Content Menu

● Introduction

● Key Benefits of 1530 Aluminum Extrusion

>> Lightweight and Durable

>> Versatility in Design

>> Cost-Effectiveness

● Common Applications of 1530 Aluminum Extrusion

>> Industrial Automation

>> DIY Projects and Prototyping

>> Architectural and Structural Uses

● How to Select the Right 1530 Aluminum Profile

>> Understanding Specifications

>> Compatibility with Other Components

● Conclusion

● Related Questions

>> 1. What are the main advantages of using aluminum extrusion over other materials?

>> 2. Can I use 1530 aluminum extrusion for outdoor applications?

>> 3. How do I assemble a structure using 1530 aluminum profiles?

>> 4. Are there any limitations to using 1530 aluminum extrusion?

>> 5. Where can I purchase 1530 aluminum extrusion?

Introduction

Aluminum extrusion has become a cornerstone in modern manufacturing and construction, offering a lightweight yet durable solution for a variety of applications. Among the many profiles available, the 1530 aluminum extrusion stands out due to its versatility and strength. This article will guide you through the process of selecting the right 1530 aluminum profile for your specific application, ensuring that you make an informed decision that meets your project requirements.

Key Benefits of 1530 Aluminum Extrusion

Lightweight and Durable

One of the primary advantages of using 1530 aluminum extrusion is its exceptional strength-to-weight ratio. Aluminum is inherently lightweight, making it an ideal choice for applications where reducing weight is crucial. This characteristic is particularly beneficial in industries such as aerospace, automotive, and construction, where every ounce counts. The durability of aluminum also means that structures made from 1530 profiles can withstand significant stress and strain, ensuring longevity and reliability.

