Content Menu

● Introduction

● Understanding Aluminum Extrusion Profiles

● Benefits of Aluminum Extrusion in Construction

>> Lightweight and Durable

>> Corrosion Resistance

>> Design Flexibility

>> Cost-Effectiveness

● Applications of Aluminum Extrusion Profiles in Construction

● Choosing the Right Aluminum Extrusion Supplier

>> Quality of Products

>> Range of Products

>> Delivery Time

>> Customer Service

>> Certifications and Industry Standards

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusion profiles in construction?

>> 2. How can I find a reliable aluminum extrusion supplier?

>> 3. What types of aluminum extrusion profiles are available?

>> 4. How does aluminum compare to other materials in construction?

>> 5. What factors influence the cost of aluminum extrusion?

Introduction

Choosing the right aluminum extrusion supplier is a critical decision that can significantly impact the success of your project. Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile, making it a versatile material for various applications, from construction to automotive parts. With a plethora of suppliers available, understanding how to select the best one for your needs is essential. This article will guide you through the key considerations when choosing an aluminum extrusion supplier, ensuring you make an informed decision that aligns with your project requirements.

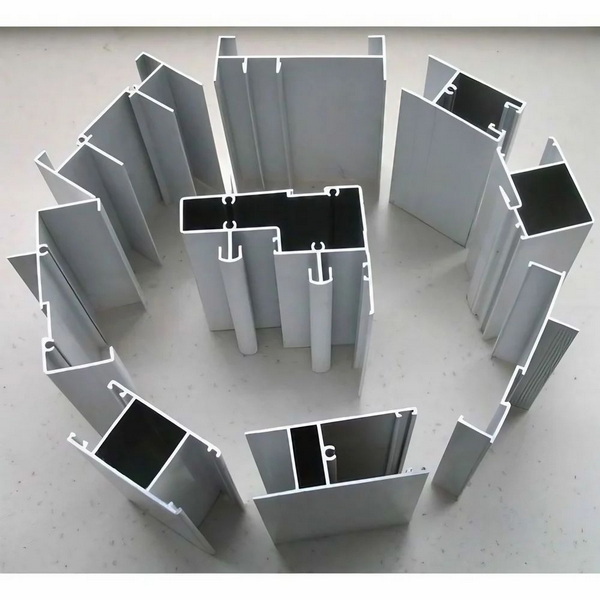

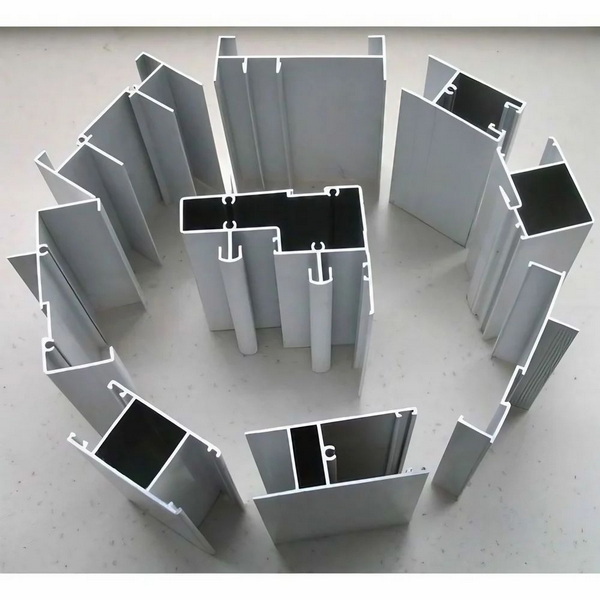

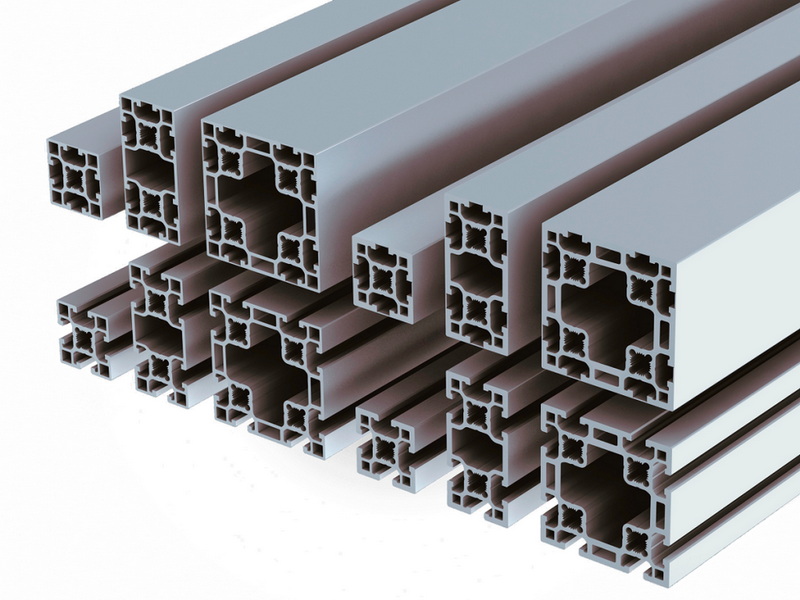

Understanding Aluminum Extrusion Profiles

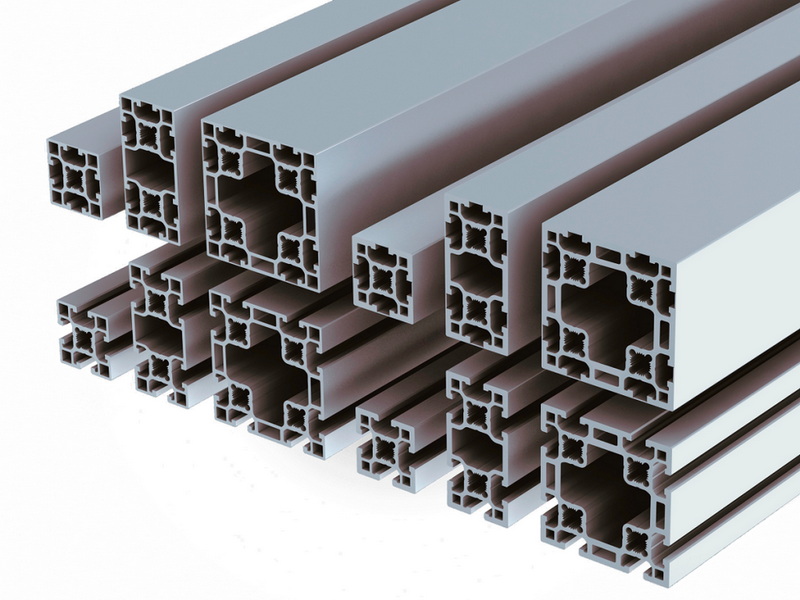

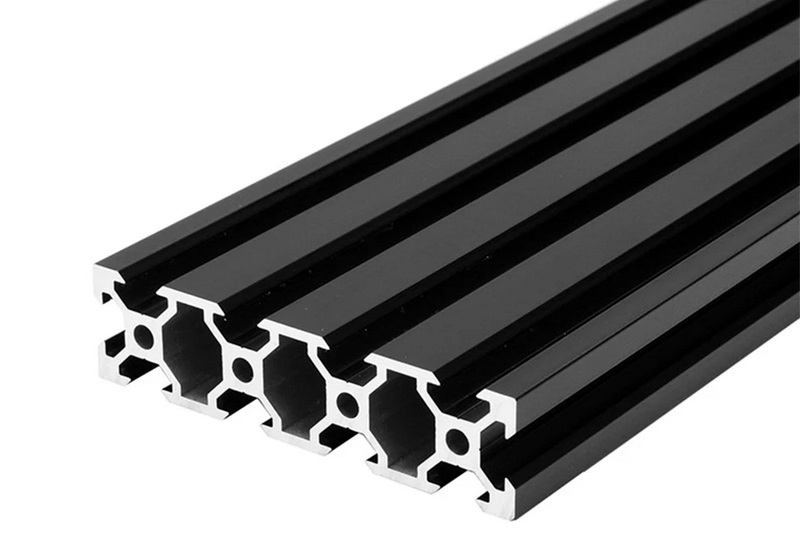

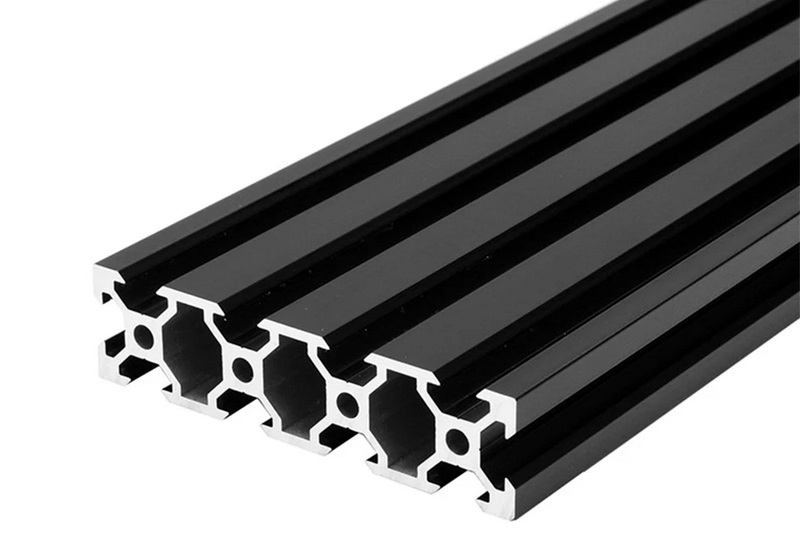

Aluminum extrusion profiles are created by forcing heated aluminum through a die, resulting in a specific shape that can be cut to length. These profiles come in various forms, including standard shapes like angles, channels, and tubes, as well as custom designs tailored to specific applications. The versatility of aluminum extrusion allows it to be used in numerous industries, including construction, automotive, aerospace, and consumer goods.

When exploring an aluminum extrusion catalog, you will find a wide range of profiles that cater to different needs. Understanding the types of profiles available is crucial in selecting the right supplier, as it helps you identify whether they can meet your specific requirements.

