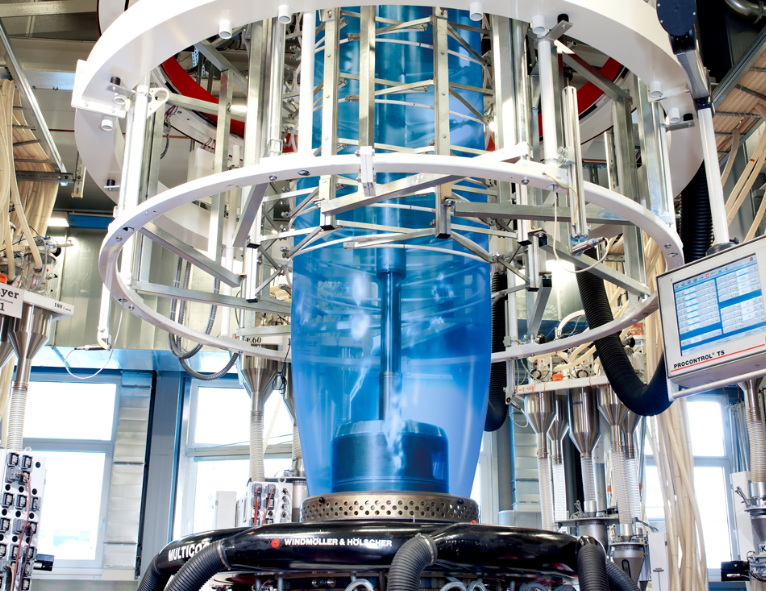

Understanding Cable Extrusion Machinery

Cable extrusion machinery is a vital component in the production of various types of cables, including power cables, communication cables, and specialty cables. These machines are responsible for applying insulation and jacketing materials to the cable core, ensuring proper protection and performance of the final product.

There are several types of cable extrusion machinery available in the market, each designed for specific applications and production requirements:

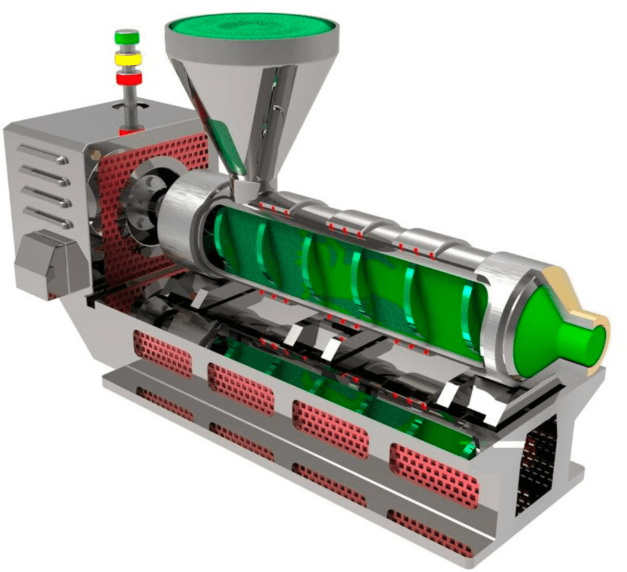

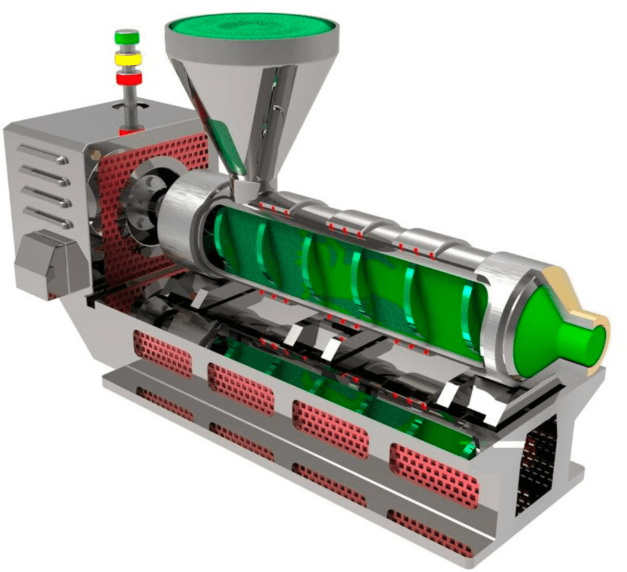

1. Single Screw Extruders: These are the most common type of extruders used in cable manufacturing. They are versatile and suitable for a wide range of materials and cable sizes[1].

2. Twin Screw Extruders: These machines offer better mixing capabilities and are often used for specialized materials or high-performance cables[1].

3. Tandem Extruders: These systems combine two or more extruders in series, allowing for multi-layer extrusion in a single process[1].

4. Planetary Extruders: These machines are known for their excellent mixing capabilities and are often used for high-precision applications[1].