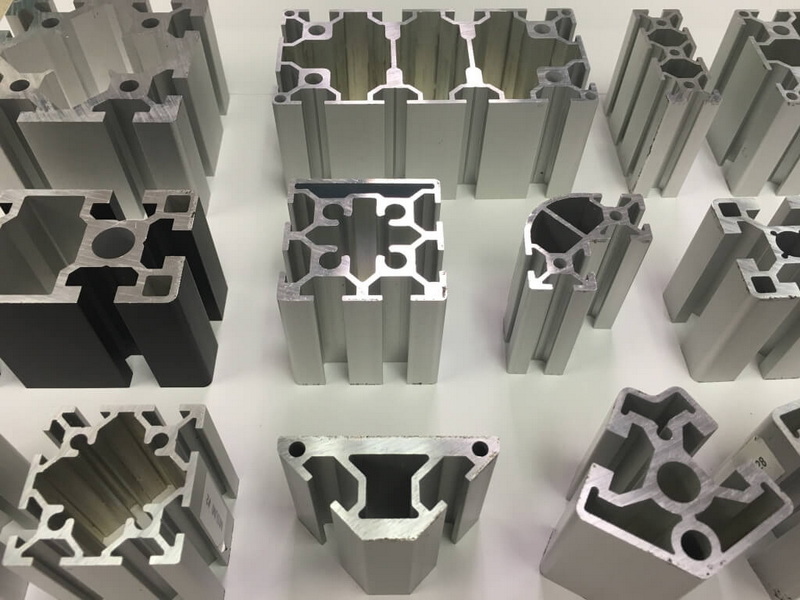

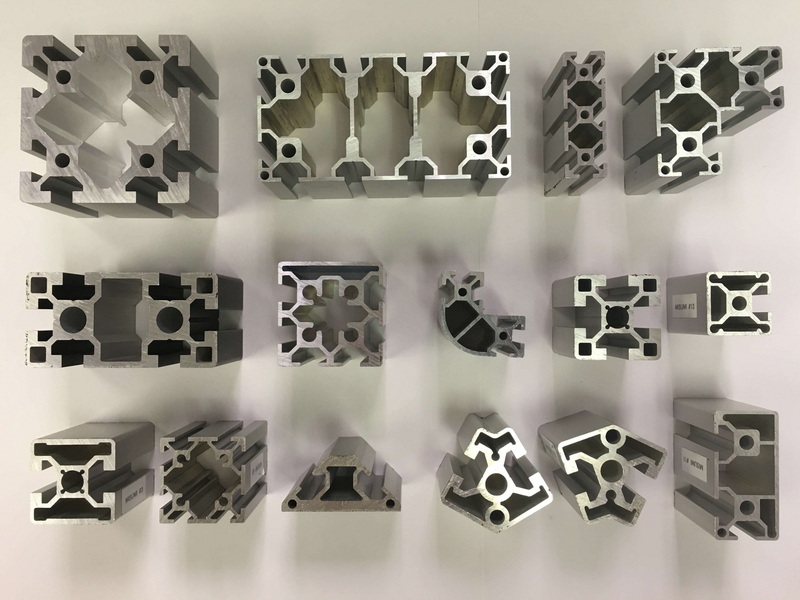

Versatility in Design

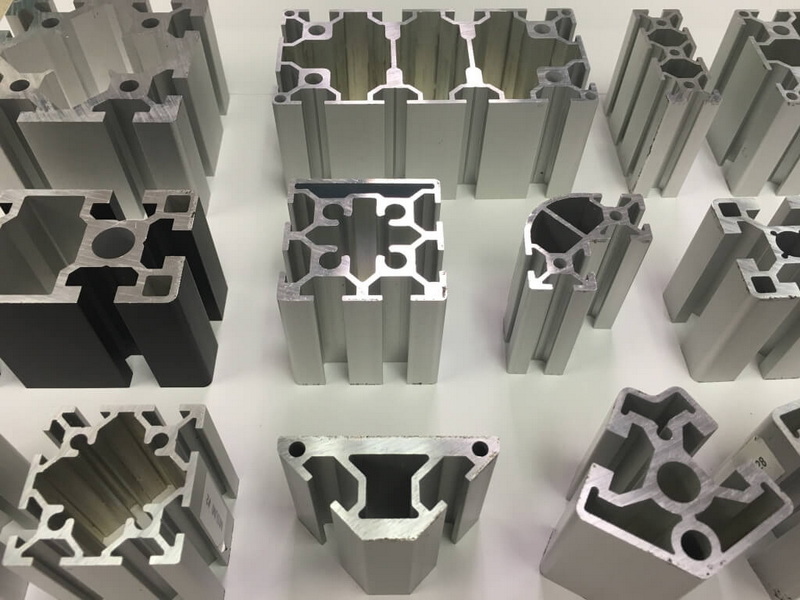

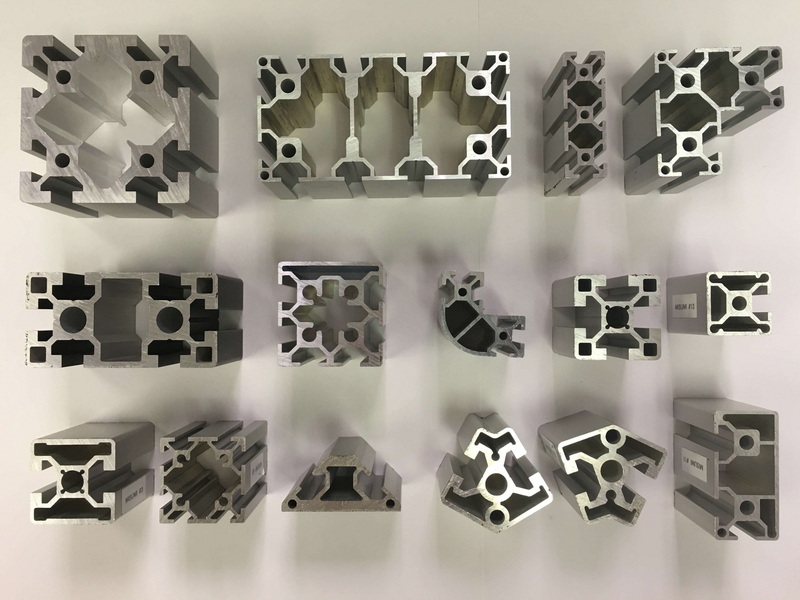

The 1530 aluminum extrusion features a T-slot design, which allows for easy assembly and customization. This modularity enables engineers and designers to create complex structures without the need for extensive machining or fabrication. The ability to connect multiple profiles at various angles makes the 1530 extrusion suitable for a wide range of applications, from simple frames to intricate machinery.

