Content Menu

● Understanding Aluminum Extrusion

● Key Factors to Evaluate in an Aluminum Extruder Supplier

>> 1. Experience and Expertise

>> 2. Product Quality

>> 3. Customization Capabilities

>> 4. Manufacturing Capabilities

>> 5. Customer Service

>> 6. Delivery Timeframes

>> 7. Competitive Pricing

● Researching Potential Suppliers

● Requesting Samples

● The Importance of Aluminum Extrusions in Various Industries

>> Construction

>> Automotive

>> Manufacturing

● Recent Advancements in Aluminum Extrusion Technology

>> Nano-Coating Technologies

>> Artificial Intelligence (AI)

>> Hybrid Extrusion Techniques

>> Environmentally Conscious Practices

>> Smart Extrusion Lines

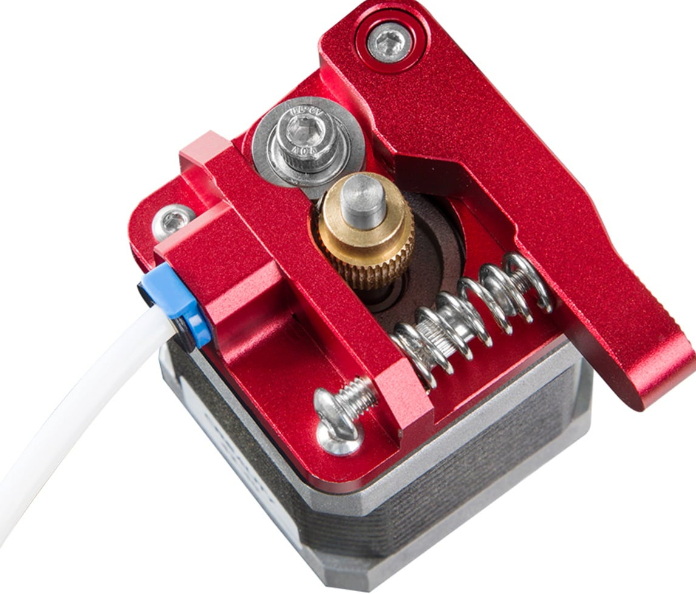

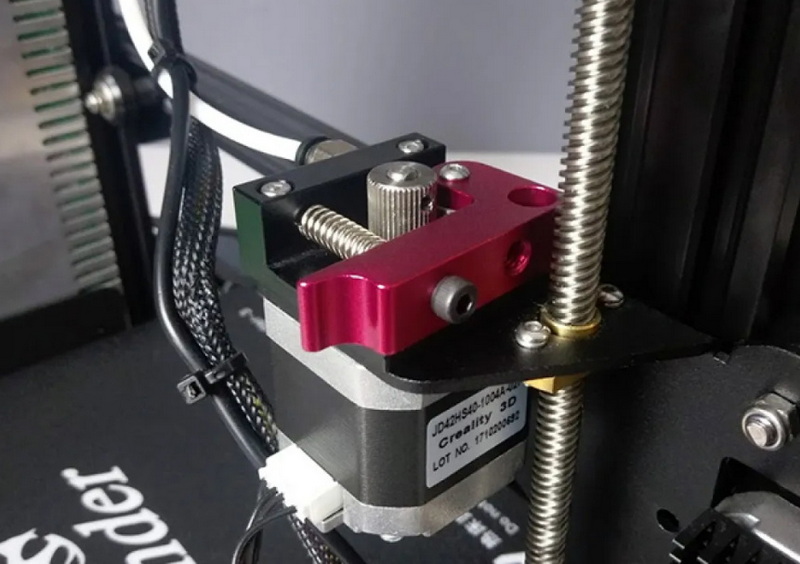

>> 3D Printing

● Sustainability in the Aluminum Extrusion Industry

>> Eco-Friendly Extrusion Practices

● Case Studies of Successful Projects Using Aluminum Extrusion Pipes

>> Skytree Tower, Tokyo

>> Louvre Abu Dhabi

>> Apple Park, Cupertino

>> Guangzhou Metro Line 3

>> Burj Khalifa, Dubai

● Conclusion

● FAQ

>> 1. What should I look for in an aluminum extruder supplier?