Key Factors to Consider When Choosing Cable Extrusion Machinery

1. Production Capacity and Speed

One of the most critical factors to consider is the production capacity and speed of the cable extrusion machinery. Assess your current and future production needs to ensure that the machine can meet your volume requirements without compromising on quality[4].

2. Material Compatibility

Different cable types require different materials for insulation and jacketing. Ensure that the extrusion machinery you choose is compatible with the materials you plan to use, such as PVC, XLPE, or specialty compounds[4].

3. Energy Efficiency

Modern cable extrusion machinery is designed to be energy-efficient, which can significantly reduce operational costs. Look for machines with energy-saving features and advanced power management systems[1].

4. Automation and Control Systems

Advanced automation and control systems can enhance the precision and consistency of your cable production. Consider machines with user-friendly interfaces, real-time monitoring capabilities, and data logging features[1].

Choose cable extrusion machinery that offers flexibility in terms of cable sizes, materials, and production configurations. This versatility can help you adapt to changing market demands and expand your product range[4].

6. Quality Control Features

Integrated quality control features, such as in-line testing and monitoring systems, can help ensure consistent product quality and reduce waste[3].

7. Maintenance and Support

Consider the availability of spare parts, technical support, and maintenance services when selecting your cable extrusion machinery. Reliable after-sales support can minimize downtime and extend the life of your equipment[4].

Advanced Features in Modern Cable Extrusion Machinery

1. IoT Integration

Many modern cable extrusion machines come equipped with IoT (Internet of Things) capabilities, allowing for remote monitoring, predictive maintenance, and real-time performance optimization[1].

2. Artificial Intelligence and Machine Learning

Some advanced cable extrusion systems incorporate AI and machine learning algorithms to optimize production parameters, predict maintenance needs, and improve overall efficiency[1].

3. Sustainable Manufacturing Features

With increasing focus on sustainability, many cable extrusion machines now offer features that reduce waste, improve energy efficiency, and support the use of recycled materials[1].

Assessing Your Business Needs

Before making a final decision on cable extrusion machinery, it's crucial to thoroughly assess your business needs and production requirements:

1. Current and Future Production Volume: Evaluate your current production needs and projected growth to ensure the machinery can accommodate future expansion[4].

2. Types of Cables Produced: Consider the range of cable types you plan to manufacture, as this will influence the type of extrusion machinery required[4].

3. Available Space and Infrastructure: Ensure that your facility can accommodate the chosen machinery, including power supply, cooling systems, and material handling equipment[4].

4. Budget and ROI: Calculate the total cost of ownership, including initial investment, operational costs, and potential return on investment (ROI)[4].

Case Studies: Successful Implementation of Cable Extrusion Machinery

Case Study 1: Small-Scale Cable Manufacturer

A small-scale cable manufacturer specializing in custom cables for industrial applications invested in a versatile single screw extruder with quick-change tooling. This allowed them to efficiently produce small batches of different cable types, increasing their product range and market competitiveness.

Case Study 2: Large-Scale Power Cable Producer

A large-scale power cable producer upgraded their extrusion line with a high-speed tandem extruder system, incorporating advanced automation and quality control features. This investment resulted in a 30% increase in production capacity and a significant reduction in material waste.

Future Trends in Cable Extrusion Machinery

The cable extrusion machinery industry is continuously evolving, with several emerging trends shaping the future of cable manufacturing:

1. Industry 4.0 Integration: Increased adoption of smart manufacturing principles, including data analytics, cloud computing, and interconnected systems[1].

2. Sustainable Manufacturing: Development of machinery that supports the use of eco-friendly materials and energy-efficient production processes[1].

3. Additive Manufacturing: Exploration of 3D printing technologies for specialized cable components and tooling[1].

4. High-Speed Extrusion: Advancements in machinery design to achieve higher production speeds without compromising quality[1].

Tips for Successful Implementation of New Cable Extrusion Machinery

1. Thorough Training: Ensure that your operators receive comprehensive training on the new machinery to maximize its potential and minimize errors.

2. Gradual Integration: If possible, integrate the new machinery gradually into your production line to minimize disruptions.

3. Regular Maintenance: Establish a rigorous maintenance schedule to keep the machinery in optimal condition and prevent unexpected downtime.

4. Continuous Optimization: Regularly review and optimize your production processes to ensure you're getting the most out of your cable extrusion machinery.

Conclusion

Choosing the right cable extrusion machinery is a critical decision that can significantly impact your business's success in the cable manufacturing industry. By carefully considering factors such as production capacity, material compatibility, energy efficiency, and advanced features, you can select machinery that not only meets your current needs but also supports your future growth and innovation.

Remember that the best choice of cable extrusion machinery will depend on your specific business requirements, production goals, and budget constraints. It's always advisable to consult with industry experts and machinery manufacturers to ensure you make an informed decision that aligns with your long-term business strategy.