Cost-Effectiveness

When considering materials for your project, cost is always a factor. The 1530 aluminum extrusion is not only affordable but also offers significant savings in manufacturing and assembly. The ease of assembly reduces labor costs, while the lightweight nature of aluminum can lead to lower shipping costs. Additionally, aluminum's resistance to corrosion means that maintenance costs are minimized over time.

Common Applications of 1530 Aluminum Extrusion

Industrial Automation

In the realm of industrial automation, the 1530 aluminum extrusion is widely used for constructing machinery frames, conveyor systems, and robotic arms. Its strength and stability make it an ideal choice for supporting heavy loads and ensuring precise movements. The modular design allows for quick adjustments and modifications, which is essential in fast-paced manufacturing environments.

DIY Projects and Prototyping

The popularity of the 1530 aluminum extrusion extends to DIY enthusiasts and makers. Its ease of use and availability make it a favorite for building custom projects, from furniture to prototypes. The ability to create a sturdy frame without specialized tools empowers hobbyists to bring their ideas to life. Many online communities share designs and tips for using 1530 profiles, fostering creativity and innovation.

Architectural and Structural Uses

Architects and engineers often turn to the 1530 aluminum extrusion for its aesthetic appeal and structural integrity. It can be used in various architectural applications, including window frames, curtain walls, and decorative elements. The sleek appearance of aluminum enhances the visual appeal of buildings while providing the necessary strength to support structural loads.

How to Select the Right 1530 Aluminum Profile

Understanding Specifications

When choosing the right 1530 aluminum profile, it is essential to understand the specifications that define its performance. Key dimensions, such as width, height, and wall thickness, will impact the profile's strength and suitability for your application. Consider the load requirements and environmental factors, such as exposure to moisture or chemicals, to ensure that the selected profile meets your needs.

Compatibility with Other Components

Another critical aspect of selecting a 1530 aluminum profile is its compatibility with other components in your system. Ensure that the profile can be easily integrated with existing machinery or structures. This may involve checking the dimensions of connectors, fasteners, and other hardware to guarantee a seamless assembly process.

Conclusion

Choosing the right 1530 aluminum profile for your application involves careful consideration of various factors, including weight, durability, design versatility, and cost-effectiveness. By understanding the benefits and applications of 1530 aluminum extrusion, you can make an informed decision that enhances the success of your project. Whether you are working in industrial automation, pursuing DIY projects, or engaging in architectural design, the 1530 aluminum profile offers a reliable solution that meets diverse needs.

Related Questions

1. What are the main advantages of using aluminum extrusion over other materials?

Aluminum extrusion offers a lightweight, durable, and corrosion-resistant solution, making it ideal for various applications. Its versatility in design and cost-effectiveness further enhance its appeal compared to other materials.

2. Can I use 1530 aluminum extrusion for outdoor applications?

Yes, 1530 aluminum extrusion is suitable for outdoor applications due to its resistance to corrosion. However, it is essential to consider the environmental conditions and select appropriate finishes if necessary.

3. How do I assemble a structure using 1530 aluminum profiles?

Assembling a structure with 1530 aluminum profiles is straightforward. Use T-slot connectors and fasteners to join the profiles at desired angles. Ensure that you have the necessary tools, such as a wrench and a drill, for a secure assembly.

4. Are there any limitations to using 1530 aluminum extrusion?

While 1530 aluminum extrusion is versatile, it may not be suitable for applications requiring extreme strength or high-temperature resistance. Always assess the specific requirements of your project before selecting the profile.

5. Where can I purchase 1530 aluminum extrusion?

1530 aluminum extrusion can be purchased from various suppliers, both online and in physical stores. It is advisable to compare prices and check for local suppliers to reduce shipping costs.