Content Menu

● Introduction to Downstream Extrusion Equipment

>> Cooling Systems

>> Pullers

>> Cutters

>> Winders

● Applications of Downstream Extrusion Equipment

>> Plastic Extrusion

>> Pipe and Profile Manufacturing

>> Specialized Products

● How to Choose the Best Downstream Extrusion Equipment

● Customizing Downstream Extrusion Equipment

>> Benefits of Customization

● Ensuring Accuracy and Reliability

>> Calibration and Maintenance

● Conclusion

● Frequently Asked Questions

>> 1. What are the main components of downstream extrusion equipment?

>> 2. How does customization affect the efficiency of downstream extrusion equipment?

>> 3. What factors should be considered when selecting downstream extrusion equipment?

>> 4. How important is maintenance for downstream extrusion equipment?

>> 5. Can customized downstream extrusion equipment be integrated into existing production lines?

● Citations:

Choosing the right downstream extrusion equipment is crucial for optimizing your production line's efficiency, quality, and overall performance. This equipment plays a vital role in the extrusion process, transforming raw materials into finished products that meet precise specifications. In this article, we will delve into the world of downstream extrusion equipment, exploring its components, applications, and how to select the best equipment for your specific needs.

Introduction to Downstream Extrusion Equipment

Downstream extrusion equipment refers to the machinery used after the extrusion process to cool, shape, cut, and collect the extruded material. This stage is essential for ensuring that the final product maintains its desired shape, dimensions, and properties. Common components of downstream extrusion equipment include cooling systems, pullers, cutters, and winders.

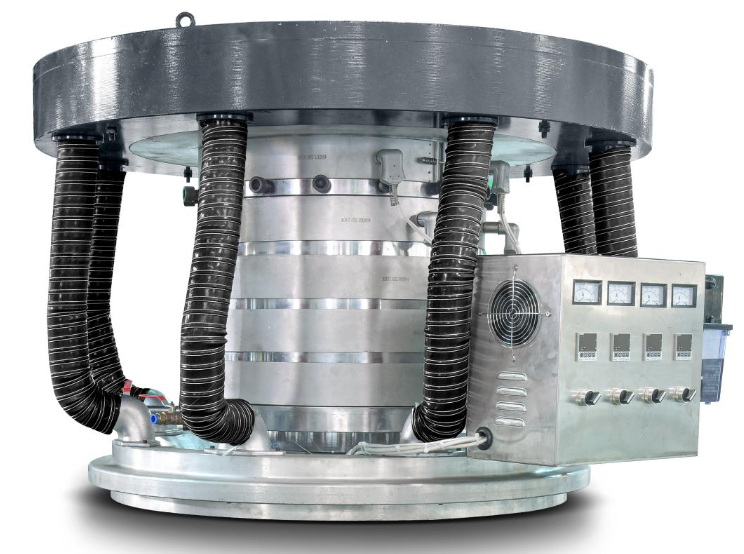

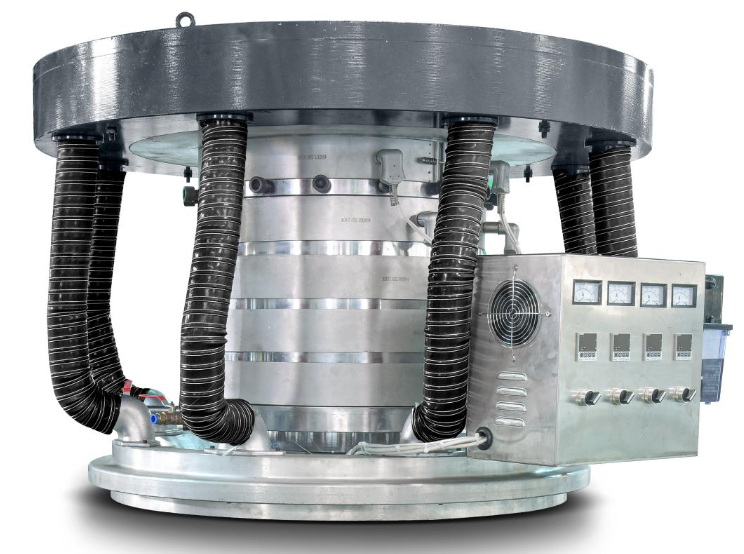

Cooling Systems

Cooling systems are used to solidify the extruded material while maintaining its shape. These can include air cooling, water baths, or chilled rollers. For example, a water bath is often used in plastic extrusion to cool down the extruded product quickly and efficiently.

