Content Menu

● Understanding Aluminum Extrusion Presses

● Key Factors to Consider

>> 1. Press Tonnage and Extrusion Force

>> 2. Container Size and Billet Dimensions

>> 3. Press Type: Direct vs. Indirect Extrusion

>> 4. Automation and Control Systems

>> 5. Energy Efficiency

>> 6. Maintenance and Support

● Matching Press Capabilities to Your Production Needs

● Additional Considerations

>> Auxiliary Equipment

>> Future Scalability

>> Environmental Considerations

● Making Your Decision

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. How do I determine the right tonnage for my aluminum extrusion press?

>> 2. What's the difference between direct and indirect extrusion presses?

>> 3. How important is energy efficiency in an aluminum extrusion press?

>> 4. What kind of maintenance does an aluminum extrusion press require?

>> 5. Can I upgrade my existing aluminum extrusion press instead of buying a new one?

● Citations:

Selecting the appropriate aluminum extrusion press is a critical decision for any business involved in manufacturing aluminum profiles. The right choice can significantly impact your production efficiency, product quality, and overall profitability. This comprehensive guide will walk you through the essential factors to consider when choosing an aluminum extrusion press, helping you make an informed decision that aligns with your business needs and goals.

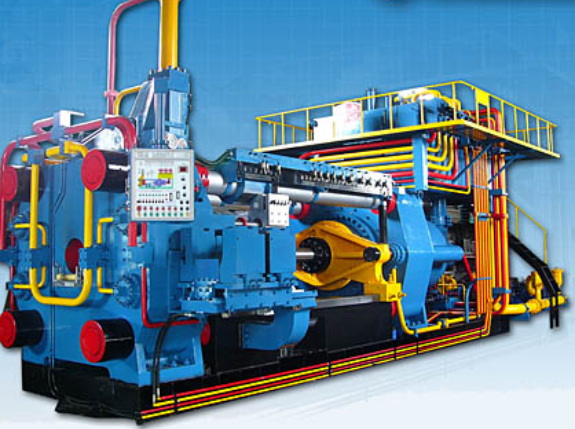

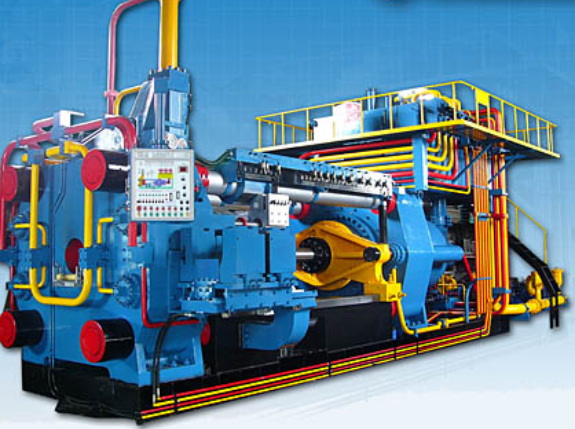

Understanding Aluminum Extrusion Presses

Aluminum extrusion presses are sophisticated machines designed to transform aluminum billets into various shapes and profiles. These presses work by forcing heated aluminum through a die, creating profiles with specific cross-sectional shapes. The process is fundamental in producing components for industries ranging from construction and automotive to aerospace and consumer goods.

Key Factors to Consider

1. Press Tonnage and Extrusion Force

The tonnage of an aluminum extrusion press is a crucial factor that determines the maximum force the machine can exert during the extrusion process[1]. The required tonnage depends on various factors, including:

- The size and complexity of the profiles you plan to produce

- The alloy types you'll be working with

- Your desired production volume

To calculate the appropriate tonnage, consider the extrusion ratio, which is the relationship between the cross-sectional area of the billet and the final extruded profile[3]. A higher extrusion ratio typically requires more force, necessitating a press with higher tonnage.