Benefits of Aluminum Extrusion in Construction

Lightweight and Durable

One of the primary advantages of aluminum extrusion is its lightweight nature. Compared to traditional materials like steel and wood, aluminum is significantly lighter, making it easier to handle and transport. This characteristic is particularly beneficial in construction, where reducing the weight of materials can lead to lower transportation costs and easier installation.

Moreover, aluminum is known for its durability. It is resistant to corrosion, which means it can withstand harsh environmental conditions without deteriorating. This durability ensures that structures built with aluminum extrusion profiles have a longer lifespan, reducing the need for frequent repairs or replacements.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent corrosion. This property makes aluminum extrusion an ideal choice for outdoor applications, such as window frames, roofing systems, and facades. Unlike steel, which can rust over time, aluminum maintains its appearance and structural integrity, even in challenging weather conditions.

Design Flexibility

Aluminum extrusion offers unparalleled design flexibility. The ability to create custom profiles means that designers and engineers can develop unique solutions tailored to their specific needs. Whether you require intricate shapes for aesthetic purposes or functional designs for structural support, aluminum extrusion can accommodate a wide range of requirements.

Additionally, the extrusion process allows for the integration of features such as grooves, holes, and channels, further enhancing the versatility of the profiles. This flexibility is a significant advantage when working on complex projects that demand innovative solutions.

Cost-Effectiveness

While the initial cost of aluminum extrusion may be higher than some alternatives, its long-term cost-effectiveness cannot be overlooked. The lightweight nature of aluminum reduces transportation and installation costs, while its durability minimizes maintenance expenses. Over time, the savings associated with using aluminum extrusion can outweigh the initial investment, making it a smart choice for many projects.

Applications of Aluminum Extrusion Profiles in Construction

Aluminum extrusion profiles are used in a variety of construction applications, showcasing their versatility and effectiveness. Some common uses include:

- Structural Components: Aluminum extrusions are often used as beams and columns in building frameworks. Their strength-to-weight ratio makes them ideal for supporting structures without adding excessive weight.

- Architectural Applications: Aluminum profiles are popular in architectural design, particularly for window frames, curtain walls, and facades. Their aesthetic appeal and ability to be finished in various colors and textures make them a preferred choice for modern buildings.

- Interior Design Elements: In addition to exterior applications, aluminum extrusion profiles are also used in interior design. They can be found in furniture, fixtures, and decorative elements, providing a sleek and contemporary look.

Choosing the Right Aluminum Extrusion Supplier

Selecting the right aluminum extrusion supplier involves several key considerations. Here are some factors to keep in mind:

Quality of Products

The quality of the aluminum extrusion profiles is paramount. Look for suppliers that adhere to industry standards and have a reputation for producing high-quality products. Request samples to assess the quality of their extrusions before making a commitment.

Range of Products

A comprehensive aluminum extrusion catalog is essential for ensuring that the supplier can meet your specific needs. Check if they offer a variety of standard profiles as well as custom options. A supplier with a diverse range of products is more likely to provide solutions that fit your project requirements.

Delivery Time

Timely delivery is crucial in any construction project. Inquire about the supplier's lead times and their ability to meet deadlines. A reliable supplier should have a track record of delivering products on time, ensuring that your project stays on schedule.

Customer Service

Excellent customer service is a vital aspect of any supplier relationship. Choose a supplier that is responsive to your inquiries and provides support throughout the purchasing process. A supplier that values customer satisfaction will be more likely to address any issues that may arise.

Certifications and Industry Standards

Ensure that the supplier complies with relevant industry standards and holds necessary certifications. This not only guarantees the quality of their products but also demonstrates their commitment to safety and environmental responsibility.

Conclusion

Choosing the right aluminum extrusion supplier is a critical step in ensuring the success of your project. By understanding the benefits of aluminum extrusion, exploring the various applications, and considering key factors such as product quality, range, delivery time, customer service, and certifications, you can make an informed decision that aligns with your needs. With the right supplier, you can leverage the advantages of aluminum extrusion to create innovative and durable solutions for your construction projects.

Related Questions

1. What are the advantages of using aluminum extrusion profiles in construction?

Aluminum extrusion profiles offer lightweight durability, corrosion resistance, design flexibility, and long-term cost-effectiveness, making them ideal for various construction applications.

2. How can I find a reliable aluminum extrusion supplier?

To find a reliable supplier, consider their product quality, range of offerings, delivery times, customer service, and adherence to industry standards and certifications.

3. What types of aluminum extrusion profiles are available?

Aluminum extrusion profiles come in various shapes, including standard profiles like angles, channels, and tubes, as well as custom designs tailored to specific applications.

4. How does aluminum compare to other materials in construction?

Aluminum is lighter and more corrosion-resistant than materials like steel and wood, making it a preferred choice for many construction applications due to its durability and design flexibility.

5. What factors influence the cost of aluminum extrusion?

The cost of aluminum extrusion can be influenced by factors such as material prices, complexity of the design, quantity ordered, and the supplier's manufacturing capabilities.