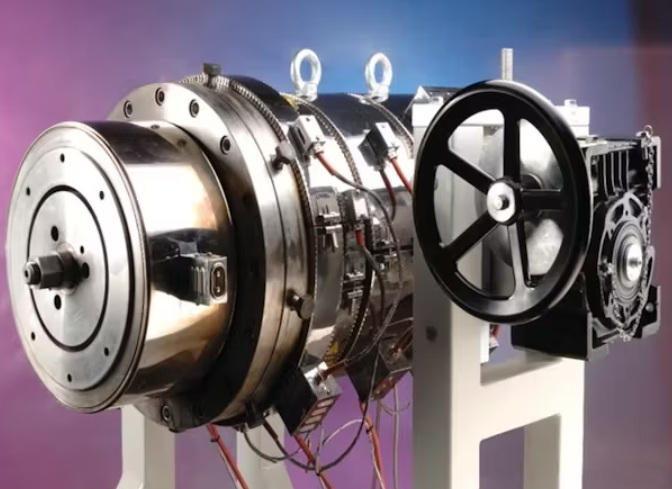

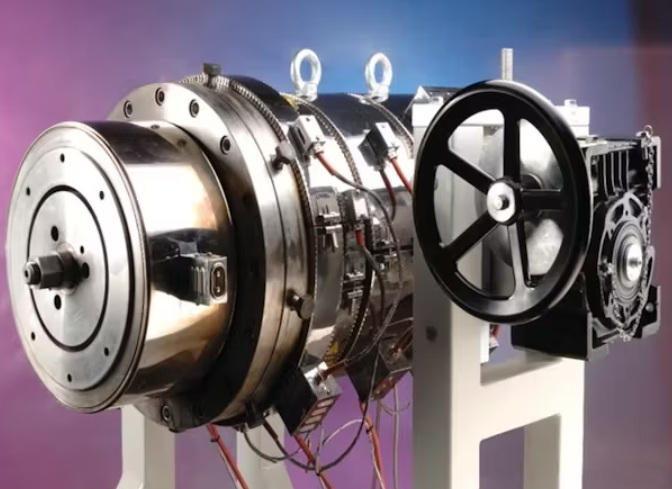

Pullers

Pullers are devices that guide the extruded material through the production line at a controlled speed. They ensure consistent dimensions and tension, which is crucial for maintaining product quality. There are several types of pullers, including belt pullers, caterpillar pullers, and roller pullers.

Cutters

Cutters are used to trim the extruded product into desired lengths. Different materials require different types of cutters, such as rotary cutters, flying knife cutters, or saws for harder materials.

Winders

Winders collect the final product in rolls or spools, making it easier to store and transport. They are particularly important for continuous products like films, sheets, or fibers.

Applications of Downstream Extrusion Equipment

Downstream extrusion equipment is used across various industries, including plastic, rubber, and metal extrusion. Each industry has specific requirements based on the material and product being produced.

Plastic Extrusion

In plastic extrusion, downstream equipment such as cooling tanks, pullers, cutters, and winders are essential for maintaining product quality and efficiency. These components help ensure uniformity and reduce material waste.

Pipe and Profile Manufacturing

For pipe and profile manufacturing, downstream equipment like vacuum calibration tables, haul-offs, and saws are critical. These ensure accurate dimensions and smooth surfaces, which are vital for cost-effective production.

Specialized Products

Specialized products, such as medical tubing or automotive parts, require customized downstream extrusion equipment. This includes precision cutters, coilers, and advanced cooling systems to meet strict industry standards.

How to Choose the Best Downstream Extrusion Equipment

Choosing the right downstream extrusion equipment involves several key considerations:

1. Material Properties: Understand the melting point, viscosity, and other properties of the material being processed. This will help determine the type of cooling and cutting equipment needed.

2. Production Requirements: Consider the desired output quality, consistency, and throughput. Ensure that the equipment can meet these demands efficiently.

3. Space and Budget Constraints: Select equipment that fits within your available space and budget. Energy efficiency and maintenance requirements should also be considered.

4. Customization Options: Consider whether customization is necessary to meet specific product requirements. Working with manufacturers can help tailor equipment to your needs.

5. Integration with Existing Lines: Ensure that new equipment can be seamlessly integrated into your existing production line without disrupting operations.

Customizing Downstream Extrusion Equipment

Customization is crucial for optimizing downstream extrusion equipment to meet specific production needs. This involves adjusting parameters such as coolant flow rates, cutting lengths, and tension control to ensure consistent product quality.

Benefits of Customization

- Improved Efficiency: Customized equipment can reduce material waste and downtime.

