Content Menu

● Understanding Aluminum Extrusions

>> Benefits of Aluminum Extrusions

● Key Factors to Consider When Choosing 15mm Aluminum Extrusions

>> 1. Material Selection

>> 2. Design Considerations

>> 3. Application Requirements

● Common Applications of 15mm Aluminum Extrusions

>> 1. Construction

>> 2. Automotive

>> 3. Furniture

>> 4. Industrial Applications

>> 5. Electronics

● Conclusion

● Related Questions

>> 1. What are the typical material costs for different aluminum alloys?

>> 2. How do manufacturing tolerances affect the final product's performance?

>> 3. What are some case studies of 15mm aluminum extrusions in specific applications?

>> 4. How can I ensure the quality of my aluminum extrusions?

>> 5. What finishing options are available for aluminum extrusions?

Choosing the right aluminum extrusion for your application can significantly impact the performance, durability, and cost-effectiveness of your project. This article will guide you through the essential factors to consider when selecting a 15mm aluminum extrusion, including material properties, design considerations, and application-specific requirements.

Understanding Aluminum Extrusions

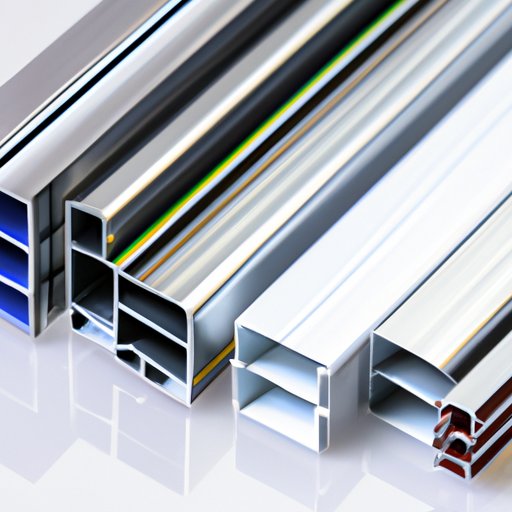

Aluminum extrusions are created by forcing aluminum alloy through a die to create a specific cross-sectional shape. This process allows for a high degree of customization and versatility, making aluminum extrusions suitable for various applications, from structural components to decorative elements.

Benefits of Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion in various environments.

3. Strength-to-Weight Ratio: Aluminum offers a high strength-to-weight ratio, making it ideal for applications where weight savings are critical.

4. Versatility: Aluminum extrusions can be manufactured in various shapes and sizes, allowing for tailored solutions to meet specific needs.

Key Factors to Consider When Choosing 15mm Aluminum Extrusions

1. Material Selection

The choice of aluminum alloy is crucial for the performance of the extrusion. Common alloys used for 15mm extrusions include:

- 6061 Aluminum: Known for its good mechanical properties and weldability, making it suitable for structural applications.

- 6063 Aluminum: Often used for architectural applications due to its excellent finish and aesthetic appeal.

- 7075 Aluminum: Offers high strength and is often used in aerospace applications, though it is less corrosion-resistant than other alloys.

2. Design Considerations

When designing your extrusion, consider the following:

- Cross-Sectional Shape: The shape of the extrusion affects its strength and functionality. Common shapes include T-slots, channels, and angles.

- Wall Thickness: Thicker walls provide greater strength but may increase weight and cost. Balance is key.

- Length and Tolerance: Ensure that the extrusion length meets your specifications and that tolerances are adhered to for proper fit and function.

3. Application Requirements

Different applications may have unique requirements that influence your choice of extrusion:

- Load-Bearing Applications: For structural components, consider the load requirements and choose an alloy and design that can support the necessary weight.

- Aesthetic Applications: If the extrusion will be visible, consider finishes such as anodizing or powder coating to enhance appearance and corrosion resistance.

- Thermal Conductivity: In applications where heat dissipation is critical, select an alloy with high thermal conductivity.

Common Applications of 15mm Aluminum Extrusions

1. Construction

In the construction industry, 15mm aluminum extrusions are often used for window frames, curtain walls, and structural supports. Their lightweight nature and resistance to corrosion make them ideal for both residential and commercial buildings.

2. Automotive

Aluminum extrusions are increasingly used in the automotive industry to reduce vehicle weight and improve fuel efficiency. Components such as chassis parts, brackets, and trim can benefit from the strength and lightweight properties of aluminum.

3. Furniture

In furniture design, 15mm aluminum extrusions are popular for creating modern, sleek designs. They are used in tables, chairs, and shelving units, providing both structural integrity and aesthetic appeal.

4. Industrial Applications

Many industrial applications utilize aluminum extrusions for machinery frames, conveyor systems, and workstations. Their versatility allows for easy customization to fit specific operational needs.

5. Electronics

In the electronics industry, aluminum extrusions are used for heat sinks and enclosures. Their thermal conductivity helps dissipate heat, ensuring the longevity and performance of electronic components.

Conclusion

Selecting the right 15mm aluminum extrusion involves careful consideration of material properties, design requirements, and application-specific needs. By understanding the benefits and characteristics of aluminum extrusions, you can make informed decisions that enhance the performance and efficiency of your projects.

Related Questions

1. What are the typical material costs for different aluminum alloys?

The cost of aluminum alloys can vary significantly based on market conditions, alloy type, and processing methods. Generally, 6061 aluminum is more affordable than 7075 due to its widespread availability and lower processing costs.

2. How do manufacturing tolerances affect the final product's performance?

Manufacturing tolerances are critical in ensuring that components fit together correctly. Tight tolerances can enhance performance and reduce the risk of failure, especially in load-bearing applications.

3. What are some case studies of 15mm aluminum extrusions in specific applications?

Case studies often highlight successful implementations in various industries, showcasing how 15mm aluminum extrusions have improved efficiency, reduced weight, and enhanced aesthetics in projects ranging from automotive to architectural designs.

4. How can I ensure the quality of my aluminum extrusions?

To ensure quality, work with reputable suppliers who provide certifications and adhere to industry standards. Additionally, consider conducting inspections and tests on the extrusions to verify their properties and performance.

5. What finishing options are available for aluminum extrusions?

Common finishing options for aluminum extrusions include anodizing, powder coating, and painting. Each method offers different benefits in terms of aesthetics, corrosion resistance, and durability.