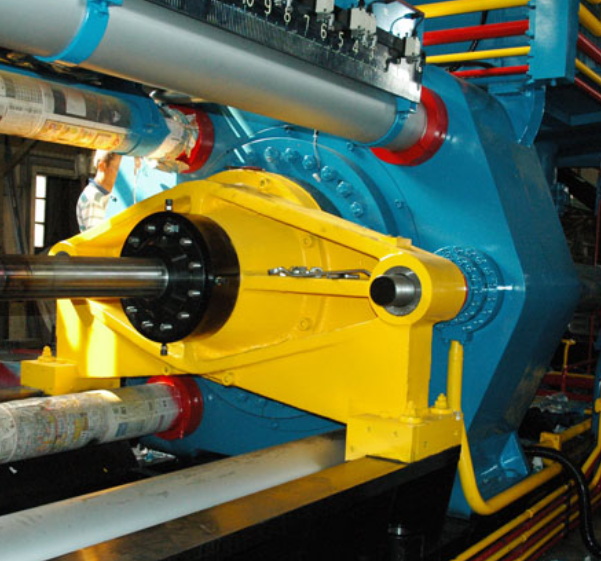

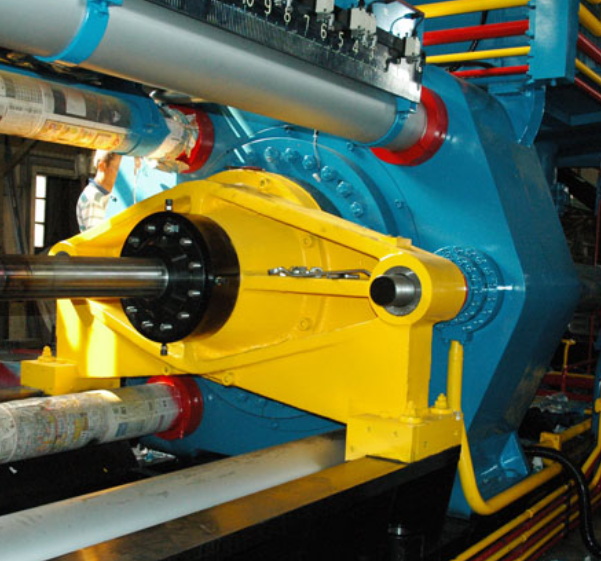

2. Container Size and Billet Dimensions

The container size of the press determines the maximum billet size you can use. Larger billets allow for longer extrusion runs and potentially higher productivity. Consider your typical production runs and the profile sizes you need to produce when selecting the container size[2].

3. Press Type: Direct vs. Indirect Extrusion

Aluminum extrusion presses come in two main types:

1. Direct Extrusion Presses: In these presses, the ram pushes the billet directly through the die. They are versatile and suitable for a wide range of profiles.

2. Indirect Extrusion Presses: Here, the die moves against the stationary billet. These presses are ideal for extruding hard alloys and producing profiles with tight tolerances.

Consider your specific production needs and the types of profiles you'll be extruding when choosing between these press types.

4. Automation and Control Systems

Modern aluminum extrusion presses come equipped with advanced automation and control systems. These features can significantly enhance productivity, consistency, and quality control. Look for presses with:

- Programmable Logic Controllers (PLCs)

- Human-Machine Interfaces (HMIs)

- Real-time monitoring and data logging capabilities

- Integration with other production line components

5. Energy Efficiency

Energy consumption is a significant factor in the operational costs of an extrusion press. Look for presses with energy-efficient features such as:

- Regenerative braking systems

- Efficient heating elements

- Hybrid drive systems (like the HybrEx® technology)[5]

These features can help reduce energy consumption and lower your operational costs in the long run.

6. Maintenance and Support

Consider the maintenance requirements and available support when choosing an aluminum extrusion press. Look for:

- Presses with easily replaceable components

- Manufacturers offering comprehensive technical support

- Availability of spare parts

- Training programs for your operators

A press that is easy to maintain and well-supported can minimize downtime and extend the machine's lifespan.

Matching Press Capabilities to Your Production Needs

To choose the right aluminum extrusion press for your business, you need to have a clear understanding of your production requirements. Consider the following:

1. Product Range: What types of profiles will you be producing? Consider the complexity, size, and variety of your product range.

2. Production Volume: What is your target production capacity? This will influence the size and speed of the press you need.

3. Alloy Types: Different aluminum alloys have varying extrusion properties. Ensure the press you choose can handle the alloys you plan to work with.

4. Quality Requirements: If you're producing profiles for industries with strict tolerances (like aerospace), you may need a press with advanced control systems and precision capabilities.

Additional Considerations

Auxiliary Equipment

Remember that an aluminum extrusion press is just one part of a complete extrusion line. Consider the compatibility and integration with other essential equipment such as:

- Billet heating systems

- Profile cooling systems

- Handling equipment (pullers, run-out tables, etc.)