>> 2. How important is experience when choosing a supplier?

>> 3. Can I request samples before placing a large order?

>> 4. What certifications should I look for?

>> 5. How can I ensure timely delivery from my supplier?

● Citations:

Selecting a reliable aluminum extruder supplier is a critical decision that can significantly impact the success of your project. Whether you are in construction, manufacturing, or any other industry requiring aluminum extrusions, the right supplier can provide the quality and service necessary to meet your needs. This guide will explore key factors to consider when choosing an aluminum extruder supplier, ensuring you make an informed decision.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process where aluminum alloy is shaped into a desired cross-sectional profile by forcing it through a die[1]. This process allows for the creation of complex shapes with excellent strength-to-weight ratios[1]. Understanding this process is essential as it informs your requirements when selecting a supplier. The aluminum extrusion process involves several key steps: first, an extrusion die is prepared to achieve the desired profile; next, an aluminum billet is preheated to ensure malleability; the preheated billet is then placed into an extrusion press, where a hydraulic ram forces it through the die, shaping it into the desired profile. Post-extrusion processes include quenching, shearing, cooling, stretching, alignment, cutting to length, and inspection[1]. This method produces strong, lightweight, and corrosion-resistant profiles, making aluminum extrusions highly valuable in various applications[1].

Key Factors to Evaluate in an Aluminum Extruder Supplier

1. Experience and Expertise

The experience of an aluminum extruder supplier is paramount. A supplier with years of experience will have the technical know-how to handle complex projects and navigate challenges effectively. Look for:

- Industry Knowledge: Suppliers familiar with your industry will better understand specific requirements and standards.

- Track Record: Review their portfolio to assess their past projects and successes.

2. Product Quality

The quality of the aluminum extrusions directly affects the performance and durability of your final product. Ensure that the supplier adheres to industry standards and conducts thorough quality checks. Key aspects include:

- Certifications: Look for ISO certifications or other relevant quality assurance measures.

- Quality Control Processes: Inquire about their quality control measures throughout the manufacturing process.

3. Customization Capabilities

Every project has unique requirements, and a reliable supplier should offer customization options. Consider:

- Design Support: A supplier that provides design assistance can help optimize your designs for manufacturability.

- Flexibility: Ensure they can accommodate complex shapes and tight tolerances.

4. Manufacturing Capabilities

Evaluate the supplier's manufacturing facilities and capabilities:

- Equipment Quality: Advanced machinery ensures precision in extrusion processes.

- Production Capacity: Confirm that they can meet your volume requirements without compromising quality.

5. Customer Service

Effective communication and customer support are crucial for a successful partnership:

- Responsiveness: A good supplier should address your inquiries promptly.

- Dedicated Support: Having a single point of contact can streamline communication.

6. Delivery Timeframes

Timely delivery is essential to keep your project on schedule:

- Logistics Network: Assess their logistics capabilities to ensure they can meet deadlines.

- Production Lead Times: Understand their typical lead times for production.

7. Competitive Pricing

While cost should not be the sole factor, it is important to choose a supplier whose pricing reflects the value they provide:

- Transparent Pricing Structure: Ensure there are no hidden costs associated with your orders.

- Comparison Shopping: Obtain quotes from multiple suppliers to gauge market rates.

Researching Potential Suppliers

Once you understand what to look for, it's time to research potential suppliers:

- Online Reviews: Check customer feedback on platforms like Trustpilot or Google Reviews.

- Case Studies: Look for case studies or testimonials that demonstrate their capabilities.

Requesting Samples

Before committing to a large order, request samples of their products. This step allows you to evaluate the quality of their aluminum extrusions firsthand.

The Importance of Aluminum Extrusions in Various Industries

Aluminum extrusions are integral to numerous industries due to their versatility and superior properties[1]. Their applications range from construction to automotive and beyond[1][4].

Construction

Aluminum extrusions are essential in both residential and commercial construction due to their versatility and superior properties[1]. Their use spans various applications, enhancing both the structural integrity and aesthetic appeal of buildings[1]. Aluminum extrusions provide a strong yet lightweight solution for structural frameworks[1]. This reduces the overall load on foundations and facilitates easier handling and installation, making them an efficient choice for creating durable, load-bearing structures[1]. Aluminum extrusions are a popular choice for window and door frames due to their durability and resistance to corrosion, ensuring a long lifespan with minimal maintenance[1]. Aluminum extrusions are also used in roofing systems, cladding, and facades[1].