Frequently Asked Questions (FAQ)

1. What is the typical lifespan of cable extrusion machinery?

The lifespan of cable extrusion machinery can vary depending on factors such as usage, maintenance, and environmental conditions. With proper care and regular maintenance, high-quality cable extrusion machinery can last 15-20 years or more. However, it's important to consider technological advancements and changing production needs, which may necessitate upgrades or replacements sooner.

2. How can I determine the right size of cable extrusion machinery for my business?

To determine the right size of cable extrusion machinery, consider your current and projected production volume, the types of cables you plan to manufacture, and your available floor space. It's often recommended to choose machinery with slightly higher capacity than your current needs to accommodate future growth. Consult with machinery manufacturers or industry experts who can help you calculate the appropriate size based on your specific requirements.

3. What are the key maintenance requirements for cable extrusion machinery?

Regular maintenance is crucial for the longevity and performance of cable extrusion machinery. Key maintenance requirements typically include:

- Regular cleaning and lubrication of moving parts

- Inspection and replacement of wear components (e.g., screws, barrels)

- Calibration of temperature and pressure sensors

- Checking and maintaining cooling systems

- Electrical system inspections

Always follow the manufacturer's recommended maintenance schedule and procedures for optimal performance and longevity.

4. How can I improve the energy efficiency of my cable extrusion process?

Improving energy efficiency in cable extrusion can be achieved through several methods:

- Investing in modern, energy-efficient machinery

- Optimizing process parameters (e.g., temperature, speed) for each product

- Implementing heat recovery systems

- Using variable frequency drives (VFDs) on motors

- Ensuring proper insulation of heating elements

- Regular maintenance to keep machinery operating at peak efficiency

Additionally, consider conducting energy audits to identify areas for improvement in your overall production process.

5. What are the latest technological advancements in cable extrusion machinery?

Recent technological advancements in cable extrusion machinery include:

- Integration of IoT and Industry 4.0 principles for real-time monitoring and predictive maintenance

- Advanced automation systems for improved precision and reduced human error

- Use of AI and machine learning for process optimization

- Development of high-speed extrusion technologies

- Improved material handling and mixing systems for better product consistency

- Enhanced quality control features, including in-line testing and monitoring

- Eco-friendly designs that support sustainable manufacturing practices

These advancements aim to improve productivity, quality, and sustainability in cable manufacturing processes.

Citations:

[1] https://mssmachinery.de/choosing-the-right-cable-stranding-machine/

[2] https://mssmachinery.de/choosing-the-right-cable-manufacturing-machine/

[3] https://jieyatwinscrew.com/extruder-applications/cable-extruder/pvc-cable-extruder-machine/

[4] https://www.wirestrander.com/portfolio/items/120mm-extruder-extrusion-machine-cable-sheath-line

[5] https://www.youtube.com/watch?v=x8nDxxiatTk

[6] https://www.supermacindia.com/blog/6-considerations-while-buying-wires-and-cables-for-heavy-duty-applications/

[7] https://www.yjing-extrusion.com/how-to-choose-the-best-wire-extrusion-production-line-for-your-business.html

[8] https://www.supermacindia.com/blog/understanding-the-key-aspects-of-wire-and-cable-extrusion/

[9] http://en.dgjinyijixie.com/wdgweb_content-87089.html

[10] https://www.youtube.com/watch?v=Fmf6XP7hxpw

[11] https://www.shutterstock.com/search/plastic-extrusion-machine

[12] https://www.youtube.com/watch?v=f-6s0lrKUIw

[13] https://www.shutterstock.com/video/search/extrusion

[14] https://www.toyomac.com/qa/

[15] https://www.electrical-cable.com/news-exhibition/company-news/2009.html

[16] https://jieyatwinscrew.com/blog/small-extrusion-machine/

[17] https://www.wirecable.in/fundamentals-of-extrusion-technology/

[18] https://www.frekansmakina.com.tr/en/understanding-the-cable-extrusion-process/

[19] https://www.youtube.com/watch?v=yY4P05n3RAQ

[20] https://www.cnsuntech.com/sale-13736817-low-voltage-cable-extruder-machine-5-0mm-30mm-cable-extrusion-line.html

[21] https://www.youtube.com/watch?v=YZtIMIlRVyQ

[22] https://www.youtube.com/watch?v=j9WQg6YwDj0

[23] https://www.wirestrander.com/cable-extruder

[24] https://www.youtube.com/watch?v=JeKgKtWWCps

[25] https://www.linkedin.com/pulse/common-issues-pvc-cable-extrusion-robyn-gai-aw8lc

[26] https://www.elastron.com/en/12-extrusion-defects-and-troubleshooting-elastron-tpe

[27] https://m.zmscable.com/new/Wire-and-cable-extrusion-defect-problem-solution

[28] https://www.handingmachinery.com/new_detail/Troubleshooting-Common-Cable-Extrusion-Issues.html

[29] https://www.linttop.com/technology-news/common-problems-and-solutions-of-cable-extruding-machine-in-production/

[30] https://www.supermacindia.com/cabel-and-wire-extrusion-lines.html