- Aging ovens

- Cutting systems

Future Scalability

While it's important to choose a press that meets your current needs, also consider your future growth plans. Opting for a press with slightly higher capacity than your immediate requirements can provide room for expansion without necessitating a major equipment upgrade in the near future.

Environmental Considerations

As sustainability becomes increasingly important, consider the environmental impact of your extrusion press. Look for features that minimize waste, reduce energy consumption, and allow for the use of recycled aluminum.

Making Your Decision

When you're ready to make a decision, consider the following steps:

1. Research Manufacturers: Look for reputable manufacturers with a track record of producing quality aluminum extrusion presses. Some well-known names in the industry include SMS group, OMAV, and Presezzi Extrusion.

2. Request Quotes: Reach out to multiple manufacturers or suppliers for quotes. Be sure to provide detailed information about your production requirements to get accurate proposals.

3. Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider factors like energy efficiency, maintenance costs, and potential downtime when calculating the total cost of ownership over the press's lifespan.

4. Check References: Ask for references from other businesses using similar presses. Their experiences can provide valuable insights into the performance and reliability of the equipment.

5. Consider Financing Options: For many businesses, an aluminum extrusion press represents a significant investment. Explore financing options that align with your company's financial strategy.

Conclusion

Choosing the right aluminum extrusion press for your business is a complex decision that requires careful consideration of numerous factors. By thoroughly assessing your production needs, understanding the key features of different press types, and considering long-term factors like energy efficiency and scalability, you can make an informed decision that will benefit your business for years to come.

Remember, the goal is not just to find an aluminum extrusion press for sale, but to invest in a machine that will enhance your production capabilities, improve product quality, and contribute to your business's growth and success.

Frequently Asked Questions (FAQ)

1. How do I determine the right tonnage for my aluminum extrusion press?

The appropriate tonnage depends on factors such as the size and complexity of your profiles, the alloys you're working with, and your production volume. Calculate the extrusion ratio based on your typical products and consult with press manufacturers to determine the optimal tonnage for your needs.

2. What's the difference between direct and indirect extrusion presses?

Direct extrusion presses push the billet through a stationary die, while indirect presses move the die against a stationary billet. Direct presses are more versatile, while indirect presses are better for hard alloys and tight tolerances. Choose based on your specific production requirements.

3. How important is energy efficiency in an aluminum extrusion press?

Energy efficiency is crucial as it significantly impacts operational costs. Look for presses with features like regenerative braking systems and efficient heating elements. Energy-efficient presses can lead to substantial savings over time and reduce your environmental footprint.

4. What kind of maintenance does an aluminum extrusion press require?

Regular maintenance typically includes checking and replacing wear parts, lubricating moving components, and calibrating control systems. The exact requirements vary by press model. Choose a press with easily replaceable components and good manufacturer support to minimize downtime.

5. Can I upgrade my existing aluminum extrusion press instead of buying a new one?

In some cases, upgrading an existing press can be a cost-effective option. This might involve updating control systems, improving hydraulics, or adding new features. However, if your current press can't meet your production needs or is significantly outdated, investing in a new press might be more beneficial in the long run.

Citations:

[1] http://www.fsnenghong.com/news/How-To-Choose-A-Suitable-Model-Of-Aluminium-Extrusion-Press--1.html

[2] https://www.outashi.com/blog/a-complete-guide-to-choosing-aluminum-extrusion-press-id21.html

[3] https://www.machine4aluminium.com/how-to-choose-the-tonnage-of-aluminum-extrusion-press/

[4] https://www.alibaba.com/showroom/aluminium-extrusion-press-for-sale.html

[5] https://www.sms-group.com/plants/light-metal-extrusion-presses

[6] https://profileprecisionextrusions.com/choosing-an-aluminum-extrusion-manufacturer-partner/

[7] https://www.industrialprofile.com/t-slot-aluminum-essential-tips-to-keep-in-mind-when-purchasing/

[8] https://www.outashi.com/blog/factors-to-consider-when-selecting-aluminum-extrusion-machine-id32.html

[9] https://www.alibaba.com/showroom/aluminium-extrusion-press.html

[10] https://www.linkedin.com/pulse/how-choose-right-product-aluminum-profile-extrusion-machine-wonsten