Automotive

In the automotive industry, aluminum extrusions are used as raw materials for automotive support structures, display stands, seat frames, and testing racks[2]. The application of aluminum extrusions in the automotive industry is growing rapidly[2]. Higher strength 6000 series aluminum alloys are being developed, particularly for automotive applications where strength and durability are paramount[7].

Manufacturing

Leading manufacturers leverage aluminum extrusions to enhance their production capabilities[6]. Common applications include assembly line construction, automated manufacturing systems, safety enclosures and machine guards, and material handling equipment[6]. Aluminum extrusion frames play an important role in supporting large-scale automation equipment or instruments[2].

Recent Advancements in Aluminum Extrusion Technology

The aluminum extrusion industry is continuously evolving, with recent advancements pushing the boundaries of what's possible[3].

Nano-Coating Technologies

Recent developments in nano-coating technologies have revolutionized the durability of aluminum extruded profiles[3]. These ultra-thin coatings provide an extra layer of protection against corrosion and abrasion, significantly extending the lifespan of extruded products in diverse applications, from construction to automotive manufacturing[3].

Artificial Intelligence (AI)

The integration of artificial intelligence (AI) in the extrusion process has ushered in a new era of precision control[3]. AI algorithms analyze real-time data from the extrusion machinery, allowing for immediate adjustments and ensuring that each profile meets exact specifications[3]. This not only enhances product quality but also contributes to resource efficiency[3]. AI and machine learning are being used to optimize plant operations, from quoting to process development for extrusion[7].

Hybrid Extrusion Techniques

Hybrid extrusion techniques, combining traditional methods with advanced processes, have emerged to address the demand for aluminum profiles with enhanced strength and formability[3]. These methods optimize the material's properties, opening up new possibilities for applications in aerospace, automotive, and other industries where both strength and malleability are critical[3].

Environmentally Conscious Practices

Sustainability is at the forefront of recent innovations[3]. From energy-efficient extrusion processes to the use of recycled aluminum, the industry is embracing environmentally conscious practices[3][4]. These advancements not only reduce the carbon footprint of aluminum production but also align with global efforts to create more sustainable manufacturing solutions[3].

Smart Extrusion Lines

The rise of smart extrusion lines equipped with IoT (Internet of Things) technology allows for seamless monitoring and control of the entire production process[3]. This connectivity optimizes efficiency, minimizes downtime, and facilitates predictive maintenance, ensuring that extrusion lines operate at peak performance[3].

3D Printing

The marriage of aluminum extrusion with 3D printing technology has opened up new frontiers in customization[3]. This combination allows for the creation of intricate and tailored designs, offering architects, engineers, and designers unparalleled freedom in realizing their visions[3].

Sustainability in the Aluminum Extrusion Industry

The aluminum extrusion industry is increasingly focused on sustainability[4]. Utilizing aluminum reduces material usage, enhances energy efficiency, and creates recyclable products[4]. The industry is actively promoting sustainability initiatives, including energy-efficient production practices and the widespread use of recycled materials[4].

Eco-Friendly Extrusion Practices

Eco-friendly extrusion practices include energy-efficient machinery, process optimization, advanced cooling systems, and automated process controls[8]. Modernizing equipment to more energy-efficient models is a significant step[8]. Companies are continuously looking for ways to optimize their extrusion processes, reducing material waste and improving operational efficiency[8]. Innovations in cooling systems have enabled plants to reduce water usage and energy consumption[8]. The aluminum extrusion industry is increasingly incorporating advanced automation and control systems in their processes[8].

Case Studies of Successful Projects Using Aluminum Extrusion Pipes

Aluminum extrusion pipes have emerged as a game-changer in engineering and construction, enabling architects and engineers to push the boundaries of design and innovation[5].

Skytree Tower, Tokyo

The iconic Skytree Tower relies heavily on aluminum extrusion pipes for its structural stability[5]. These pipes, with their exceptional strength-to-weight ratio, allowed for a lightweight yet robust tower that can withstand seismic forces and strong winds[5].