- Enhanced Quality: Tailored equipment ensures that products meet precise specifications.

- Flexibility: Customization allows for easier adaptation to new materials or product designs.

Ensuring Accuracy and Reliability

To ensure accuracy and reliability in downstream extrusion equipment, regular maintenance and calibration are essential. This includes monitoring equipment performance in real-time and conducting predictive maintenance to prevent breakdowns.

Calibration and Maintenance

- Calibration Tanks: Use calibration tanks to maintain precise product dimensions.

- Real-Time Monitoring: Implement sensor systems to monitor equipment performance continuously.

- Predictive Maintenance: Schedule maintenance based on performance data to prevent downtime.

Conclusion

Choosing the best downstream extrusion equipment for your production line is a critical decision that impacts efficiency, quality, and profitability. By understanding the components, applications, and customization options available, manufacturers can optimize their processes to meet specific product requirements. Whether you are involved in plastic, rubber, or metal extrusion, selecting the right downstream extrusion equipment is key to achieving high-quality outputs and maintaining a competitive edge in the market.

Frequently Asked Questions

1. What are the main components of downstream extrusion equipment?

The main components include cooling systems, pullers, cutters, and winders. Each plays a crucial role in shaping and processing the extruded material.

2. How does customization affect the efficiency of downstream extrusion equipment?

Customization improves efficiency by reducing material waste, ensuring uniform product quality, and allowing for easier adaptation to new materials or designs.

3. What factors should be considered when selecting downstream extrusion equipment?

Key factors include material properties, production requirements, space and budget constraints, and the need for customization.

4. How important is maintenance for downstream extrusion equipment?

Regular maintenance is crucial for ensuring accuracy and reliability. It involves real-time monitoring and predictive maintenance to prevent breakdowns.

5. Can customized downstream extrusion equipment be integrated into existing production lines?

Yes, customized equipment can be integrated into existing lines. It is important to consider specific requirements based on the setup of your current production line.

Citations:

[1] https://jieyatwinscrew.com/blog/downstream-equipment/

[2] https://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/downstream_extrusion_equipment

[3] https://jieyatwinscrew.com/blog/everything-you-need-to-know-about-plastic-extrusion-machines/

[4] https://www.made-in-china.com/products-search/hot-china-products/Downstream_Extrusion_Equipment_For_Sale.html

[5] https://videos.thermofisher.com/detail/video/6161475650001/process-11-parallel-twin-screw-extruder---overview

[6] https://www.techicy.com/downstream-extrusion-definition-equipment-and-applications.html

[7] https://www.adremac.com/complete-guide-to-pipe-extrusion-machinery-equipment-and-advanced-cutting-solutions/

[8] https://extrudex.de/en/products/downstream-equipment

[9] https://omnexus.specialchem.com/selection-guide/an-in-depth-look-at-extrusion

[10] https://www.linkedin.com/posts/plastics-technology-magazine_how-to-select-the-right-tooling-for-pipe-activity-7143247175307673600-IRIw

[11] https://www.thermofisher.com/blog/materials/webinar-downstream-options-for-extrusion/

[12] https://devikrupagroup.com/things-to-consider-before-choosing-extruder-machine-manufacturer/

[13] https://www.troester.de/content/uploads/2022/05/Extr_Equipment_Cable_2020-03_web1.pdf

[14] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[15] https://jydjx.com/how-to-choose-a-extrusion-machine/

[16] http://www.mgahv.in/blog/zbwj-how-to-select-the-right-tooling-for-pipe-extrusion-plastics-technology/

[17] https://www.bausano.com/en/press-and-news/are-there-objective-parameters-to-choose-the-right-machine

[18] https://sicaindia.com/how-to-choose-a-belling-machine/

[19] https://drts.com/what-to-look-for-extruder-machine/

[20] https://www.grahamengineering.com/about/ge-connect/proper-extruder-maintenance-a-key-to-success/

[21] https://devikrupagroup.com/choose-an-extruder-machine/

[22] https://sicaindia.com/downstream-pipe-extrusion-equipment/

[23] https://www.bausano.com/en/downstream-equipment/end-of-line-for-pipe

[24] https://sicaindia.com/category/gallery/page/2/

[25] https://www.youtube.com/watch?v=9Hmp4K3NwB0

[26] https://www.rdnmfg.com/products/combination-puller-cutters/

[27] https://cdsmachines.com

[28] https://www.youtube.com/watch?v=8oD_nLFGomo

[29] https://www.schmitt-spezialmaschinenbau.de/en/extrusion-downstream-maschines/

[30] https://versamachinery.com