Louvre Abu Dhabi

The Louvre Abu Dhabi art museum features a breathtaking dome that resembles an intricate web[5]. Aluminum extrusion pipes, with their intricate shapes and adaptability, were instrumental in creating this stunning architectural masterpiece[5].

Apple Park, Cupertino

Apple's iconic headquarters boasts a 1-mile ring-shaped building that is covered by a massive canopy[5]. Aluminum extrusion pipes played a crucial role in supporting the canopy's weight and ensuring its structural integrity[5].

Guangzhou Metro Line 3

Aluminum extrusion pipes were used for the construction of the tunnels and stations, providing a durable and corrosion-resistant solution that could withstand the harsh conditions of underground transportation[5].

Burj Khalifa, Dubai

The Burj Khalifa owes its towering height to aluminum extrusion pipes[5]. The pipes, with their high strength and ability to withstand extreme temperatures, were used in the construction of the tower's exterior cladding and interior framing, contributing to its architectural grandeur and structural efficiency[5].

These case studies demonstrate the exceptional versatility and transformative power of aluminum extrusion pipes[5]. From monumental structures to intricate architectural details, these profiles have revolutionized the construction industry, enabling the realization of ambitious and innovative projects[5].

Conclusion

Choosing a reliable aluminum extruder supplier involves careful consideration of various factors, including experience, product quality, customization capabilities, manufacturing facilities, customer service, delivery timeframes, and pricing. By conducting thorough research and evaluating potential suppliers against these criteria, you can establish a productive partnership that meets your project needs effectively. The aluminum extrusion industry is continuously evolving with advancements in technology and a growing focus on sustainability, making it crucial to select a supplier that stays at the forefront of these developments.

FAQ

1. What should I look for in an aluminum extruder supplier?

You should consider their experience, product quality, customization capabilities, manufacturing facilities, customer service, delivery timeframes, and competitive pricing.

2. How important is experience when choosing a supplier?

Experience is crucial as it indicates the supplier's ability to handle complex projects and navigate challenges effectively.

3. Can I request samples before placing a large order?

Yes, requesting samples is advisable as it allows you to evaluate the quality of their aluminum extrusions firsthand.

4. What certifications should I look for?

Look for ISO certifications or other relevant quality assurance measures that indicate adherence to industry standards.

5. How can I ensure timely delivery from my supplier?

Assess their logistics capabilities and inquire about typical lead times for production during your initial discussions.

Citations:

[1] https://shop.machinemfg.com/understanding-aluminum-extrusions-importance-in-construction/

[2] https://www.china-me.com/news/article/common-applications-of-industrial-aluminum-extrusion

[3] https://yamunaind.com/innovation-spotlight-recent-advancements-in-aluminium-extrusion-technology/

[4] https://taberextrusions.com/not-just-a-new-years-resolution-aluminum-extrusion-sustainability/

[5] https://www.goldapple-alu.com/case-studies-successful-projects-using-aluminium-extrusion-pipes.html

[6] https://proax.ca/en/blog/post/aluminum-extrusion-manufacturing-applications

[7] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[8] https://aluminumextrusions.net/sustainability-practices/

[9] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[10] https://www.atieuno.com/aluminium-extrusion-case-studies/

[11] http://scaluminum.com/2017/08/why-aluminum-extrusion-is-excellent-for-housing-construction/

[12] https://www.mechatronicscanada.ca/latest-articles/10-aluminum-extrusions/

[13] https://www.alcircle.com/news/tech-trends-driving-the-aluminium-extrusion-industry-111131

[14] https://aec.org/sustainability

[15] https://www.linkedin.com/pulse/aluminium-extrusion-simulation-two-97j6f

[16] https://aec.org/features-benefits

[17] https://www.zetwerk.com/resources/knowledge-base/aluminum-extrusions/top-applications-of-aluminum-extrusion-profiles-in-various-industries/

[18] https://nationalindustries.world/2025/01/02/the-future-of-aluminum-how-extrusion-technology-is-transforming-industries/

[19] https://www.nicerapid.com/project/the-impact-of-aluminum-extrusion-process-on-the-environment/

[20] https://www.goldapple-alu.com/yo/case-studies-successful-projects-by-top-aluminum-extrusion-suppliers.html